Industrial engineering

Industrial engineering is an engineering profession that is concerned with the optimization of complex processes, systems, or organizations by developing, improving and implementing integrated systems of people, money, knowledge, information, equipment, energy and materials.[1]

Industrial engineers use specialized knowledge and skills in the mathematical, physical and social sciences, together with the principles and methods of engineering analysis and design, to specify, predict, and evaluate the results obtained from systems and processes.[1] From these results, they are able to create new systems, processes or situations for the useful coordination of labour, materials and machines and also improve the quality and productivity of systems, physical or social.[2][3] Depending on the sub-specialties involved, industrial engineering may also overlap with, operations research, systems engineering, manufacturing engineering, production engineering, supply chain engineering, management science, management engineering, financial engineering, ergonomics or human factors engineering, safety engineering, or others, depending on the viewpoint or motives of the user.

History

Origins

Industrial Revolution

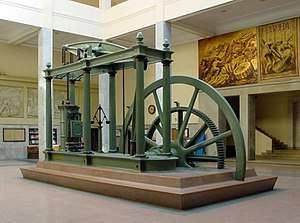

There is a general consensus among historians that the roots of the industrial engineering profession date back to the Industrial Revolution. The technologies that helped mechanize traditional manual operations in the textile industry including the flying shuttle, the spinning jenny, and perhaps most importantly the steam engine generated economies of scale that made Mass production in centralized locations attractive for the first time. The concept of the production system had its genesis in the factories created by these innovations.[4]

Specialization of labor

Adam Smith's concepts of Division of Labour and the "Invisible Hand" of capitalism introduced in his treatise "The Wealth of Nations" motivated many of the technological innovators of the Industrial revolution to establish and implement factory systems. The efforts of James Watt and Matthew Boulton led to the first integrated machine manufacturing facility in the world, including the implementation of concepts such as cost control systems to reduce waste and increase productivity and the institution of skills training for craftsmen.[4]

Charles Babbage became associated with Industrial engineering because of the concepts he introduced in his book "On the Economy of Machinery and Manufacturers" which he wrote as a result of his visits to factories in England and the United States in the early 1800s. The book includes subjects such as the time required to perform a specific task, the effects of subdividing tasks into smaller and less detailed elements, and the advantages to be gained from repetitive tasks.[4]

Interchangeable parts

Eli Whitney and Simeon North proved the feasibility of the notion of Interchangeable parts in the manufacture of muskets and pistols for the US Government. Under this system, individual parts were mass-produced to tolerances to enable their use in any finished product. The result was a significant reduction in the need for skill from specialized workers, which eventually led to the industrial environment to be studied later.[4]

Pioneers

Frederick Taylor (1856 – 1915) is generally credited as being the father of the Industrial Engineering discipline. He earned a degree in mechanical engineering from Steven's University and earned several patents from his inventions. His books, Shop Management and The Principles of Scientific Management which were published in the early 1900s, were the beginning of Industrial Engineering.[5] Improvements in work efficiency under his methods was based on improving work methods, developing of work standards, and reduction in time required to carry out the work. With an abiding faith in the scientific method, Taylor's contribution to "Time Study" sought a high level of precision and predictability for manual tasks.[4]

The husband-and-wife team of Frank Gilbreth (1868 – 1924) and Lillian Gilbreth (1878 – 1972) was the other cornerstone of the Industrial Engineering movement whose work is housed at Purdue University School of Industrial Engineering. They categorized the elements of human motion into 18 basic elements called therbligs. This development permitted analysts to design jobs without knowledge of the time required to do a job. These developments were the beginning of a much broader field known as human factors or ergonomics.[4]

In 1908, the first course on Industrial Engineering was offered as an elective at Pennsylvania State University, which became a separate program in 1909 through the efforts of Hugo Diemer.[6] The first doctoral degree in industrial engineering was awarded in 1933 by Cornell University.

In 1912 Henry Laurence Gantt developed the Gantt chart which outlines actions the organization along with their relationships. This chart opens later form familiar to us today by Wallace Clark.

With the development of assembly lines, the factory of Henry Ford (1913) accounted for a significant leap forward in the field. Ford reduced the assembly time of a car more than 700 hours to 1.5 hours. In addition, he was a pioneer of the economy of the capitalist welfare ("welfare capitalism") and the flag of providing financial incentives for employees to increase productivity.

In 1927, the then Technische Hochschule Berlin was the first German university to introduce the degree.[7] The course of studies developed by Willi Prion was then still called "Business and Technology" and was intended to provide descendants of industrialists with an adequate education.

Comprehensive quality management system (Total quality management or TQM) developed in the forties was gaining momentum after World War II and was part of the recovery of Japan after the war.

The American Institute of Industrial Engineering was formed in 1948. The early work by F. W. Taylor and the Gilbreths was documented in papers presented to the American Society of Mechanical Engineers as interest grew from merely improving machine performance to the performance of the overall manufacturing process; most notably starting with the presentation by Henry R. Towne (1844 - 1924) of his paper The Engineer as An Economist (1186).[8]

Modern practice

In the 1960 to 1975, with the development of decision support systems in supply such as the Material requirements planning (MRP), one can emphasize the timing issue (inventory, production, compounding, transportation, etc.) of industrial organization. Israeli scientist Dr. Jacob Rubinovitz installed the CMMS program developed in IAI and Control-Data (Israel) in 1976 in South Africa and worldwide.

In the seventies, with the penetration of Japanese management theories such as Kaizen and Kanban, Japan realized very high levels of quality and productivity. These theories improved issues of quality, delivery time, and flexibility. Companies in the west realized the great impact of Kaizen and started implementing their own Continuous improvement programs.

In the nineties, following the global industry globalization process, the emphasis was on supply chain management and customer-oriented business process design. Theory of constraints developed by an Israeli scientist Eliyahu M. Goldratt (1985) is also a significant milestone in the field.

Compared to other engineering disciplines

Engineering is traditionally decompositional. To understand the whole, it is first broken into its parts. One then masters the parts and puts them back together, becoming the master of the whole. Industrial and systems engineering's (ISE) approach is the opposite; any one part cannot be understood without the context of the whole. Changes in one part affect the whole, and the role of a part is a projection into the whole. In traditional engineering, people understand the parts first, then they can understand the whole. In ISE, they understand the whole first, and then they can understand the role of each part.

Also, Industrial engineering considers the human factor and its relation to the technical aspect of the situation and the all of the other factors that influence the entire situation,[3] while other engineering disciplines focus on the design of inanimate objects.

"Industrial Engineers integrate combinations of people, information, materials, and equipment that produce innovative and efficient organizations. In addition to manufacturing, Industrial Engineers work and consult in every industry, including hospitals, communications, e-commerce, entertainment, government, finance, food, pharmaceuticals, semiconductors, sports, insurance, sales, accounting, banking, travel, and transportation."[9]

"Industrial Engineering is the branch of Engineering most closely related to human resources in that we apply social skills to work with all types of employees, from engineers to salespeople to top management. One of the main focuses of an Industrial Engineer is to improve the working environments of people – not to change the worker, but to change the workplace."[9]

"All engineers, including Industrial Engineers, take mathematics through calculus and differential equations. Industrial Engineering is different in that it is based on discrete variable math, whereas all other engineering is based on continuous variable math. We emphasize the use of linear algebra and difference equations, as opposed to the use of differential equations which are so prevalent in other engineering disciplines. This emphasis becomes evident in optimization of production systems in which we are sequencing orders, scheduling batches, determining the number of materials handling units, arranging factory layouts, finding sequences of motions, etc. As, Industrial Engineers, we deal almost exclusively with systems of discrete components."[9]

Etymology

Etymology

While originally applied to manufacturing, the use of "industrial" in "industrial engineering" can be somewhat misleading, since it has grown to encompass any methodical or quantitative approach to optimizing how a process, system, or organization operates. In fact, the "Industrial" in Industrial engineering means the "industry" in its broadest sense.[10] People have changed the term "industrial" to broader terms such as Industrial and Manufacturing Engineering, Industrial and Systems Engineering, Industrial Engineering & Operations Research, Industrial Engineering & Management.

Sub-disciplines

Industrial engineering has many sub-disciplines, the most common of which are listed below. Although there are industrial engineers who focus exclusively on one of these sub-disciplines, many deal with a combination of them such as Supply Chain and Logistics, and Facilities and Energy Management.[11][12]

Facilities Engineering & Energy Management

Financial Engineering

Energy Engineering

Human Factors & Safety Engineering

Information Systems Engineering & Management

Manufacturing Engineering

Operations Engineering & Management

Operations Research & Optimization

Policy Planning

Production Engineering

Quality & Reliability Engineering

Supply Chain Management & Logistics

System Analysis

Systems Engineering

Systems Simulation

Related Disciplines

Organization Development & Change Management

Behavioral Economics

Education

Industrial engineers study the interaction of human beings with machines, materials, information, procedures and environments in such developments and in designing a technological system.[13]

Universities offer degrees at the bachelor, masters, and doctoral level.

Undergraduate curriculum

| 2020 U.S. News undergraduate rankings[14] | |

|---|---|

| University | Rank |

|

| |

| Georgia Institute of Technology | 1 |

| University of Michigan | 2 |

| Purdue University | 3 |

| Virginia Tech | 4 |

| University of California, Berkeley | 5 |

| Cornell University | 6 |

| Northwestern University | 6 |

| Pennsylvania State University | 8 |

| University of Illinois, Urbana-Champaign | 9 |

| Stanford University | 10 |

In the United States, the undergraduate degree earned is the bachelor of science (B.S.) or bachelor of science and engineering (B.S.E.) in industrial engineering (IE). Variations of the title include Industrial & Operations Engineering (IOE), and Industrial & Systems Engineering (ISE or ISyE). The typical curriculum includes a broad math and science foundation spanning chemistry, physics, mechanics (i.e., statics, kinematics, and dynamics), materials science, computer science, electronics/circuits, engineering design, and the standard range of engineering mathematics (i.e., calculus, linear algebra, differential equations, statistics). For any engineering undergraduate program to be accredited, regardless of concentration, it must cover a largely similar span of such foundational work - which also overlaps heavily with the content tested on one or more engineering licensure exams in most jurisdictions.

The coursework specific to IE entails specialized courses in areas such as optimization, applied probability, stochastic modeling, design of experiments, statistical process control, simulation, manufacturing engineering, ergonomics/safety engineering, and engineering economics. Industrial engineering elective courses typically cover more specialized topics in areas such as manufacturing, supply chains and logistics, analytics and machine learning, production systems, human factors and industrial design, and service systems.[15][16][17][18][19]

Certain business schools may offer programs with some overlapping relevance to IE, but the engineering programs are distinguished by a much more intensely quantitative focus, required engineering science electives, and the core math and science courses required of all engineering programs.

Graduate curriculum

| 2019 U.S. News graduate rankings[20] | |

|---|---|

| University | Rank |

|

| |

| Georgia Institute of Technology | 1 |

| University of Michigan | 2 |

| Northwestern University | 3 |

| University of California, Berkeley | 4 |

| Virginia Tech | 4 |

| Pennsylvania State University | 6 |

| Purdue University | 6 |

| University of Wisconsin–Madison | 6 |

| Cornell University | 9 |

| Massachusetts Institute of Technology | 9 |

The usual graduate degree earned is the master of science (MS) or master of science and engineering (MSE) in industrial engineering or various alternative related concentration titles.

Typical MS curricula may cover:

- Manufacturing Engineering

- Analytics and machine learning

- Computer-aided manufacturing

- Engineering economics

- Financial engineering

- Human factors engineering and ergonomics (safety engineering)

- Lean Six Sigma

- Management sciences

- Materials management

- Operations management

- Operations research and optimization techniques

- Predetermined motion time system and computer use for IE

- Product development

- Production planning and control

- Productivity improvement

- Project management

- Reliability engineering and life testing

- Robotics

- Statistical process control or quality control

- Supply chain management and logistics

- System dynamics and policy planning

- Systems simulation and stochastic processes

- Time and motion study

- Facilities design and work-space design

- Quality engineering

- System analysis and techniques

Differences in teaching

While industrial engineering as a formal degree has been around for years, consensus on what topics should be taught and studied differs across countries. For example, Turkey focuses on a very technical degree while Denmark, Finland and the United Kingdom have a management focus degree, thus making it less technical. The United States, meanwhile, focuses on case-studies, group problem solving and maintains a balance between the technical and non technical side.[21]

Practicing engineers

Traditionally, a major aspect of industrial engineering was planning the layouts of factories and designing assembly lines and other manufacturing paradigms. And now, in lean manufacturing systems, industrial engineers work to eliminate wastes of time, money, materials, energy, and other resources.

Examples of where industrial engineering might be used include flow process charting, process mapping, designing an assembly workstation, strategizing for various operational logistics, consulting as an efficiency expert, developing a new financial algorithm or loan system for a bank, streamlining operation and emergency room location or usage in a hospital, planning complex distribution schemes for materials or products (referred to as supply-chain management), and shortening lines (or queues) at a bank, hospital, or a theme park.

Modern industrial engineers typically use predetermined motion time system, computer simulation (especially discrete event simulation), along with extensive mathematical tools for modeling, such as mathematical optimization and queueing theory, and computational methods for system analysis, evaluation, and optimization. Industrial engineers also use the tools of data science and machine learning in their work owing to the strong relatedness of these disciplines with the field and the similar technical background required of industrial engineers (including a strong foundation in probability theory, linear algebra, and statistics, as well as having coding skills).

See also

Related topics

- Engineering economics

- Engineering management

- Enterprise engineering

- Environment, health and safety

- Human factors and ergonomics – Application of psychological and physiological principles to engineering and design

- Industrial and production engineering

- Industrial design – Process of design applied to products that are to be manufactured through techniques of mass production

- Maintenance engineering

- Manufacturing engineering

- Occupational safety and health – Field concerned with the safety, health and welfare of people at work

- Operations engineering

- Operations research

- Outline of production – Overview of and topical guide to production

- Overall equipment effectiveness

- Product design – Process that leads to new products

- Production engineering

- Project management – Practice of leading the work of a team to achieve goals and criteria at a specified time

- Project production management

- Quality engineering – Principles and practice of product and service quality assurance and control

- Reverse engineering – Process of extracting design information from anything man-made

- Safety engineering – Engineering discipline which assures that engineered systems provide acceptable levels of safety

- Sales process engineering

- Sociotechnical system

- Statistical process control

- Systems engineering – Interdisciplinary field of engineering and engineering management that focuses on how to design and manage complex systems over their life cycles

- Toyota Production System – System developed by Toyota

Associations

- Institute of Industrial and Systems Engineers – Professional society for the support of the industrial engineering profession

- Institute for Operations Research and the Management Sciences (INFORMS)

- Institute of Industrial and Systems Engineers – Professional society for the support of the industrial engineering profession

- American Society for Engineering Education

- American Society for Quality

- European Students of Industrial Engineering and Management (ESTIEM)

- Indian Institution of Industrial Engineering

- Washington Accord

Notes

- Salvendy, Gabriel. Handbook of Industrial Engineering. John Wiley & Sons, Inc; 3rd edition p. 5

- "What IEs Do". www.iienet2.org. Retrieved September 24, 2015.

- Lehrer, Robert. "The Nature of Industrial Engineering". The Journal of Industrial Engineering. 5: 4.

- Maynard & Zandin. Maynard's Industrial Engineering Handbook. McGraw Hill Professional 5th Edition. June 5, 2001. p. 1.4-1.6

- All about industrial engineering

- "Industrial Engineering - Definition, Explanation, History, and Programs".

- Geschichte und Bedeutung des Wirtschaftsingenieurwesens, archived from the original on July 7, 2017, retrieved June 22, 2020

- Engineer as Economist

- Savory, Paul. "DETAILS AND DESCRIPTION OF INDUSTRIAL ENGINEERING".

- Darwish, H; van Dyk, L (2016). "The industrial engineering identity: from historic skills to modern values, duties, and roles". South African Journal of Industrial Engineering. 27 (3): 50–63.

- "What is Industrial Engineering?". Wonderful Engineering.

- "Industrial Engineering".

- Rahman, Chowdury; Uddin, Syed; Iqbal, Mohammad. "Importance of Human Factors in Industrial Engineering and Design". SEU Journal of Science and Engineering. 8 – via Research Gate.

- "Best Undergraduate Industrial / Manufacturing Engineering Program Rankings". U.S. News & World Report. Retrieved March 2, 2017.

- "ISyE Undergraduate Courses". Georgia Institute of Technology. Retrieved March 2, 2017.

- "Industrial Engineering and Operations Research (IND ENG)". University of California, Berkeley. Retrieved March 2, 2017.

- "Courses". University of Michigan, Ann Arbor. Archived from the original on March 3, 2017. Retrieved March 2, 2017.

- "Courses". Northwestern University. Retrieved March 2, 2017.

- "ISE Electives". University of Illinois at Urbana–Champaign. Retrieved March 2, 2017.

- "Best Industrial Engineering Programs". U.S. News & World Report. Retrieved March 2, 2017.

- Oanca, Alexandra. "What is Industrial Engineering and Why Should I Study It?".

Further reading

- Badiru, A. (Ed.) (2005). Handbook of industrial and systems engineering. CRC Press. ISBN 0-8493-2719-9.

- B. S. Blanchard and Fabrycky, W. (2005). Systems Engineering and Analysis (4th Edition). Prentice-Hall. ISBN 0-13-186977-9.

- Salvendy, G. (Ed.) (2001). Handbook of industrial engineering: Technology and operations management. Wiley-Interscience. ISBN 0-471-33057-4.

- Turner, W. et al. (1992). Introduction to industrial and systems engineering (Third edition). Prentice Hall. ISBN 0-13-481789-3.

- Eliyahu M. Goldratt, Jeff Cox (1984). The Goal North River Press; 2nd Rev edition (1992). ISBN 0-88427-061-0; 20th Anniversary edition (2004) ISBN 0-88427-178-1

- Miller, Doug, Towards Sustainable Labour Costing in UK Fashion Retail (February 5, 2013). doi:10.2139/ssrn.2212100

- Malakooti, B. (2013). Operations and Production Systems with Multiple Objectives. John Wiley & Sons.ISBN 978-1-118-58537-5

- Systems Engineering Body of Knowledge (SEBoK)

- Traditional Engineering

- Master of Engineering Administration (MEA)

External links