Bicycle tire

A bicycle tire is a tire that fits on the wheel of a bicycle or similar vehicle. They may also be used on wheelchairs and handcycles, especially for racing. Bicycle tires provide an important source of suspension, generate the lateral forces necessary for balancing and turning, and generate the longitudinal forces necessary for propulsion and braking. Although the use of a pneumatic tire greatly reduces rolling resistance compared to the use of a rigid wheel or solid tire, the tires are still typically the second largest source, after air drag, of power consumption on a level road.[1] The modern detachable pneumatic bicycle tire contributed to the popularity and eventual dominance of the safety bicycle.[2]

Bicycle tires are also used on unicycles, tricycles, quadracycles, tandem bicycles, bicycle trailers, and trailer bikes.

History

The first bicycle "tires" were iron bands on the wooden wheels of velocipedes.[3] These were followed by solid rubber tires on penny-farthings.[4] The first patent for "rubberized wheels" was granted to Clément Ader in 1868.[5] In an attempt to soften the ride, rubber tires with a hollow core were also tried.[6]

The first practical pneumatic tire was made by John Boyd Dunlop in 1887 for his son's bicycle, in an effort to prevent the headaches his son had while riding on rough roads. (Dunlop's patent was later declared invalid because of prior art by fellow Scot Robert William Thomson.) Dunlop is credited with "realizing rubber could withstand the wear and tear of being a tire while retaining its resilience".[7] This led to the founding of Dunlop Pneumatic Tyre Co. Ltd in 1889. By 1890, it began adding a tough canvas layer to the rubber to reduce punctures. Racers quickly adopted the pneumatic tire for the increase in speed it enabled.

Finally, the detachable tire was introduced in 1891 by Édouard Michelin. It was held on the rim with clamps, instead of glue, and could be removed to replace or patch the separate inner tube.[2]

Attaching to the rim

Three main techniques for attaching a bicycle tire to a rim have been developed: clincher, wired and tubular.[8] Clinchers originally did not have wire in the beads and the shape of the bead interlocked with a flange on the rim, relying on air pressure to hold the tire bead in place. However, this type of tire is no longer in general use and the term clincher has transferred to the modern wired-on tire. For the remainder of this article, the modern use of the word clincher will be assumed.

In an attempt to provide the best attributes of both wired and tubular methods, tubular clinchers have also been offered.[9]

Clincher

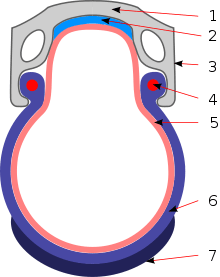

Most bicycle tires are clincher for use with "clincher" rims. These tires have a steel wire or Kevlar fiber bead that interlocks with flanges in the rim. A separate airtight inner tube enclosed by the rim supports the tire carcass and maintains the bead lock. An advantage of this system is that the inner tube can be easily accessed in the case of a leak to be patched or replaced.

The ISO 5775-2 standard defines designations for bicycle rims. It distinguishes between

- Straight-side (SS) rims

- Crochet-type (C) rims

- Hooked-bead (HB) rims

Traditional wired-on rims were straight-sided. Various "hook" (also called "crochet") designs re-emerged in the 1970s to hold the bead of the tire in place,[10][11] resulting in the modern clincher design. This allows higher (80–150 psi or 6–10 bar) air pressures than older wired-on tires. In these designs, it is the interlocking of the bead with the rim, not the tight fit or resistance to stretching of the bead, that keeps the tire on the rim and contains the air pressure.[12]

Some clincher tires can be used without tubes in a system which is referred to as tubeless. Typical tubeless tires have airtight sidewalls and beads which are designed to maximize the seal against the rim.

Tubular or sew-up

Some tires are torus-shaped and attached to tubular rims with adhesive. The rim provides a shallow circular outer cross-section in which the tire lies instead of flanges on which tire beads seat.

Providing suspension

Adequate stiffness is necessary to support the rider, while softness is desirable for cushioning. Most bicycle tires are pneumatic—the stiffness is provided by pressurized air. Airless tires use some kind of elastomer instead.

Pneumatic tires

In a pneumatic tire, pressurized air is held inside either with a separate, relatively impermeable inner tube, or by the tire and rim, in a tubeless system. Pneumatic tires are superior in providing effective cushioning while keeping rolling resistance very low.

Tubed

A tubed tire has a separate inner tube, made of butyl rubber or latex, that provides a relatively airtight barrier inside the tire.[13] A vast majority of the tire systems in use are clinchers, due to the relative simplicity of repairs and wide availability of replacement inner tubes.

Most of bicycle inner tubes are torus-shaped balloons while some are not. For example, inner tubes in bicycles of the Moscow bike-sharing service are simply rubber tubes long enough to be coiled and inserted into a tire.[14]

Tubeless

Tubeless tires are primarily used on mountain bikes due to their ability to use low air pressure for better traction without getting pinch flats.[15] Tubeless tires work similarly to clinchers in that the bead of the tire is specifically designed to interlock into a corresponding tubeless rim, but without an inner tube. Air is inflated directly into the tire, and once "locked" into the rim, the system is airtight. Liquid sealants are often injected into tubeless tires to improve sealing and to stop leaks caused by punctures. An advantage is that pinch flats are less common in a tubeless setup because they require a hole through the tire carcass, not just the inner tube. A disadvantage is that air can escape if the bead lock is compromised from too much lateral force on the tire or deformation of the rim/tire due to hard impact with an object.

Tubeless tires require tubeless-compatible rims, which do not allow air to escape where the spokes connect and have a different shape groove for the tire bead to seat.

Road tubeless

In 2006, Shimano and Hutchinson introduced a tubeless system for road bicycles.[16] Tubeless tires have not yet gained popular acceptance in road racing due to lack of sponsorship, the tradition of using tubular tires and the fact that, even without the inner tube, the combined weight of tubeless rims and tires is more than top-of-the-line tubular tire wheelsets.[17] Road tubeless is gaining popularity among riders for whom the benefits are worth the costs.[18] Road tubeless tires tend to be a much tighter fit than traditional clincher tires, which makes mounting and removing the tire more difficult.

Airless tires

Airless were used before pneumatic tires were developed, appearing on velocipedes by 1869.[19][20] They continue to be developed in an effort to solve the problem of losing air pressure, either from a puncture or from permeability. Modern examples of airless tires for bicycles include BriTek's Energy Return Wheel,[21] an airless bicycle tire from Bridgestone,[22] the tire pictured to the right on a Mobike, and solid tires discussed below. Although modern airless tires are better than early ones, most give a rough ride and may damage the wheel or bicycle.[23]

Solid

The most common form of airless tire is simply the solid tire. Besides solid rubber, solid tires made of polyurethane[24][25][26][27][28] or microcellular foam[29] are also offered for 100% flat prevention. Much of the desirable suspension quality of the pneumatic tire is lost, however, and ride quality suffers.[30]

Many bicycle-sharing systems use these tires to reduce maintenance, and examples of solid tires include those available from Greentyre,[31] Puncture Proof Tyres Ltd,[32] KIK-Reifen,[33] Tannus,[31] Hutchinson,[34] and Specialized.[35]

Construction

Bicycle tires consist of a rubber-impregnated cloth casing, also called the carcass, with additional rubber, called the tread, on the surface that contacts the road. In the case of clinchers, the casing wraps around two beads, one on each edge.

Casing

Bicycle tire casing is made of cloth, usually nylon, though cotton and silk have also been used. The casing provides the resistance against stretching necessary to contain the internal air pressure while remaining flexible enough to conform to the ground surface. The thread count of the cloth affects the weight and performance of the tire, and high thread counts improve ride quality and reduce rolling resistance at the expense of durability and puncture resistance.

Bias ply

The fibers of the cloth in most bicycle tires are not woven together, but kept in separate plies so that they can move more freely to reduce wear and rolling resistance. They are also usually oriented diagonally, forming bias plies.[36]

Radial ply

Radial ply has been attempted, and examples include Panasonic in the 1980s and the Maxxis in the 2010s,[36] but often found to provide undesirable handling characteristics.[37]

Tread

The tread is the part of the tire that contacts the ground to provide grip and protect the casing from ware.

- Compound

The tread is made of natural and synthetic rubber that often includes fillers such as carbon black, which gives it its characteristic color, and silica.[38] The type and amount of filler is selected based on characteristics such as wear, traction (wet and dry), rolling resistance, and cost. Oils and lubricants may be added as softeners.[38] Sulphur and zinc oxide facilitate vulcanization.[38] Some tires have a dual-compound tread that is tougher in the middle and grippier on the edges.[39] Many modern tires are available with treads in a variety or combination of colors.[40][41] Road racing tires with different tread compounds for the front and rear have been developed, thereby attempting to provide more traction in front and less rolling resistance in the rear.[42]

- Pattern

Treads fall somewhere along the spectrum from smooth or slick to knobby. Smooth treads are intended for on-road use, where a tread pattern offers little to no improvement in traction.[43] However, many otherwise slick tires have a light tread pattern, due to the common belief that a slick tire will be slippery in wet conditions. Knobby treads are intended for off-road use, where the tread texture can help improve traction on soft surfaces. Many treads are omnidirectional—the tire can be installed in either orientation—but some are unidirectional and designed to be oriented in a specific direction. Some tires, especially for mountain bikes, have a tread which is intended either for the front wheel or the rear wheel.[44] A special tread pattern, with small dimples, has been developed to reduce air drag.[45]

- Profile

The profile of the tread is usually circular, matching the shape of the casing inside it and allowing the tire to roll to the side as the bicycle leans for turning or balancing. More-squared profiles are sometimes used on mountain bike tires and novelty tires designed to look like automotive racing slicks,[46] as on wheelie bikes.

Bead

The bead of clincher tires must be made of a material that will stretch very little to prevent the tire from expanding off of the rim under internal air pressure.

- Wire

Steel wire beads are used on inexpensive tires. Though they cannot be folded, they can often be twisted into three smaller hoops.[47]

- Kevlar

Kevlar beads are used on expensive tires, and these are also called "foldable". They should not be used on straight sidewall rims as they may blow off the rim.

Sidewall

The sidewall of the casing, the part not intended to contact the ground, may receive one of several treatments.

- Gum wall

Tires with sidewalls made of natural rubber are called "gum wall". The tan colored, natural rubber lacks carbon black to decrease rolling resistance, as its added wear resistance isn't needed in the sidewall.[48]

- Skin wall

Tires with very little rubber, if any, covering the sidewall are called "skin wall". This reduces rolling resistance by reducing sidewall stiffness at the cost of reducing damage protection.[49]

Variations

Puncture resistance

Some tires include an extra layer between the tread and the casing (as shown in the cross section pictured above) to help prevent punctures either by being tough or simply by being thick. These extra layers are usually associated with higher rolling resistance.[50]

Studs

Metal studs may be embedded in the tread of knobby tires to improve traction on ice.[51] Inexpensive studded tires use steel studs, while pricier tires use more durable carbide studs.[52] A studded, knobby tread that zips onto a smoother, non-studded tire has been developed to ease the transition between the two types of tires.[53][54][55]

Reflective

Some tires have a reflective strip on their sidewalls to improve visibility at night. Others have reflective material embedded in the tread.[41]

Aerodynamics

In addition to the dimple tread pattern mentioned above, at least one tire has an extra "wing" to cover the gap between the tire sidewall and the wheel rim and reduce drag.[56]

Indoor use

At least one modern bicycle tire has been designed specifically for indoor use on rollers or trainers. It minimizes excessive wear that traditional tires experience in this environment and is not suitable for use on pavement.[57]

Different front and rear

Besides the different tread patterns available on some mountain bike tires mentioned above, front and rear tire sets are available for road bikes with different tread patterns, tread compounds, and sizes for the front and rear wheels.[58] Other scenarios involve replacing a damaged tire, and leaving the other one unchanged.

Parameters

Sizes

The modern tire-size designations (e.g. "37-622", also known as ETRTO) are defined by international standard ISO 5775, along with corresponding rim size designations (e.g., "622×19C"). Older English (inch, e.g. "28 x 1 ⅝ x 1 ⅜") and French (metric, e.g. "700x35C") designations are also still used, but can be ambiguous. The diameter of the tire must match the diameter of the rim, but the width of the tire only has to be in the range of widths appropriate for the width of the rim,[61] while also not exceeding the clearances allowed by the frame, brakes, and any accessories such as fenders. Diameters vary from a large 910 mm, for touring unicycles, to a small 125 mm, for roller skiing.[62] Widths vary from a narrow 18 mm to a wide 119 mm for the Surly Big Fat Larry.[63]

Lightweight tires

Lightweight tires range in size from 3⁄4 to 1 1⁄8 inches (19 to 29 mm) wide.

Middleweight or Demi-balloon tires

Middleweight or Demi-balloon tires range in size from 1 1⁄8 to 1 3⁄4 inches (29 to 44 mm) wide.

Balloon tires

A balloon tire is a type of wide, large-volume, low-pressure tire that first appeared on cruiser bicycles in the US in the 1930s. They are typically 2 to 2.5 inches (51 to 64 mm) wide.

In the 1960s Raleigh made its small-wheeled RSW 16 with balloon tires[64] so it would have a soft ride like the fully suspended Moulton Bicycle. Other manufacturers then used the same idea for their own small wheelers. Examples include the Stanningley (UK)-made Bootie Folding Bicycle, the Co-operative Wholesale Society (CWS) Commuter, and the Trusty Spacemaster.

Plus-size tires

A plus-size tire has a width of typically 2.5–3.25 inches (64–83 mm). Three bead seat diameters are available: 559 mm for 26+, 584 mm for 27.5+ (650B+), and 622 mm for 29+. They fill the gap between balloon and fat tires.[65]

Fat tires

A fat tire is a type of wide oversized bicycle tire, typically 3.8 in (97 mm) or larger and rims 2.6 in (66 mm) or wider, designed for low ground pressure to allow riding on soft unstable terrain, such as snow, sand, bogs, and mud.[66] Since the 1980s, fat tires of width 3.8 to 5 in (97 to 127 mm), and diameters similar to conventional bicycle wheels, have been used on "fatbikes" and all-terrain bikes designed for riding in snow and sand.[67][68]

Inflation pressure

The inflation pressure of bicycle tires ranges from 4.5 psi (0.31 bar; 31 kPa) for fat bike tires in snow[69] to 220 psi (15 bar; 1,500 kPa) for tubular track racing tires.[70] The maximum pressure rating of tires is usually stamped on the sidewall, indicated as "Maximum Pressure", or "Inflate to ..." or sometimes expressed as a range like "5–7 bar (73–102 psi; 500–700 kPa)". Decreasing pressure tends to increase traction and make the ride more comfortable while increasing pressure tends to make the ride more efficient and decreases the chances of getting pinch flats.[71]

One published guideline for clincher inflation pressure is to pick the value for each wheel that produces a 15% reduction in the distance between the wheel rim and the ground when loaded (i.e. with the rider and cargo) compared to when unloaded. Pressures below this led to increased rolling resistance and likelihood of pinch-flats. Pressures above this led to less rolling resistance in the tire itself, but to larger energy losses in the frame and rider.[72]

Inner tubes are not completely impermeable to air and slowly lose pressure over time. Butyl inner tubes hold pressure better than latex.[73] Tires inflated from carbon dioxide canisters (often used for roadside repairs) or helium (occasionally used for elite track racing) lose pressure more quickly, because carbon dioxide, despite being a large molecule, is slightly soluble in rubber,[74] and helium is a very small atom which passes quickly through any porous material. At least one public bicycle sharing system, London's Santander Cycles, is inflating tires with nitrogen, instead of simple air, which is already 78% nitrogen, in an attempt to keep the tires at the proper inflation pressure longer,[75] though the effectiveness of this is debatable.[76][77][78]

Effect of temperature

Since the volume of gas and the gas itself inside a tire is not altered significantly by a change of temperature, the ideal gas law states that the pressure of the gas should be directly proportional to the absolute temperature. Thus, if a tire is inflated to 4 bar (400 kPa; 58 psi) at room temperature, 20 °C (68 °F), the pressure will increase to 4.4 bar (440 kPa; 64 psi) (+10%) at 40 °C (104 °F) and decrease to 3.6 bar (360 kPa; 52 psi) (-10%) at −20 °C (−4 °F).

In the example above, a 7% difference in absolute temperature resulted in a 10% difference in tire pressure. This is a result of the difference between gauge pressure and absolute pressure. For low inflation pressures, this distinction is more important, as the ideal gas law applies to absolute pressure, including atmospheric pressure. For example, if a fat-bike tire is inflated to 0.5 bar (50 kPa; 7.3 psi) gauge pressure at room temperature 20 °C (68 °F) and then the temperature is decreased to −10 °C (14 °F) (a 9% decrease in absolute temperature), the absolute pressure of 1.5 bar (150 kPa; 22 psi) will be decreased by 9% to 1.35 bar (135 kPa; 19.6 psi), which translates to a 30% decrease in gauge pressure, to 0.35 bar (35 kPa; 5.1 psi).

Effect of atmospheric pressure

The net air pressure on the tire is the difference between the internal inflation pressure and the external atmospheric pressure, 1 bar (100 kPa; 15 psi), and most tire pressure gauges report this difference. If a tire is inflated to 4 bar (400 kPa; 58 psi) at sea level, the absolute internal pressure would be 5 bar (500 kPa; 73 psi) (+25%), and this is the pressure that the tire would need to contain if it were moved to a location with no atmospheric pressure, such as the vacuum of free space. At the highest elevation of commercial air travel, 12,000 metres (39,000 ft), the atmospheric pressure is reduced to 0.2 bar (20 kPa; 2.9 psi), and that same tire would have to contain 4.8 bar (480 kPa; 70 psi) (+20%).

Effect on carcass stress

Bicycle tires are essentially toroidal thin-walled pressure vessels and if the carcass is treated as a homogeneous and isotropic material then stress in the toroidal direction (longitudinal or axial stress if the tire is considered a long cylinder) can be calculated as:[79][80]

- ,

where:

- p is internal gauge pressure

- r is the inner, minor radius of the carcass

- t is thickness of the carcass

Stress in the poloidal direction (hoop or circumferential stress if the tire is considered a long cylinder) is more complicated, varying around the minor circumference and depending on the ratio between the major and minor radii, but if the major radius is much larger than the minor radius, as on most bicycle tires where the major radius is measure in hundreds of mm and the minor radius is measured in tens of mm, then stress in the Poloidal direction is close to the hoop stress of cylindrical thin-walled pressure vessels:[79][80]

- .

In reality, of course, the tire carcass is not homogeneous nor isotropic, but instead is a composite material with fibers imbedded in a rubber matrix, which complicates things further.

Rim width

While not strictly a tire parameter, the width of the rim on which any given tire is mounted has an influence on the size and shape of the contact patch, and possibly the rolling resistance and handling characteristics.[81] The European Tyre and Rim Technical Organisation (ETRTO) publishes a guideline of recommended rim widths for different tire widths:[82]

| tire width | straight rim width | crotchet rim width |

|---|---|---|

| 18 | - | 13C |

| 20 | - | 13C |

| 23 | 16 | 13C-15C |

| 25 | 16-18 | 13C-17C |

| 28 | 16-20 | 15C-19C |

| 32 | 16-20 | 15C-19C |

| 35 | 18-22 | 17C-21C |

| 37 | 18-22 | 17C-21C |

| 40 | 20-24 | 19C-23C |

| 44 | 20-27 | 19C-25C |

| 47 | 20-27 | 19C-25C |

| 50 | 22-30.5 | 21C-25C |

| 54 | 27-30.5 | 25C-29C |

| 57 | 27-30.5 | 25C-29C |

| 62 | 30.5 | 29C |

In 2006, it was expanded for allowing wide tires up to 50mm on 17C rims and 62mm on 19C rims.[83] Ideally, the tire width should be 1.8 to 2 times the rim width, but a ratio from 1.4 to 2.2 should fit, and even 3 for hooked rims.[84]

Tire pressure versus width

Mavic recommends maximum pressures in addition to rim width,[85] and Schwalbe recommends specific pressures:[86]

| tire width | Schwalbe rec. | Mavic max. | rim |

|---|---|---|---|

| 18 mm (0.71 in) | 10.0 bars (145 psi) | 13C | |

| 20 mm (0.79 in) | 9.0 bars (131 psi) | 9.5 bars (138 psi) | 13C |

| 23 mm (0.91 in) | 8.0 bars (116 psi) | 9.5 bars (138 psi) | 13C-15C |

| 25 mm (0.98 in) | 7.0 bars (102 psi) | 9.0 bars (131 psi) | 13C-17C |

| 28 mm (1.1 in) | 6.0 bars (87 psi) | 8.0 bars (116 psi) | 15C-19C |

| 32 mm (1.3 in) | 5.0 bars (73 psi) | 6.7 bars (97 psi) | 15C-19C |

| 35 mm (1.4 in) | 4.5 bars (65 psi) | 6.3 bars (91 psi) | 17C-21C |

| 37 mm (1.5 in) | 4.5 bars (65 psi) | 6.0 bars (87 psi) | 17C-23C |

| 40 mm (1.6 in) | 4.0 bars (58 psi) | 5.7 bars (83 psi) | 17C-23C |

| 44 mm (1.7 in) | 3.5 bars (51 psi) | 5.2 bars (75 psi) | 17C-25C |

| 47 mm (1.9 in) | 3.5 bars (51 psi) | 4.8 bars (70 psi) | 17C-27C |

| 50 mm (2.0 in) | 3.0 bars (44 psi) | 4.5 bars (65 psi) | 17C-27C |

| 54 mm (2.1 in) | 2.5 bars (36 psi) | 4.0 bars (58 psi) | 19C-29C |

| 56 mm (2.2 in) | 2.2 bars (32 psi) | 3.7 bars (54 psi) | 19C-29C |

| 60 mm (2.4 in) | 2.0 bars (29 psi) | 3.4 bars (49 psi) | 19C-29C |

| 63 mm (2.5 in) | 3.0 bars (44 psi) | 21C-29C | |

| 66 mm (2.6 in) | 2.8 bars (41 psi) | 21C-29C | |

| 71 mm (2.8 in) | 2.5 bars (36 psi) | 23C-29C | |

| 76 mm (3.0 in) | 2.1 bars (30 psi) | 23C-29C |

Fatbike tires of 100 to 130 mm (4 to 5 inches) width are typically mounted on 65 to 100 mm rims.[87]

Forces and moments generated

Bicycle tires generate forces and moments between the wheel rim and the pavement that can affect bicycle performance, stability, and handling.

Vertical force

The vertical force generated by a bicycle tire is approximately equal to the product of inflation pressure and contact patch area.[88] In reality, it is usually slightly more than this because of the small but finite rigidity of the sidewalls.

The vertical stiffness, or spring rate, of a bicycle tire, as with motorcycle and automobile tires, increases with inflation pressure.[89]

Rolling resistance

Rolling resistance is a complex function of vertical load, inflation pressure, tire width, wheel diameter, the materials and methods used to construct the tire, roughness of the surface on which it rolls, and the speed at which it rolls.[1] Rolling resistance coefficients may vary from 0.002 to 0.010,[1][70][90][91] and have been found to increase with vertical load, surface roughness, and speed.[1][92] Conversely, increased inflation pressure (up to a limit), wider tires (compared to narrower tires at the same pressure and of the same material and construction),[93] larger-diameter wheels,[94] thinner casing layers, and more-elastic tread material all tend to decrease rolling resistance.

For example, a study at the University of Oldenburg found that Schwalbe Standard GW HS 159 tires, all with a width of 47 mm and an inflation pressure of 300 kPa (3.0 bar; 44 psi), but made for various diameter rims, had the following rolling resistances:[95]

ISO Size Tire diameter (mm) Crr 47-305 351 0.00614 47-406 452 0.00455 47-507 553 0.00408 47-559 605 0.00332 47-622 668 0.00336

The author of the cited paper concludes, based on the data presented therein, that Crr is inversely proportional to inflation pressure and to wheel diameter.

Cornering force and camber thrust

As with other pneumatic tires, bicycle tires generate cornering force that varies with slip angle and camber thrust that varies with camber angle. These forces have been measured by several researchers since the 1970s,[96][97] and have been shown to influence bicycle stability.[98][99]

Moments

Moments generated in the contact patch by a pneumatic tire include the self aligning torque associated with cornering force, twisting torque associated with camber thrust, both about a vertical axis, and an overturning moment about the roll axis of the bike.[100]

Brands and manufacturing companies

- Bontrager (owned by Trek)

- Cheng Shin Rubber (also branded as Maxxis and CST)

- Coker Tire

- Continental

- Fyxation

- Hutchinson

- IRC Tire

- Kenda

- Maxxis

- Michelin

- Nokian (Nokian and Suomi Tyres bicycle tire brands now owned and manufactured by LieksaTyres in Finland)

- Panasonic

- Schwalbe

- SOMA Fabrications

- Specialized Bicycle Components

- Vittoria

- Vredestein

- Wilderness Trail Bikes

References

- Wilson, David Gordon; Jim Papadopoulos (2004). Bicycling Science (Third ed.). The MIT Press. pp. 215–235. ISBN 0-262-73154-1.

Bicycle tire rolling resistance coefficients for smooth surfaces are widely accepted to range between 0.002 and 0.010

- Herlihy, David V. (2004). Bicycle, The History. Yale University Press. p. 252. ISBN 0-300-10418-9.

As the pneumatic-tire safety gained popularity, the sport generated unprecedented popular interest.

- Herlihy, David V. (2004). Bicycle, The History. Yale University Press. pp. 76. ISBN 0-300-10418-9.

- Herlihy, David V. (2004). Bicycle, The History. Yale University Press. pp. 159. ISBN 0-300-10418-9.

- Tony Hadland & Hans-Erhard Lessing (2014). Bicycle Design, An Illustrated History. MIT Press. p. 59. ISBN 978-0-262-02675-8.

- Herlihy, David V. (2004). Bicycle, The History. Yale University Press. pp. 246. ISBN 0-300-10418-9.

- Dunlop, John Boyd (2008). Hutchinson Dictionary of Scientific Biography. AccessScience, MCTC. Retrieved July 9, 2009.

- Sharp, Archibald, Bicycles & Tricycles: An Elementary Treatise on Their Design and Construction, Longmans Green, London and New York, 1896, pages 494-502; reprinted by MIT Press, 1977, ISBN 0-262-69066-7

- Guy Andrews (May 20, 2005). "Tufo C Elite Road Tubular Clincher". Road Cycling UK. Retrieved June 14, 2010.

- Brown, Sheldon. "ISO/E.T.R.T.O. 630 mm, Note on tire/rim compatibility". Sheldon Brown. Archived from the original on June 22, 2008. Retrieved May 23, 2008.

- "Mistral Demystified: Development of the AM 17" rim". Archived from the original on July 17, 2008. Retrieved May 23, 2008.

- Damon Rinard (2000). "Tire Bead Test". Sheldon Brown. Retrieved March 10, 2013.

Conclusion: Clincher tires stay on the rim primarily by the clinch of the hooked sidewall that retains the tire bead, not the circumferential tension in the bead.

- Brown, Sheldon. "Bicycle Tires and Tubes: Inner tubes". Sheldon Brown. Retrieved June 12, 2010.

- Gershman, Arkady (2017). "How a city bike rental's maintenance works" Как обслуживают городской велопрокат. Веломосква (in Russian). Retrieved February 20, 2018.

- Felton, Vernon (2008). "Are Tubeless Tires Worth It?". Bike Magazine. Archived from the original on August 23, 2010. Retrieved August 31, 2011.

- Phillips, Matt (December 2008). "The Scoop on Tubeless". Bicycling. Rodale: 90.

- Zinn, Lennard. "Lennard Zinn Technical FAQ". Velo News. Archived from the original on August 14, 2011. Retrieved August 31, 2011.

- "road tubeless tires yea or nay". roadbikereview.com. Archived from the original on April 2, 2015. Retrieved March 2, 2015.

- Herlihy, David V. (2004). Bicycle, The History. Yale University Press. pp. 125. ISBN 0-300-10418-9.

- Tony Hadland & Hans-Erhard Lessing (2014). Bicycle Design, An Illustrated History. MIT Press. p. 188. ISBN 978-0-262-02675-8.

- Lidija Grozdanic (May 30, 2014). "BriTek's Brilliant Airless Bicycle Tire Reinvents the Wheel". InHabitat. Retrieved March 3, 2018.

- Andrew Liszewski (April 20, 2017). "Bridgestone's Airless Tires Will Soon Let Cyclists Abandon Their Bike Pumps". Gizmodo. Retrieved March 3, 2018.

- Brown, Sheldon. "Bicycle Tires and Tubes: Inner tubes". Sheldon Brown. Retrieved July 13, 2017.

- Jim Davis (November 1974). "For bike tires: fill 'em up with rubber?". Popular Science. p. 47. Retrieved June 1, 2016.

Punctures have plagued cyclists ever since they began putting air into tires. Now there's a cure: a resilient rubber called BykFil that replaces all the air in the tire, ending leaks forever.

- "Solid polyurethane as tire fill". Modern Plastic. March 1975: 32–33.

Solid polyurethane replaces air in rubber tires in a new method of tire filling developed by Synair Corp., Tustin, Calif. The material is Tyrfil, marketed in the U.S. by B.F. Goodrich Tire Co. The two-component polyurethane system is pumped into rim-mounted tires through air valves, and become a solid with a specific gravity of 1.02. A similar product, Bykfil, for bicycle tires has been developed by Synair. About 21/4 lb. of Bykfil is needed to fill a standard bicycle tire: about lb. for racing bike tires. Cost of Bykfil to the end user is about $7 for a standard bicycle tire. Cost of Tyrfil is about $1.25/ lb.

Cite journal requires|journal=(help) - "BykFil By: Vita Industrieal, Inc". Trademark247. July 22, 2006. Retrieved June 2, 2016.

Two-component resin preparation useful for filling tires

- Michael Bluejay. "Flat-Free Tubes & Tires". Bicycle Universe. Retrieved June 12, 2010.

- "Engineering Next Generation Bicycle Components for Developing Country Consumers". USAID. April 7, 2013. Retrieved May 25, 2013.

- Enid Burns (July 24, 2012). "Bicycle wheelsets with no-flat tires premounted". GizMag. Retrieved November 28, 2013.

- Brown, Sheldon. "Bicycle Tires and Tubes: Airless Tires". Sheldon Brown. Retrieved June 12, 2010.

They are heavy, slow and give a harsh ride. They are also likely to cause wheel damage, due to their poor cushioning ability.

- Paul Norman (April 5, 2017). "Puncture proof: are solid tyres an option for road bikes?". CyclingWeekly. Retrieved February 26, 2018.

- "puncture-proof-tyres.co.uk". Archived from the original on February 27, 2018. Retrieved February 26, 2018.

- "KIK-Reifen". Retrieved February 26, 2018.

- Brad (September 24, 2010). "Hutchinson Serenity Flat Proof Tire System". UrbanVelo. Retrieved February 26, 2018.

- Zach Overholt (January 2, 2017). "Review: Rolling into the new year with airless tires on the Specialized Alibi Sport". BikeRumor. Retrieved February 26, 2018.

- Tony Hadland & Hans-Erhard Lessing (2014). Bicycle Design, An Illustrated History. MIT Press. p. 193. ISBN 978-0-262-02675-8.

- Brown, Sheldon. "Bicycle Tires and Tubes: Parts of a tire". Sheldon Brown. Retrieved June 13, 2010.

- "What components make up a tire?". Schwalbe. Retrieved October 19, 2018.

- Brown, Sheldon. "Bicycle Tires and Tubes: Rubber". Sheldon Brown. Retrieved June 12, 2010.

- "Pro-2 Race 25c Tires". November 2009. Archived from the original on 12 June 2010. Retrieved 20 June 2010.

- "SWEETSKINZ – Reflective bike tires". November 11, 2006. Archived from the original on July 28, 2010. Retrieved June 20, 2010.

- Guy Andrews (April 20, 2005). "Schwalbe Stelvio Evolution". RoadCyclingUK. Retrieved February 23, 2011.

- Brown, Sheldon. "Bicycle Tires and Tubes: Tread Patterns". Sheldon Brown. Retrieved June 12, 2010.

- "How to Choose a Bike Tire". REI. Archived from the original on 19 July 2010. Retrieved 17 June 2010.

- "Gear ang Bike Review Finder: Tangente Tubular tires". Bicycling Magazine. August 2007. Archived from the original on 1 December 2010. Retrieved 16 June 2010.

- "1967 Schwinn Sting-Ray". SchwinnStingRay.net. Retrieved June 22, 2010.

- Jobst Brandt (October 17, 1997). "Coiling a Wire Bead Clincher". Retrieved January 31, 2019.

The three coil pack must be secured to prevent it from springing open again.

- Brown, Sheldon. "Gum". Sheldon Brown. Retrieved June 12, 2010.

- Brown, Sheldon. "Skinwall". Sheldon Brown. Retrieved June 12, 2010.

- Lennard Zinn (December 2, 2008). "Technical Q&A with Lennard Zinn – Fight flats, lose speed?". Velonews. Retrieved June 15, 2010.

- "Tires for Icebiking". Icebike. Archived from the original on April 6, 2010. Retrieved June 12, 2010.

- John Andersen. "The Ultimate Guide to Winter Bike Tires and Studded Tires". Icebike. Retrieved February 24, 2019.

- Adam Ruggiero (September 27, 2018). "Zip-On Bike Tires Are Real, and They Look Crazy". GearJunkie.com. Retrieved February 24, 2019.

- Ben Coxworth (June 1, 2018). "reTyre bike tires feature interchangeable skins". NewAtlas.com. Retrieved February 24, 2019.

- Mat Brett (May 25, 2018). "reTyre: they're tyres that zip into place!". road.cc. Retrieved February 24, 2019.

- "Race X Lite Aero TT". Bicycling Magazine. September 2009. Archived from the original on 7 February 2010. Retrieved 20 June 2010.

- Corey Whalen (May 18, 2005). "Product Review: Continental Ultra Sport Hometrainer Tire". Roadcycling.com. Archived from the original on August 19, 2014. Retrieved August 17, 2014.

- Paul Vincent (April 19, 2008). "Continental GP Force and Attack Black Chilli review". BikeRadar.com. Retrieved January 14, 2012.

- Ben Coxworth (August 24, 2011). "Self-inflating tire keeps the pressure up for cyclists". GizMag. Retrieved November 28, 2013.

- Charlie Sorrel (August 26, 2011). "Magic: The Self-Inflating Bike Tire". Wired. Retrieved November 28, 2013.

- Brown, Sheldon. "Tire sizing". Sheldon Brown. Retrieved June 13, 2010.

- Mike Muha (July 22, 2002). "The Perfect Rollerski? The V2 Aero 150S". A Michigan Nordic Ski Racer. Retrieved June 18, 2010.

- "Big Fat Larry". SurlyBikes.com. Retrieved April 26, 2012.

- www.bootiebike.com Raleigh RSW tyres - Retrieved February 25, 2017.

- Matt Phillips (May 19, 2015). "A Plus-Size Tire Primer". Bicycling. Retrieved March 4, 2019.

This new, wider tire size is meant to bridge the gap between standard mountain bike tires and fat bikes. How fat are plus-size? There’s no rigid definition, but Trek’s designation is about as good a starting place as any: a 2.8- to 3.25-inch tire on a 35- to 50mm (external) rim.

- Adam Fisher. "Rollin' Large". Bicycling. Archived from the original on August 30, 2014. Retrieved March 2, 2017.

- Brown, Sheldon. "Balloon". Sheldon Brown. Retrieved June 27, 2010.

- "Pugsley". Retrieved September 20, 2011.

- Danielle Musto (March 1, 2016). "Rules of fat: dialing in tire pressure". 45NRTH.

- "Tire Pressure Instruction". Nimble. 1997. Archived from the original on July 29, 2010. Retrieved June 14, 2010.

- Frank Berto (2006). "All About Tire Inflation" (PDF). Beach Cities Cycling Club. Archived from the original (PDF) on September 14, 2012. Retrieved August 6, 2012.

- Jan Heine (March 2009). "PSI RX - Tire pressure and load" (PDF). Adventure Cyclist magazine.

- Brown, Sheldon. "Tube (inner)". Sheldon Brown. Retrieved June 29, 2010.

- Lennard Zinn (February 3, 2009). "Technical Q&A with Lennard Zinn – Large molecules and short frames". VeloNews.com. Retrieved January 20, 2013.

It turns out however that the leakage rate of CO2 is huge, and the reason is that it is actually soluble in butyl rubber and is thus not constrained to normal permeation loss, it can transfer straight through the bulk rubber resulting in severe tire pressure loss on the order of a single day.

- Ross Lydall (21 May 2010). "Taking a ride on Boris's hot wheels hire bikes". London Evening Standard. Archived from the original on June 29, 2010. Retrieved June 29, 2010.

- "Do Nitrogen-Filled Tires Enhance Fuel-Efficiency?". Scientific American. September 30, 2008. Retrieved June 29, 2010.

- Tom & Ray Magliozzi (February 2005). "Dear Tom and Ray". CarTalk.com. Retrieved June 29, 2010.

- Gene Petersen (October 4, 2007). "Tires – Nitrogen air loss study". Consumer Reports. Archived from the original on November 26, 2011. Retrieved December 10, 2011.

Bottom line: Overall, consumers can use nitrogen and might enjoy the slight improvement in air retention provided, but it's not a substitute for regular inflation checks.

- Vladan Veličković (2007). "Stress and Strain States in the Material of the Stressed Toroidal Container for Liquefied Petroleum Gas" (PDF). Scientific Technical Review. Retrieved March 15, 2019.

- Gere & Timoshenko (1990). Mechanics of Materials. PWS Publishing Company. pp. 408–416.CS1 maint: uses authors parameter (link)

- Greg Kopecky (May 30, 2012). "Implications of Rim Width". slowtwitch.com. Retrieved March 21, 2013.

- "Standards Manual" (PDF). European Tyre and Rim Technical Organisation. 2003. p. M.15 (151). Archived from the original (PDF) on March 4, 2016. Retrieved April 22, 2015.

- "Tire Dimensions". Schwalbe (tire manufacturer).

- "Tyre sizes". Cyclists' Touring Club.

- "Manuel Technique 2012" (PDF) (in French). Mavic. p. 23.

- "Technical information – bicycle tires". Schwalbe.

- "Tire geometries" (PDF). Surly Bikes.

- Lennard Zinn (March 27, 2012). "Tech FAQ: More on fast-rolling tires". VeloNews. Retrieved April 29, 2013.

If you were to pump your rear tire up to 100 psi, then your contact patch would be exactly one square inch in area. (This is because the tire would push down on the ground with 100 pounds of force while the ground would push up against the tire with the equal and opposite 100 pounds of force, and since there is a pressure of 100 pounds per square inch in your tire, then the area of contact is one square inch.

- Foale, Tony (2006). Motorcycle Handling and Chassis Design (Second ed.). Tony Foale Designs. ISBN 978-84-933286-3-4.

- Jobst Brandt (August 8, 1996). "Rolling resistance of Tires". Retrieved February 20, 2011.

- "Tire Rolling Resistance". Roues Artisanales. January 1, 2006. Archived from the original on January 6, 2011. Retrieved February 20, 2011.

- F. Grappe; R. Candau; B. Barbier; M. D. Hoffman; A. Belli & J. D. Rouillon (1999). "Influence of tyre pressure and vertical load on coefficient of rolling resistance and simulated cycling performance" (PDF). Ergonomics. 10: 1361–1371. doi:10.1080/001401399185009. Archived from the original (PDF) on 26 March 2012. Retrieved 3 July 2011.

- Lennard Zinn (March 13, 2012). "Tech FAQ: Seriously, wider tires have lower rolling resistance than their narrower brethren". VeloNews. Retrieved August 6, 2012.

- James Huang (February 12, 2011). "Bicycle tires – puncturing the myths". BikeRadar. Retrieved March 21, 2011.

- Thomas Senkel (1992). "Plädoyer für einen guten Reifen" (PDF). Pro Velo 32. Retrieved 31 October 2018.

- "Measuring sideslip and camber characteristics of bicycle tyres". Vehicle System Dynamics. 2011. doi:10.1080/00423114.2011.615408.

- Alberto Doria; Mauro Tognazzo; Gianmaria Cusimano; Vera Bulsink; Adrian Cooke & Bart Koopman (2012). "Identification of the mechanical properties of bicycle tyres for modelling of bicycle dynamics". Vehicle System Dynamics. doi:10.1080/00423114.2012.754048.

- Sharp, Robin S. (November 2008). "On the Stability and Control of the Bicycle". Applied Mechanics Reviews. ASME. 61 (6): 060803-01–060803-24. doi:10.1115/1.2983014. ISSN 0003-6900.

- Manfred Plochl; Johannes Edelmann; Bernhard Angrosch & Christoph Ott (July 2011). "On the wobble mode of a bicycle". Vehicle System Dynamics. 50 (3): 415–429. doi:10.1080/00423114.2011.594164.

- Cossalter, Vittore (2006). Motorcycle Dynamics (Second ed.). Lulu.com. p. 38. ISBN 978-1-4303-0861-4.

External links

| Look up bicycle tire in Wiktionary, the free dictionary. |

| Wikimedia Commons has media related to Bicycle tires. |