Flash-gas (petroleum)

In an oil and gas production, flash-gas is a spontaneous vapor that is produced from the heating or depressurization of the extracted oil mixture during different phases of production.[1] Flash evaporation, or flashing, is the process of volatile components suddenly vaporizing from their liquid state. This often happens during the transportation of petroleum products through pipelines and into vessels, such as when the stream from a common separation unit flows into an on-site atmospheric storage tank. Vessels that are used to intentionally “flash” a mixture of gas and saturated liquids are aptly named "flash drums." A type of vapor-liquid separator. A venting apparatus is used in these vessels to prevent damage due to increasing pressure, extreme cases of this are referred to as boiling liquid expanding vapor explosion (BLEVE).

The composition of the gas that is flashed is dependent on many factors, therefore it is suggested that all extractions be analyzed to determine accurate compositional values. As a generality, this definition applies to the nature of flashing hydrocarbons (HC) that make up oil and natural gas, “If the saturated liquid is a multi-component liquid (for example, a mixture of propane, isobutane and normal butane), the flashed vapor is richer in the more volatile components than is the remaining liquid".[2] Although the flashed portion will be primarily components with higher volatilities (lighter HC), heavier HC will also flash into the vapor phase to some extent.[1] Composition of flash gas is highly dependent on temperature and pressure and can therefore be manipulated using these control variables to become a usable resource (natural gas, natural gas liquids (NGL’s), alternative fuels, etc.) if proper infrastructure and sponsorship is in place.[3]

The production of flash-gas and its release into the atmosphere, via venting and improper handling during production, is of concern to environmental efforts due to the presence of Hazardous Air Pollutants (HAP), Greenhouse Gases (GHG), and Volatile Organic Compounds (VOC) which have been suggested to have harmful long-term environmental impacts. Various efforts by organizations around the world have been made to develop appropriate guidelines for handling flash gas as well as tools for evaluating flash emissions through model based calculations.

Natural Gas Liquids/Liquid Petroleum Gas

Natural gas liquids (NGL) are the fraction of the hydrocarbons, primarily having 2-8 carbon atoms,[4] that are present in the flash gas during oil production or as liquids in natural gas production. In other words, NGL is the liquids removed from natural gas such as ethane and heavier products.[5] Components of NGL’s have varying states during production, meaning that some will exist solely as a liquid or vapor, and some will be a mixture of the two depending on the current temperature and pressure. Therefore, it is necessary that components of NGL are distinguished as either natural-gas condensate, heavier components (C5+), or “other NGL”, lighter components that typically remain in the vapor phase during production.[4] NGL is not to be confused with its subcategory LPG, liquefied petroleum gas, described as “hydrocarbon mixtures in which the main components are propane, iso and normal butane, propylene and butylenes.”[5]

Capturing NGL’s has shown an uptick in their economic share of U.S. production levels the past few years,[6] sparking interest for advancement in recovery techniques for petroleum extraction. Uses of NGLs vary, from other combustible fuels like autogas and natural gasoline, to the manufacturing of plastics. The apparent value of these materials has put the level of products developed from NGLs at an all-time high in the United States in 2015.[6] Despite its value and use, many of the components that make up NGL and LPG become considered “waste gas” during production and are flared on-site or vented into the atmosphere as flash gas.[7] This can be due to a lack of infrastructure to capture and store and/or transport these liquids to market. Profitability under current models is highly dependent on the access to pipeline infrastructure, gas volume produced, and the number of/distance between production facilities (batteries).[8]

Environmental Concerns

Flash gas is the emissions from flash evaporation, breathing emissions, and working emissions. Breathing, or standing emissions, occur naturally as liquid sits in a vessel and undergoes normal evaporation into the atmosphere. Working emissions are created when the liquid is agitated, such as during transportation, emptying/filling of tanks, sampling, etc.[9] Contained within all of these emissions are materials that have been deemed hazardous to humans and the environment by regulatory agencies and scientific bodies worldwide.[10][11] The complex nature of chemical interactions in flare, flash, and other production vapors have spawned many efforts to describe and control how these hydrocarbons interact with other materials in the atmosphere to create air pollution.[12] The study of these interactions is encompassed by the field of atmospheric chemistry.

Hazardous Air Pollutants (HAP)

The environmental impact of emissions can be quantified in terms of the amount of hazardous air pollutants (HAP) they contain. HAPs, also known as toxic air contaminants, are defined by the EPA as “those known to cause cancer and other serious health impacts”.[13] In the United States, legislation known as the Clean Air Act mandated the EPA to regulate appropriate levels of HAP emissions from source categories such as industrial and mobile.[14]

There are currently 187 different chemical compounds that are classified as HAP which are declared in the National Emissions Standards for Hazardous Air Pollutants (NESHAP).[15] Oil and natural gas production is known as a stationary source and is therefore required by the Clean Air Act to follow guidelines put forth by NESHAP, New Source Performance Standards (NSPS), and Control Techniques Guidelines to reduce the amount of emissions the industry produces.[16]

The EPA, as of 2015, has public record of two [2005/2011] National Air Toxics Assessments (NATA) which present the effects of air toxic emissions on a national-scale.[17] In addition to identifying and prioritizing air toxins, the assessment determines specific locations that are at risk so that corrective measures may be implemented. Reports also go into detail about potential cancers and health problems associated with the level of reported toxins.

Greenhouse Gases (GHG)

Greenhouse gases are classified by their ability to absorb and emit radiation energy in atmosphere. This process of energy capture and release is what allows for the greenhouse effect, when energy trapped within the gas causes a resulting warming of the atmospheric temperature. Greenhouse gases are necessary for keeping our atmosphere warm enough to sustain life but also serve as a medium for over-heating to occur, a phenomenon referred to as global warming. GHGs are produced both directly and indirectly during many production phases of the oil and gas industry.[18][19]

It is estimated that 90% of GHG emissions from fossil fuels is due to its combustion.[20] As of 2009, energy-related CO2 emissions made up more than 80% of total U.S. greenhouse gas emissions.[21] Flare and flash gas both contain GHGs and therefore contribute to their release into the atmosphere, estimates of their emission levels during petroleum production vary due to largely unmeasured release of flash gas and other forms of fugitive emissions.

One study estimated a 40% increase in the atmospheric concentration of the GHG carbon dioxide (CO2) is due directly to human activities since 1750.[21][22] GHGs other than CO2 which are produced during petroleum operations are also a concern to the environment. On average, 43.6% of waste gas from a typical plant is methane.[23] Methane has 28-36 times the amount of global warming potential (GWP) as CO2 because of its ability to absorb more radiation energy.[24] Nitrous oxide has a GWP of 265-298 times that of CO2 and is known to also be released during flaring and combustion of fossil fuels.[25]

Volatile Organic Compounds (VOC)

.jpg)

Volatile organic compounds (VOCs) are organic chemicals, some of which occur naturally in oil and gas, that have high vapor pressure at ordinary room temperature. As a result, these chemicals exhibit an ease of transition from the liquid to the vapor state under atmospheric (ambient) conditions. In general chemistry terms, VOCs are organic molecules with low molecular weights, boiling points below 200 ˚C, and low to medium solubility in water. The EPA defines VOC’s as, “Any compound of carbon, excluding carbon monoxide, carbon dioxide, carbonic acid, metallic carbides or carbonates and ammonium carbonate, which participates is atmospheric photochemical reactions, except those designated by the EPA as having negligible photochemical reactivity.”[26]

In 1977, the EPA released “Recommended Policy on Control of Volatile Organic Compounds” in which they separated VOCs based on three criteria: photochemical reactivity, role in stratospheric O3 depletion, and direct health effects.[27] The Safe Drinking Water act lays out guidelines for levels of hazardous materials, including some VOCs, that are acceptable in the water of the United States.[28] VOCs are hazardous to the environment due to their ability to form tropospheric ozone or smog through photochemical reactions.[29][30][31] As well as contributing to indoor pollutants,[32] VOCs are also known to have “respiratory, allergic, or immune effects in infants and children”.[33] There are concerns that these compounds can be cancer causing in both humans and animals.[34] In particular, exposure to the VOC benzene during crude oil production could pose potentially serious health risks to workers.[35]

Photochemical Reactions

Much of the negative impact associated with VOCs stems from their ability to participate in photochemical reactions with primary pollutants (NOx) in the atmosphere.[36] Photochemical reactions are defined as, “a chemical reaction initiated by the absorption of energy in the form of light”.[37] These reactions often result in the production of photo-chemical oxidants, such as nitrogen dioxide (NO2), ozone (O3), and other peroxy compounds in the atmosphere. These oxidants participate in further atmospheric reactions which are said to “produce haze, damage plant and animal life, and materials such as rubber, induce discomfort and are suspected to have toxic effects on humans.”[23]

Mechanistic description for the formation of Photochemical Smog

- (1)

Nitrogen dioxide reacts with UV radiation to form nitrogen oxide and an oxygen radical.

- (2)

The radical oxygen combines with O2 gas in the atmosphere to form ozone.

- (3)

Ozone reacts with nitrogen oxide to form nitrogen dioxide and oxygen.

- (4)

A species of VOC bound to hydrogen reacts with hydroxide to form a VOC free-radical and water vapor.

- (5)

The free-radical VOC reacts with oxygen to form a VOC bound with oxygen gas.

- (6)

The VOC oxygen bond is broken in the presence of nitrogen oxide, forming a VOC-oxygen anion and nitrogen dioxide to further participate in reaction 3. Where hv is UV radiation and R is a volatile organic compound (VOC).[38] Additionally, some organic compounds (notably aldehydes) can photolyze in the atmosphere to form radicals which participate in atmospheric reactions. [46] VOCs or oxidant precursors are emitted to the atmosphere from both natural and man-made sources. Globally, natural emissions appear to outweigh anthropogenic emissions. However, it is the high concentration of anthropogenic sources of volatile organics together with NOx emissions from combustion processes in urban areas which increase the risk of the urban ozone problem. Wind and other climatological activities (transport mechanisms) then carry the formed oxidant into rural areas.

VOC Diagnostics

Studies have been done to try to find if VOCs can be directly related to cancers in the human body. One such example is a group that collected breath samples from a lung cancer patient to determine the VOC content of the lungs before and after surgery.[39] This study suggests that there may be certain biomarker VOCs that indicate the presence of a disease or cancer in a patient. Additional researchers have also begun trying to identify ties between the onset of cancer and the levels of VOCs in the environment.[40] A database to gather information on cancer and other aspects of VOCs in human cell lines, the human volatilome, has been started by researchers.[41]

Secondary Organic Aerosols (SOA)

Secondary Organic Aerosols (SOA) are a type of hazardous particulate that is not currently well understood, but is thought to make up a significant portion of the tropospheric aerosol or submicron atmospheric particle mass. [50,51] Aerosols effect the atmospheric radiative balance through the absorption and scattering of radiant energy, leading to shifts in weather via changes in cloud drop nucleation and the solar radiation budget.[42][43][44][45] They are said to be formed “when the atmospheric oxidation products of volatile organic compounds undergo gas-particle transfer.”[46] The contribution of VOCs to the levels of SOA in the atmosphere have been modeled using simulation chamber experiments to gain a better understanding of the chemistry involved.[47] SOAs are said to be a major causative factor to the mortality rates associated with the exposure to harmful fine particulate air pollution however there is an absence of in vitro particle exposure techniques to test for toxicity. There is research currently being done to find the interaction between SOA’s and lung cells to see their potential harmful effects.[48]

Methods for Calculating and Estimating Flash Gas Composition and Flash Loss

Flash Gas Calculations

Calculation of flash gas content is often based on the principle of vapor-liquid equilibrium (VLE) and combines theories like Raoult’s Law with component mass/energy balances, similar to those used in distillation unit operations.[49] Since the mixture is of multiple components, more complex equations like the Rachford-Rice equation are applicable in ideal situations and have frequently been used in chemical plants and refineries.[50] It is important to note that these equations are based on the ideal gas law and liquids at thermodynamic equilibrium, while hydrocarbons in oil and gas production are considered to be non-ideal or real, and may not be in equilibrium. Additional relationships, such as the Van Der Waals equation and other equations of state (EOS) can be applied to account for these discrepancies and can be used to provide a better estimation of flash gas content. Higher molecular weight hydrocarbons show even further deviation from ideal behavior and need additional computational adjustments, such as Sutton’s[51] modification to Steward et al.[52]

Chemical Simulation

More realistic modelling techniques encompass variable conditions that can occur on-site during petroleum processing by using sample analysis software at the flash site, e.g. ProMax Software, which is able to predict emissions and losses due to flash, i.e. working and standing losses.[53] Other techniques that are used to make calculations of flash losses (without sampling and analysis) are referred to as chemical process simulators, e.g. WinSim, Designer II, HYSIM, and VMG. These programs can also have the ability to incorporate data from site-specific samples to give more accurate results. Alternatively, a captured liquid or gas sample can be analyzed in a laboratory setting to determine the composition and dissolved gas-oil-ratio (GOR) using precise measurement techniques. However, this only provides insight on the sample of flash gas and does not account for real time fluctuations of all on-site sources of flash gas, including working and standing losses.

Estimations Based on Volatile Organic Compounds

Another acceptable technique in flash estimation is the Vasques-Beggs Equation (VBE)[54] which calculates the amount of flash gas in terms of total VOC and not into their individual components.[55] This model can only calculate the instantaneous flash gas and does not calculate the working or standing flash gas losses.[9] Additional equations have been developed to use in accordance with the VBE equation to determine species-specific losses, such as HAP-calc for determining the amount of Hazardous Air Pollution (HAP) produced.[9]

Equations of State

An equation of state (EOS) is a thermodynamic equation relating state variables which describes the state of matter under a given set of physical conditions.[56] EOS are used to make calculations about the predicted phase-behavior of hydrocarbons before extraction from a reservoir.[57] Soave-Redlich-Kwong and Peng-Robinson are examples of two commonly used EOS in industry for determining critical properties of multicomponent mixtures.[58] These equations can be useful for the prediction and estimation of flash loss when used in conjunction with sampling and reservoir data.

Reduction of Flare Gas

Vapor Recovery Units

Vapor Recovery Units (VRU’s) have commonly been used to capture vented gas and other waste gas (vapor recovery) during petroleum production, it was originally created to capture hydrogen sulfide from oilfield stock tanks. A VRU works by compressing the flash gas that is produced in storage tanks and other units to be put into a pipeline. A basic VRU is made up of a scrubber, compressor, and a switch. Once the pressure in the tank reaches the set-point, the switch kicks on the compressor and sends the vapor to a scrubber where the liquid portion is separated out.[59] The gas portions can be used to fuel on-site operation, be transported to storage tanks for further separation, can be piped out directly to another facility, or be injected into a compressor; the liquid portions (NGLs) that commonly form are normally sent to the water tank. If they are sent to oil storage they will re-vaporize and go through the VRU, creating an endless cycle.

VRU’s can create revenue through the resale and use of the captured vapors that would have been vented into the environment and lost. The revenue produced is dependent on the amount of vapor captured and sold into a pipeline. Analysis has been done to show the economic impacts from emission reduction and capture using VRU and other technology.[60] These units also reduce the amount of emissions of VOCs associated with oil and natural gas production, again by preventing them from being vented directly into the atmosphere.

There have been concerns raised about the efficiency of VRU’s.[61] It has been pointed out that vapor recovery units (VRU’s) cannot recover lighter hydrocarbons that have been dissolved into the liquid phase because the units are designed to recover what is already in the vapor phase. Also, when the gas in put under high pipeline pressure, NGLs are condensed out and are returned to the water tank (in rare instances they are processed and sold as NGL’s).

Thief Hatch Alternatives/Vapor Recovery Towers

Thief hatch, also known as a gauge hatch, is a term given to a close-able aperture on a tank or vessel used in the oil and gas industry.[62] These hatches are placed in atmospheric or low pressure tanks in order to allow for level or sample measurements and to provide vacuum relief to the vessel. Thief hatches are also used in gauge tanks and in transport vehicles where they must be opened to the atmosphere to take measurements and samples. Flash gas is readily leaked whenever these hatches are opened and therefore they can pose a problem in terms of emissions. There have also been reports of fatalities caused by manual tank gauging and sampling via thief hatches.[63]

Vapor recovery towers (VRT) have been posed as a potential solution for vapor loss via thief hatches. VRTs are a way to reduce the vapor loading on storage tanks by removing some of the flash gas before it gets to the oil tanks. The VRT can improve safety by reducing the potential for issues relating to high vapor evolution from the oil tanks.

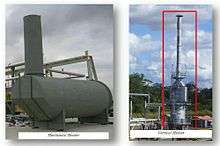

Heater Treaters

Heater treaters are often used in industry for the following: To break up emulsions to separate the oil from produced water, stabilize the crude oil or condensate by separating volatile, lighter hydrocarbon fractions, (C1-C8) from the heavy, less volatile fraction (C9+) for safety reasons.[64] Vent gas from heater treaters is known as a significant source of flash gas and consequential VOCs. It is possible to re-route this vent gas to a VRU to capture some of the stream or other processing units in order to reduce emissions and make additional revenue.

Oil and Gas Separators/Pressure Optimization

Three phase separators are used in oil and gas production to separate water, oil, and gas into isolated streams.[65] A separator, in general, is a pressurized vessel that is used to divide a product based on principles of chemical separation such as phase and density. These vessels are also known as de-liquidizers or degassers because they either remove liquid from the bulk gas stream or remove gas from the bulk liquid stream during processing. Pressure optimization based on sample compositions taken upstream can provide a solution to inefficient separations and can help to reduce the overall amount of flash gas produced.[66]

See also

References

- Taylor Miles (2016-12-29). "1 Step for the Oil and Gas Industry / Capture Flash Gases from Oil Production / Stop Intentional Methane and Hydrocarbon Pollution". One Step In Foundation. Retrieved 2017-03-28.

- "Flash Evaporation". ChemEngineering. Retrieved 24 March 2017.

- "flash gas, wasted oil and gas emissions". One Step In Foundation. 2016-09-07. Retrieved 2017-03-28.

- International Energy Agency. Natural Gas Liquids Supply Outlook, 2008-2015. Paris: International Energy Agency, 2010. Print

- GPSA Engineering Data Book. S.l.: GSAP, 2004. Print.

- "U.S. Energy Information Administration - EIA - Independent Statistics and Analysis." What are natural gas liquids and how are they used? - Today in Energy - U.S. Energy Information Administration (EIA). Web. 26 Mar. 2017.

- Peterson, J.; Cooper, H.; Baukal, C.: Hydrocarbon processing, 2007, 111-115.

- Johnson, M.R.; Coderre, A.R.: Canada, International Journal of Greenhouse Gas Control. 2012, 8, 121–131.

- United States. Texas Commission on Environmental Quality. Calculating Volatile Organic Compounds (VOC) Flash Emissions from Crude Oil and Condensate Tanks at Oil and Gas Production Sites. Vol. 5942. Print. Air Permit Reference Guide.

- Sources:

- "Health Effects of Air Pollution". ca.gov. California Environmental Protection Agency Air Resources Board. May 6, 2016.

- "Benzene, Toluene, Ethylbenzene, and Xylenes (BTEX)". cdc.gov. Agency for Toxic Substances & Disease Registry. May 2004.

- Williams, H. F. L.; Havens, D. L.; Banks, K. E.; Wachal, D. J. (October 2008). "Field-based monitoring of sediment runoff from natural gas well sites in Denton County, Texas, USA". Environmental Geology. 55 (7): 1463–1471. doi:10.1007/s00254-007-1096-9.

- Colborn, Theo; Kwiatkowski, Carol; Schultz, Kim; Bachran, Mary (September 2011). "Natural Gas Operations from a Public Health Perspective". Human and Ecological Risk Assessment: An International Journal. 17 (5): 1039–1056. doi:10.1080/10807039.2011.605662. S2CID 53996198.

- Sources:

- Vidic, R. D.; Brantley, S. L.; Vandenbossche, J. M.; Yoxtheimer, D.; Abad, J. D. (May 16, 2013). "Impact of Shale Gas Development on Regional Water Quality". Science. 340 (6134): 1235009. doi:10.1126/science.1235009. PMID 23687049. S2CID 32414422.

- Harrison, Samuel S. (November 1983). "Evaluating System for Ground-Water Contamination Hazards Due to Gas-Well Drilling on the Glaciated Appalachian Plateau". Ground Water. 21 (6): 689–700. doi:10.1111/j.1745-6584.1983.tb01940.x.

- McBroom, Matthew (2013). The Effects of Induced Hydraulic Fracturing on the Environment: Commercial Demands vs. Water, Wildlife, and Human Ecosystems. CRC Press. ISBN 978-1-4822-3095-6.

- Sources:

- Understanding Multiple Environmental Stresses: Report of a Workshop (2007). Atmosphere-Ecosystem Interactions. nap.edu. National Academies Press. doi:10.17226/11748. ISBN 978-0-309-10331-2.

- The Habitable Planet. "Atmospheric Pollution" (PDF). learner.org. Annenberg Learner.

- "Chemical Reactions in the Atmosphere". Libre Texts. September 16, 2014.

- Gases And The Atmosphere. "Chemical Reactions in the Atmosphere" (PDF).

- Hazardous Air Pollutants. (2017, March 17). Retrieved April 11, 2017, from https://www.epa.gov/haps

- Rules and Implementation. Retrieved April 11, 2017, from https://www3.epa.gov/ttn/atw/eparules.html

- What are Hazardous Air Pollutants? (2017, February 09). Retrieved April 11, 2017, from https://www.epa.gov/haps/what-are-hazardous-air-pollutants

- National Air Toxics Assessment. (2016, May 18). Retrieved April 11, 2017, from https://www.epa.gov/national-air-toxics-assessment

- GHGRP and the Oil and Gas Industry. (2017, March 12). Retrieved April 11, 2017, from https://www.epa.gov/ghgreporting/ghgrp-and-oil-and-gas-industry

- Emissions from oil and gas production operations. Retrieved April 11, 2017, from http://petrowiki.org/Emissions_from_oil_and_gas_production_operations

- https://www.ssb.no/en/forskning/discussion-papers/_attachment/225118?_ts=14de17b6918.

- Blasing, T. Recent Greenhouse Gas Concentrations. Carbon Dioxide Information Analysis Center (CDIAC) Datasets. doi:10.3334/cdiac/atg.032

- Emissions of Greenhouse Gases in the United States 2009. Retrieved April 11, 2017, from https://www.eia.gov/environment/emissions/ghg_report/pdf/0573(2009).pdf

- Team, E. W. (2005, October 01). ESRL Global Monitoring Division - Global Greenhouse Gas Reference Network. Retrieved April 11, 2017, from https://www.esrl.noaa.gov/gmd/ccgg/trends/global.html

- United States, EPA, Air Quality. (1994). Control techniques for volatile organic compound emissions from stationary sources. Rockville, MD, Oklahoma: Government Institutes, Inc.

- Understanding Global Warming Potentials. (2017, February 14). Retrieved April 11, 2017, from https://www.epa.gov/ghgemissions/understanding-global-warming-potentials)

- Sources:

- Johnson, Matthew R.; Coderre, Adam R. (May 2012). "Opportunities for CO2 equivalent emissions reductions via flare and vent mitigation: A case study for Alberta, Canada". International Journal of Greenhouse Gas Control. 8: 121–131. doi:10.1016/j.ijggc.2012.02.004.

- Sangsaraki, M.E.; Anajafi, E.: International Conference on Chemical, Food and Environment Engineering (ICCFEE'15), Dubai (UAE), January 11–12, 2015.

- Rahimpour, M.R.; Jokar, S.M.: Journal of Hazardous Materials, 2012, 204-217, Ezersky, A.; Lips, H.: Characterisation of refinery flare emissions: assumptions, assertions and AP-42, Bay Area Air Quality Management District (BAAQMD), 2003.

- "Liquefied Petroleum Gas Combustion" (PDF). epa.gov. Environmental Protection Agency.

- Code of Federal Regulations, 40: Chapter 1, Subchapter C, Part 51, Subpart F, 51100, and EPA's Terms of Environment Glossary, Abbreviations, and Acronyms.

- United States, EPA, Air Quality. (n.d.). Recommended Policy on Control of Volatile Organic Compounds (131st ed., Vol. 42, 35313-35316). https://www3.epa.gov/ttn/naaqs/aqmguide/collection/Doc_0002_VOCFR0708771.pdf

- Safe Drinking Water Act (SDWA). (2017, January 12). Retrieved April 11, 2017, from https://www.epa.gov/sdwa

- (Technical Overview of Volatile Organic Compounds. (2017, February 22). Retrieved April 11, 2017, from https://www.epa.gov/indoor-air-quality-iaq/technical-overview-volatile-organic-compounds#overview)

- http://www.epa.sa.gov.au/files/8238_info_photosmog.pdf

- Demerjian, K. L.; Kerr, J. A.; Calvert, J. G. (1974). "The mechanisms of photochemical smog formation". Adv Environ. Sci. Technol. 4: 1–262.

- Wolkoff, P.; Wilkins, C. K.; Clausen, P. A.; Nielsen, G. D. (2006). "Organic compounds in office environments - sensory irritation, odor, measurements and the role of reactive chemistry". Indoor Air. 16 (1): 7–19. doi:10.1111/j.1600-0668.2005.00393.x. PMID 16420493.

- Mendell, M. J. (2007). "Indoor residential chemical emissions as risk factors for respiratory and allergic effects in children: A review". Indoor Air. 17 (4): 259–77. doi:10.1111/j.1600-0668.2007.00478.x. PMID 17661923.

- "What is Smog?", Canadian Council of Ministers of the Environment, CCME.caArchived September 28, 2011.

- KIRKELEIT, J., RIISE, T., BRÅTVEIT, M., & MOEN, B. E. (2005, December 21). Benzene Exposure on a Crude Oil Production Vessel. Retrieved April 11, 2017, from https://academic.oup.com/annweh/article/50/2/123/204990/Benzene-Exposure-on-a-Crude-Oil-Production-Vessel

- Pinto, D. M.; Blande, J. D.; Souza, S. R.; Nerg, A.; Holopainen, J. K. (2010). "Plant Volatile Organic Compounds (VOCs) in Ozone (O3) Polluted Atmospheres: The Ecological Effects". Journal of Chemical Ecology. 36 (1): 22–34. doi:10.1007/s10886-009-9732-3. PMID 20084432.

- Fleming, G. R., & Longworth, J. (2016, April 15). Photochemical reaction. Retrieved April 11, 2017, from https://www.britannica.com/science/photochemical-reaction

- L. (2016, July 21). Smog. Retrieved April 11, 2017, from https://chem.libretexts.org/Core/Physical_and_Theoretical_Chemistry/Kinetics/Case_Studies%3A_Kinetics/Smog

- Schmidt, K.; Podmore, I. (2015). "Current Challenges in Volatile Organic Compounds Analysis as Potential Biomarkers of Cancer". Journal of Biomarkers. 2015: 1–16. doi:10.1155/2015/981458. PMC 4437398. PMID 26317039.

- EPA-450/2-78-041 and "Measurement of Volatile Organic Compounds – Supplement 1" (EPA-450/3-82-0m19, July 1982.

- Filipiak, W.; Mochalski, P.; Filipiak, A.; Ager, C.; Cumeras, R.; Davis, C.; Troppmair, J. (2016). "A Compendium of Volatile Organic Compounds (VOCs) Released By Human Cell Lines". Current Medicinal Chemistry. 23 (20): 2112–2131. doi:10.2174/0929867323666160510122913. PMC 5086670. PMID 27160536.

- Carslaw, K. S.; Boucher, O.; Spracklen, D. V.; Mann, G. W.; Rae, J. G.; Woodward, S.; Kulmala, M. (2010). "A review of natural aerosol interactions and feedbacks within the Earth system". Atmospheric Chemistry and Physics. 10 (4): 1701–1737. doi:10.5194/acp-10-1701-2010.

- Hallquist, M.; et al. (2009). ""The formation, properties and impact of secondary organic aerosol " current and emerging issues". Atmos. Chem. Phys. 9 (14): 5155–5236. doi:10.5194/acp-9-5155-2009.

- Jimenez, J. L.; et al. (2009). "Evolution of organic aerosols in the atmosphere". Science. 326 (5959): 1525–1529. doi:10.1126/science.1180353. PMID 20007897.

- Williams, J., & Koppmann, R. (2007). Volatile Organic Compounds in the Atmosphere: An Overview. Volatile Organic Compounds in the Atmosphere, 1-32. doi:10.1002/9780470988657.ch1

- Kalberer, M.; et al. (2004). "Identification of polymers as major components of atmospheric organic aerosols". Science. 303 (5664): 1659–1662. doi:10.1126/science.1092185. PMID 15016998.

- Volkamer, R.; Jimenez, J. L.; Martini, F. S.; Dzepina, K.; Zhang, Q.; Salcedo, D.; Molina, M. J. (2006). "Secondary organic aerosol formation from anthropogenic air pollution: Rapid and higher than expected". Geophysical Research Letters. 33 (17): 17. doi:10.1029/2006gl026899.

- Pariselli, F.; Sacco, M.; Ponti, J.; Rembges, D. (2009). "Effects of toluene and benzene air mixtures on human lung cells (A549)". Experimental and Toxicologic Pathology. 61 (4): 381–386. doi:10.1016/j.etp.2008.10.004. PMID 19046626.

- Skogestad, Sigurd. Chemical and energy process engineering. Boca Raton: CRC Press, 2009. Print.

- Rachford, H.H. and Rice, J.D.: “Procedure for Use of Electrical Digital Computers in Calculating Flash Vaporization Hydrocarbon Equilibrium,” Journal of Petroleum Technology, Sec. 1, p. 19, Oct. 1952.)

- (Sutton, R.P. 1985. Compressibility Factors for High-Molecular-Weight Reservoir Gases. Presented at the SPE Annual Technical Conference and Exhibition, Las Vegas, Nevada, USA, 22–26 September. SPE-14265-MS. https://dx.doi.org/10.2118/14265-MS)

- (Stewart, W.F., Burkhardt, S.F., and Voo, D. 1959. Prediction of Pseudo-critical Parameters for Mixtures. Presented at the AIChE Meeting, Kansas City, Missouri, USA, 18 May 1959.)

- "Bryan Research & Engineering, Inc".

- Vazquez, M.; Beggs, H.D. (1980). "Correlations for Fluid Physical Property Prediction". Journal of Petroleum Technology. 32 (6): 968–70. doi:10.2118/6719-PA.

- Cheremisinoff, Nicholas P. Pollution control handbook for oil and gas engineering. Beverly, MA: Schrivener Publishing, 2016. Print.

- Perrot, Pierre (1998). A to Z of Thermodynamics. Oxford University Press. ISBN 0-19-856552-6.

- Ashour, I., 2011. Applications of Equations of State in the Oil and Gas Industry. Oman: Department of Petroleum and Chemical Engineering College of Engineering, Sultan Qaboos University

- Sadus, R. J. (1994) Calculating Critical Transitions of Fluid Mixtures: Theory Vs. Experiment, AIChE J., 40, 1376-1403.

- "Vapor recovery unit." Schlumberger. Web. 27 Mar. 2017. http://www.glossary.oilfield.slb.com/Terms/v/vapor_recovery_unit.aspx

- ICF International (ICF). (2014). Economic Analysis of Methane Emission Reduction Opportunities in the U.S. Onshore Oil and Natural Gas Industries. Fairfax, VA: ICF. Accessed September 2014: https://www.edf.org/sites/default/files/methane_cost_curve_report.pdf.

- "whats wrong with vapor recovery units". 23 August 2016.

- http://www.oilfieldpartsxpress.com/thief_hatches.html)

- "UPDATE: Reports of Worker Fatalities during Manual Tank Gauging and Sampling in the Oil and Gas Extraction Industry - - Blogs - CDC".

- "heater treater - Schlumberger Oilfield Glossary".

- "Oil and gas separators -".

- Edward, Boyer, Brian; Steve, O'Connell (1 January 2005). Optimize Separator Operating Pressures to Reduce Flash Losses. doi:10.2118/94373-MS. ISBN 9781613990148.