Manufacturing

Manufacturing is the production of products for use or sale, using labor and machines, tools, and chemical or biological processing or formulation. It is the essence of secondary industry. The term may refer to a range of human activity, from handicraft to high-tech, but is most commonly applied to industrial design, in which raw materials from primary industry are transformed into finished goods on a large scale. Such goods may be sold to other manufacturers for the production of other more complex products (such as aircraft, household appliances, furniture, sports equipment or automobiles), or distributed via the tertiary industry to end users and consumers (usually through wholesalers, who in turn sell to retailers, who then sell them to individual customers).

| Part of a series of articles on |

| Machine industry |

|---|

|

| Manufacturing methods |

| Industrial technologies |

| Information and communication |

| Process control |

Manufacturing engineering, or the manufacturing process, are the steps through which raw materials are transformed into a final product. The manufacturing process begins with the product design, and materials specification from which the product is made. These materials are then modified through manufacturing processes to become the required part.

Modern manufacturing includes all intermediate processes required in the production and integration of a product's components. Some industries, such as semiconductor and steel manufacturers, use the term fabrication instead.

The manufacturing sector is closely connected with engineering and industrial design. Examples of major manufacturers in North America include General Motors Corporation, General Electric, Procter & Gamble, General Dynamics, Boeing, Pfizer, Precision Castparts, and Fiat Chrysler Automobiles. Examples in Europe include Volkswagen Group, Siemens, BASF and Michelin. Examples in Asia include Toyota, Yamaha, Panasonic, LG, Samsung and Tata Motors.

History and development

In its earliest form, manufacturing was usually carried out by a single skilled artisan with assistants. Training was by apprenticeship. In much of the pre-industrial world, the guild system protected the privileges and trade secrets of urban artisans.

In the pre-industrial world, most manufacturing occurred in rural areas, where household-based manufacturing served as a supplemental subsistence strategy to agriculture (and continues to do so in places). Entrepreneurs organized a number of manufacturing households into a single enterprise through the putting-out system.

The factory system was first adopted in Britain at the beginning of the Industrial Revolution in the late 18th century and later spread around the world.[1] The main characteristic of the factory system is the use of machinery, originally powered by water or steam and later by electricity. Increased use of economies of scale, the centralization of factories, and standardization of interchangeable parts were adopted in the American system of manufacturing in the nineteenth century.

The mechanized assembly line was introduced to assemble parts in a repeatable fashion, with individual workers performing specific steps during the process. This led to significant increases in efficiency, lowering the cost of the end process. Later, automation was introduced to incrementally replace human operators, a trend that has accelerated with the development of the computer and the robot.

Manufacturing in the Soviet Union was based on collectivism.

Manufacturing systems: methods of manufacturing

- Agile manufacturing

- Fabrication

- Flexible manufacturing

- Just-in-time manufacturing

- Lean manufacturing

- Manufacturing engineering

- Mass customization

- Mass production

- Numerical control

- Prefabrication

- Rapid manufacturing

- Reconfigurable manufacturing system

Industrial policy

Economics of manufacturing

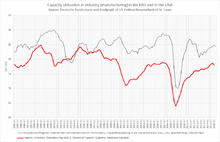

Emerging technologies have provided some new growth in advanced manufacturing employment opportunities in the Manufacturing Belt in the United States. Manufacturing provides important material support for national infrastructure and for national defense.

On the other hand, most manufacturing may involve significant social and environmental costs. The clean-up costs of hazardous waste, for example, may outweigh the benefits of a product that creates it. Hazardous materials may expose workers to health risks. These costs are now well known and there is effort to address them by improving efficiency, reducing waste, using industrial symbiosis, and eliminating harmful chemicals.

The negative costs of manufacturing can also be addressed legally. Developed countries regulate manufacturing activity with labor laws and environmental laws. Across the globe, manufacturers can be subject to regulations and pollution taxes to offset the environmental costs of manufacturing activities. Labor unions and craft guilds have played a historic role in the negotiation of worker rights and wages. Environment laws and labor protections that are available in developed nations may not be available in the third world. Tort law and product liability impose additional costs on manufacturing. These are significant dynamics in the ongoing process, occurring over the last few decades, of manufacture-based industries relocating operations to "developing-world" economies where the costs of production are significantly lower than in "developed-world" economies.

Safety

Manufacturing has unique health and safety challenges and has been recognized by the National Institute for Occupational Safety and Health (NIOSH) as a priority industry sector in the National Occupational Research Agenda (NORA) to identify and provide intervention strategies regarding occupational health and safety issues.[2][3]

Manufacturing and investment

Surveys and analyses of trends and issues in manufacturing and investment around the world focus on such things as:

- The nature and sources of the considerable variations that occur cross-nationally in levels of manufacturing and wider industrial-economic growth;

- Competitiveness; and

- Attractiveness to foreign direct investors.

In addition to general overviews, researchers have examined the features and factors affecting particular key aspects of manufacturing development. They have compared production and investment in a range of Western and non-Western countries and presented case studies of growth and performance in important individual industries and market-economic sectors.[4][5]

On June 26, 2009, Jeff Immelt, the CEO of General Electric, called for the United States to increase its manufacturing base employment to 20% of the workforce, commenting that the U.S. has outsourced too much in some areas and can no longer rely on the financial sector and consumer spending to drive demand.[6] Further, while U.S. manufacturing performs well compared to the rest of the U.S. economy, research shows that it performs poorly compared to manufacturing in other high-wage countries.[7] A total of 3.2 million – one in six U.S. manufacturing jobs – have disappeared between 2000 and 2007.[8] In the UK, EEF the manufacturers organization has led calls for the UK economy to be rebalanced to rely less on financial services and has actively promoted the manufacturing agenda.

List of countries by manufacturing output

List of top 20 manufacturing countries by total value of manufacturing in US dollars for its noted year according to World Bank.[9]

| Rank | Country/Region | Millions of $US | Year |

|---|---|---|---|

| World | 13,171,000 | 2017 | |

| 1 | 4,002,752 | 2018 | |

| 2 | 2,173,319 | 2017 | |

| 3 | 1,007,330 | 2017 | |

| 4 | 832,431 | 2018 | |

| 5 | 440,941 | 2018 | |

| 6 | 408,693 | 2018 | |

| 7 | 310,897 | 2018 | |

| 8 | 273,971 | 2018 | |

| 9 | 251,985 | 2018 | |

| 10 | 208,498 | 2018 | |

| 11 | 207,017 | 2018 | |

| 12 | 203,988 | 2018 | |

| 13 | 180,541 | 2018 | |

| 14 | 180,264 | 2018 | |

| 15 | 160,531 | 2015 | |

| 16 | 146,077 | 2018 | |

| 17 | 135,927 | 2018 | |

| 18 | 129,162 | 2018 | |

| 19 | 115,591 | 2018 | |

| 20 | 100,232 | 2018 | |

Manufacturing processes

- List of manufacturing processes

- Manufacturing Process Management

Control

- Management

- List of management topics

- Total quality management

- Quality control

See also

- List of largest manufacturing companies by revenue

- Industrial robot

- National Occupational Research Agenda Manufacturing Sector Council, USA

- Manufacturing engineering

- Process manufacturing

- Manufacturing in the United States

- Industrial engineering

- Advanced manufacturing

- Metal fabrication

- Microfabrication

- Optics fabrication

- Semiconductor device fabrication

- Biomanufacturing

- Mesoscale Manufacturing

- Cyber manufacturing

- Taylorism/Scientific management

- Fordism

References

- Walker, William (1993). "National Innovation Systems: Britain". In Nelson, Richard R. (ed.). National innovation systems: a comparative analysis. New York: Oxford University Press. ISBN 0195076176.

- "Manufacturing Program | NORA | CDC". www.cdc.gov. 2019-02-11. Retrieved 2019-03-14.

- "National Occupational Research Agenda for Manufacturing | NIOSH | CDC". www.cdc.gov. 2019-02-04. Retrieved 2019-03-14.

- Manufacturing & Investment Around The World: An International Survey Of Factors Affecting Growth & Performance, ISR Publications/Google Books, revised second edition, 2002. ISBN 978-0-906321-25-6.

- Research, Industrial Systems (2002-05-20). Manufacturing and Investment Around the World: An International Survey of Factors Affecting Growth and Performance. ISBN 978-0-906321-25-6.

- Bailey, David and Soyoung Kim (June 26, 2009).GE's Immelt says U.S. economy needs industrial renewal. UK Guardian. Retrieved on June 28, 2009.

- Brookings Institution, Why Does Manufacturing Matter? Which Manufacturing Matters?, February 2012 Archived 2012-10-08 at the Wayback Machine

- "Factory jobs: 3 million lost since 2000". USATODAY.com. April 20, 2007.

- "Manufacturing, value added (current US$) | Data". data.worldbank.org. Retrieved 2018-11-11.

Sources

- Kalpakjian, Serope; Steven Schmid (August 2005). Manufacturing, Engineering & Technology. Prentice Hall. pp. 22–36, 951–88. ISBN 978-0-13-148965-3.

External links

| Look up manufacturing in Wiktionary, the free dictionary. |

| Wikimedia Commons has media related to Manufacturing. |

| Wikiquote has quotations related to: Manufacturing |

- How Everyday Things Are Made: video presentations

- Grant Thornton IBR 2008 Manufacturing industry focus

- EEF, the manufacturers' organisation – industry group representing uk manufacturers

- Enabling the Digital Thread for Smart Manufacturing

- Evidences of Metal Manufacturing History

- Manufacturing Sector of the National Occupational Research Agenda, USA, 2018.

- . New International Encyclopedia. 1905.