Iron germanide

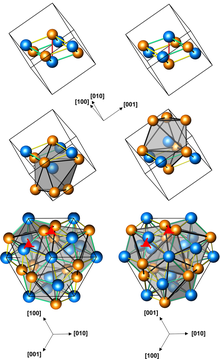

Iron germanide (FeGe) is an intermetallic compound, a germanide of iron. At ambient conditions it crystallizes in three polymorphs with monoclinic, hexagonal and cubic structures. The cubic polymorph has no inversion center, it is therefore helical, with right-hand and left-handed chiralities.[1]

Structures of left-handed and right-handed FeGe crystals (3 presentations, with different numbers of atoms per unit cell; orange atoms are Ge) | |

| Names | |

|---|---|

| IUPAC name

Iron germanide | |

| Identifiers | |

3D model (JSmol) |

|

PubChem CID |

|

CompTox Dashboard (EPA) |

|

| |

| |

| Properties | |

| FeGe | |

| Molar mass | 128.47 g/mol |

| Structure | |

| Cubic[1] | |

| P213 (No. 198), cP8 | |

a = 0.4689 nm | |

Formula units (Z) |

4 |

| Hazards | |

| Flash point | Non-flammable |

| Related compounds | |

Other anions |

Iron silicide |

Other cations |

Manganese germanide |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| Infobox references | |

Magnetism

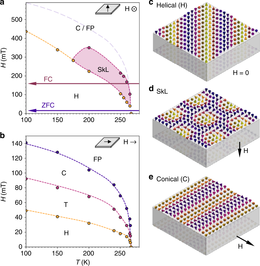

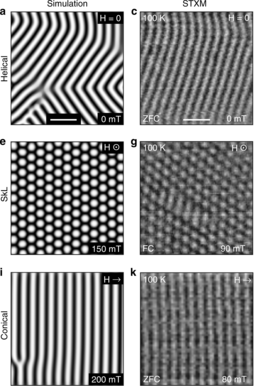

FeGe is extensively studied for its unusual magnetic properties. Electron spins in this material show dissimilar, yet regular spatial arrangements at different values of applied magnetic field. Those arrangements are named helical, skyrmion lattice, and conical. They can be controlled not only by temperature and magnetic field, but also by electric current, and the current density required for manipulating skyrmions (~106 A/m2) is approximately one million times smaller than that needed for moving magnetic domains in traditional ferromagnets. As a result, skyrmions have potential application in ultrahigh-density magnetic storage devices.[2]

The helical, conical and skyrmion structures are not unique to FeGe; they are also found in MnSi, MnGe and similar compounds, but contrary to those materials, the observation of magnetic ordering patterns in FeGe does not require cryogenic cooling.[2] The disadvantage of FeGe over MnSi is its polymorphism, which hinders the growth of large homogeneous crystals.[1]

Synthesis

Polycrystalline FeGe is produced by vacuum arc remelting, spark plasma sintering, or high-pressure high-temperature treatment of a mixture of elemental iron and germanium. Single crystals of FeGe ca. 1 mm in size can be grown from the powder using a chemical transport reaction and iodine as transporting agent. The source temperature is maintained at 450 °C and the temperature gradient at ca. 50 °C across the reaction tube, over 1–2 weeks.[3][4]

Structure

Iron germanide is a non-stoichiometric compound where the Ge:Fe ratio often deviates from 1. The Fe2Ge3 compound is a Nowotny phase exhibiting a chimney ladder structure. It is a semiconductor with a band gap or 0.03 eV.[5]

References

- Lebech, B; Bernhard, J; Freltoft, T (1989). "Magnetic structures of cubic FeGe studied by small-angle neutron scattering". Journal of Physics: Condensed Matter. 1 (35): 6105–6122. doi:10.1088/0953-8984/1/35/010.

- Nagaosa, Naoto; Tokura, Yoshinori (2013). "Topological properties and dynamics of magnetic skyrmions". Nature Nanotechnology. 8 (12): 899–911. doi:10.1038/nnano.2013.243.

- Hiroto, Takanobu; So, Yeong-Gi; Kimura, Kaoru (2018). "Synthesis and Thermal Stability of B20-Type TMGe (TM = Mn, Fe and Co) Intermetallic Compounds Prepared by Mechanical Milling". MATERIALS TRANSACTIONS. 59 (6): 1005–1008. doi:10.2320/matertrans.M2018016.

- Birch, M. T.; Cortés-Ortuño, D.; Turnbull, L. A.; Wilson, M. N.; Groß, F.; Träger, N.; Laurenson, A.; Bukin, N.; Moody, S. H.; Weigand, M.; Schütz, G.; Popescu, H.; Fan, R.; Steadman, P.; Verezhak, J. A. T.; Balakrishnan, G.; Loudon, J. C.; Twitchett-Harrison, A. C.; Hovorka, O.; Fangohr, H.; Ogrin, F. Y.; Gräfe, J.; Hatton, P. D. (2020). "Real-space imaging of confined magnetic skyrmion tubes". Nature Communications. 11 (1). doi:10.1038/s41467-020-15474-8.

- Verchenko, Valeriy Yu.; Wei, Zheng; Tsirlin, Alexander A.; Callaert, Carolien; Jesche, Anton; Hadermann, Joke; Dikarev, Evgeny V.; Shevelkov, Andrei V. (2017). "Crystal Growth of the Nowotny Chimney Ladder Phase Fe2Ge3: Exploring New Fe-Based Narrow-Gap Semiconductor with Promising Thermoelectric Performance". Chemistry of Materials. 29 (23): 9954–9963. doi:10.1021/acs.chemmater.7b03300. ISSN 0897-4756.