Tire

A tire (American English) or tyre (British English; see spelling differences) is a ring-shaped component that surrounds a wheel's rim to transfer a vehicle's load from the axle through the wheel to the ground and to provide traction on the surface over which the wheel travels. Most tires, such as those for automobiles and bicycles, are pneumatically inflated structures, which also provide a flexible cushion that absorbs shock as the tire rolls over rough features on the surface. Tires provide a footprint, called a contact patch, that is designed to match the weight of the vehicle with the bearing strength of the surface that it rolls over by providing a bearing pressure that will not deform the surface excessively.

The materials of modern pneumatic tires are synthetic rubber, natural rubber, fabric and wire, along with carbon black and other chemical compounds. They consist of a tread and a body. The tread provides traction while the body provides containment for a quantity of compressed air. Before rubber was developed, the first versions of tires were simply bands of metal fitted around wooden wheels to prevent wear and tear. Early rubber tires were solid (not pneumatic). Pneumatic tires are used on many types of vehicles, including cars, bicycles, motorcycles, buses, trucks, heavy equipment, and aircraft. Metal tires are still used on locomotives and railcars, and solid rubber (or other polymer) tires are still used in various non-automotive applications, such as some casters, carts, lawnmowers, and wheelbarrows.

Etymology and spelling

The word tire is a short form of attire, from the idea that a wheel with a tire is a dressed wheel.[1][2]

The spelling tyre does not appear until the 1840s when the English began shrink fitting railway car wheels with malleable iron. Nevertheless, traditional publishers continued using tire. The Times newspaper in Britain was still using tire as late as 1905.[3] The spelling tyre began to be commonly used in the 19th century for pneumatic tires in the UK. The 1911 edition of the Encyclopædia Britannica states that "[t]he spelling 'tyre' is not now accepted by the best English authorities, and is unrecognized in the US",[4] while Fowler's Modern English Usage of 1926 says that "there is nothing to be said for 'tyre', which is etymologically wrong, as well as needlessly divergent from our own [sc. British] older & the present American usage".[5] However, over the course of the 20th century, tyre became established as the standard British spelling.[2]

History

.jpg)

The earliest tires were bands of leather,[6] then iron (later steel) placed on wooden wheels used on carts and wagons. A skilled worker, known as a wheelwright, would cause the tire to expand by heating it in a forge fire, place it over the wheel and quench it, causing the metal to contract back to its original size so that it would fit tightly on the wheel.

The first patent for what appears to be a standard pneumatic tire appeared in 1847[7] lodged by the Scottish inventor Robert William Thomson. However, this never went into production. The first practical pneumatic tire was made in 1888 on May Street, Belfast, by Scots-born John Boyd Dunlop, owner of one of Ireland's most prosperous veterinary practices. It was an effort to prevent the headaches of his 10-year-old son Johnnie, while riding his tricycle on rough pavements. His doctor, John, later Sir John Fagan, had prescribed cycling as an exercise for the boy, and was a regular visitor. Fagan participated in designing the first pneumatic tires. Cyclist Willie Hume demonstrated the supremacy of Dunlop's tires in 1889, winning the tire's first-ever races in Ireland and then England.[8][9] In Dunlop's tire patent specification dated 31 October 1888, his interest is only in its use in cycles and light vehicles. In September 1890, he was made aware of an earlier development but the company kept the information to itself.[10]

In 1892, Dunlop's patent was declared invalid because of prior art by forgotten fellow Scot Robert William Thomson of London (patents London 1845, France 1846, USA 1847), although Dunlop is credited with "realizing rubber could withstand the wear and tear of being a tire while retaining its resilience".[11] John Boyd Dunlop and Harvey du Cros together worked through the ensuing considerable difficulties. They employed inventor Charles Kingston Welch and also acquired other rights and patents which allowed them some limited protection of their Pneumatic Tyre business's position. Pneumatic Tyre would become Dunlop Rubber and Dunlop Tyres. The development of this technology hinged on myriad engineering advances, including the vulcanization of natural rubber using sulfur, as well as by the development of the "clincher" rim for holding the tire in place laterally on the wheel rim.

Synthetic rubbers were invented in the laboratories of Bayer in the 1920s.[12] In 1946, Michelin developed the radial tire method of construction. Michelin had bought the bankrupt Citroën automobile company in 1934, so it was able to fit this new technology immediately. Because of its superiority in handling and fuel economy,[13] use of this technology quickly spread throughout Europe and Asia.[14] In the U.S., the outdated bias-ply tire construction persisted, until the Ford Motor Company adopted radial tires in the early 1970s,[15] following the 1968 article in an influential American magazine, Consumer Reports, highlighting the superiority of radial construction.[16][17] The US tire industry lost its market share to Japanese and European manufacturers,[18] which bought out US companies.[19]

Applications

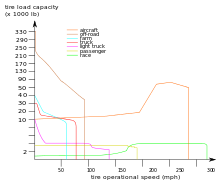

Tires may be classified according to the type of vehicle they serve. They may be distinguished by the load they carry and by their application, e.g. to a motor vehicle, aircraft or bicycle.

Automotive

Light–medium duty

Light-duty tires for passenger vehicles carry loads in the range of 550 to 1,100 pounds (250 to 500 kg) on the drive wheel. Light-to-medium duty trucks and vans carry loads in the range of 1,100 to 3,300 pounds (500 to 1,500 kg) on the drive wheel.[21] They are differentiated by speed rating for different vehicles, including (starting from the lowest speed to the highest): winter tires, light truck tires, entry-level car tires, sedans and vans, sport sedans, and high-performance cars.[22] Apart from road tires, there are special categories:

- Snow tires are designed for use on snow and ice. They have a tread design with larger gaps than those on summer tires, increasing traction on snow and ice. Such tires that have passed a specific winter traction performance test are entitled to display a "Three-Peak Mountain Snow Flake" symbol on their sidewalls. Tires designed for winter conditions are optimized to drive at temperatures below 7 °C (45 °F). Some snow tires have metal or ceramic studs that protrude from the tire to increase traction on hard-packed snow or ice. Studs abrade dry pavement, causing dust and creating wear in the wheel path.[23] Regulations that require the use of snow tires or permit the use of studs vary by country in Asia and Europe, and by state or province in North America.

- All-season tires are typically rated for mud and snow (M+S). These tires have tread gaps that are smaller than snow tires and larger than conventional tires. They are quieter than snow tires on clear roads, but less capable on snow or ice.[24]

- All-terrain tires are designed to have adequate traction off-road, yet have benign handling and noise characteristics for highway driving.[25] Such tires are rated better on snow and rain than street tires and "good" on ice, rock and sand.[26]

- Mud-terrain tires have a deeper, more open tread for good grip in mud, than all-terrain tires, but perform less well on pavement.[27]

- High-performance tires are rated for speeds up to 168 miles per hour (270 km/h) and ultra-high-performance tires are rated for speeds up to 186 miles per hour (299 km/h), but have harsher ride characteristics and durability.[28]

Other types of light-duty automotive tires include run-flat tires and race car tires:

- Run-flat tires obviate the need for a spare tire, because they can be travelled on at a reduced speed in the event of a puncture, using a stiff sidewall to prevent damage to the tire rim.[29] Vehicles without run-flat tires rely on a spare tire, which may be a compact tire, to replace a damaged tire.[29]

- Race car tires come in three main categories, DOT (street-legal), slick, and rain. Race car tires are designed to maximize cornering and acceleration friction at the expense of longevity. Racing slicks have no tread to maximize contact with the pavement and rain tires have channels to eject water to avoid hydroplaning.[30]

Heavy duty

Heavy duty tires for large trucks and buses come in a variety of profiles and carry loads in the range of 4,000 to 5,500 pounds (1,800 to 2,500 kg) on the drive wheel.[21] These are typically be mounted in tandem on the drive axle.[29]

- Truck tires come in a variety of profiles that include "low profile" with a section height that is 70 to 45% of the tread width, "wide-base" for heavy vehicles, and a "super-single" tire that has the same total contact pressure as a dual-mounted tire combination.[29]

- Off-road tires are used on construction vehicles, agricultural and forestry equipment and other applications that take place on soft terrain. The category also includes machinery that travels over hardened surfaces at industrial sites, ports and airports.[31] Tires designed for soft terrain have a deep, wide tread to provide traction in loose dirt, mud, sand or gravel.[32]

Other

Aircraft, bicycle and a variety of industrial applications have distinct design requirements.

- Aircraft tires are designed for landing on paved surfaces and rely on their landing gear to absorb the shock of landing. To conserve weight and space required, they are typically small in proportion to the vehicle that they support. Most are radial-ply construction. They are designed for a peak load when the aircraft is stationary, although side loads upon landing are an important factor.[33] Although hydroplaning is a concern for aircraft tires, they typically have radial grooves and no lateral grooves or sipes.[34] Some light aircraft employ large-diameter, low-pressure "tundra tires" for landing on unprepared surfaces in wilderness areas.[35]

- Bicycle tires may be designed for riding on roads or over unimproved terrain and may be mounted on vehicles with more than two wheels. There are three main types: clincher, wired and tubular.[36] Most bicycle tires are clincher and have a bead that presses against the wheel rim. An inner tube provides the air pressure and the contact pressure between bead and wheel rim.[37]

- Industrial tires support such vehicles as forklifts, tractors, excavators, road rollers, and bucket loaders. Those used on smooth surfaces have a smooth tread, whereas those used on soft surfaces typically have large tread features.[38] Some industrial tires are solid or filled with foam.[39]

- Motorcycle tires provide traction, resisting wear, absorbing surface irregularities, and allow the motorcycle to turn via countersteering. The two tires' contact with the ground affect safety, braking, fuel economy, noise, and rider comfort.[40]

Construction types

Tire construction spans pneumatic tires used on cars, trucks and aircraft, but also includes non-automotive applications with slow-moving, light-duty, or railroad applications, which may have non-pneumatic tires.

Automotive

Following the 1968 Consumer Reports announcement of the superiority of the radial design, radial tires began an inexorable climb in market share, reaching 100% of the North America market in the 1980s.[16] Radial tire technology is now the standard design for essentially all automotive tires, but other methods have been used.[22]

Radial tire construction utilizes body ply cords extending from the beads and across the tread so that the cords are laid at approximately right angles to the centerline of the tread, and parallel to each other, as well as stabilizer belts directly beneath the tread. The belts may be cord or steel. The advantages of this construction include longer tread life, better steering control, fewer blowouts, improved fuel economy, and lower rolling resistance. Disadvantages of the radial tire are a harder ride at low speeds on rough roads and in the context of off-roading, decreased "self-cleaning" ability and lower grip ability at low speeds.[22]

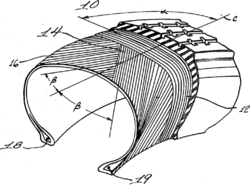

Bias tire (or cross ply) construction utilizes body ply cords that extend diagonally from bead to bead, usually at angles in the range of 30 to 40 degrees, with successive plies laid at opposing angles forming a crisscross pattern to which the tread is applied. The design allows the entire tire body to flex easily, providing the main advantage of this construction, a smooth ride on rough surfaces. This cushioning characteristic also causes the major disadvantages of a bias tire: increased rolling resistance and less control and traction at higher speeds.[22]

A belted bias tire starts with two or more bias-plies to which stabilizer belts are bonded directly beneath the tread. This construction provides smoother ride that is similar to the bias tire, while lessening rolling resistance because the belts increase tread stiffness. The design was introduced by Armstrong, while Goodyear made it popular with the "Polyglas" trademark tire featuring a polyester carcass with belts of fiberglass.[41] The "belted" tire starts two main plies of polyester, rayon, or nylon annealed as in conventional tires, and then placed on top are circumferential belts at different angles that improve performance compared to non-belted bias tires. The belts may be fiberglass or steel.[41]

Other

Tubeless tires are pneumatic tires that do not require a separate inner tube.

Semi-pneumatic tires have a hollow center, but they are not pressurized. They are light-weight, low-cost, puncture proof, and provide cushioning.[42] These tires often come as a complete assembly with the wheel and even integral ball bearings. They are used on lawn mowers, wheelchairs, and wheelbarrows. They can also be rugged, typically used in industrial applications,[43] and are designed to not pull off their rim under use.

An airless tire is a non-pneumatic tire that is not supported by air pressure. They are most commonly used on small vehicles, such as golf carts, and on utility vehicles in situations where the risk of puncture is high, such as on construction equipment. Many tires used in industrial and commercial applications are non-pneumatic, and are manufactured from solid rubber and plastic compounds via molding operations. Solid tires include those used for lawn mowers, skateboards, golf carts, scooters, and many types of light industrial vehicles, carts, and trailers. One of the most common applications for solid tires is for material handling equipment (forklifts). Such tires are installed by means of a hydraulic tire press.

Some railway wheels and other older types of rolling stock are fitted with railway tires in order to prevent the need to replace the entirety of a wheel. The tire, usually made of steel, surrounds the wheel and is primarily held in place by interference fit.

Aircraft tires are usually inflated with nitrogen to minimize expansion and contraction from extreme changes in ambient temperature and pressure experienced during flight.[44] Dry nitrogen expands at the same rate as other dry atmospheric gases (normal air is about 80% nitrogen), but common compressed air sources may contain moisture, which increases the expansion rate with temperature.[45] Aircraft tires generally operate at high pressures, up to 200 pounds per square inch (14 bar; 1,400 kPa) for airliners, and even higher for business jets. Tests of airliner aircraft tires have shown that they are able to sustain pressures of maximum 800 pounds per square inch (55 bar; 5,500 kPa) before bursting. During the tests the tires have to be filled with water, to prevent the test room being blown apart by the energy that would be released by a gas when the tire bursts.

Aircraft tires also include fusible plugs (which are assembled on the inside of the wheels), designed to melt at a certain temperature. Tires often overheat if maximum braking is applied during an aborted takeoff or an emergency landing. The fuses provide a safer failure mode that prevents tire explosions by deflating in a controlled manner, thus minimizing damage to aircraft and objects in the surrounding environment.

The requirement that an inert gas, such as nitrogen, be used instead of air for inflation of tires on certain transport category airplanes was prompted by at least three cases in which the oxygen in air-filled tires combined with volatile gases given off by a severely overheated tire and exploded upon reaching autoignition temperature. The use of an inert gas for tire inflation eliminates the possibility of a tire explosion.[46]

Manufacturing

Pneumatic tires are manufactured in about 450 tire factories around the world. Tire production starts with bulk raw materials such as rubber (60% -70% synthetic[47][48]), carbon black, and chemicals and produces numerous specialized components that are assembled and cured. Many kinds of rubber are used, the most common being styrene-butadiene copolymer. The article Tire manufacturing describes the components assembled to make a tire, the various materials used, the manufacturing processes and machinery, and the overall business model.

In 2004, $80 billion of tires were sold worldwide,[49] in 2010 it was $140 billion[50] (approximately 34% growth adjusting for inflation), and is expected to grow to $258 billion per year by 2019.[51] In 2015, the US manufactured almost 170 million tires.[52] Over 2.5 billion tires are manufactured annually, making the tire industry a major consumer of natural rubber. It is estimated that by 2019, 3 billion tires will be to be sold globally every year.[51]

As of 2011, the top three tire manufacturing companies by revenue were Bridgestone (manufacturing 190 million tires), Michelin (184 million), Goodyear (181 million); they were followed by Continental, and Pirelli.[53][54] The Lego group produced over 318 million toy tires in 2011 and was recognized by Guinness World Records as having the highest annual production of tires by any manufacturer.[55][56]

Components

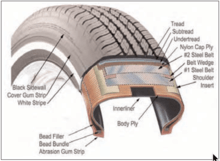

A tire comprises several components: the tread, bead, sidewall, shoulder, and ply.

Tread

The tread is the part of the tire that comes in contact with the road surface. The portion that is in contact with the road at a given instant in time is the contact patch. The tread is a thick rubber, or rubber/composite compound formulated to provide an appropriate level of traction that does not wear away too quickly.[57]

The tread pattern is characterized by a system of circumferential grooves, lateral sipes, and slots for road tires[22] or a system of lugs and voids for tires designed for soft terrain or snow. Grooves run circumferentially around the tire, and are needed to channel away water. Lugs are that portion of the tread design that contacts the road surface. Grooves, sipes and slots allow tires to evacuate water.

The design of treads and the interaction of specific tire types with the roadway surface affects roadway noise, a source of noise pollution emanating from moving vehicles. These sound intensities increase with higher vehicle speeds.[58] Tires treads may incorporate a variety of distances between slots (pitch lengths) to minimize noise levels at discrete frequencies. Sipes are slits cut across the tire, usually perpendicular to the grooves, which allow the water from the grooves to escape sideways and mitigate hydroplaning.[22]

Different tread designs address a variety of driving conditions. As the ratio of tire tread area to groove area increases, so does tire friction on dry pavement, as seen on Formula One tires, some of which have no grooves. High-performance tires often have smaller void areas to provide more rubber in contact with the road for higher traction, but may be compounded with softer rubber that provides better traction, but wears quickly.[59] Mud and snow (M&S) tires employ larger and deeper slots to engage mud and snow.[22] Snow tires have still larger and deeper slots that compact snow and create shear strength within the compacted snow to improve braking and cornering performance.[60]

Wear bars (or wear indicators) are raised features located at the bottom of the tread grooves that indicate the tire has reached its wear limit. When the tread lugs are worn to the point that the wear bars connect across the lugs, the tires are fully worn and should be taken out of service, typically at a remaining tread depth of 1.6 millimetres (0.063 in).[61]

Other

The tire bead is the part of the tire that contacts the rim on the wheel. The bead is typically reinforced with steel wire and compounded of high strength, low flexibility rubber. The bead seats tightly against the two rims on the wheel to ensure that a tubeless tire holds air without leakage. The bead fit is tight to ensure the tire does not shift circumferentially as the wheel rotates. The width of the rim in relationship to the tire is a factor in the handling characteristics of an automobile, because the rim supports the tire's profile.

The sidewall is that part of the tire, or bicycle tire, that bridges between the tread and bead. The sidewall is largely rubber but reinforced with fabric or steel cords that provide for tensile strength and flexibility. The sidewall contains air pressure and transmits the torque applied by the drive axle to the tread to create traction but supports little of the weight of the vehicle, as is clear from the total collapse of the tire when punctured. Sidewalls are molded with manufacturer-specific detail, government mandated warning labels, and other consumer information, and sometimes decorative ornamentation, like whitewalls or tire lettering.

The shoulder is that part of the tire at the edge of the tread as it makes transition to the sidewall.

Plies are layers of relatively inextensible cords embedded in the rubber[62] to hold its shape by preventing the rubber from stretching in response to the internal pressure. The orientations of the plies play a large role in the performance of the tire and is one of the main ways that tires are categorized.[63]

Materials

The materials of modern pneumatic tires can be divided into two groups, the cords that make up the ply and the elastomer which encases them.

Cords

The cords, which form the ply and bead and provide the tensile strength necessary to contain the inflation pressure, can be composed of steel, natural fibers such as cotton or silk, or synthetic fibers such as nylon or kevlar.

Elastomer

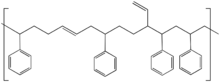

The elastomer, which forms the tread and encases the cords to protect them from abrasion and hold them in place, is a key component of pneumatic tire design. It can be composed of various composites of rubber material – the most common being styrene-butadiene copolymer – with other chemical compound such as silica and carbon black.

Optimizing rolling resistance in the elastomer material is a key challenge for reducing fuel consumption in the transportation sector. It is estimated that passenger vehicles consume approximately 5~15% of its fuel to overcome rolling resistance, while the estimate is understood to be higher for heavy trucks.[64] However, there is a trade-off between rolling resistance and wet traction and grip: while low rolling resistance can be achieved by reducing the viscoelastic properties of the rubber compound (low tangent (δ)), it comes at the cost of wet traction and grip, which requires hysteresis and energy dissipation (high tangent (δ)). A low tangent (δ) value at 60 °C is used as an indicator of low rolling resistance, while a high tangent (δ) value at 0 °C is used as an indicator of high wet traction.[27] Designing an elastomer material that can achieve both high wet traction and low rolling resistance is key in achieving safety and fuel efficiency in the transportation sector.

The most common elastomer material used today is a styrene-butadiene copolymer. It combines the properties of polybutadiene, which is a highly rubbery polymer (Tg = -100 °C) having high hysteresis and thus offering good wet grip properties, with the properties of polystyrene, which is a glassy polymer (Tg = 100 °C) having low hysteresis and thus offering low rolling resistance in addition to wear resistance. Therefore, the ratio the two monomers in the styrene-butadiene copolymer is considered key in determining the glass transition temperature of the material, which is correlated to its grip and resistance properties.[65]

On the wheel

Associated components of a tires, includes the wheel on which it is mounted, the valve stem through which air is introduced, and, for some tires, an inner tube that provides the airtight means for maintaining tire pressure.

- Wheel—Pneumatic tires are mounted onto wheels that most often have integral rims on their outer edges to hold the tire. Automotive wheels are typically made from pressed and welded steel, or a composite of lightweight metal alloys, such as aluminum or magnesium. There are two aspects to how pneumatic tires support the rim of the wheel on which they are mounted.[66] First, tension in the cords pull on the bead uniformly around the wheel, except where it is reduced above the contact patch.[67] Second, the bead transfers that net force to the rim.[68][67] Tires are mounted on the wheel by forcing its beads into the channel formed by the wheel's inner and outer rims.[69][70]

- Valve stem—Pneumatic tires receive their air through a valve stem—a tube made of metal or rubber, with a check valve, typically a Schrader valve on automobiles and most bicycle tires, or a Presta valve on high-performance bicycles. They mount directly to the rim, in the case of tubeless tires, or are an integral part of the inner tube. Most modern passenger vehicles are now required to have a tire pressure monitoring system which usually consists of a valve stem attached to an electronic module.[29]

- Inner tube—Most bicycle tires, many motorcycle tires, and many tires for large vehicles such as buses, heavy trucks, and tractors are designed for use with inner tubes. Inner tubes are torus-shaped balloons made from an impermeable material, such as soft, elastic synthetic rubber, to prevent air leakage. The inner tubes are inserted into the tire and inflated to retain air pressure. Large inner tubes can be re-used for other purposes, such as swimming and rafting (see swim ring), tubing (recreation), sledding, and skitching. Purpose-built inflatable tori are also manufactured for these uses, offering choice of colors, fabric covering, handles, decks, and other accessories, and eliminating the protruding valve stem.

Performance characteristics

The interactions of a tire with the pavement are complex. A commonly used (empirical) model of tire properties is Pacejka's "Magic Formula".[71] Some are explained below, alphabetically, by section.

Dynamics

- Balance—Wheel-tire combinations require an even distribution of mass around their circumferences to maintain tire balance, while turning at speed. Tires are checked at the point of manufacture for excessive static imbalance and dynamic imbalance using automatic tire balance machines. Tires are checked again in the auto assembly plant or tire retail shop after mounting the tire to the wheel. Assemblies that exhibit excessive imbalance are corrected by applying balance weights to the wheels to counteract the tire/wheel imbalance. An alternative method to tire balancing is the use of internal tire balancing agents. These agents take advantage of centrifugal force and inertia to counteract the tire imbalance. To facilitate proper balancing, most high-performance tire manufacturers place red and yellow marks on the sidewalls to enable the best possible match-mounting of the tire/wheel assembly. There are two methods of match-mounting high-performance tire to wheel assemblies using these red (uniformity) or yellow (weight) marks.[72]

- Centrifugal growth—A tire rotating at higher speeds tends to develop a larger diameter, due to centrifugal forces that force the tread rubber away from the axis of rotation. This may cause speedometer error. As the tire diameter grows, the tire width decreases. This centrifugal growth can cause rubbing of the tire against the vehicle at high speeds. Motorcycle tires are often designed with reinforcements aimed at minimizing centrifugal growth.[22]

- Pneumatic trail—Pneumatic trail of a tire is the trail-like effect generated by compliant tires rolling on a hard surface and subject to side loads, as in a turn. More technically, it is the distance that the resultant force of side-slip occurs behind the geometric center of the contact patch.[73]

- Slip angle—Slip angle or sideslip angle is the angle between a rolling wheel's actual direction of travel and the direction towards which it is pointing (i.e., the angle of the vector sum of wheel translational velocity and sideslip velocity ).[22]

- Relaxation length—Relaxation length is the delay between when a slip angle is introduced and when the cornering force reaches its steady-state value.[22]

- Spring rate—Vertical stiffness, or spring rate, is the ratio of vertical force to vertical deflection of the tire, and it contributes to the overall suspension performance of the vehicle. In general, spring rate increases with inflation pressure.[74]

- Stopping distance—Performance-oriented tires have a tread pattern and rubber compounds designed to grip the road surface, and so usually have a slightly shorter stopping distance. However, specific braking tests are necessary for data beyond generalizations.[22]

Forces

- Camber thrust—Camber thrust and camber force are the force generated perpendicular to the direction of travel of a rolling tire due to its camber angle and finite contact patch.[22]

- Circle of forces—The circle of forces, traction circle, friction circle, or friction ellipse is a useful way to think about the dynamic interaction between a vehicle's tire and the road surface.[75]

- Contact patch—The contact patch, or footprint, of the tire, is the area of the tread that is in contact with the road surface. This area transmits forces between the tire and the road via friction. The length-to-width ratio of the contact patch affects steering and cornering behavior.[22]

- Cornering force—Cornering force or side force is the lateral (i.e. parallel to the road surface) force produced by a vehicle tire during cornering.[22]

- Dry traction—Dry traction is measure of the tire's ability to deliver traction, or grip, under dry conditions. Dry traction is a function of the tackiness of the rubber compound.[22]

- Force variation—The tire tread and sidewall elements undergo deformation and recovery as they enter and exit the footprint. Since the rubber is elastomeric, it is deformed during this cycle. As the rubber deforms and recovers, it imparts cyclical forces into the vehicle. These variations are collectively referred to as tire uniformity. Tire uniformity is characterized by radial force variation (RFV), lateral force variation (LFV) and tangential force variation. Radial and lateral force variation is measured on a force variation machine at the end of the manufacturing process. Tires outside the specified limits for RFV and LFV are rejected. Geometric parameters, including radial runout, lateral runout, and sidewall bulge, are measured using a tire uniformity machine at the tire factory at the end of the manufacturing process as a quality check.[22]

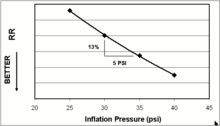

- Rolling resistance—Rolling resistance is the resistance to rolling caused by deformation of the tire in contact with the road surface. As the tire rolls, tread enters the contact area and is deformed flat to conform to the roadway. The energy required to make the deformation depends on the inflation pressure, rotating speed, and numerous physical properties of the tire structure, such as spring force and stiffness. Tire makers seek lower rolling resistance tire constructions to improve fuel economy in cars and especially trucks, where rolling resistance accounts for a high proportion of fuel consumption. Pneumatic tires also have a much lower rolling resistance than solid tires. Because the internal air pressure acts in all directions, a pneumatic tire is able to "absorb" bumps in the road as it rolls over them without experiencing a reaction force opposite to the direction of travel, as is the case with a solid (or foam-filled) tire.[22]

- Self aligning torque—Self-aligning torque, also known as the aligning torque, SAT or Mz, is the torque that a tire creates as it rolls along that tends to steer it, i.e. rotate it around its vertical axis.[22]

- Wet traction—Wet traction is the tire's traction, or grip, under wet conditions. Wet traction is improved by the tread design's ability to channel water out of the tire footprint and reduce hydroplaning. However, tires with a circular cross-section, such as those found on racing bicycles, when properly inflated have a sufficiently small footprint to not be susceptible to hydroplaning. For such tires, it is observed that fully slick tires will give superior traction on both wet and dry pavement.[76]

Load

- Load sensitivity—Load sensitivity is the behaviour of tires under load. Conventional pneumatic tires do not behave as classical friction theory would suggest. Namely, the load sensitivity of most real tires in their typical operating range is such that the coefficient of friction decreases as the vertical load, Fz, increases.[22]

- Work load—The work load of a tire is monitored so that it is not put under undue stress, which may lead to its premature failure.[77] Work load is measured in Ton Kilometer Per Hour (TKPH). The measurement's appellation and units are the same. The recent shortage and increasing cost of tires for heavy equipment has made TKPH an important parameter in tire selection and equipment maintenance for the mining industry. For this reason, manufacturers of tires for large earth-moving and mining vehicles assign TKPH ratings to their tires based on their size, construction, tread type, and rubber compound.[78][79] The rating is based on the weight and speed that the tire can handle without overheating and causing it to deteriorate prematurely. The equivalent measure used in the United States is Ton Mile Per Hour (TMPH).

Wear

- Tread wear

- This occurs through normal contact with roads or terrain; there are several types of abnormal tread wear. Poor wheel alignment can cause excessive wear of the innermost or outermost ribs. Gravel roads, rocky terrain, and other rough terrain causes accelerated wear. Over-inflation above the sidewall maximum can cause excessive wear to the center of the tread. Modern tires have steel belts built in to prevent this. Under-inflation causes excessive wear to the outer ribs. Unbalanced wheels can cause uneven tire wear, as the rotation may not be perfectly circular. Tire manufacturers and car companies have mutually established standards for tread wear testing that include measurement parameters for tread loss profile, lug count, and heel-toe wear.[22]

- Tread wear indicators (T.W.I.)

- Raised bars in the tread channels, which indicate that the tread is becoming worn and therefore unsafe. Indicators have been required on all new tires since 1968 in the US.[80] In many countries the Highway Code forbids driving on public roads when the contact surface is flush with any of any of these bars - this is often defined when the groove depth is approximately 1.5 or 1.6 mm (2/32 inch). TWI can also be used to refer to small arrows or icons on the tire sidewall, indicating the location of the raised wear bars.

- Damage by aging

- Tire aging or "thermo-oxidative degradation" can be caused by time, ambient and operating temperatures, partial pressure of O2 in a tire, flex fatigue, or construction and compounding characteristics. For example, prolonged UV exposure leads to rubber's chemicals warp, potentially causing dry rot. Various storage methods may slow the aging process, but will not eliminate tire degradation.[81]

Regulation

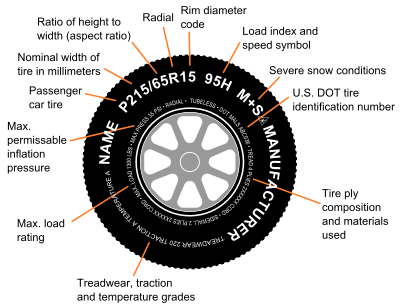

Automotive tires have a variety of identifying markings molded onto the sidewall as a tire code. They denote size, rating, and other information pertinent to that individual tire.

Americas

The National Highway and Traffic Safety Administration (NHTSA) is a U.S. government body within the Department of Transportation (DOT) tasked with regulating automotive safety in the United States.[82] NHTSA established the Uniform Tire Quality Grading System (UTQG), is a system for comparing the performance of tires according to the Code of Federal Regulations 49 CFR 575.104; it requires labeling of tires for tread wear, traction, and temperature. The DOT Code is an alphanumeric character sequence molded into the sidewall of the tire and allows the identification of the tire and its age. The code is mandated by the U.S. Department of Transportation[82] but is used worldwide.[83] The DOT Code is also useful in identifying tires subject to product recall[84] or at end of life due to age. The Tire and Rim Association (T&RA) is a voluntary U.S. standards organization that promotes the interchangeability of tires, rims, and allied parts. Of particular interest, they publish key tire dimension, rim contour dimension, tire valve dimension standards, and load/inflation standards.

The National Institute of Metrology Standardization and Industrial Quality (INMETRO) is the Brazilian federal body responsible for automotive wheel and tyre certification.[85]

Europe

The European Tyre and Rim Technical Organisation (ETRTO) is the European standards organization "to establish engineering dimensions, load/pressure characteristics and operating guidelines".[86] All tires sold for road use in Europe after July 1997 must carry an E-mark. The mark itself is either an upper case "E" or lower case "e" – followed by a number in a circle or rectangle, followed by a further number. An (upper case) "E" indicates that the tire is certified to comply with the dimensional, performance and marking requirements of ECE regulation 30. A (lower case) "e" indicates that the tire is certified to comply with the dimensional, performance and marking requirements of Directive 92/23/EEC. The number in the circle or rectangle denotes the country code of the government that granted the type approval. The last number outside the circle or rectangle is the number of the type approval certificate issued for that particular tire size and type.[87]

The British Rubber Manufacturers Association (BRMA) recommended practice, issued June 2001, states, "BRMA members strongly recommend that unused tyres should not be put into service if they are over six years old and that all tyres should be replaced ten years from the date of their manufacture."[88]

Asia

The Japanese Automobile Tire Manufacturers Association (JATMA) is the Japanese standards organization for tires, rims and valves.[89] It performs similar functions as the T&RA and ETRTO.

The China Compulsory Certification (CCC) is a mandatory certification system concerning product safety in China that went into effect in August 2002. The CCC certification system is operated by the State General Administration for Quality Supervision and Inspection and Quarantine of the People's Republic of China (AQSIQ) and the Certification and Accreditation Administration of the People's Republic of China (CNCA).[90]

Maintenance

%2C_tire_repair_shop.jpg)

To maintain tire health, several actions are appropriate, tire rotation, wheel alignment, and, sometimes, retreading the tire.

- Rotation—Tires may exhibit irregular wear patterns once installed on a vehicle and partially worn. Front-wheel drive vehicles tend to wear the front tires at a greater rate compared to the rear tires. Tire rotation is moving the tires to different car positions, such as front-to-rear, in order to even out the wear, with the objective of extending the life of the tire.[91]

- Alignment—Wheel alignment helps prevent wear by having the tire rotate in a direction, other than the path of the vehicle. When mounted on the vehicle, the wheel and tire may not be perfectly aligned to the direction of travel, and therefore may exhibit irregular wear. If the discrepancy in alignment is large, then the irregular wear will become substantial if left uncorrected. Wheel alignment is the procedure for checking and correcting this condition through adjustment of camber, caster and toe angles. The adjustment of the angles should be done as per the OEM specifications.

Inflation

Inflation is key to proper wear and rolling resistance of pneumatic tires. Many vehicles have monitoring systems to assure proper inflation.

- Specification—Tires are specified by the vehicle manufacturer with a recommended inflation pressure, which permits safe operation within the specified load rating and vehicle loading. Most tires are stamped with a maximum pressure rating. For passenger vehicles and light trucks, the tires should be inflated to what the vehicle manufacturer recommends, which is usually located on a decal just inside the driver's door or in the vehicle owners handbook. Tires should not generally be inflated to the pressure on the sidewall; this is the maximum pressure, rather than the recommended pressure.[92]

- Ground contact—The tire contact patch is readily changed by both over- and underinflation. Overinflation may increase the wear on the center contact patch, and underinflation will cause a concave tread, resulting in less center contact, though the overall contact patch will still be larger.[93] Most modern tires will wear evenly at high tire pressures, but will degrade prematurely if underinflated. An increased tire pressure may decrease rolling resistance, and may also result in shorter stopping distances[94] If tire pressure is too low, the tire contact patch is greatly increased. This increases rolling resistance, tire flexing, and friction between the road and tire. Under-inflation can lead to tire overheating, premature tread wear, and tread separation in severe cases.[95]

- Monitoring—Tire pressure monitoring systems (TPMS) are electronic systems that monitor the tire pressures on individual wheels on a vehicle, and alert the driver when the pressure goes below a warning limit. There are several types of designs to monitor tire pressure. Some actually measure the air pressure, and some make indirect measurements, such as gauging when the relative size of the tire changes due to lower air pressure.

Hazards

Tire hazards may occur from failure of the tire, itself, or from loss of traction on the surface over which it is rolling.

Failure

Tires may fail for any of a variety of reasons, including:[96]

- Belt Separation—Belt separation may be belt-to-belt, tread and belt, or separation of the edge of the belt. Belt-to-belt separation may occur having the tire deflect too much, from high pavement temperatures, from road hazard impacts and other causes having to do with maintenance and storage.

- Non-Belt Separations—Non-Belt Separations include those at the tire tread, in the bead area, in the lower sidewall, between reinforcing plies, and of the reinforcing steel or fabric materials.

- Other—Other types of failure include run-flat damage, chemical degradation, cracking, indentations and bulges

Loss of traction

- Melting rubber—As tire rubber compounds heat, owing to the friction of stopping, cornering or accelerating, they may begin to melt, lubricate the tire-road contact area, and become deposited on the pavement. This effect is stronger with increased ambient temperature.[22]

- Hydroplaning—Motor vehicle or aircraft tires passing over a wet pavement may lose contact with sufficient speed or water depth for a given tread design. In this case, the tire contact area is riding on a film of water and loses the friction needed for braking or cornering and begin to hydroplane (or aquaplane). Hydroplaning may occur as dynamic hydroplaning where standing water is present with a depth of at least 0.12 inches (3 mm) above the texture of the pavement and speed is sustained above a threshold level. It may also occur as viscous hydroplaning whereby tire rubber melts for a brief interval and causes slippage; this may leave deposits of rubber on the landing portion of a runway.[97] Dynamic hydroplaning causes decreased friction and contact with increased tire speed.[98]

- Snow—The degree to which a tire can maintain traction in snow depends on its ability to compact snow, which material then develops strength against slippage along a shear plane parallel to the contact area of the tire on the ground.[99] At the same time, the bottom of the tire treads compress the snow on which they are bearing, also creating friction. The process of compacting snow within the treads requires it to be expelled in time for the tread to compact snow anew on the next rotation. The compaction/contact process works both in the direction of travel for propulsion and braking, but also laterally for cornering.[60]

- Ice—Ice is typically close to its melting point when a tire travels over it. This, combined with a smooth texture, promotes a low coefficient of friction and reduced traction during braking, cornering or acceleration.[22]

- Soft ground—Soil can become lubricated with water, which reduces its ability to maintain shear strength when a tire tries to apply force in acceleration, braking or cornering. Dry sand also has low shear strength, owing to poor cohesiveness among sand particles.[100]

End of use

Once tires are discarded, they are considered scrap tires. Scrap tires are often re-used for things from bumper car barriers to weights to hold down tarps. Tires are not desired at landfills, due to their large volumes and 75% void space, which quickly consumes valuable space. Rubber tires are likely to contain some traces of heavy metals or other serious pollutants, but these are tightly bonded within the actual rubber compound they are unlikely to be hazardous unless the tire structure is seriously damaged by fire or strong chemicals.[101] Some facilities are permitted to recycle scrap tires through chipping, and processing into new products, or selling the material to licensed power plants for fuel. Some tires may also be retreaded for re-use.

Environmental issues

Americans generate about 285 million scrap tires per year.[102] Many states have regulations as to the number of scrap tires that can be held on site, due to concerns with dumping, fire hazards, and mosquitoes. In the past, millions of tires have been discarded into open fields. This creates a breeding ground for mosquitoes, since the tires often hold water inside and remain warm enough for mosquito breeding. Mosquitoes create a nuisance and may increase the likelihood of spreading disease. It also creates a fire danger, since such a large tire pile is a lot of fuel. Some tire fires have burned for months, since water does not adequately penetrate or cool the burning tires. Tires have been known to liquefy, releasing hydrocarbons and other contaminants to the ground and even ground water, under extreme heat and temperatures from a fire. The black smoke from a tire fire causes air pollution and is a hazard to down wind properties.

The use of scrap tire chips for landscaping has become controversial, due to the leaching of metals and other contaminants from the tire pieces. Zinc is concentrated (up to 2% by weight) to levels high enough to be highly toxic to aquatic life and plants.[103] Of particular concern is evidence that some of the compounds that leach from tires into water, contain hormone disruptors and cause liver lesions.[104]

Tires are a major source of microplastic pollution.[105]

Retreading

Tires that are fully worn can be retreaded, re-manufactured to replace the worn tread.[106] This is known as retreading or recapping, a process of buffing away the worn tread and applying a new tread.[107] There are two main processes used for retreading tires, called mold-cure and pre-cure methods. Both processes start with the inspection of the tire, followed by non-destructive inspection method such as shearography[108] to locate non-visible damage and embedded debris and nails. Some casings are repaired and some are discarded. Tires can be retreaded multiple times if the casing is in usable condition. Tires used for short delivery vehicles are retreaded more than long haul tires over the life of the tire body. Casings fit for retreading have the old tread buffed away to prepare for retreading.[109]

During the retreading process, retread technicians must ensure the casing is in the best condition possible to minimize the possibility of a casing failure. Casings with problems such as capped tread, tread separation, irreparable cuts, corroded belts or sidewall damage, or any run-flat or skidded tires, will be rejected. The mold cure method involves the application of raw rubber on the previously buffed and prepared casing, which is later cured in matrices. During the curing period, vulcanization takes place and the raw rubber bonds to the casing, taking the tread shape of the matrix. On the other hand, the pre-cure method involves the application of a ready-made tread band on the buffed and prepared casing, which later is cured in an autoclave so that vulcanization can occur.[109]

Recycling

Tires can be recycled into, among other things, the hot melt asphalt, typically as crumb rubber modifier—recycled asphalt pavement (CRM—RAP),[110][111] and as an aggregate in portland cement concrete.[112] Shredded tires can create rubber mulch on playgrounds to diminish fall injuries.[113] There are some "green" buildings that are being made both private and public buildings that are made from old tires.[114]

The tire pyrolysis method for recycling used tires is a technique which heats whole or shredded tires in a reactor vessel containing an oxygen-free atmosphere and a heat source. In the reactor the rubber is softened after which the rubber polymers continuously break down into smaller molecules.

Other uses

Other downstream uses have been developed for worn-out tires, including:

- Building elements—Tires filled with earth have been used as garden containers[115] house foundations,[116] bullet-proof walls[117] and to prevent soil erosion in flood plains.[118]

- Recreational equipment—Used tires are employed as exercise equipment for athletic programs such as American football.[119] One classic conditioning drill that hones players' speed and agility is the "Tire Run" where tires are laid out side by side, with each tire on the left a few inches ahead of the tire on the right in a zigzag pattern. Athletes then run through the tire pattern by stepping in the center of each tire. The drill forces athletes to lift their feet above the ground higher than normal to avoid tripping on the tires.[120] Old tires are sometimes converted into a swing for play.[121]

See also

- Dry steering

- List of inflatable manufactured goods

- Outline of tires

- Rubber-tyred metro

- Rubber-tyred trams

References

- Harper, Douglas. "tire". Online Etymology Dictionary.

- "tire, n.2." OED Online. Oxford University Press, December 2016. Web. 26 January 2017.

- Peters, Pam (2004). The Cambridge Guide to English Usage. Cambridge University Press. p. 553. ISBN 978-0-521-62181-6.

- Chisholm, Hugh, ed. (1911). Encyclopædia Britannica, vol. 26. Encyclopædia Britannica. p. 1007.

- Fowler, H. W. (2009). David Crystal (ed.). A Dictionary of Modern English Usage: The Classic First Edition. Oxford University Press. p. 655. ISBN 978-0-19-953534-7. Retrieved 23 October 2010.

- Bertman, Stephen (2005). Handbook to Life in Ancient Mesopotamia. Oxford University Press. p. 35. ISBN 9780195183641. Retrieved 2 August 2014.

- ( see US Patent 5104 )

- The Golden Book of Cycling – William Hume, 1938. Archive maintained by 'The Pedal Club'. Archived 3 April 2012 at the Wayback Machine

- "Technology & Innovation". www.dunlop.eu.

- Sir Arthur Du Cros, Bt, Wheels of Fortune, a salute to pioneers, Chapman & Hall, London 1938

- Dunlop, John Boyd (2008). Hutchinson Dictionary of Scientific Biography. AccessScience. Retrieved 9 July 2009.

- Werner Obrecht, Jean-Pierre Lambert, Michael Happ, Christiane Oppenheimer-Stix, John Dunn and Ralf Krüger "Rubber, 4. Emulsion Rubbers" in Ullmann's Encyclopedia of Industrial Chemistry, 2012, Wiley-VCH, Weinheim. doi:10.1002/14356007.o23_o01

- Michelin. "Radial or bias, the right choice / Properly use your tires - Michelin Agricultural Tires". www.michelinag.com. Retrieved 4 August 2017.

- "History". www.jags.org.

- Schultz, Mort (June 1985). Tires: A century of progress. New York City: Popular Mechanics. p. 64.

- Welch, Ted (4 May 2006). "A Tale of Two Tires". Bloomberg. Retrieved 5 May 2019.

- Renn, Aaron M. (16 July 2018). "Middle City, USA". City Journal. Retrieved 6 May 2019.

- Milner, Helen V. (21 September 1989). Resisting Protectionism: Global Industries and the Politics of International Trade. Princeton University Press. p. 151. ISBN 9780691010748.

radial tire market share.

- Morris, Peter (2010). "Rubber". Berkshire Encyclopedia of World History. Berkshire Publishing. p. 2218.

- Heißing, Bernd; Ersoy, Metin (2010). Chassis Handbook: Fundamentals, Driving Dynamics, Components, Mechatronics, Perspectives. Springer Science & Business Media. p. 591. ISBN 9783834897893.

- Duffy, Owen C.; Wright, Gus (20 July 2015). Fundamentals of Medium/Heavy Duty Commercial Vehicle Systems. Jones & Bartlett Publishers. pp. 663–672. ISBN 9781284041170.

- Gent, Alan N.; Walter, Joseph D. (2006). The Pneumatic Tire (PDF). DOT HS 810 561. Washington, DC: National Highway Transportation Safety Administration.

- "Prall Tester - Studded Tyre Wear Test". www.cooper.co.uk. Cooper Research Technology Ltd. Retrieved 1 September 2014.

- Newton, Richard (2007). Wheel and Tire Performance Handbook. St. Paul: MotorBooks International. p. 35. ISBN 9781610592512.

- Allen, Jim. Jeep 4X4 Performance Handbook. MotorBooks International. ISBN 9781616730536.

- Hanseen, Michael (15 August 2018). Jeep TJ 1997-2006: How to Build & Modify. CarTech Inc. ISBN 9781613254288.

- "Dynamic Mechanical Properties Of Passenger And Light Truck Tire Treads". Report No. DOT HS 811 270. National Highway Traffic Safety Administration, U.S. Department of Transportation. 2010.

- Alexander, Don (15 February 2013). High-Performance Handling for Street or Track. Motorbooks. ISBN 9780760339947.

- Erjavec, Jack (2005). Automotive Technology: A Systems Approach. Cengage Learning. p. 1100. ISBN 9781401848316.

- Newton, Richard. Wheel and Tire Performance Handbook. MotorBooks International. p. 52. ISBN 9781610592512.

- Haines, Elizabeth. Certain Off-the-Road Tires from China (701-TA-448 and 731-TA-1117 ed.). U.S. International Trade Commission. p. 4. ISBN 9781457817304.

- Staff (8 May 2019). "Global Off The Road Tire Market: Development History, Current Analysis and Estimated Forecast to 2025 | Industrial Journalism". Industrial Journalism. Retrieved 9 May 2019.

- Currey, Norman S. (1988). Aircraft Landing Gear Design: Principles and Practices. AIAA. pp. 123–5. ISBN 9781600860188.

- McKenny, Earl F. (May 1964). Aerospace safety. Washington, DC: United States Dept of the Air Force. pp. 5–7.

- Richfield, Paul J. (September 2005). Tundra Tire Nation. New York: Flying Magazine. pp. 88–92.

- Sharp, Archibald, Bicycles & Tricycles: An Elementary Treatise on Their Design and Construction, Longmans Green, London and New York, 1896, pages 494-502; reprinted by MIT Press, 1977, ISBN 0-262-69066-7

- Damon Rinard (2000). "Tire Bead Test". Sheldon Brown. Retrieved 10 March 2013.

Conclusion: Clincher tires stay on the rim primarily by the clinch of the hooked sidewall that retains the tire bead, not the circumferential tension in the bead.

- Jinkya, A. (10 May 2019). "Industrial Tire Market: Size Estimated To Observe Significant Growth By 2018 – 2026". Market Talk News. Retrieved 10 May 2019.

- Tribunal, Canada Anti-dumping (1971). Industrial Press-on Solid Rubber Tires: Exported Into Canada by Bearcat Tire Company, Chicago, Illinois, United States of America. Information Canada.

- Cossalter, Vittore (2006). Motorcycle Dynamics (Second ed.). Lulu.com. pp. 37–72. ISBN 978-1-4303-0861-4.

- "Plies and angles - see how they run". Popular Mechanics. 136 (3): 62. March 1972. Retrieved 13 March 2014.

- Jones, Thomas H. (1980). "Get things moving with casters, glides, and wheels". Popular Science. 216 (5): 148. ISSN 0161-7370.

- "Thomas Net sources for industrial use 'Semi-Pneumatic Wheels'". Thomasnet.com. Retrieved 23 October 2010.

- "FAA Airworthiness Directive". Retrieved 15 June 2013.

- "Why Nitrogen". Retrieved 15 June 2013.

- Federal Aviation Administration, Use of Nitrogen or Other Inert Gas for Tire Inflation in Lieu of Air

- "An unknow object: the tire - Materials". Michelin The tire digest. Retrieved 21 July 2017.

- "What's the Difference Between Natural and Synthetic Rubber for Tires?". Kal Tire. 21 July 2017. Retrieved 21 July 2017.

- "Find Local Contractors - Home Remodeling Contractors on Ecnext". goliath.ecnext.com.

- Archived May 11, 2015, at the Wayback Machine

- "World Tires". Freedonia. Freedonia Group. Retrieved 19 May 2017.

- Davis, Bruce. "2015 was strong year for U.S. tire industry". Tire Business. Crain Communications. Retrieved 13 December 2016.

- "Research Report on World's Top 50 Tire Enterprises, 2010-2011 Market Research Report", Companiesandmarkets.com, Vertical Edge Limited, 2 December 2010, archived from the original on 20 January 2011

- "The world's largest tire manufacturers in Q1 and Q2 2016, based on tire-related sales (in billion U.S. dollars)", Statista, 2016

- "Shift of emphasis". Rubber World. 1 April 2012.

- Cook, David (2015). Robot Building for Beginners (3 ed.). Apress. p. 458. ISBN 9781484213599.

- Meyer, W. E. (1983). Frictional Interaction of Tire and Pavement. ASTM International.

- Hogan, C. Michael (September 1973). "Analysis of highway noise". Journal of Water, Air, & Soil Pollution. Springer Verlag. 2 (3): 387–392. Bibcode:1973WASP....2..387H. doi:10.1007/BF00159677. ISSN 0049-6979.

- Ernst, Kurt (12 August 2013). "Montjuic, 1971: When Formula 1 met racing slicks". Hemmings Daily. Retrieved 1 May 2019.

- Hays, Donald (2013). The Physics of Tire Traction: Theory and Experiment. Springer Science & Business Media. p. 428. ISBN 9781475713701. Retrieved 25 December 2016.

- Duffy, Owen C.; Wright, Gus (20 July 2015). Fundamentals of Medium/Heavy Duty Commercial Vehicle Systems. Jones & Bartlett Publishers. p. 678. ISBN 9781284041170.

- Jazar, Reza N. (2008). Vehicle dynamics: theory and applications. Springer. p. 11. ISBN 978-0-387-74243-4. Retrieved 16 March 2011.

Inner layers are made of different fabrics, called plies.

- "Winter Tires: FAQs & How To's". TDot Performance. Retrieved 16 April 2020.

- "Alternative Fuels Data Center: Low Rolling Resistance Tires". www.afdc.energy.gov. Retrieved 31 October 2015.

- Hao, P. T., Ismail, H., & Hashim, A. S. (2001). Study of two types of styrene butadiene rubber in tire tread compounds. Polymer Testing, 20(5), 539-544.

- Samuel K. Clark, V. E. Gough (1981). Mechanics of Pneumatic Tires. U.S. Department of Transportation. p. 245.

Consider two mechanisms of force transmission acting in parallel.

- Samuel K. Clark, V. E. Gough (1981). Mechanics of Pneumatic Tires. U.S. Department of Transportation. p. 246.

The only possible way in which the reaction can develop at the rim is by the changes in magnitude and direction of the membrane stresses at their points of attachment to the rim, in the region of the membrane near the point where the plate is pressed against it.

- Samuel K. Clark, V. E. Gough (1981). Mechanics of Pneumatic Tires. U.S. Department of Transportation. p. 246.

This force pulls the bead coil against the base of the wheel rim above the contact area, thus transmitting the upward force to the wheel.

- American Machinist, Volume 40. 2 April 1914. pp. 597–598. Retrieved 14 March 2012.

- "Demounting and Mounting Procedures" (PDF). Occupational Safety and Health Administration. 2011. Retrieved 14 March 2012.

- "Tribute: Hans Pacejka 1934-2017". Tire Technology International. 19 September 2017. Retrieved 1 October 2017.

- Agency, INK. "Tire Match Mounting and Balancing - Yokohama Tire". www.yokohamatire.com. Archived from the original on 29 September 2007. Retrieved 24 July 2007.

- Clark, Samuel Kelly (1981). Mechanics of pneumatic tires (PDF). U.S. Dept. of Transportation, National Highway Traffic Safety Administration, Washington, D.C.

- Nicholas D. Smith (2003). "Understanding Parameters Influencing Tire Modeling" (PDF). Department of Mechanical Engineering, Colorado State University. Archived from the original (PDF) on 20 September 2008. Retrieved 23 November 2014.

- Wong, Jo Yung (2008). Theory of ground vehicles (Second ed.). Wiley. pp. 52–53. ISBN 978-0-470-17038-0.

- Brown, Sheldon. "Sheldon Brown on tires". Retrieved 1 July 2008.

- SAE. "TKPH application". Retrieved 7 October 2007.

- Bridgestone. "How to use TKPH". Archived from the original on 27 September 2006. Retrieved 7 October 2007.

- Goodyear. "New temperature prediction model improves on current TKPH formula". Archived from the original on 6 November 2006. Retrieved 7 October 2007.

- "Tire". The Rubber Age. Palmerton Publishing Company. 100 (1): 102. 1968. Retrieved 7 August 2019.

One requirement provides that ... all new tires shall be equipped with a tread-wear indicator that will show at a glance when the tread depth has been worn to 1/16 of an inch.

- Kane, Sean (10 December 2014). "Tire Aging and Service Life NTSB Tire Safety Symposium" (PDF). NTSB. Retrieved 7 August 2019.

- "49 CFR 574.5 - Tire identification requirements.".

- "Dept. of Transportation issues new DOT codes". 9 March 2016. Archived from the original on 7 May 2019. Retrieved 29 December 2018.

- "Goodyear Tire Recall - Goodyear Tires". www.goodyear.com.

- Londono, Carmina (July 1999). Free Trade Area of the Americas (FTAA) Conformity Assessment Infrastructure (PDF). Gaithersburg, MD: National Institute of Standards and Technology.

- ETRTO Standards Manual 2007. Bruxelles, Belgium: ETRTO. 2007. pp. I.

- Jazar, Reza N. (19 November 2013). Vehicle Dynamics: Theory and Application. Springer Science & Business Media. ISBN 9781461485445.

- Russell, Richard (31 October 2018). "Have your tires reached their expiration date? | The Chronicle Herald". The Chronicle Herald. Retrieved 6 May 2019.

- Staff (2019). JATMA year book : tyre standards. 2019. Tokyo: The Japan Automobile Tyre Manufacturers Association. ISBN 9784909716026. OCLC 1086187385.

- Busch, Julian (2013). A brief guide to CCC : China Compulsory Certification. CreateSpace Independent Publ. Platform. ISBN 9781484115534. OCLC 959836294.

- Gilles, Tim (2005). Automotive Chassis: Brakes, Suspension, and Steering. Santa Barbara: Thompson Delmar Learning. p. 551. ISBN 9781401856304.

- "Car Talk Service Advice: Tire Pressure". Archived from the original on 3 December 2011. Retrieved 16 January 2009.

- "Air or Tire". Retrieved 15 April 2015.

- "FEA Chapter III: Tire pressure survey and test results". Retrieved 16 January 2009.

- "NHTSA test". Retrieved 16 January 2009.

- Giapponi, Thomas R. (2008). Tire forensic investigation : analyzing tire failure. Warrendale, Pa.: SAE International. ISBN 9780768019551. OCLC 213080702.

- Swatton, Peter J. (30 April 2008). Aircraft Performance Theory for Pilots. New York: John Wiley & Sons. pp. 89–91. ISBN 9780470693056.

- Heisler, Heinz (17 July 2002). Advanced Vehicle Technology. Elsevier. ISBN 9780080493442.

- Blaisdell, George L. (1983). Driving Traction on Ice with All-season and Mud-and-snow Radial Tires. US Army Corps of Engineers, Cold Regions Research & Engineering Laboratory.

- Allen, Jim (2009). Four-Wheeler's Bible. MotorBooks International. ISBN 9781616730888.

- Liu, H., Mead, J., Stacer, R. Chelsea Center For Recycling And Economic Development. (1998). Environmental Impacts Of Recycling Rubber In Light Fill Applications: Summary & Evaluation Of Existing Literature University of Massachusetts

- "Tire-Derived Fuel". U.S. Environmental Protection Agency. Retrieved 29 December 2011.

- Sullivan, Joseph P. (2006). "An Assessment of Environmental Toxicity and Potential Contamination from Artificial Turf using Shredded or Crumb Rubber" (PDF). Retrieved 1 June 2009.

- Chalker-Scott, Linda. "The Myth of Rubberized Landscapes" (PDF). Archived from the original (PDF) on 7 October 2009. Retrieved 1 June 2009.

- "Car tires and brake pads produce harmful microplastics". Science News. 12 November 2018. Retrieved 6 October 2019.

- Beukering, P. J. van (28 February 2001). Recycling, International Trade and the Environment. Springer Science & Business Media. ISBN 9780792368984.

- "What are Retread Tires?". Best Tires Guide. Archived from the original on 17 July 2014. Retrieved 6 April 2014.

- MK Meybodi, I Dobrev, P Klausmeyer, EJ Harrington, C Furlong, "Investigation of thermomechanical effects of lighting conditions on canvas paintings by laser shearography",SPIE Optical Engineering+ Applications, 2012

- Bodziak, William (2008). Tire Tread and Tire Track Evidence: Recovery and Forensic Examination Practical Aspects of Criminal & Forensic Investigations. CRC Press. p. 90. ISBN 978-1420006827.

- Kandhal PS. (1992). WASTE MATERIALS IN HOT MIX ASPHALT - AN OVERVIEW. National Center for Asphalt Technology.

- T. E. Baker (2003). Evaluation of the Use of Scrap Tires in Transportation Related Applications in the State of Washington Archived 2011-06-10 at the Wayback Machine

- M Nehdi, A Khan, (2001). Cementitious Composites Containing Recycled Tire Rubber: An Overview of Engineering Properties and Potential Applications. Cement, Concrete, and Aggregates.

- Ask the garden doctor : 1,200 cures for common garden problems. Schrock, Denny. Hoboken, N.J.: Wiley. 2010. ISBN 9780470878422. OCLC 656770746.CS1 maint: others (link)

- Bignozzi, Maria Chiara (2011). "Sustainable Cements for Green Buildings Construction". Procedia Engineering. 21: 915–921. doi:10.1016/j.proeng.2011.11.2094.

- "A new use for old tires: A garden using tires - Backwoods Home Magazine". www.backwoodshome.com.

- "'Earthships' in the Desert Save Owners Cash". ABC News. 30 December 2010.

- "404 Not Found - The Survivalist Blog". www.thesurvivalistblog.net.

- ROTSTEIN, ARTHUR H. (28 July 1996). "Tire Dam to Tread on Erosion Problem" – via LA Times.

- McCormick, Sean. "No Frills Football Conditioning". About.com. Archived from the original on 3 April 2013.

- Ireland, Jae (24 November 2010). "Football Tire Drills". LiveStrong. Retrieved 1 April 2013.

- Sawyers, Harry. "One Day Project: Kid's Backyard Tire Swing". Popular Mechanics. Retrieved 1 April 2013.

External links

| Look up inner tube, tire, or tyre in Wiktionary, the free dictionary. |

| Wikimedia Commons has media related to Tires. |

- National Highway Traffic Safety Adm "Tire Safety" Brochure

- U.S. Government tire rating and maintenance site.