Chemical synthesis

In chemistry, chemical synthesis is the artificial execution of useful chemical reactions to obtain one or several products.[1] This occurs by physical and chemical manipulations usually involving one or more reactions. In modern laboratory uses, the process is reproducible and reliable.

A chemical synthesis involves one or more compounds (known as reagents or reactants) that will undergo a transformation when subjected to certain conditions. Various reaction types can be applied to formulate a desired product. This requires mixing the compounds in a reaction vessel, such as a chemical reactor or a simple round-bottom flask. Many reactions require some form of work-up or purification procedure to isolate the final product.[1]

The amount of product produced in a chemical synthesis is known as the reaction yield. Typically, chemical yields are expressed as a mass in grams (in a laboratory setting) or as a percentage of the total theoretical quantity of product that could be produced based on the limiting reagent. A side reaction is an unwanted chemical reaction taking place which reduces the yield of the desired product. The word synthesis was first used by the chemist Hermann Kolbe.[2]

Strategies

Many strategies exist in chemical synthesis that go beyond converting reactant A to reaction product B in a single step. In multistep synthesis, a chemical compound is synthesised though a series of individual chemical reactions, each with their own work-up.[3] For example, a laboratory synthesis of paracetamol can consist of three individual synthetic steps. In cascade reactions multiple chemical transformations take place within a single reactant, in multi-component reactions up to 11 different reactants form a single reaction product and in a telescopic synthesis one reactant goes through multiple transformations without isolation of intermediates.

Organic synthesis

Organic synthesis is a special branch of chemical synthesis dealing with the synthesis of organic compounds. In the total synthesis of a complex product it may take multiple steps to synthesize the product of interest, and inordinate amounts of time. Skill in organic synthesis is prized among chemists and the synthesis of exceptionally valuable or difficult compounds has won chemists such as Robert Burns Woodward the Nobel Prize for Chemistry. If a chemical synthesis starts from basic laboratory compounds, it is considered a purely synthetic process. If it starts from a product isolated from plants or animals and then proceeds to new compounds, the synthesis is described as a semisynthetic process.

Inorganic synthesis

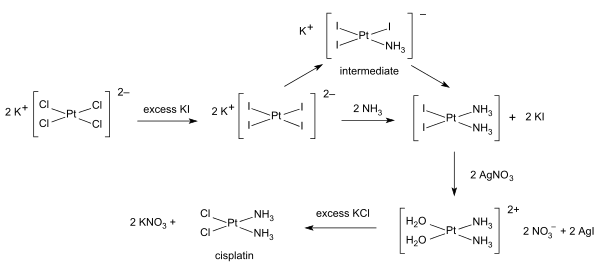

Inorganic synthesis and organometallic synthesis are applied to the preparation of compounds with significant non-organic content. An illustrative example is the preparation of the anticancer drug cisplatin from potassium tetrachloroplatinate.[4]

See also

- Beilstein database

- Chemical engineering

- Electrosynthesis

- Methods in Organic Synthesis

- Organic synthesis

- Peptide synthesis

- Total synthesis

- Automated synthesis

References

- Vogel, A.I., Tatchell, A.R., Furnis, B.S., Hannaford, A.J. and P.W.G. Smith. Vogel's Textbook of Practical Organic Chemistry, 5th Edition. Prentice Hall, 1996. ISBN 0-582-46236-3.

- Kolbe, H. (1845). "Beiträge zur Kenntniss der gepaarten Verbindungen". Annalen der Chemie und Pharmacie. 54 (2): 145–188. doi:10.1002/jlac.18450540202. ISSN 0075-4617.

- Advanced Organic Chemistry Part B: Reactions and Synthesis Francis A. Carey,Richard J. Sundberg Springer 2013

- Alderden, Rebecca A.; Hall, Matthew D.; Hambley, Trevor W. (2006). "The Discovery and Development of Cisplatin". J. Chem. Educ. 83 (5): 728. Bibcode:2006JChEd..83..728A. doi:10.1021/ed083p728.