Nylon

Nylon is a generic designation for a family of synthetic polymers, based on aliphatic or semi-aromatic polyamides. Nylon is a thermoplastic silky material[1] that can be melt-processed into fibers, films, or shapes.[2]:2 It is made of repeating units linked by amide links[3] similar to the peptide bonds in proteins. Nylon polymers can be mixed with a wide variety of additives to achieve many different property variations. Nylon polymers have found significant commercial applications in fabric and fibers (apparel, flooring and rubber reinforcement), in shapes (molded parts for cars, electrical equipment, etc.), and in films (mostly for food packaging).[4]

| |

|---|---|

| Density | 1.15 g/cm3 |

| Electrical conductivity (σ) | 10−12 S/m |

| Thermal conductivity | 0.25 W/(m·K) |

| Melting point | 463–624 K 190–350 °C 374–663 °F |

Nylon was the first commercially successful synthetic thermoplastic polymer.[5] DuPont began its research project in 1927.[6] The first example of nylon (nylon 6,6) using diamines on February 28, 1935, by Wallace Hume Carothers at DuPont's research facility at the DuPont Experimental Station.[7][8] In response to Carothers' work, Paul Schlack at IG Farben developed nylon 6, a different molecule based on caprolactam, on January 29, 1938.[9]:10[10]

Nylon was first used commercially in a nylon-bristled toothbrush in 1938,[11][12] followed more famously in women's stockings or "nylons" which were shown at the 1939 New York World's Fair and first sold commercially in 1940.[13] During World War II, almost all nylon production was diverted to the military for use in parachutes and parachute cord. Wartime uses of nylon and other plastics greatly increased the market for the new materials.[14]

History

DuPont and the invention of Nylon

DuPont, founded by Éleuthère Irénée du Pont, first produced gunpowder and later cellulose-based paints. Following WWI, DuPont produced synthetic ammonia and other chemicals. DuPont began experimenting with the development of cellulose based fibers, eventually producing the synthetic fiber rayon. DuPont's experience with rayon was an important precursor to its development and marketing of nylon.[15]:8,64,236

DuPont's invention of nylon spanned an eleven-year period, ranging from the initial research program in polymers in 1927 to its announcement in 1938, shortly before the opening of the 1939 New York World's Fair.[6] The project grew from a new organizational structure at DuPont, suggested by Charles Stine in 1927, in which the chemical department would be composed of several small research teams that would focus on "pioneering research" in chemistry and would "lead to practical applications".[15]:92 Harvard instructor Wallace Hume Carothers was hired to direct the polymer research group. Initially he was allowed to focus on pure research, building on and testing the theories of German chemist Hermann Staudinger.[16] He was very successful, as research he undertook greatly improved the knowledge of polymers and contributed to science.[17]

In the spring of 1930, Carothers and his team had already synthesized two new polymers. One was neoprene, a synthetic rubber greatly used during World War II.[18] The other was a white elastic but strong paste that would later become nylon. After these discoveries, Carothers' team was made to shift its research from a more pure research approach investigating general polymerization to a more practically-focused goal of finding "one chemical combination that would lend itself to industrial applications".[15]:94

It wasn't until the beginning of 1935 that a polymer called "polymer 6-6" was finally produced. Carothers' coworker, Washington University alumnus Julian W. Hill had used a cold drawing method to produce a polyester in 1930.[19] This cold drawing method was later used by Carothers in 1935 to fully develop nylon.[20] The first example of nylon (nylon 6,6) was produced on February 28, 1935, at DuPont's research facility at the DuPont Experimental Station.[7] It had all the desired properties of elasticity and strength. However, it also required a complex manufacturing process that would become the basis of industrial production in the future. DuPont obtained a patent for the polymer in September 1938,[21] and quickly achieved a monopoly of the fiber.[17] Carothers died 16 months before the announcement of nylon, therefore he was never able to see his success.[6]

The production of nylon required interdepartmental collaboration between three departments at DuPont: the Department of Chemical Research, the Ammonia Department, and the Department of Rayon. Some of the key ingredients of nylon had to be produced using high pressure chemistry, the main area of expertise of the Ammonia Department. Nylon was considered a “godsend to the Ammonia Department”,[15] which had been in financial difficulties. The reactants of nylon soon constituted half of the Ammonia department's sales and helped them come out of the period of the Great Depression by creating jobs and revenue at DuPont.[15]

DuPont's nylon project demonstrated the importance of chemical engineering in industry, helped create jobs, and furthered the advancement of chemical engineering techniques. In fact, it developed a chemical plant that provided 1800 jobs and used the latest technologies of the time, which are still used as a model for chemical plants today.[15] The ability to acquire a large number of chemists and engineers quickly was a huge contribution to the success of DuPont's nylon project.[15]:100–101 The first nylon plant was located at Seaford, Delaware, beginning commercial production on December 15, 1939. On October 26, 1995, the Seaford plant was designated a National Historic Chemical Landmark by the American Chemical Society.[22]

Early marketing strategies

An important part of nylon's popularity stems from DuPont's marketing strategy. DuPont promoted the fiber to increase demand before the product was available to the general market. Nylon's commercial announcement occurred on October 27, 1938, at the final session of the Herald Tribune's yearly "Forum on Current Problems", on the site of the approaching New York City world's fair.[16][17]:141 The "first man-made organic textile fiber" which was derived from "coal, water and air" and promised to be "as strong as steel, as fine as the spider's web" was received enthusiastically by the audience, many of them middle-class women, and made the headlines of most newspapers.[17]:141 Nylon was introduced as part of "The world of tomorrow" at the 1939 New York World's Fair[23] and was featured at DuPont's "Wonder World of Chemistry" at the Golden Gate International Exposition in San Francisco in 1939.[16][24] Actual nylon stockings were not shipped to selected stores in the national market until May 15, 1940. However, a limited number were released for sale in Delaware before that.[17]:145–146 The first public sale of nylon stockings occurred on October 24, 1939, in Wilmington, Delaware. 4,000 pairs of stockings were available, all of which were sold within three hours.[16]

Another added bonus to the campaign was that it meant reducing silk imports from Japan, an argument that won over many wary customers. Nylon was even mentioned by President Roosevelt's cabinet, which addressed its "vast and interesting economic possibilities" five days after the material was formally announced.[17]

However, the early excitement over nylon also caused problems. It fueled unreasonable expectations that nylon would be better than silk, a miracle fabric as strong as steel that would last forever and never run.[17]:145–147[13] Realizing the danger of claims such as "New Hosiery Held Strong as Steel" and "No More Runs", DuPont scaled back the terms of the original announcement, especially those stating that nylon would possess the strength of steel.[17]

Also, DuPont executives marketing nylon as a revolutionary man-made material did not at first realize that some consumers experienced a sense of unease and distrust, even fear, towards synthetic fabrics.[17]:126–128 A particularly damaging news story, drawing on DuPont's 1938 patent for the new polymer, suggested that one method of producing nylon might be to use cadaverine (pentamethylenediamine),[lower-alpha 1] a chemical extracted from corpses. Although scientists asserted that cadaverine was also extracted by heating coal, the public often refused to listen. A woman confronted one of the lead scientists at DuPont and refused to accept that the rumour was not true.[17]:146–147

DuPont changed its campaign strategy, emphasizing that nylon was made from "coal, air and water", and started focusing on the personal and aesthetic aspects of nylon, rather than its intrinsic qualities.[17]:146–147 Nylon was thus domesticated,[17]:151–152 and attention shifted to the material and consumer aspect of the fiber with slogans like "If it's nylon, it's prettier, and oh! How fast it dries!".[15]:2

Production of nylon fabric

After nylon's nationwide release in 1940, production was increased. 1300 tons of the fabric were produced during 1940.[15]:100 During their first year on the market, 64 million pairs of nylon stockings were sold.[15]:101 In 1941, a second plant was opened in Martinsville, Virginia due to the success of the fabric.[25]

While nylon was marketed as the durable and indestructible material of the people, it was sold at almost twice the price of silk stockings ($4.27 per pound of nylon versus $2.79 per pound of silk).[15]:101 Sales of nylon stockings were strong in part due to changes in women's fashion. As Lauren Olds explains: "by 1939 [hemlines] had inched back up to the knee, closing the decade just as it started off". The shorter skirts were accompanied by a demand for stockings that offered fuller coverage without the use of garters to hold them up.[26]

However, as of February 11, 1942, nylon production was redirected from being a consumer material to one used by the military.[16] DuPont's production of nylon stockings and other lingerie stopped, and most manufactured nylon was used to make parachutes and tents for World War II.[27] Although nylon stockings already made before the war could be purchased, they were generally sold on the black market for as high as $20.[25]

Once the war ended, the return of nylon was awaited with great anticipation. Although DuPont projected yearly production of 360 million pairs of stockings, there were delays in converting back to consumer rather than wartime production.[16] In 1946, the demand for nylon stockings could not be satisfied, which led to the Nylon riots. In one case, an estimated 40,000 people lined up in Pittsburgh to buy 13,000 pairs of nylons.[13] In the meantime, women cut up nylon tents and parachutes left from the war in order to make blouses and wedding dresses.[28][29] Between the end of the war and 1952, production of stockings and lingerie used 80% of the world's nylon. DuPont put a lot of focus on catering to the civilian demand, and continually expanded its production.

Introduction of nylon blends

As pure nylon hosiery was sold in a wider market, problems became apparent. Nylon stockings were found to be fragile, in the sense that the thread often tended to unravel lengthwise, creating 'runs'.[15]:101 People also reported that pure nylon textiles could be uncomfortable due to nylon's lack of absorbency.[30] Moisture stayed inside the fabric near the skin under hot or moist conditions instead of being "wicked" away.[31] Nylon fabric could also be itchy, and tended to cling and sometimes spark as a result of static electrical charge built up by friction.[32][33] Also, under some conditions stockings could decompose[17] turning back into nylon's original components of air, coal, and water. Scientists explained this as a result of air pollution, attributing it to London smog in 1952, as well as poor air quality in New York and Los Angeles.[34][35][36]

The solution found to problems with pure nylon fabric was to blend nylon with other existing fibers or polymers such as cotton, polyester, and spandex. This led to the development of a wide array of blended fabrics. The new nylon blends retained the desirable properties of nylon (elasticity, durability, ability to be dyed) and kept clothes prices low and affordable.[27]:2 As of 1950, the New York Quartermaster Procurement Agency (NYQMPA), which developed and tested textiles for the army and navy, had committed to developing a wool-nylon blend. They were not the only ones to introduce blends of both natural and synthetic fibers. America's Textile Reporter referred to 1951 as the "Year of the blending of the fibers".[37] Fabric blends included mixes like "Bunara" (wool-rabbit-nylon) and "Casmet" (wool-nylon-fur).[38] In Britain in November 1951, the inaugural address of the 198th session of the Royal Society for the Encouragement of Arts, Manufactures and Commerce focused on the blending of textiles.[39]

DuPont's Fabric Development Department cleverly targeted French fashion designers, supplying them with fabric samples. In 1955, designers such as Coco Chanel, Jean Patou, and Christian Dior showed gowns created with DuPont fibers, and fashion photographer Horst P. Horst was hired to document their use of DuPont fabrics.[13] American Fabrics credited blends with providing "creative possibilities and new ideas for fashions which had been hitherto undreamed of."[38]

Origin of the name

DuPont went through an extensive process to generate names for its new product.[17]:138–139 In 1940, John W. Eckelberry of DuPont stated that the letters "nyl" were arbitrary and the "on" was copied from the suffixes of other fibers such as cotton and Rayon. A later publication by DuPont (Context, vol. 7, no. 2, 1978) explained that the name was originally intended to be "No-Run" ("run" meaning "unravel"), but was modified to avoid making such an unjustified claim. Since the products were not really run-proof, the vowels were swapped to produce "nuron", which was changed to "nilon" "to make it sound less like a nerve tonic". For clarity in pronunciation, the "i" was changed to "y."[13][40]

Longer-term popularity

In spite of oil shortages in the 1970s, consumption of nylon textiles continued to grow by 7.5 per cent per annum between the 1960s and 1980s.[41] Overall production of synthetic fibers, however, dropped from 63% of the worlds textile production in 1965, to 45% of the world's textile production in early 1970s.[41] The appeal of "new" technologies wore off, and nylon fabric "was going out of style in the 1970s".[15] Also, consumers became concerned about environmental costs throughout the production cycle: obtaining the raw materials (oil), energy use during production, waste produced during creation of the fiber, and eventual waste disposal of materials that were not biodegradable.[41] Synthetic fibers have not dominated the market since the 1950s and 1960s. As of 2007, nylon continued to represent about 12% (8 million pounds) of the world's production of synthetic fibers.[13] As one of the largest engineering polymer families, the global demand of nylon resins and compounds was valued at roughly US$20.5 billion in 2013. The market is expected to reach US$30 billion by 2020 by following an average annual growth of 5.5%.[42]

Although pure nylon has many flaws and is now rarely used, its derivatives have greatly influenced and contributed to society. From scientific discoveries relating to the production of plastics and polymerization, to economic impact during the depression and the changing of women's fashion, nylon was a revolutionary product.[13] The Lunar Flag Assembly, the first flag planted on the moon in a symbolic gesture of celebration, was made of nylon. The flag itself cost $5.50, but had to have a specially-designed flagpole with a horizontal bar so that it would appear to "fly".[43][44] One historian describes nylon as "an object of desire", comparing the invention to Coca-Cola in the eyes of 20th century consumers.[15]

Chemistry

| External video | |

|---|---|

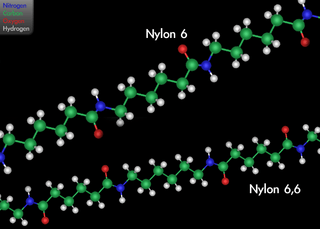

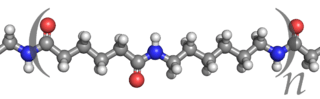

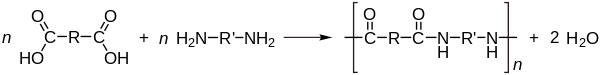

Nylons are condensation polymers or copolymers, formed by reacting difunctional monomers containing equal parts of amine and carboxylic acid, so that amides are formed at both ends of each monomer in a process analogous to polypeptide biopolymers. Most nylons are made from the reaction of a dicarboxylic acid with a diamine (e.g. PA66) or a lactam or amino acid with itself (e.g. PA6).[45] In the first case, the "repeating unit" consists of one of each monomer, so that they alternate in the chain, similar to the so-called ABAB structure of polyesters and polyurethanes. Since each monomer in this copolymer has the same reactive group on both ends, the direction of the amide bond reverses between each monomer, unlike natural polyamide proteins, which have overall directionality: C terminal → N terminal. In the second case (so called AA), the repeating unit corresponds to the single monomer.[9]:45–50[46]

Nomenclature

In common usage, the prefix "PA" (polyamide) or the name "Nylon" are used interchangeably and are equivalent in meaning.

The nomenclature used for nylon polymers was devised during the synthesis of the first simple aliphatic nylons and uses numbers to describe the number of carbons in each monomer unit, including the carbon(s) of the carboxylic acid(s).[47][48] Subsequent use of cyclic and aromatic monomers required the use of letters or sets of letters. One number after "PA" or "Nylon" indicates a homopolymer which is monadic or based on one amino acid (minus H2O) as monomer:

- PA 6 or Nylon 6: [NH−(CH2)5−CO]n made from ε-Caprolactam.

Two numbers or sets of letters indicate a dyadic homopolymer formed from two monomers: one diamine and one dicarboxylic acid. The first number indicates the number of carbons in the diamine. The two numbers should be separated by a comma for clarity, but the comma is often omitted.

- PA or Nylon 6,10 (or 610) : [NH−(CH2)6−NH−CO−(CH2)8−CO]n made from hexamethylenediamine and sebacic acid;

For copolymers the comonomers or pairs of comonomers are separated by slashes:

- PA 6/66 : [NH-(CH2)6−NH−CO−(CH2)4−CO]n−[NH−(CH2)5−CO]m made from caprolactam, hexamethylenediamine and adipic acid ;

- PA 66/610 : [NH−(CH2)6−NH−CO−(CH2)4−CO]n−[NH−(CH2)6−NH−CO−(CH2)8−CO]m made from hexamethylenediamine, adipic acid and sebacic acid.

The term polyphthalamide (abbreviated to PPA) is used when 60% or more moles of the carboxylic acid portion of the repeating unit in the polymer chain is composed of a combination of terephthalic acid (TPA) and isophthalic acid (IPA).

Types of nylon

Nylon 66

Wallace Carothers at DuPont patented nylon 66 using amides.[21][49][50] In the case of nylons that involve reaction of a diamine and a dicarboxylic acid, it is difficult to get the proportions exactly correct, and deviations can lead to chain termination at molecular weights less than a desirable 10,000 daltons (u). To overcome this problem, a crystalline, solid "nylon salt" can be formed at room temperature, using an exact 1:1 ratio of the acid and the base to neutralize each other. The salt is crystallized to purify it and obtain the desired precise stoichiometry. Heated to 285 °C (545 °F), the salt reacts to form nylon polymer with the production of water.

Nylon 6

The synthetic route using lactams (cyclic amides) was developed by Paul Schlack at IG Farben, leading to nylon 6, or polycaprolactam — formed by a ring-opening polymerization. The peptide bond within the caprolactam is broken with the exposed active groups on each side being incorporated into two new bonds as the monomer becomes part of the polymer backbone.

The 428 °F (220 °C) melting point of nylon 6 is lower than the 509 °F (265 °C) melting point of nylon 66.[51]

Nylon 510

Nylon 510, made from pentamethylene diamine and sebacic acid, was studied by Carothers even before nylon 66 and has superior properties, but is more expensive to make. In keeping with this naming convention, "nylon 6,12" or "PA 612" is a copolymer of a 6C diamine and a 12C diacid. Similarly for PA 510 PA 611; PA 1012, etc. Other nylons include copolymerized dicarboxylic acid/diamine products that are not based upon the monomers listed above. For example, some fully aromatic nylons (known as "aramids") are polymerized with the addition of diacids like terephthalic acid (→ Kevlar, Twaron) or isophthalic acid (→ Nomex), more commonly associated with polyesters. There are copolymers of PA 66/6; copolymers of PA 66/6/12; and others. In general linear polymers are the most useful, but it is possible to introduce branches in nylon by the condensation of dicarboxylic acids with polyamines having three or more amino groups.

The general reaction is:

Two molecules of water are given off and the nylon is formed. Its properties are determined by the R and R' groups in the monomers. In nylon 6,6, R = 4C and R' = 6C alkanes, but one also has to include the two carboxyl carbons in the diacid to get the number it donates to the chain. In Kevlar, both R and R' are benzene rings.

Industrial synthesis is usually done by heating the acids, amines or lactams to remove water, but in the laboratory, diacid chlorides can be reacted with diamines. For example, a popular demonstration of interfacial polymerization (the "nylon rope trick") is the synthesis of nylon 66 from adipoyl chloride and hexamethylene diamine.

Nylon 1,6

Nylons can also be synthesized from dinitriles using acid catalysis. For example, this method is applicable for preparation of nylon 1,6 from adiponitrile, formaldehyde and water.[52] Additionally, nylons can be synthesized from diols and dinitriles using this method as well.[53]

Monomers

Nylon monomers are manufactured by a variety of routes, starting in most cases from crude oil but sometimes from biomass. Those in current production are described below.

Amino acids and lactams

- ε-Caprolactam: Crude oil → benzene → cyclohexane → cyclohexanone → cyclohexanone oxime → caprolactam

- 11-aminoundecanoic acid: Castor oil → ricinoleic acid → methylricinoleate → methyl-11-undecenoate → undecenoic acid → 11-undecenoic acid → 11-bromoundecanoic acid → 11-aminoundecanoic acid[54]

- Laurolactam: Butadiene → cyclododecatriene → cyclododecane → cyclododecanone → cyclododecanone oxime → laurolactam

Diacids

- Adipic acid: Crude oil → benzene → cyclohexane → cyclohexanone + cyclohexanol → adipic acid

- Sebacic acid (decanedioic acid): Castor oil → ricinoleic acid → sebacic acid

- Dodecanedioic acid: Butadiene → Cyloclododecatriene → cyclododecane → (oxidation) → Dodecanedioic acid

- Terephthalic acid: Crude oil → p-xylene → terephthalic acid

- Isophthalic acid: Crude oil → m-xylene → isophthalic acid

Diamines

Various diamine components can be used, which are derived from a variety of sources. Most are petrochemicals, but bio-based materials are also being developed.

- Tetramethylene diamine (putrescine): Crude oil → propylene → acrylonitrile → succinonitrile → tetramethylene diamine

- Hexamethylene diamine (HMD): Crude oil → butadiene → adiponitrile → hexamethylene diamine

- 1,9-diaminononane: Crude oil → butadiene → 7-octen-1-al → 1,9-nonanedial → 1,9-diaminononane[55]

- 2-methyl pentamethylene diamine: a by product of HMD production

- Trimethyl Hexamethylene diamine (TMD): Crude oil → propylene → acetone → isophorone → TMD

- m-xylylene diamine (MXD): Crude oil → m-xylene → isophthalic acid → isophthalonitrile → m-xylylene diamine[56]

- 1,5-pentanediamine (cadaverine) (PMD): starch (e.g. cassava) → glucose → lysine → PMD.[57]

Polymers

Due to the large number of diamines, diacids and aminoacids that can be synthesized, many nylon polymers have been made experimentally and characterized to varying degrees. A smaller number have been scaled up and offered commercially, and these are detailed below.

Homopolymers

Homopolymer nylons derived from one monomer

| Monomer | Polymer |

|---|---|

| caprolactam | 6 |

| 11-aminoundecanoic acid | 11 |

| ω-aminolauric acid | 12 |

Examples of these polymers that are or were commercially available

Homopolymer polyamides derived from pairs of diamines and diacids (or diacid derivatives). Shown in the table below are polymers which are or have been offered commercially either as homopolymers or as a part of a copolymer.

| 1,4-diaminobutane | 1,5-diaminopentane | MPMD | HMD | MXD | Nonanediamine | Decanediamine | Dodecanediamine | bis(para-aminocyclohexyl)methane | trimethylhexamethylenediamine | |

|---|---|---|---|---|---|---|---|---|---|---|

| Adipic acid | 46 | D6 | 66 | MXD6 | ||||||

| Sebacic acid | 410 | 510 | 610 | 1010 | ||||||

| Dodecanedioic acid | 612 | 1212 | PACM12 | |||||||

| Terephthalic acid | 4T | DT | 6T | 9T | 10T | 12T | TMDT | |||

| Isophthalic acid | DI | 6I |

Examples of these polymers that are or were commercially available

Copolymers

It is easy to make mixtures of the monomers or sets of monomers used to make nylons to obtain copolymers. This lowers crystallinity and can therefore lower the melting point.

Some copolymers that have been or are commercially available are listed below:

Blends

Most nylon polymers are miscible with each other allowing a range of blends to be made. The two polymers can react with one another by transamidation to form random copolymers.[69]

According to their crystallinity, polyamides can be:

- semi-crystalline:

- high crystallinity: PA46 and PA66;

- low crystallinity: PAMXD6 made from m-xylylenediamine and adipic acid;

- amorphous: PA6I made from hexamethylenediamine and isophthalic acid.

According to this classification, PA66, for example, is an aliphatic semi-crystalline homopolyamide.

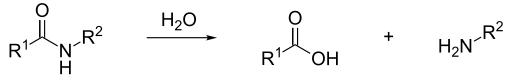

Hydrolysis and degradation

All nylons are susceptible to hydrolysis, especially by strong acids, a reaction essentially the reverse of the synthetic reaction shown above. The molecular weight of nylon products so attacked drops, and cracks form quickly at the affected zones. Lower members of the nylons (such as nylon 6) are affected more than higher members such as nylon 12. This means that nylon parts cannot be used in contact with sulfuric acid for example, such as the electrolyte used in lead–acid batteries.

When being molded, nylon must be dried to prevent hydrolysis in the molding machine barrel since water at high temperatures can also degrade the polymer.[70] The reaction is of the type:

Environmental impact, incineration and recycling

Berners-Lee calculates the average greenhouse gas footprint of nylon in manufacturing carpets at 5.43 kg CO2 equivalent per kg, when produced in Europe. This gives it almost the same carbon footprint as wool, but with greater durability and therefore a lower overall carbon footprint.[71]

Data published by PlasticsEurope indicates for nylon 66 a greenhouse gas footprint of 6.4 kg CO2 equivalent per kg, and an energy consumption of 138 kJ/kg.[72] When considering the environmental impact of nylon, it is important to consider the use phase. In particular when cars are lightweight, significant savings in fuel consumption and CO2 emissions are achieved.

Various nylons break down in fire and form hazardous smoke, and toxic fumes or ash, typically containing hydrogen cyanide. Incinerating nylons to recover the high energy used to create them is usually expensive, so most nylons reach the garbage dumps, decaying slowly.[lower-alpha 2] Discarded nylon fabric takes 30–40 years to decompose.[73] Nylon is a robust polymer and lends itself well to recycling. Much nylon resin is recycled directly in a closed loop at the injection molding machine, by grinding sprues and runners and mixing them with the virgin granules being consumed by the molding machine.[74]

Nylon can be recycled but only a few companies do so. Aquafil has demonstrated recycling fishing nets lost in the ocean into apparel[75] Vanden recycles Nylon and other polyamides (PA) and has operations in UK, Australia, Hong Kong, UAE, Turkey and Finland.[76]

Bulk properties

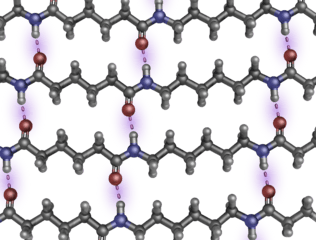

Above their melting temperatures, Tm, thermoplastics like nylon are amorphous solids or viscous fluids in which the chains approximate random coils. Below Tm, amorphous regions alternate with regions which are lamellar crystals.[77] The amorphous regions contribute elasticity and the crystalline regions contribute strength and rigidity. The planar amide (-CO-NH-) groups are very polar, so nylon forms multiple hydrogen bonds among adjacent strands. Because the nylon backbone is so regular and symmetrical, especially if all the amide bonds are in the trans configuration, nylons often have high crystallinity and make excellent fibers. The amount of crystallinity depends on the details of formation, as well as on the kind of nylon.

Nylon 66 can have multiple parallel strands aligned with their neighboring peptide bonds at coordinated separations of exactly 6 and 4 carbons for considerable lengths, so the carbonyl oxygens and amide hydrogens can line up to form interchain hydrogen bonds repeatedly, without interruption (see the figure opposite). Nylon 510 can have coordinated runs of 5 and 8 carbons. Thus parallel (but not antiparallel) strands can participate in extended, unbroken, multi-chain β-pleated sheets, a strong and tough supermolecular structure similar to that found in natural silk fibroin and the β-keratins in feathers. (Proteins have only an amino acid α-carbon separating sequential -CO-NH- groups.) Nylon 6 will form uninterrupted H-bonded sheets with mixed directionalities, but the β-sheet wrinkling is somewhat different. The three-dimensional disposition of each alkane hydrocarbon chain depends on rotations about the 109.47° tetrahedral bonds of singly bonded carbon atoms.

When extruded into fibers through pores in an industry spinneret, the individual polymer chains tend to align because of viscous flow. If subjected to cold drawing afterwards, the fibers align further, increasing their crystallinity, and the material acquires additional tensile strength. In practice, nylon fibers are most often drawn using heated rolls at high speeds.[78]

Block nylon tends to be less crystalline, except near the surfaces due to shearing stresses during formation. Nylon is clear and colorless, or milky, but is easily dyed. Multistranded nylon cord and rope is slippery and tends to unravel. The ends can be melted and fused with a heat source such as a flame or electrode to prevent this.

Nylons are hygroscopic, and will absorb or desorb moisture as a function of the ambient humidity. Variations in moisture content have several effects on the polymer. Firstly, the dimensions will change, but more importantly moisture acts as a plasticizer, lowering the glass transition temperature (Tg), and consequently the elastic modulus at temperatures below the Tg[79]

When dry, polyamide is a good electrical insulator. However, polyamide is hygroscopic. The absorption of water will change some of the material's properties such as its electrical resistance. Nylon is less absorbent than wool or cotton.

Characteristics

The characteristic features of nylon 6,6 include:

- Pleats and creases can be heat-set at higher temperatures

- More compact molecular structure

- Better weathering properties; better sunlight resistance

- Softer "Hand"

- High melting point (256 °C, 492.8 °F)

- Superior colorfastness

- Excellent abrasion resistance

On the other hand, nylon 6 is easy to dye, more readily fades; it has a higher impact resistance, a more rapid moisture absorption, greater elasticity and elastic recovery.

- Variation of luster: nylon has the ability to be very lustrous, semi-lustrous or dull.

- Durability: its high tenacity fibers are used for seatbelts, tire cords, ballistic cloth and other uses.

- High elongation

- Excellent abrasion resistance

- Highly resilient (nylon fabrics are heat-set)

- Paved the way for easy-care garments

- High resistance to insects, fungi, animals, as well as molds, mildew, rot and many chemicals

- Used in carpets and nylon stockings

- Melts instead of burning

- Used in many military applications

- Good specific strength

- Transparent to infrared light (−12 dB)[80]

Uses of nylon

Nylon was first used commercially in a nylon-bristled toothbrush in 1938,[11][12] followed more famously in women's stockings or "nylons" which were shown at the 1939 New York World's Fair and first sold commercially in 1940.[13] Its use increased dramatically during World War II, when the need for fabrics increased dramatically.

Nylon fibers

Bill Pittendreigh, DuPont, and other individuals and corporations worked diligently during the first few months of World War II to find a way to replace Asian silk and hemp with nylon in parachutes. It was also used to make tires, tents, ropes, ponchos, and other military supplies. It was even used in the production of a high-grade paper for U.S. currency. At the outset of the war, cotton accounted for more than 80% of all fibers used and manufactured, and wool fibers accounted for nearly all of the rest. By August 1945, manufactured fibers had taken a market share of 25%, at the expense of cotton. After the war, because of shortages of both silk and nylon, nylon parachute material was sometimes repurposed to make dresses.[83]

Nylon 6 and 66 fibers are used in carpet manufacture.

Nylon is one kind of fibers used in tire cord. Herman E. Schroeder pioneered application of nylon in tires.

Molds and resins

Nylon resins are widely used in the automobile industry especially in the engine compartment.[84][2]:514

Molded nylon is used in hair combs and mechanical parts such as machine screws, gears, gaskets, and other low- to medium-stress components previously cast in metal.[85][86] Engineering-grade nylon is processed by extrusion, casting, and injection molding. Type 6,6 Nylon 101 is the most common commercial grade of nylon, and Nylon 6 is the most common commercial grade of molded nylon.[87][88] For use in tools such as spudgers, nylon is available in glass-filled variants which increase structural and impact strength and rigidity, and molybdenum disulfide-filled variants which increase lubricity. Nylon can be used as the matrix material in composite materials, with reinforcing fibers like glass or carbon fiber; such a composite has a higher density than pure nylon.[89] Such thermoplastic composites (25% to 30% glass fiber) are frequently used in car components next to the engine, such as intake manifolds, where the good heat resistance of such materials makes them feasible competitors to metals.[90]

Nylon was used to make the stock of the Remington Nylon 66 rifle.[91] The frame of the modern Glock pistol is made of a nylon composite.[92]

Food packaging

Nylon resins are used as a component of food packaging films where an oxygen barrier is needed.[4] Some of the terpolymers based upon nylon are used every day in packaging. Nylon has been used for meat wrappings and sausage sheaths.[93] The high temperature resistance of nylon makes it useful for oven bags.[94]

Filaments

Nylon filaments are primarily used in brushes especially toothbrushes[11] and string trimmers. They are also used as monofilaments in fishing line. Nylon 610 and 612 are the most used polymers for filaments.

Its various properties also make it very useful as a material in additive manufacturing; specifically as a filament in consumer and professional grade fused deposition modeling 3D printers.

Other forms

Extruded profiles

Nylon resins can be extruded into rods, tubes and sheets.[2]:209

Powder coating

Nylon powders are used to powder coat metals. Nylon 11 and nylon 12 are the most widely used.[2]:53

Instrument strings

In the mid-1940s, classical guitarist Andrés Segovia mentioned the shortage of good guitar strings in the United States, particularly his favorite Pirastro catgut strings, to a number of foreign diplomats at a party, including General Lindeman of the British Embassy. A month later, the General presented Segovia with some nylon strings which he had obtained via some members of the DuPont family. Segovia found that although the strings produced a clear sound, they had a faint metallic timbre which he hoped could be eliminated.[95]

Nylon strings were first tried on stage by Olga Coelho in New York in January, 1944.[96]

In 1946, Segovia and string maker Albert Augustine were introduced by their mutual friend Vladimir Bobri, editor of Guitar Review. On the basis of Segovia's interest and Augustine's past experiments, they decided to pursue the development of nylon strings. DuPont, skeptical of the idea, agreed to supply the nylon if Augustine would endeavor to develop and produce the actual strings. After three years of development, Augustine demonstrated a nylon first string whose quality impressed guitarists, including Segovia, in addition to DuPont.[95]

Wound strings, however, were more problematic. Eventually, however, after experimenting with various types of metal and smoothing and polishing techniques, Augustine was also able to produce high quality nylon wound strings.[95]

See also

Notes

- Actually the most common nylon polymers are made from hexamethylenediamine, with one more CH2 group than cadaverine.

- Typically 80 to 100% is sent to landfill or garbage dumps, while less than 18% are incinerated while recovering the energy. See Francesco La Mantia (August 2002). Handbook of plastics recycling. iSmithers Rapra Publishing. pp. 19–. ISBN 978-1-85957-325-9.

References

- Vogler, H. (2013). "Wettstreit um die Polyamidfasern". Chemie in Unserer Zeit. 47: 62–63. doi:10.1002/ciuz.201390006.

- Kohan, Melvin (1995). Nylon Plastics Handbook. Munich: Carl Hanser Verlag. ISBN 1569901899.

- Clark, Jim. "Polyamides". Chemguide. Retrieved 27 January 2015.

- "Nylons (Polyamide)". British Plastics Federation. Retrieved 19 June 2017.

- "Science of Plastics". Science History Institute. 2016-07-18. Retrieved 26 March 2018.

- DuPont (1988). Nylon: A DuPont Invention. DuPont International, Public Affairs. pp. 2–3.

- American Chemical Society National Historic Chemical Landmarks. "Foundations of Polymer Science: Wallace Hume Carothers and the Development of Nylon". ACS Chemistry for Life. Retrieved 27 January 2015.

- "Wallace Hume Carothers". Science History Institute. June 2016. Retrieved 20 March 2018.

- McIntyre, J. E. (2005). Synthetic fibres : nylon, polyester, acrylic, polyolefin (1st ed.). Cambridge: Woodhead. p. 10. ISBN 9780849325922. Retrieved 5 July 2017.

- Travis, Anthony S. (1998). Determinants in the evolution of the European chemical industry : 1900-1939 : new technologies, political frameworks, markets and companies. Dordrecht: Kluwer Acad. Publ. p. 115. ISBN 9780792348900. Retrieved 5 July 2017.

- "Nylon, a Petroleum Polymer". American Oil and Gas Historical Society. Retrieved 21 June 2017.

- Nicholson, Joseph L.; Leighton, George R. (August 1942). "Plastics Come of Age". Harper's Magazine. pp. 300–307. Retrieved 5 July 2017.

- Wolfe, Audra J. (2008). "Nylon: A Revolution in Textiles". Chemical Heritage Magazine. 26 (3). Retrieved 20 March 2018.

- "The History and Future of Plastics". Conflicts in Chemistry: The Case of Plastics. 2016-07-18. Retrieved 20 March 2018.

- Ndiaye, Pap A.; Forster, Elborg (2007). Nylon and bombs : DuPont and the march of modern America. Baltimore: Johns Hopkins University Press. p. 182. ISBN 9780801884443. Retrieved 19 June 2017.

- Kativa, Hillary (2016). "Synthetic Threads". Distillations. 2 (3): 16–21. Retrieved 20 March 2018.

- Meikle, Jeffrey L. (1995). American plastic : A cultural history (1. ppb. print ed.). New Brunswick, NJ: Rutgers University Press. ISBN 0813522358.

- "Neoprene: The First Synthetic Rubber". chlorine.americanchemistry.com. Retrieved 2018-12-06.

- "Wallace Carothers and the Development of Nylon - Landmark". American Chemical Society. Retrieved 2019-08-14.

- Stout, David (1996-02-01). "Julian W. Hill, Nylon's Discoverer, Dies at 91". The New York Times. ISSN 0362-4331. Retrieved 2019-08-14.

- "Linear polyamides and their production US 2130523 A". Patents. Retrieved 19 June 2017.

- "A NATIONAL HISTORIC CHEMICAL LANDMARK THE FIRST NYLON PLANT" (PDF). AMERICAN CHEMICAL SOCIETY. Retrieved 26 June 2017.

- Blakinger, Keri (April 30, 2016). "A look back at some of the coolest attractions at the 1939 World's Fair". New York Daily News. Retrieved 20 June 2017.

- Sundberg, Richard J. (2017). The Chemical Century: Molecular Manipulation and Its Impact on the 20th Century. Apple Academic Press, Incorporated. ISBN 9781771883665.

- Colbert, Judy (2013). It Happened in Delaware. Rowman & Littlefield. p. 60. ISBN 978-0-7627-9577-2.

- Olds, Lauren (2001). "World War II and Fashion: The Birth of the New Look". Constructing the Past. 2 (1): Article 6. Retrieved 19 June 2017.

- Krier, Beth Ann (27 October 1988). "How Nylon Changed the World : 50 Years Ago Today, It Reshaped the Way We Live--and Think". LA Times.

- "Parachute Wedding Dress, 1947". Smithsonian National Museum of American History. Retrieved 20 June 2017.

- Woman's Home Companion. Crowell-Collier Publishing Company. 75: 155. 1948. Missing or empty

|title=(help) - Reader's Digest (2002). New complete guide to sewing: step-by-step techniques for making clothes and home accessories. London: Reader's Digest. p. 19. ISBN 9780762104208. Retrieved 26 June 2017.

- "How to buy a trail bed". Backpacker. 5 (3): 70. June 1977. Retrieved 26 June 2017.

- Mendelson, Cheryl (2005). Home comforts : the art and science of keeping house. New York: Scribner. p. 224. ISBN 978-0743272865. Retrieved 26 June 2017.

- Shaeffer, Claire (2008). Claire Shaeffer's fabric sewing guide (2nd ed.). Cincinnati, Ohio: Krause Publications. pp. 88–90. ISBN 978-0896895362.

- Cheremisinoff, Nicholas P. (2002). Handbook of air pollution prevention and control. Amsterdam: Butterworth-Heinemann. p. 65. ISBN 9780080507927.

- Stern, Arthur C., ed. (1970). Air pollution and its effects (2nd ed.). New York: Academic press. p. 72. ISBN 978-0-12-666551-2. Retrieved 26 June 2017.

- Garte, Seymour (2008). Where we stand : a surprising look at the real state of our planet. New York: AMACOM. p. 60. ISBN 978-0814409107. Retrieved 26 June 2017.

- Haggard, John V. (16 May 1957). "Chapter III: Collaborative Procurement of Textiles". Procurement of Clothing and Textiles, 1945-53. 2 (3): 79–84.

- Handley, Susannah (1999). Nylon: The Story of a Fashion Revolution. Baltimore, MD: Johns Hopkins University Press. p. 68. ISBN 978-0756771720. Retrieved 26 June 2017.

- Goodale, Ernest W. (16 November 1951). "The Blending & Mixture of Textile Fibres & Yarns". Journal of the Royal Society of Arts. 100 (4860): 4–15. JSTOR 41368063.

- Algeo, John (2009). The Origins and Development of the English Language. 6. Cengage. p. 224. ISBN 9781428231450.

- Wilson, Sheena; Carlson, Adam; Szeman, Imre (2017). Petrocultures: Oil, Politics, Culture. Montreal, Quebec: McGill-Queen's University Press. p. 246. ISBN 9780773550391. Retrieved 26 June 2017.

- "Market Report: Global Polyamide Market". Acmite Market Intelligence. December 2014.

- Welsh, Jennifer (21 May 2016). "The American Flags on the Moon Have All Turned White". Business Insider. Retrieved 14 April 2017.

- Platoff, Anne M. (1993). "NASA Contractor Report 188251 Where No Flag Has Gone Before: Political and Technical Aspects of Placing a Flag on the Moon". NASA. Retrieved 26 June 2017.

- Ratner, Buddy D. (2013). Biomaterials science : an introduction to materials in medicine (3rd ed.). Amsterdam: Elsevier. pp. 74–77. ISBN 9780080877808. Retrieved 5 July 2017.

- Denby, Derek; Otter, Chris; Stephenson, Kay (2008). Chemical storylines (3rd ed.). Oxford: Heinemann. p. 96. ISBN 9780435631475. Retrieved 5 July 2017.

- Cowie, J.M.G. (1991). Polymers: Chemistry and Physics of Modern Materials (2nd ed.). Blackie. pp. 16-17. ISBN 0-216-92980-6.

- Rudin, Alfred (1982). Elements of Polymer Science and Engineering. Academic Press. pp. 32-33. ISBN 0-12-601680-1.

- "Diamine-dicarboxylic acid salts and process of preparing same US 2130947 A". Patents. Retrieved 19 June 2017.

- "Synthetic fiber US 2130948 A". Patents. Retrieved 19 June 2017.

- "Fiber-reinforced composite articles and methods of making them CA 2853925 A1". Patents. Retrieved 19 June 2017.

- Magat, Eugene E.; Faris, Burt F.; Reith, John E.; Salisbury, L. Frank (1951-03-01). "Acid-catalyzed Reactions of Nitriles. I. The Reaction of Nitriles with Formaldehyde1". Journal of the American Chemical Society. 73 (3): 1028–1031. doi:10.1021/ja01147a042. ISSN 0002-7863.

- Lakouraj, Moslem Mansour; Mokhtary, Masoud (2009-02-20). "Synthesis of polyamides from p-Xylylene glycol and dinitriles". Journal of Polymer Research. 16 (6): 681. doi:10.1007/s10965-009-9273-z. ISSN 1022-9760.

- Gotro, Jeffrey (May 6, 2013). "Bio-Polyamides: Where Do They Come From?". Polymer Innovation Blog.

- "Process for producing 1,9-nonanedial US 4510332 A". Patents. Retrieved 19 June 2017.

- "Preparation of xylylenediamines US 2970170 A". Patents. Retrieved 19 June 2017.

- "Ajinomoto and Toray to Conduct Joint Research on Biobased Nylon". Toray. 3 Feb 2012. Retrieved 23 May 2015.

- "Durethan® is the trade name for our range of engineering thermoplastics based on polyamide 6 and polyamide 66". LANXESS Energizing Chemistry. Retrieved 19 June 2017.

- "Polyamide Resins for an Extreme World Flagship Rilsan® PA11 and Complementary Resins & Alloys". Arkema. Retrieved 19 June 2017.

- "VESTAMID® L—polyamide 12". EVONIK. Retrieved 19 June 2017.

- "Stanyl® Polyamide 46: Driving change in automotive". DSM. Retrieved 19 June 2017.

- "EcoPaXX: The green performer". DSM. Retrieved 19 June 2017.

- "ForTii® Pushing peak performance". DSM. Retrieved 19 June 2017.

- "zytel - PA6, PA610, PA612, PA66 - dupont". Material Data Center. Retrieved 19 June 2017.

- "Zytel® 74G33EHSL NC010". DISTRUPOL. Retrieved 19 June 2017.

- Kutz, Myer (2011). Applied plastics engineering handbook processing and materials (1st ed.). Amsterdam: William Andrew. p. 5. ISBN 9781437735154. Retrieved 19 June 2017.

- "DuPont TM Selar® PA 2072" (PDF). DuPont. Archived from the original (PDF) on 2015-04-19. Retrieved 19 June 2017.

- "Grilamid L PA12". EMS. Retrieved 19 June 2017.

- Samperi, Filippo; Montaudo, Maurizio S.; Puglisi, Concetto; Di Giorgi, Sabrina; Montaudo, Giorgio (August 2004). "Structural Characterization of Copolyamides Synthesized via the Facile Blending of Polyamides". Macromolecules. 37 (17): 6449–6459. Bibcode:2004MaMol..37.6449S. doi:10.1021/ma049575x.

- "Adhesive for nylon & kevlar". Reltek. Retrieved 27 January 2015.

- Berners-Lee, Mike (2010). How bad are bananas? : the carbon footprint of everything. London: Profile Books. p. 112, table 6.1.

- Eco-profiles and Environmental Product Declarations of the European Plastics Manufacturers: Polyamide 6.6. Brussels: PlasticsEurope AISBL. 2014. Archived from the original on 2015-04-27. Retrieved 2015-04-19.

- "Approximate Time it Takes for Garbage to Decompose in the Environment" (PDF). NH Department of Environmental Services. Archived from the original (PDF) on 2009-04-13. Retrieved 31 March 2018.

- Boydell, P; Bradfield, C; von Falkenhausen, V; Prautzsch, G (1995). "Recycling of Waste from Glass-reinforced nylon resins". Engineering Design. 2: 8–10.

- Maile, Kelly (January 18, 2019). "How abandoned fishing nets are recycled into nylon". Recycling Today. Retrieved 15 March 2019.

- Vanden Recycling. "PA / Nylon fibres are used in textiles, fishing line and carpets". Retrieved 7 Feb 2020.

- Valerie Menzer's Nylon 66 Webpage. Arizona University

- Campbell, Ian M. (2000). Introduction to synthetic polymers. Oxford: Oxford Univ. Press. ISBN 978-0198564706.

- "Measurement of Moisture Effects on the Mechanical Properties of 66 Nylon - TA Instruments Thermal Analysis Application Brief TA-133" (PDF). TA Instruments. Retrieved 19 June 2017.

- Bjarnason, J. E.; Chan, T. L. J.; Lee, A. W. M.; Celis, M. A.; Brown, E. R. (2004). "Millimeter-wave, terahertz, and mid-infrared transmission through common clothing". Applied Physics Letters. 85 (4): 519. Bibcode:2004ApPhL..85..519B. doi:10.1063/1.1771814.

- "Flammable clothing". The Children's Hospital at Westmead. Retrieved 5 July 2017.

- Workshop on Mass Burns (1968 : Washington, D.C.) (1969). Phillips, Anne W.; Walter, Carl W. (eds.). Mass burns : proceeding of a workshop, 13-14 March 1968 / sponsored by the Committee on Fire Research, Division of Engineering, National Research Council and the Office of Civil Defense, Dept. of the Army. Washington, D.C.: National Academy of Sciences ; Springfield, Va. : reproduced by the Clearinghouse for Federal Scientific & Technical Information. p. 30. Retrieved 5 July 2017.

- Caruso, David (2009). "Saving the (Wedding) Day: Oral History Spotlight" (PDF). Transmutations. Fall (5): 2. Archived from the original (PDF) on July 12, 2016.

- "Engine Oil Pan". www.materialdatacenter.com. Retrieved 19 June 2017.

- "Nylon Machining & Fabrication | ESPE". www.espemfg.com. Retrieved 2018-08-28.

- Youssef, Helmi A.; El-Hofy, Hassan A.; Ahmed, Mahmoud H. (2011). Manufacturing technology : materials, processes, and equipment. Boca Raton, FL: Taylor & Francis/CRC Press. p. 350. ISBN 9781439810859.

- "NYLON 6,6 (Nylon 6)" (PDF). Serrata. Retrieved 19 June 2017.

- "Nylon 6 vs. Nylon 66: What's the Difference?". PolyOne. Retrieved 5 July 2017.

- "Fiberglass and Composite Material Design Guide". Performance Composites Inc. Retrieved 27 January 2015.

- Page, I. B. (2000). Polyamides as engineering thermoplastic materials. Shawbury, Shrewsbury: Rapra Technology Ltd. p. 115. ISBN 9781859572207.

- "How do you take care of a nylon 66 or 77? You don't". Field & Stream. 75 (9). 1971.

- Sweeney, Patrick (2013). Glock deconstructed. Iola, Wis.: Krause. p. 92. ISBN 978-1440232787.

- Colbert, Judy (2013). It happened in Delaware : remarkable events that shaped history (First ed.). Morris Book Publishing. ISBN 978-0-7627-6968-1.

- "Oven Bags". Cooks Info. Retrieved 19 April 2015.

- "The History of Classical guitar strings". Maestros of the Guitar. Retrieved 27 January 2015.

- Bellow, Alexander (1970). The Illustrated History of the Guitar. New York: Franco Colombo. p. 193.

Further reading

- Kadolph, Sara J. (2007). Textiles. Pearson Prentice Hall. ISBN 978-0-13-118769-6.

- Kohan, Melvin (1995). Nylon Plastics Handbook. Munich: Carl Hanser Verlag. ISBN 1569901899.

- "How Nylon Yarn is Made". Popular Science. Bonnier Corporation: 132–3. December 1946.

External links

| Wikimedia Commons has media related to Nylon. |

- Making Nylon, Bob Burk, CHEM 1000, Carleton University, Ottawa, Canada on YouTube

- Polyamide Nylon Plastic

- Joseph X. Labovsky Collection of Nylon Photographs and Ephemera Science History Institute Digital Collections. (High-resolution scans of nylon-related photographs and ephemera collected by Joseph X. Labovsky, a lab assistant to Wallace Carothers, during the early stages of nylon development and production at DuPont).

.svg.png)