Locomotive

A locomotive or engine is a rail transport vehicle that provides the motive power for a train. If a locomotive is capable of carrying a payload, it is usually rather referred to as a multiple unit, motor coach, railcar or power car; the use of these self-propelled vehicles is increasingly common for passenger trains, but rare for freight (see CargoSprinter and Iron Highway).

.jpg)

Traditionally, locomotives pulled trains from the front. However, push-pull operation has become common, where the train may have a locomotive (or locomotives) at the front, at the rear, or at each end. Most recently railroads have begun adopting DPU or distributed power. The front may have one or two locomotives followed by a mid train locomotive that is controlled remotely from the lead unit.

Etymology

The word locomotive originates from the Latin loco – "from a place", ablative of locus "place", and the Medieval Latin motivus, "causing motion", and is a shortened form of the term locomotive engine,[1] which was first used in 1814[2] to distinguish between self-propelled and stationary steam engines.

Classifications

Prior to locomotives, the motive force for railways had been generated by various lower-technology methods such as human power, horse power, gravity or stationary engines that drove cable systems. Few such systems are still in existence today. Locomotives may generate their power from fuel (wood, coal, petroleum or natural gas), or they may take power from an outside source of electricity. It is common to classify locomotives by their source of energy. The common ones include:

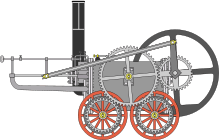

Steam

A steam locomotive is a locomotive whose primary power source is a steam engine. The most common form of steam locomotive also contains a boiler to generate the steam used by the engine. The water in the boiler is heated by burning combustible material – usually coal, wood, or oil – to produce steam. The steam moves reciprocating pistons which are connected to the locomotive's main wheels, known as the "driving wheels". Both fuel and water supplies are carried with the locomotive, either on the locomotive itself, in bunkers and tanks, (this arrangement is known as a "tank locomotive") or pulled behind the locomotive, in tenders, (this arrangement is known as a "tender locomotive").

The first full-scale working railway steam locomotive was built by Richard Trevithick in 1802. It was constructed for the Coalbrookdale ironworks in Shropshire in the United Kingdom though no record of it working there has survived.[3] On 21 February 1804, the first recorded steam-hauled railway journey took place as another of Trevithick's locomotives hauled a train from the Pen-y-darren ironworks, in Merthyr Tydfil, to Abercynon in South Wales.[4][5] Accompanied by Andrew Vivian, it ran with mixed success.[6] The design incorporated a number of important innovations including the use of high-pressure steam which reduced the weight of the engine and increased its efficiency.

In 1812, Matthew Murray's twin-cylinder rack locomotive Salamanca first ran on the edge-railed rack-and-pinion Middleton Railway;[7] this is generally regarded as the first commercially successful locomotive.[8][9] Another well-known early locomotive was Puffing Billy, built 1813–14 by engineer William Hedley for the Wylam Colliery near Newcastle upon Tyne. This locomotive is the oldest preserved, and is on static display in the Science Museum, London. George Stephenson built Locomotion No. 1 for the Stockton and Darlington Railway in the north-east of England, which was the first public steam railway in the world. In 1829, his son Robert built The Rocket in Newcastle-upon-Tyne. Rocket was entered into, and won, the Rainhill Trials. This success led to the company emerging as the pre-eminent early builder of steam locomotives used on railways in the UK, US and much of Europe.[10] The Liverpool and Manchester Railway, built by Stephenson, opened a year later making exclusive use of steam power for passenger and goods trains.

The steam locomotive remained by far the most common type of locomotive until after World War II.[11] Steam locomotives are less efficient than modern diesel and electric locomotives, and a significantly larger workforce is required to operate and service them.[12] British Rail figures showed that the cost of crewing and fuelling a steam locomotive was about two and a half times larger than the cost of supporting an equivalent diesel locomotive, and the daily mileage they could run was lower. Between about 1950 and 1970, the majority of steam locomotives were retired from commercial service and replaced with electric and diesel-electric locomotives.[13][14] While North America transitioned from steam during the 1950s, and continental Europe by the 1970s, in other parts of the world, the transition happened later. Steam was a familiar technology that used widely-available fuels and in low-wage economies did not suffer as wide a cost disparity. It continued to be used in many countries until the end of the 20th century. By the end of the 20th century, almost the only steam power remaining in regular use around the world was on heritage railways.

Internal combustion

Internal combustion locomotives use an internal combustion engine, connected to the driving wheels by a transmission. Typically they keep the engine running at a near-constant speed whether the locomotive is stationary or moving.

Kerosene

Kerosene locomotives use kerosene as the fuel. They were the world's first oil locomotives, preceding diesel and other oil locomotives by some years.

The first known kerosene rail vehicle was a draisine built by Gottlieb Daimler in 1887,[15] but this was not technically a locomotive as it carried a payload.

A kerosene locomotive was built in 1894 by the Priestman Brothers of Kingston upon Hull for use on Hull docks. This locomotive was built using a 12 hp double-acting marine type engine, running at 300 rpm, mounted on a 4-wheel wagon chassis. It was only able to haul one loaded wagon at a time, due to its low power output, and was not a great success.[16] The first successful kerosene locomotive was "Lachesis" built by Richard Hornsby & Sons Ltd. and delivered to Woolwich Arsenal railway in 1896. The company built a series of kerosene locomotives between 1896 and 1903, for use by the British military.

History

The first commercially successful petrol locomotive was a petrol-mechanical locomotive built by the Maudslay Motor Company in 1902, for the Deptford Cattle Market in London. It was an 80 hp locomotive using a 3-cylinder vertical petrol engine, with a two speed mechanical gearbox.

The second locomotive was built by F.C. Blake of Kew in January 1903 for the Richmond Main Sewerage Board.[17][18][16]

In 1916, "Simplex" petrol locomotives built by Motor Rail, with 20-40 hp motors and 4-wheel mechanical transmission began to be used on 600 mm (1 ft 11 5⁄8 in) gauge trench railways on the Western Front. The War Department also ordered 100 larger petrol-electric locomotives from Dick, Kerr & Co. and British Westinghouse, which used a 45 hp Dorman 4JO four-cylinder petrol engine driving a 30 kW DC generator at 1000rpm.[19] Many of the petrol locomotives supplied to the armed forces were sold off as surplus after the end of hostilities, and found work on small industrial railways. Motor Rail continued to develop and manufacture and develop the design, for several decades.

Petrol-mechanical

The most common type of petrol locomotive are petrol-mechanical locomotives, which use mechanical transmission in the form of gearboxes (sometimes in conjunction with chain drives) to deliver the power output of the engine to the driving wheels, in the same way as a car.

Petrol-electric

Petrol-electric locomotives are petrol locomotives which use electric transmission to deliver the power output of the engine to the driving wheels. This avoids the need for gearboxes by converting the rotary mechanical force of the engine into electrical energy by a dynamo, and then powering the wheels by multi-speed electric traction motors. This allows for smoother acceleration, as it avoids the need for gear changes, however is more expensive, heavier, and sometimes bulkier than mechanical transmission.

Diesel

Diesel locomotives are powered by diesel engines. In the early days of Diesel propulsion development, various transmission systems were employed with varying degrees of success, with electric transmission proving to be the most popular.

Diesel-mechanical

A diesel–mechanical locomotive uses mechanical transmission to transfer power to the wheels. This type of transmission is generally limited to low-powered, low speed shunting (switching) locomotives, lightweight multiple units and self-propelled railcars. The earliest diesel locomotives were diesel-mechanical.

The mechanical transmissions used for railroad propulsion are generally more complex and much more robust than standard-road versions. There is usually a fluid coupling interposed between the engine and gearbox, and the gearbox is often of the epicyclic (planetary) type to permit shifting while under load. Various systems have been devised to minimise the break in transmission during gear changing; e.g., the S.S.S. (synchro-self-shifting) gearbox used by Hudswell Clarke. Diesel–mechanical propulsion is limited by the difficulty of building a reasonably sized transmission capable of coping with the power and torque required to move a heavy train.

In 1906, Rudolf Diesel, Adolf Klose and the steam and diesel engine manufacturer Gebrüder Sulzer founded Diesel-Sulzer-Klose GmbH to manufacture diesel-powered locomotives. The Prussian State Railways ordered a diesel locomotive from the company in 1909. The world's first diesel-powered locomotive (a diesel-mechanical locomotive) was operated in the summer of 1912 on the Winterthur–Romanshorn railway in Switzerland, but was not a commercial success.[20] The locomotive weight was 95 tonnes and the power was 883 kW with a maximum speed of 100 km/h.[21] Small numbers of prototype diesel locomotives were produced in a number of countries through the mid-1920s.

Diesel-electric

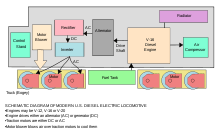

Diesel–electric locomotives are diesel locomotives using electric transmission. In this arrangement, the diesel engine drives either an electrical DC generator (generally, less than 3,000 horsepower (2,200 kW) net for traction), or an electrical AC alternator-rectifier (generally 3,000 horsepower (2,200 kW) net or more for traction), the output of which provides power to the traction motors that drive the locomotive. There is no mechanical connection between the diesel engine and the wheels. The vast majority of diesel locomotives today are diesel-electric.

The important components of diesel–electric propulsion are the diesel engine (also known as the prime mover), the main generator/alternator-rectifier, traction motors (usually with four or six axles), and a control system consisting of the engine governor and electrical or electronic components, including switchgear, rectifiers and other components, which control or modify the electrical supply to the traction motors. In the most elementary case, the generator may be directly connected to the motors with only very simple switchgear.

Originally, the traction motors and generator were DC machines. Following the development of high-capacity silicon rectifiers in the 1960s, the DC generator was replaced by an alternator using a diode bridge to convert its output to DC. This advance greatly improved locomotive reliability and decreased generator maintenance costs by elimination of the commutator and brushes in the generator. Elimination of the brushes and commutator, in turn, disposed of the possibility of a particularly destructive type of event referred to as a flashover, which could result in immediate generator failure and, in some cases, start an engine room fire.

In the late 1980s, the development of high-power variable-frequency/variable-voltage (VVVF) drives, or "traction inverters," has allowed the use of polyphase AC traction motors, thus also eliminating the motor commutator and brushes. The result is a more efficient and reliable drive that requires relatively little maintenance and is better able to cope with overload conditions that often destroyed the older types of motors.

In 1914, Hermann Lemp, a General Electric electrical engineer, developed and patented a reliable direct current electrical control system (subsequent improvements were also patented by Lemp).[22] Lemp's design used a single lever to control both engine and generator in a coordinated fashion, and was the prototype for all diesel–electric locomotive control. In 1917–18, GE produced three experimental diesel–electric locomotives using Lemp's control design.[23] In 1924, a diesel-electric locomotive (Eel2 original number Юэ 001/Yu-e 001) started operations. It had been designed by a team led by Yuri Lomonosov and built 1923–1924 by Maschinenfabrik Esslingen in Germany. It had 5 driving axles (1'E1'). After several test rides, it hauled trains for almost three decades from 1925 to 1954.[24] It was the world's first functional diesel locomotive.

Diesel-hydraulic

Diesel–hydraulic locomotives are diesel locomotives using hydraulic transmission. In this arrangement, they use one or more torque converters, in combination with gears, with a mechanical final drive to convey the power from the diesel engine to the wheels.

Hydrokinetic transmission (also called hydrodynamic transmission) uses a torque converter. A torque converter consists of three main parts, two of which rotate, and one (the stator) that has a lock preventing backwards rotation and adding output torque by redirecting the oil flow at low output RPM. All three main parts are sealed in an oil-filled housing. To match engine speed to load speed over the entire speed range of a locomotive some additional method is required to give sufficient range. One method is to follow the torque converter with a mechanical gearbox which switches ratios automatically, similar to an automatic transmission on a car. Another method is to provide several torque converters each with a range of variability covering part of the total required; all the torque converters are mechanically connected all the time, and the appropriate one for the speed range required is selected by filling it with oil and draining the others. The filling and draining is carried out with the transmission under load, and results in very smooth range changes with no break in the transmitted power.

The main worldwide user of main-line hydraulic transmissions was the Federal Republic of Germany, with designs including the 1950s DB class V 200, and the 1960 and 1970s DB Class V 160 family. British Rail introduced a number of diesel hydraulic designs during it 1955 Modernisation Plan, initially license built versions of German designs. In Spain RENFE used high power to weight ratio twin engined German designs to haul high speed trains from the 1960s to 1990s. (see RENFE Classes 340, 350, 352, 353, 354).

Hydrostatic drive systems have also been applied to rail use, for example 350 to 750 hp (260 to 560 kW) shunting locomotives by CMI Group (Belgium),[25] and 4 to 12 tonne 35 to 58 kW (47 to 78 hp) industrial locomotives by Atlas Copco subsidiary GIA.[26] Hydrostatic drives are also used in railway maintenance machines such as tampers and rail grinders.[27]

Gas turbine

A gas turbine locomotive is an internal combustion engine locomotive consisting of a gas turbine. ICE engines require a transmission to power the wheels. The engine must be allowed to continue to run when the locomotive is stopped.

Gas turbine-mechanical locomotives use a mechanical transmission to deliver the power output of gas turbines to the wheels. A gas turbine locomotive was patented in 1861 by Marc Antoine Francois Mennons (British patent no. 1633).[28] There is no evidence that the locomotive was actually built but the design includes the essential features of gas turbine locomotives built in the 20th century, including compressor, combustion chamber, turbine and air pre-heater. In 1952, Renault delivered a prototype four-axle 1150 hp gas-turbine-mechanical locomotive fitted with the Pescara "free turbine" gas- and compressed-air producing system, rather than a co-axial multi-stage compressor integral to the turbine. This model was succeeded by a pair of six-axle 2400 hp locomotives with two turbines and Pescara feeds in 1959. Several similar locomotives were built in USSR by Kharkov Locomotive Works.[29]

Gas turbine-electric locomotives, use a gas turbine to drive an electrical generator or alternator which produced electric current powers the traction motor which drive the wheels. In 1939 the Swiss Federal Railways ordered Am 4/6, a GTEL with a 1,620 kW (2,170 hp) of maximum engine power from Brown Boveri. It was completed in 1941, and then underwent testing before entering regular service. The Am 4/6 was the first gas turbine – electric locomotive. British Rail 18000 was built by Brown Boveri and delivered in 1949. British Rail 18100 was built by Metropolitan-Vickers and delivered in 1951. A third locomotive, the British Rail GT3, was constructed in 1961. Union Pacific ran a large fleet of turbine-powered freight locomotives starting in the 1950s.[30] These were widely used on long-haul routes, and were cost-effective despite their poor fuel economy due to their use of "leftover" fuels from the petroleum industry. At their height the railroad estimated that they powered about 10% of Union Pacific's freight trains, a much wider use than any other example of this class.

A gas turbine offers some advantages over a piston engine. There are few moving parts, decreasing the need for lubrication and potentially reducing maintenance costs, and the power-to-weight ratio is much higher. A turbine of a given power output is also physically smaller than an equally powerful piston engine, allowing a locomotive to be very powerful without being inordinately large. However, a turbine's power output and efficiency both drop dramatically with rotational speed, unlike a piston engine, which has a comparatively flat power curve. This makes GTEL systems useful primarily for long-distance high-speed runs. Additional problems with gas turbine-electric locomotives included that they were very noisy. [31]

Electric

An electric locomotive is a locomotive powered only by electricity. Electricity is supplied to moving trains with a (nearly) continuous conductor running along the track that usually takes one of three forms: an overhead line, suspended from poles or towers along the track or from structure or tunnel ceilings; a third rail mounted at track level; or an onboard battery. Both overhead wire and third-rail systems usually use the running rails as the return conductor but some systems use a separate fourth rail for this purpose. The type of electrical power used is either direct current (DC) or alternating current (AC).

Various collection methods exist: a trolley pole, which is a long flexible pole that engages the line with a wheel or shoe; a bow collector, which is a frame that holds a long collecting rod against the wire; a pantograph, which is a hinged frame that holds the collecting shoes against the wire in a fixed geometry; or a contact shoe, which is a shoe in contact with the third rail. Of the three, the pantograph method is best suited for high-speed operation.

Electric locomotives almost universally use axle-hung traction motors, with one motor for each powered axle. In this arrangement, one side of the motor housing is supported by plain bearings riding on a ground and polished journal that is integral to the axle. The other side of the housing has a tongue-shaped protuberance that engages a matching slot in the truck (bogie) bolster, its purpose being to act as a torque reaction device, as well as a support. Power transfer from motor to axle is effected by spur gearing, in which a pinion on the motor shaft engages a bull gear on the axle. Both gears are enclosed in a liquid-tight housing containing lubricating oil. The type of service in which the locomotive is used dictates the gear ratio employed. Numerically high ratios are commonly found on freight units, whereas numerically low ratios are typical of passenger engines.

Electricity is typically generated in large and relatively efficient generating stations, transmitted to the railway network and distributed to the trains. Some electric railways have their own dedicated generating stations and transmission lines but most purchase power from an electric utility. The railway usually provides its own distribution lines, switches and transformers.

Electric locomotives usually cost 20% less than diesel locomotives, their maintenance costs are 25-35% lower, and cost up to 50% less to run. [32]

Direct current

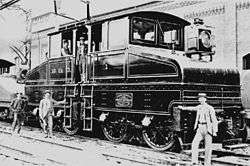

The earliest systems were DC systems. The first electric passenger train was presented by Werner von Siemens at Berlin in 1879. The locomotive was driven by a 2.2 kW, series-wound motor, and the train, consisting of the locomotive and three cars, reached a speed of 13 km/h. During four months, the train carried 90,000 passengers on a 300-metre-long (984 feet) circular track. The electricity (150 V DC) was supplied through a third insulated rail between the tracks. A contact roller was used to collect the electricity. The world's first electric tram line opened in Lichterfelde near Berlin, Germany, in 1881. It was built by Werner von Siemens (see Gross-Lichterfelde Tramway and Berlin Straßenbahn). The Volk's Electric Railway opened in 1883 in Brighton, and is the oldest surviving electric railway. Also in 1883, Mödling and Hinterbrühl Tram opened near Vienna in Austria. It was the first in the world in regular service powered from an overhead line. Five years later, in the U.S. electric trolleys were pioneered in 1888 on the Richmond Union Passenger Railway, using equipment designed by Frank J. Sprague.[33]

The first electrically-worked underground line was the City and South London Railway, prompted by a clause in its enabling act prohibiting use of steam power.[34] It opened in 1890, using electric locomotives built by Mather and Platt. Electricity quickly became the power supply of choice for subways, abetted by the Sprague's invention of multiple-unit train control in 1897.

The first use of electrification on a main line was on a four-mile stretch of the Baltimore Belt Line of the Baltimore and Ohio Railroad (B&O) in 1895 connecting the main portion of the B&O to the new line to New York through a series of tunnels around the edges of Baltimore's downtown. Three Bo+Bo units were initially used, at the south end of the electrified section; they coupled onto the locomotive and train and pulled it through the tunnels.[35]

DC was used on earlier systems. These systems were gradually replaced by AC. Today, almost all main-line railways use AC systems. DC systems are confined mostly to urban transit such as metro systems, light rail and trams, where power requirement is less.

Alternating current

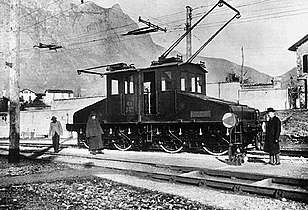

The first practical AC electric locomotive was designed by Charles Brown, then working for Oerlikon, Zürich. In 1891, Brown had demonstrated long-distance power transmission, using three-phase AC, between a hydro-electric plant at Lauffen am Neckar and Frankfurt am Main West, a distance of 280 km. Using experience he had gained while working for Jean Heilmann on steam-electric locomotive designs, Brown observed that three-phase motors had a higher power-to-weight ratio than DC motors and, because of the absence of a commutator, were simpler to manufacture and maintain.[36] However, they were much larger than the DC motors of the time and could not be mounted in underfloor bogies: they could only be carried within locomotive bodies.[37]

In 1894, Hungarian engineer Kálmán Kandó developed a new type 3-phase asynchronous electric drive motors and generators for electric locomotives. Kandó's early 1894 designs were first applied in a short three-phase AC tramway in Evian-les-Bains (France), which was constructed between 1896 and 1898.[38][39][40][41][42] In 1918,[43] Kandó invented and developed the rotary phase converter, enabling electric locomotives to use three-phase motors whilst supplied via a single overhead wire, carrying the simple industrial frequency (50 Hz) single phase AC of the high voltage national networks.[44]

In 1896, Oerlikon installed the first commercial example of the system on the Lugano Tramway. Each 30-tonne locomotive had two 110 kW (150 hp) motors run by three-phase 750 V 40 Hz fed from double overhead lines. Three-phase motors run at constant speed and provide regenerative braking, and are well suited to steeply graded routes, and the first main-line three-phase locomotives were supplied by Brown (by then in partnership with Walter Boveri) in 1899 on the 40 km Burgdorf—Thun line, Switzerland. The first implementation of industrial frequency single-phase AC supply for locomotives came from Oerlikon in 1901, using the designs of Hans Behn-Eschenburg and Emil Huber-Stockar; installation on the Seebach-Wettingen line of the Swiss Federal Railways was completed in 1904. The 15 kV, 50 Hz 345 kW (460 hp), 48 tonne locomotives used transformers and rotary converters to power DC traction motors.[45]

Italian railways were the first in the world to introduce electric traction for the entire length of a main line rather than just a short stretch. The 106 km Valtellina line was opened on 4 September 1902, designed by Kandó and a team from the Ganz works.[46][44] The electrical system was three-phase at 3 kV 15 Hz. The voltage was significantly higher than used earlier and it required new designs for electric motors and switching devices.[47][48] The three-phase two-wire system was used on several railways in Northern Italy and became known as "the Italian system". Kandó was invited in 1905 to undertake the management of Società Italiana Westinghouse and led the development of several Italian electric locomotives.[47]

Battery-electric

A battery-electric locomotive (or battery locomotive) is an electric locomotive powered by on-board batteries; a kind of battery electric vehicle.

Such locomotives are used where a conventional diesel or electric locomotive would be unsuitable. An example is maintenance trains on electrified lines when the electricity supply is turned off. Another use is in industrial facilities where a combustion-powered locomotive (i.e., steam- or diesel-powered) could cause a safety issue due to the risks of fire, explosion or fumes in a confined space. Battery locomotives are preferred for mines where gas could be ignited by trolley-powered units arcing at the collection shoes, or where electrical resistance could develop in the supply or return circuits, especially at rail joints, and allow dangerous current leakage into the ground.[49]

The first known electric locomotive was built in 1837 by chemist Robert Davidson of Aberdeen, and it was powered by galvanic cells (batteries). Davidson later built a larger locomotive named Galvani, exhibited at the Royal Scottish Society of Arts Exhibition in 1841. The seven-ton vehicle had two direct-drive reluctance motors, with fixed electromagnets acting on iron bars attached to a wooden cylinder on each axle, and simple commutators. It hauled a load of six tons at four miles per hour (6 kilometers per hour) for a distance of one and a half miles (2.4 kilometres). It was tested on the Edinburgh and Glasgow Railway in September of the following year, but the limited power from batteries prevented its general use.[50][51][52]

Another example was at the Kennecott Copper Mine, Latouche, Alaska, where in 1917 the underground haulage ways were widened to enable working by two battery locomotives of 4 1⁄2 tons.[53] In 1928, Kennecott Copper ordered four 700-series electric locomotives with on-board batteries. These locomotives weighed 85 tons and operated on 750-volt overhead trolley wire with considerable further range whilst running on batteries.[54] The locomotives provided several decades of service using Nickel-iron battery (Edison) technology. The batteries were replaced with lead-acid batteries, and the locomotives were retired shortly afterward. All four locomotives were donated to museums, but one was scrapped. The others can be seen at the Boone and Scenic Valley Railroad, Iowa, and at the Western Railway Museum in Rio Vista, California. The Toronto Transit Commission previously operated a battery electric locomotive built by Nippon-Sharyo in 1968 and retired in 2009.[55]

London Underground regularly operates battery-electric locomotives for general maintenance work.

In the 1960s, development of very high-speed service brought further electrification. The Japanese Shinkansen and the French TGV were the first systems for which devoted high-speed lines were built from scratch. Similar programs were undertaken in Italy, Germany and Spain; and many countries around the world. Railway electrification has constantly increased in the past decades, and as of 2012, electrified tracks account for nearly one third of total tracks globally.[56]

In comparison to the principal alternative, the diesel engine, electric railways offer substantially better energy efficiency, lower emissions and lower operating costs. Electric locomotives are also usually quieter, more powerful, and more responsive and reliable than diesels. They have no local emissions, an important advantage in tunnels and urban areas. Some electric traction systems provide regenerative braking that turns the train's kinetic energy back into electricity and returns it to the supply system to be used by other trains or the general utility grid. While diesel locomotives burn petroleum, electricity can be generated from diverse sources including renewable energy.

Other types

Diesel-steam

Steam-diesel hybrid locomotives can use steam generated from a boiler or diesel to power a piston engine. The Cristiani Compressed Steam System used a diesel engine to power a compressor to drive and recirculate steam produced by a boiler; effectively using steam as the power transmission medium, with the diesel engine being the prime mover[57]

In the 1940s, diesel locomotives began to displace steam power on American railroads. Following the end of World War II, diesel power began to appear on railroads in many countries. The significantly better economics of diesel operation triggered a dash to diesel power, a process known as Dieselization. By the late 1990s, only heritage railways continued to operate steam locomotives in most countries.

Diesel locomotives require considerably less maintenance than steam, with a corresponding reduction in the number of personnel needed to keep the fleet in service. The best steam locomotives spent an average of three to five days per month in the shop for routine maintenance and running repairs. Heavy overhauls were frequent, often involving removal of the boiler from the frame for major repairs. In contrast, a typical diesel locomotive requires no more than eight to ten hours of maintenance per month (maintenance intervals are 92 days or 184 days, depending upon a locomotive's age), and may run for decades between major overhauls. Diesel units do not pollute as much as steam trains; modern units produce low levels of exhaust emissions.

Atomic-electric

In the early 1950s, Dr. Lyle Borst of the University of Utah was given funding by various US railroad line and manufacturers to study the feasibility of an electric-drive locomotive, in which an onboard atomic reactor produced the steam to generate the electricity. At that time, atomic power was not fully understood; Borst believed the major stumbling block was the price of uranium. With the Borst atomic locomotive, the center section would have a 200-ton reactor chamber and steel walls 5 feet thick to prevent releases of radioactivity in case of accidents. He estimated a cost to manufacture atomic locomotives with 7000 h.p. engines at approximately $1,200,000 each.[58] Consequently, trains with onboard nuclear generators were generally deemed unfeasible due to prohibitive costs.

Fuel cell-electric

In 2002, the first 3.6 tonne, 17 kW hydrogen (fuel cell) -powered mining locomotive was demonstrated in Val-d'Or, Quebec. In 2007 the educational mini-hydrail in Kaohsiung, Taiwan went into service. The Railpower GG20B finally is another example of a fuel cell-electric locomotive.

Hybrid locomotives

There are many different types of hybrid or dual-mode locomotives using two or more types of motive power. The most common hybrids are electro-diesel locomotives powered either from an electricity supply or else by an onboard diesel engine. These are used to provide continuous journeys along routes that are only partly electrified. Examples include the EMD FL9 and Bombardier ALP-45DP

Use

There are three main uses of locomotives in rail transport operations: for hauling passenger trains, freight trains, and for switching (UK English: shunting).

Freight locomotives are normally designed to deliver high starting tractive effort and high sustained power. This allows them to start and move heavy trains, but usually comes at the cost of relatively low maximum speeds. Passenger locomotives usually develop lower starting tractive effort but are able to operate at the high speeds required to maintain passenger schedules. Mixed traffic locomotives (US English: general purpose or road switcher locomotives) do not develop as much starting tractive effort as a freight locomotive but are able to haul heavier trains than a passenger engine.

Most steam locomotives have reciprocating engines, with pistons coupled to the driving wheels by means of connecting rods, with no intervening gearbox. This means the combination of starting tractive effort and maximum speed is greatly influenced by the diameter of the driving wheels. Steam locomotives intended for freight service generally have smaller diameter driving wheels than passenger locomotives.

In diesel-electric and electric locomotives the control system between the traction motors and axles adapts the power output to the rails for freight or passenger service. Passenger locomotives may include other features, such as head-end power (also referred to as hotel power or electric train supply) or a steam generator.

Some locomotives are designed specifically to work steep grade railways, and feature extensive additional braking mechanisms and sometimes rack and pinion. Steam locomotives built for steep rack and pinion railways frequently have the boiler tilted relative to the locomotive frame, so that the boiler remains roughly level on steep grades.

Locomotives are also used on some High-speed trains: All TGV, many AVE, some KTX and the now-retired ICE 2 and ICE 1 trains all use locomotives, which may also be known as power cars. Using power cars easily allows for a high ride quality and less electrical equipment, [59] but when compared with electric multiple units, they also offer lower acceleration and higher axle weights (for the power cars) The KTX-II and ICE 1 use a mixture of electric multiple units and power cars.

Operational role

Locomotives occasionally work in a specific role, such as:

- Train engine is the technical name for a locomotive attached to the front of a railway train to haul that train. Alternatively, where facilities exist for push-pull operation, the train engine might be attached to the rear of the train;

- Pilot engine – a locomotive attached in front of the train engine, to enable double-heading;

- Banking engine – a locomotive temporarily assisting a train from the rear, due to a difficult start or a sharp incline gradient;

- Light engine – a locomotive operating without a train behind it, for relocation or operational reasons.

- Station pilot – a locomotive used to shunt passenger trains at a railway station.

Wheel arrangement

The wheel arrangement of a locomotive describes how many wheels it has; common methods include the AAR wheel arrangement, UIC classification, and Whyte notation systems.

Remote control locomotives

In the second half of the twentieth century remote control locomotives started to enter service in switching operations, being remotely controlled by an operator outside of the locomotive cab. The main benefit is one operator can control the loading of grain, coal, gravel, etc. into the cars. In addition, the same operator can move the train as needed. Thus, the locomotive is loaded or unloaded in about a third of the time.

Comparison to multiple units

Advantages

There are a few basic reasons to isolate locomotive train power, as compared to self-propelled trains.[60]

- Ease

- Whether out of necessity to replace the locomotive due to failure, or for reason of needing to maintain the power unit, it is relatively easy to replace the locomotive with another, while not removing the entire train from service.

- Maximum utilization of power cars

- Separate locomotives facilitate movement of costly motive power assets as needed; thereby avoiding the expense associated with tied up or idle power resources.

- Flexibility

- Large locomotives can substitute for small locomotives when more power is required, for example, where grades are steeper. As needed, a locomotive can be used for either freight duties, or passenger service.

- Obsolescence cycles

- Separating motive power from payload-hauling cars enables replacement of one without affecting the other. To illustrate, locomotives might become obsolete when their associated cars are not, and vice versa.

- Safety

- In an accident, the locomotive may act as a buffer zone to the rest of the train. Depending on the obstacle encountered on the rail line, the heavier mass of a locomotive is less likely to deviate from its normal course. In the event of fire, it might be safer, for example, with diesel locomotives.

- Noise

- A single source of tractive power (i.e., motors in one place), is quieter than multiple operational power units, where one or more motors are located under every carriage. The noise problem is particularly noticeable in diesel multiple units.

- Saves time

- The motive power accompanies the cars to be hauled and consequently there is a saving in time.

- Maintenance

- It may be easier to maintain one power unit than multiple engines/motors. Especially for steam locomotives but also for other types, maintenance facilities can be very dirty environments and it is advantageous not to have to take passenger accommodation into the same depot. This was one reason for the demise of the GWR steam railmotors.

Disadvantages

There are several advantages of multiple unit (MU) trains compared to locomotives.

- Energy efficiency

- Multiple units are more energy efficient than locomotive-hauled trains and more nimble, especially on down grades, as much more of the train's weight (sometimes all of it) is placed on driven wheels, rather than suffering the dead weight of unpowered coaches.

- No need to turn the locomotive

- Many multiple units have cabs at both ends; therefore, the train may be reversed without uncoupling/re-coupling the locomotive, providing quicker turnaround times, reduced crew costs, and enhanced safety. In practice, the development of driving van trailers and cab cars has removed the need for locomotives to run-around, giving easy bi-directional operation and removing this MU advantage.

- Reliability

- Multiple unit trains have multiple engines, where the failure of one engine usually does not prevent the train from continuing on its journey. A locomotive drawn passenger train typically has only a single power unit; the failure of this single unit temporarily disables the train. However, as is often the case with locomotive hauled freight trains, some passenger trains utilize multiple locomotives, and are thus able to continue at reduced speed after the failure of one locomotive.

Locomotives in numismatics

Locomotives have been a subject for collectors' coins and medals. One of the most famous and recent ones is the 25 Euro 150 Years Semmering Alpine Railway commemorative coin. The obverse shows two locomotives: a historical and a modern one. This represents the technical development in locomotive construction between the years 1854 and 2004. The upper half depicts the “Taurus”, a high performance locomotive. The lower half depicts the first functional Alpine locomotive, the Engerth; constructed by Wilhelm Freiherr von Engerth.

See also

- Air brake

- Articulated locomotive

- Autorail

- Bank engine

- Builder's plate

- Control car (rail)

- Duplex locomotive

- Electric multiple unit

- Headboard (train)

- Headstock (rolling stock)

- Kryšpín's system

- List of locomotive builders

- List of locomotives

- Locomotives in art

- Railway brakes

- Regenerative (dynamic) brakes

- Traction engine

- Train horn

- Vacuum brake

- World's largest locomotive

References

- "Locomotive". (etymology). Online Etymology Dictionary. Retrieved 2 June 2008.

- "Most Important and highly Valuable Sea-Sale Colliery, Near Newcastle-on-Tyne, to be sold by auction, by Mr. Burrell". Leeds Mercury. 12 February 1814. p. 2.

- Francis Trevithick (1872). Life of Richard Trevithick: With an Account of His Inventions, Volume 1. E.&F.N.Spon.

- "Richard Trevithick's steam locomotive | Rhagor". Museumwales.ac.uk. Archived from the original on 15 April 2011. Retrieved 3 November 2009.

- "Steam train anniversary begins". BBC. 21 February 2004. Retrieved 13 June 2009.

A south Wales town has begun months of celebrations to mark the 200th anniversary of the invention of the steam locomotive. Merthyr Tydfil was the location where, on 21 February 1804, Richard Trevithick took the world into the railway age when he set one of his high-pressure steam engines on a local iron master's tram rails

- Payton, Philip (2004). Oxford Dictionary of National Biography. Oxford University Press.

- Young, Robert (2000) [1923]. Timothy Hackworth and the Locomotive (reprint ed.). Lewes, UK: The Book Guild.

- P. Mathur; K. Mathur; S. Mathur (2014). Developments and Changes in Science Based Technologies. Partridge Publishing. p. 139.

- Nock, Oswald Stevens (1977). Encyclopedia of Railroads. Galahad Books.

- Hamilton Ellis (1968). The Pictorial Encyclopedia of Railways. The Hamlyn Publishing Group. pp. 24–30.

- Ellis, p. 355

- "Diesel Locomotives. The Construction of and Performance Obtained from the Oil Engine". 1935.

- Meiklejohn, Bernard (January 1906). "New Motors on Railroads: Electric and Gasoline Cars Replacing the Steam Locomotive". The World's Work: A History of Our Time. XIII: 8437–54. Retrieved 10 July 2009.

- "The Construction of and Performance Obtained from the Oil Engine".

- Winkler, Thomas. "Daimler Motorwagen".

- Webb, Brian (1973). The British Internal Combustion Locomotive 1894–1940. David & Charles. ISBN 0715361155.

- "Gasoline locomotives". Time.com. 28 September 1925. Retrieved 1 January 2012.

- "Direct drive gasoline locomotives". Yardlimit.railfan.net. Retrieved 1 January 2012.

- "Locomotive Notes and News". The Model Engineer: 225–226. 3 April 1919.

- Churella 1998, p. 12.

- Glatte, Wolfgang (1993). Deutsches Lok-Archiv: Diesellokomotiven 4. Auflage. Berlin: Transpress. ISBN 3-344-70767-1.

- Lemp, Hermann. US Patent No. 1,154,785, filed April 8, 1914, and issued September 28, 1915. Accessed via Google Patent Search at: US Patent #1,154,785 on February 8, 2007.

- Pinkepank 1973, pp. 139–141

- Russian page on Э-эл2

- "Shunting locomotives", www.cmigroupe.com, archived from the original on 30 September 2016, retrieved 2 December 2017

- "Locomotives", www.gia.se, archived from the original on 30 March 2014, retrieved 2 December 2017

- Solomon, Brian (2001), Railway Maintenance Equipment: The Men and Machines That Keep the Railroads Running, Voyager Press, pp. 78, 96, ISBN 0760309752

- "Espacenet - Original document".

- "Archived copy". Archived from the original on 2 December 2017. Retrieved 2 December 2017.CS1 maint: archived copy as title (link)

- "Gas Turbine Locomotive" Popular Mechanics, July 1949, cutaway drawing of development by GE for Union Pacific

- "Rails and Gas Turbines". Archived from the original on 22 April 2016. Retrieved 12 April 2016.

- https://www.eesi.org/articles/view/electrification-of-u.s.-railways-pie-in-the-sky-or-realistic-goal

- "Richmond Union Passenger Railway". IEEE History Center. Archived from the original on 1 December 2008. Retrieved 18 January 2008.

- Badsey-Ellis, Antony (2005). London's Lost Tube Schemes. Harrow: Capital Transport. p. 36. ISBN 1-85414-293-3.

- B&O Power, Sagle, Lawrence, Alvin Stauffer

- Heilmann evaluated both AC and DC electric transmission for his locomotives, but eventually settled on a design based on Thomas Edison's DC system — Duffy (2003), p.39–41

- Duffy (2003), p. 129.

- Andrew L. Simon (1998). Made in Hungary: Hungarian Contributions to Universal Culture. Simon Publications LLC. p. 264. ISBN 978-0-9665734-2-8.

Evian-les-Bains kando.

- Francis S. Wagner (1977). Hungarian Contributions to World Civilization. Alpha Publications. p. 67. ISBN 978-0-912404-04-2.

- C.W. Kreidel (1904). Organ für die fortschritte des eisenbahnwesens in technischer beziehung. p. 315.

- Elektrotechnische Zeitschrift: Beihefte, Volumes 11-23. VDE Verlag. 1904. p. 163.

- L'Eclairage électrique, Volume 48. 1906. p. 554.

- Michael C. Duffy (2003). Electric Railways 1880–1990. IET. p. 137. ISBN 978-0-85296-805-5.

- Hungarian Patent Office. "Kálmán Kandó (1869–1931)". www.mszh.hu. Retrieved 10 August 2008.

- Duffy (2003), p. 124.

- Duffy (2003), p. 120–121.

- "Kalman Kando". Retrieved 26 October 2011.

- "Kalman Kando". Archived from the original on 12 July 2012. Retrieved 5 December 2009.

- Strakoš, Vladimír; et al. (1997). Mine Planning and Equipment Selection. Rotterdam, Netherlands: Balkema. p. 435. ISBN 90-5410-915-7.

- Day, Lance; McNeil, Ian (1966). "Davidson, Robert". Biographical dictionary of the history of technology. London: Routledge. ISBN 978-0-415-06042-4.

- Gordon, William (1910). "The Underground Electric". Our Home Railways. 2. London: Frederick Warne and Co. p. 156.

- Renzo Pocaterra, Treni, De Agostini, 2003

- Martin, George Curtis (1919). Mineral resources of Alaska. Washington, DC: Government Printing Office. p. 144.

- List of Kennecott Copper locomotives

- "A Rogue's Gallery: The TTC's Subway Work Car Fleet - Transit Toronto - Content".

- "Railway Handbook 2015" (PDF). International Energy Agency. p. 18. Retrieved 4 August 2017.

- The Paragon-Cristiani Compressed Steam System Archived 11 December 2017 at the Wayback Machine dslef.dsl.pipex.com

- "Atomic Locomotive Produces 7000 h.p." Popular Mechanics, April 1954, p. 86.

- http://www.ejrcf.or.jp/jrtr/jrtr17/pdf/f40_technology.pdf

- "Comparison of locomotive hauled and multiple unit trains". Archived from the original on 1 July 2007. Retrieved 26 April 2011.

Bibliography

- Ellis, Hamilton (1968). The Pictorial Encyclopedia of Railways. The Hamlyn Publishing Group.

- Churella, Albert J. (1998). From Steam To Diesel: Managerial Customs and Organizational Capabilities in the Twentieth-Century American Locomotive Industry. Princeton: Princeton University Press. ISBN 978-0-691-02776-0.CS1 maint: ref=harv (link)

External links

![]()

- An engineer's guide from 1891

- Locomotive cutaways and historical locomotives of several countries ordered by dates

- Pickzone Locomotive Model

- International Steam Locomotives

- Turning a Locomotive into a Stationary Engine, Popular Science monthly, February 1919, page 72, Scanned by Google Books: https://books.google.com/books?id=7igDAAAAMBAJ&pg=PA72

.jpg)

.jpg)