Bleaching of wood pulp

Bleaching of wood pulp is the chemical processing of wood pulp to lighten its color and whiten the pulp. The primary product of wood pulp is paper, for which whiteness (similar to, but distinct from brightness) is an important characteristic.[1] These processes and chemistry are also applicable to the bleaching of non-wood pulps, such as those made from bamboo or kenaf.

Paper brightness

Brightness is the amount of incident light reflected from paper under specified conditions,[2] usually reported as the percentage of light reflected, so a higher number means a brighter or whiter paper. In the US, the TAPPI T 452 [3] or T 525 standards are used. The international community uses ISO standards. Table 1 shows how the two systems rate high brightness papers, but there is no simple way to convert between the two systems because the test methods are so different.[4] The ISO rating is higher and can be over 100. This is because contemporary white paper incorporates fluorescent whitening agents (FWA). Because the ISO standard only measures a narrow range of blue light, it is not directly comparable to human vision of whiteness or brightness.[5]

| Table 1 | |

|---|---|

| TAPPI brightness | ISO brightness |

| 84 | 88 |

| 92 | 104 |

| 96 | 108 |

| 97 | 109+ |

Newsprint ranges from 55-75 ISO brightness.[6] Writing and printer paper would typically be as bright as 104 ISO.

While the results are the same, the processes and fundamental chemistry involved in bleaching chemical pulps (like kraft or sulfite) are very different from those involved in bleaching mechanical pulps (like stoneground, thermomechanical or chemithermomechanical). Chemical pulps contain very little lignin while mechanical pulps contain most of the lignin that was present in the wood used to make the pulp. Lignin is the main source of color in pulp due to the presence of a variety of chromophores naturally present in the wood or created in the pulp mill.

Bleaching mechanical pulps

Mechanical pulp retains most of the lignin present in the wood used to make the pulp and thus contain almost as much lignin as they do cellulose and hemicellulose. It would be impractical to remove this much lignin by bleaching, and undesirable since one of the big advantages of mechanical pulp is the high yield of pulp based on wood used. Therefore, the objective of bleaching mechanical pulp (also referred to as brightening) is to remove only the chromophores (color-causing groups). This is possible because the structures responsible for color are also more susceptible to oxidation or reduction.

Alkaline hydrogen peroxide is the most commonly used bleaching agent for mechanical pulp. The amount of base such as sodium hydroxide is less than that used in bleaching chemical pulps and the temperatures are lower. These conditions allow alkaline peroxide to selectively oxidize non-aromatic conjugated groups responsible for absorbing visible light. The decomposition of hydrogen peroxide is catalyzed by transition metals, and iron, manganese and copper are of particular importance in pulp bleaching. The use of chelating agents like EDTA to remove some of these metal ions from the pulp prior to adding peroxide allows the peroxide to be used more efficiently. Magnesium salts and sodium silicate are also added to improve bleaching with alkaline peroxide.[7]

Sodium dithionite (Na2S2O4), also known as sodium hydrosulfite, is the other main reagent used to brighten mechanical pulps. In contrast to hydrogen peroxide, which oxidizes the chromophores, dithionite reduces these color-causing groups. Dithionite reacts with oxygen, so efficient use of dithionite requires that oxygen exposure be minimized during its use.[2]

Chelating agents can contribute to brightness gain by sequestering iron ions, for example as EDTA complexes, which are less colored than the complexes formed between iron and lignin.[2]

The brightness gains achieved in bleaching mechanical pulps are temporary since almost all of the lignin present in the wood is still present in the pulp. Exposure to air and light can produce new chromophores from this residual lignin.[8] This is why newspaper yellows as it ages. yellowing also occurs due to the acidic sizing

Bleaching of recycled pulp

Hydrogen peroxide and sodium dithionite are used to increase the brightness of deinked pulp.[9] The bleaching methods are similar for mechanical pulp in which the goal is to make the fibers brighter.

Bleaching chemical pulps

Chemical pulps, such as those from the kraft process or sulfite pulping, contain much less lignin than mechanical pulps, (<5% compared to approximately 40%). The goal in bleaching chemical pulps is to remove essentially all of the residual lignin, hence the process is often referred to as delignification. Sodium hypochlorite (household bleach) was initially used to bleach chemical pulps, but was largely replaced in the 1930s by chlorine. Concerns about the release of organochlorine compounds into the environment prompted the development of Elemental Chlorine Free (ECF) and Totally Chlorine Free (TCF) bleaching processes.

Delignification of chemical pulps is frequently composed of four or more discrete steps, with each step designated by a letter in the Table:[10]

| Table 2 | |

|---|---|

| Chemical or process used | Letter designation |

| Chlorine | C |

| Sodium hypochlorite | H |

| Chlorine dioxide | D |

| Extraction with sodium hydroxide | E |

| Oxygen | O |

| Alkaline hydrogen peroxide | P |

| Ozone | Z |

| Chelation to remove metals | Q |

| Enzymes (especially xylanase) | X |

| Peracids (peroxy acids) | Paa |

| Sodium dithionite (sodium hydrosulfite) | Y |

A bleaching sequence from the 1950s could look like: CEHEH . The pulp would have been exposed to chlorine, extracted (washed) with a sodium hydroxide solution to remove lignin fragmented by the chlorination, treated with sodium hypochlorite, washed with sodium hydroxide again and given a final treatment with hypochlorite. An example of a modern totally chlorine-free (TCF) sequence is OZEPY where the pulp would be treated with oxygen, then ozone, washed with sodium hydroxide then treated in sequence with alkaline peroxide and sodium dithionite.

Chlorine and hypochlorite

Chlorine replaces hydrogen on the aromatic rings of lignin via aromatic substitution, oxidizes pendant groups to carboxylic acids and adds across carbon carbon double bonds in the lignin sidechains. Chlorine also attacks cellulose, but this reaction occurs predominantly at pH 7, where un-ionized hypochlorous acid, HClO, is the main chlorine species in solution.[11] To avoid excessive cellulose degradation, chlorination is carried out at pH <1.5.

- Cl2 + H2O ⇌ H+ + Cl− + HClO

At pH >8 the dominant species is hypochlorite, ClO−, which is also useful for lignin removal. Sodium hypochlorite can be purchased or generated in situ by reacting chlorine with sodium hydroxide.

- 2 NaOH + Cl2 ⇌ NaOCl + NaCl + H2O

The main objection to the use of chlorine for bleaching pulp is the large amounts of soluble organochlorine compounds produced and released into the environment.

Chlorine dioxide

Chlorine dioxide, ClO2 is an unstable gas with moderate solubility in water. It is usually generated in an aqueous solution and used immediately because it decomposes and is explosive in higher concentrations. It is produced by reacting sodium chlorate with a reducing agent like sulfur dioxide.

- 2 NaClO3 + H2SO4 + SO2 → 2 ClO2 + 2 NaHSO4

Chlorine dioxide is sometimes used in combination with chlorine, but it is used alone in ECF (elemental chlorine-free) bleaching sequences. It is used at moderately acidic pH (3.5 to 6). The use of chlorine dioxide minimizes the amount of organochlorine compounds produced.[8] Chlorine dioxide (ECF technology) currently is the most important bleaching method worldwide. About 95% of all bleached Kraft pulp is made using chlorine dioxide in ECF bleaching sequences.[12]

Extraction or washing

All bleaching agents used to delignify chemical pulp, with the exception of sodium dithionite, break lignin down into smaller, oxygen-containing molecules. These breakdown products are generally soluble in water, especially if the pH is greater than 7 (many of the products are carboxylic acids). These materials must be removed between bleaching stages to avoid excessive use of bleaching chemicals since many of these smaller molecules are still susceptible to oxidation. The need to minimize water use in modern pulp mills has driven the development of equipment and techniques for the efficient use of available water.[13]

Oxygen

Oxygen exists as a ground state triplet state, which is relatively unreactive and needs free radicals or very electron-rich substrates such as deprotonated lignin phenolic groups. The production of these phenoxide groups requires that delignification with oxygen be carried out under very basic conditions (pH >12). The reactions involved are primarily single electron (radical) reactions.[14][15] Oxygen opens rings and cleaves sidechains giving a complex mixture of small oxygenated molecules. Transition metal compounds, particularly those of iron, manganese and copper, which have multiple oxidation states, facilitate many radical reactions and impact oxygen delignification.[16][17] While the radical reactions are largely responsible for delignification, they are detrimental to cellulose. Oxygen-based radicals, especially hydroxyl radicals, HO•, can oxidize hydroxyl groups in the cellulose chains to ketones, and under the strongly basic conditions used in oxygen delignification, these compounds undergo reverse aldol reactions leading to cleavage of cellulose chains. Magnesium salts are added to oxygen delignification to help preserve the cellulose chains,[16] but mechanism of this protection has not been confirmed

Hydrogen peroxide

Using hydrogen peroxide to delignify chemical pulp requires more vigorous conditions than for brightening mechanical pulp. Both pH and temperature are higher when treating chemical pulp. The chemistry is very similar to that involved in oxygen delignification, in terms of the radical species involved and the products produced.[18] Hydrogen peroxide is sometimes used with oxygen in the same bleaching stage and this is give the letter designation Op in bleaching sequences. Metal ions, particularly manganese catalyze the decomposition of hydrogen peroxide, so some improvement in the efficiency of peroxide bleaching can be achieved if the metal levels are controlled.[19]

Ozone

Ozone is a very powerful oxidizing agent and the biggest challenge in using it to bleach wood pulp is to get sufficient selectivity so that the desirable cellulose is not degraded. Ozone reacts with the carbon carbon double bonds in lignin, including those within aromatic rings. In the 1990s ozone was touted as good reagent to allow pulp to be bleached without any chlorine-containing chemicals (totally chlorine-free, TCF). The emphasis has changed and ozone is seen as an adjunct to chlorine dioxide in bleaching sequences not using any elemental chlorine (elemental chlorine-free, ECF). Over twenty-five pulp mills worldwide have installed equipment to generate and use ozone.[20]

Chelant wash

The effect of transition metals on some of the bleaching stages has already been mentioned. Sometimes it is beneficial to remove some of these metal ions from the pulp by washing the pulp with a chelating agent such as EDTA or DTPA. This is more common in TCF bleaching sequences for two reasons: the acidic chlorine or chlorine dioxide stages tend to remove metal ions (metal ions usually being more soluble at lower pH) and TCF stages rely more heavily on oxygen-based bleaching agents, which are more susceptible to the detrimental effects of these metal ions. Chelant washes are usually carried out at or near pH 7. Lower pH solutions are more effective at removing transition metals, but also remove more of the beneficial metal ions, especially magnesium[21]

Other bleaching agents

A variety of more exotic bleaching agents have been used on chemical pulps. They include peroxyacetic acid,[22] peroxyformic acid,[22] potassium peroxymonosulfate (Oxone),[22] dimethyldioxirane,[23] which is generated in situ from acetone and potassium peroxymonosulfate, and peroxymonophosphoric acid.[24]

Enzymes like xylanase have been used in pulp bleaching[22] to increase the efficiency of other bleaching chemicals. It is believed that xylanase does this by cleaving lignin-xylan bonds to make lignin more accessible to other reagents.[2] It is possible that other enzymes such as those found in fungi that degrade lignin may be useful in pulp bleaching.[25]

Environmental considerations

The bleaching of chemical pulps has the potential to cause significant environmental damage, primarily through the release of organic materials into waterways. Pulp mills are almost always located near large bodies of water because they require substantial quantities of water for their processes. An increased public awareness of environmental issues from the 1970s and 1980s, as evidenced by the formation of organizations like Greenpeace, influenced the pulping industry and governments to address the release of these materials into the environment.[26]

Conventional bleaching using elemental chlorine produces and releases into the environment large amounts of chlorinated organic compounds, including chlorinated dioxins.[27] Dioxins are recognized as a persistent environmental pollutant, regulated internationally by the Stockholm Convention on Persistent Organic Pollutants.

Dioxins are highly toxic, and health effects on humans include reproductive, developmental, immune and hormonal problems. They are known to be carcinogenic. Over 90% of human exposure is through food, primarily meat, dairy, fish and shellfish, as dioxins accumulate in the food chain in the fatty tissue of animals.[28]

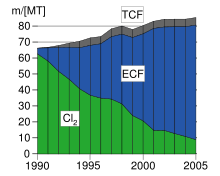

As a result, from the 1990s onwards, the use of elemental chlorine in the delignification process was substantially reduced and replaced with ECF (Elemental Chlorine Free) and TCF (Totally Chlorine Free) bleaching processes. In 2005, elemental chlorine was used in 19-20% of kraft pulp production globally, down from over 90% in 1990. 75% of kraft pulp used ECF, with the remaining 5-6% using TCF.[29] Most TCF pulp is produced in Sweden and Finland for sale in Germany,[29] all markets with a high level of environmental awareness. In 1999, TCF pulp represented 25% of the European market.[30]

TCF bleaching, by removing chlorine from the process, reduces chlorinated organic compounds to background levels in pulp mill effluent.[31] ECF bleaching can substantially reduce but not fully eliminate chlorinated organic compounds, including dioxins, from effluent. While modern ECF plants can achieve chlorinated organic compounds (AOX) emissions of less than 0.05 kg per tonne of pulp produced, most do not achieve this level of emissions. Within the EU, the average chlorinated organic compound emissions for ECF plants is 0.15 kg per tonne.[32]

However, there has been disagreement about the comparative environmental effects of ECF and TCF bleaching. Some researchers found that there is no environmental difference between ECF and TCF[33] while others concluded that among ECF and TCF effluents before and after secondary treatment, TCF effluents are the least toxic.[34]

See also

- Johan Richter - inventor of the continuous process for bleaching wood pulp

- Paper chemicals

References

- "PaperOnWeb discussion of brightness and whiteness". Retrieved 17 September 2007.

- Biermann, Christopher J. (1993). Essentials of Pulping and Papermaking. San Diego: Academic Press, Inc. ISBN 0-12-097360-X. OCLC 27173529.

- "Page Not Found". Archived from the original on 15 April 2013. Retrieved 26 February 2016.

- "TAPPI comparison of TAPPI and ISO brightness". Archived from the original on 6 October 2007. Retrieved 15 September 2007.

- http://www.axiphos.com/BrightnessReview.pdf

- Ducey, Michael (June 2004). "Matching newsprint qualities to press technology". The International Journal of Newspaper Technology. Archived from the original on 16 August 2007. Retrieved 15 September 2007.

- "Pulp bleaching chemicals information from PQ Corp". Archived from the original on 2 April 2007. Retrieved 17 September 2007.

- E. Sjöström (1993). Wood Chemistry: Fundamentals and Applications. Academic Press. ISBN 0-12-647480-X. OCLC 58509724.

- "Treecycle Recycled Paper; About Recycling and Recycled Paper". treecycle.com.

- "PaperOnWeb description of bleaching sequences". Retrieved 17 September 2007.

- Fair, G. M.; Morris, J. C.; Chang, S. L.; Weil, I.; Burden, R. P. (1948). "The behavior of chlorine as a water disinfectant". J. Am. Water Works Assoc. 40: 1051–1061.

- "AET - Reports - Science - Trends in World Bleached Chemical Pulp Production: 1990-2005". Archived from the original on 30 July 2017. Retrieved 26 February 2016.

- Sillanpää, Mervi (2005). "Studies on washing in kraft pulp bleaching" (Thesis; PDF). Faculty of Technology University of Oulu, Finland. Retrieved 19 September 2007. Cite journal requires

|journal=(help) - Starnes, W.H. (1991). Chemistry of Delignification with Oxygen, Ozone and Peroxides. Ann Arbor, MI: UMI Out-of-print Books on Demand.

- Singh, R.P. (1979). The Bleaching of Pulp (3rd ed.). Atlanta: TAPPI Press.

- McDonough, Thomas Joseph (January 1983). "Oxygen bleaching processes : an overview" (PDF). IPC technical paper series. 132. Archived from the original (PDF) on 20 February 2009. Retrieved 19 September 2007.

- Johansson, E.; S. Ljunggren (1991). "The reactivity of lignin model compounds and the influence of metal ions during bleaching with oxygen and hydrogen peroxide". Proceedings of the Seventh International Symposium on Wood and Pulping Chemistry vol. I. Beijing, PR China. pp. 180–187.

- Suss, H.U.; N.F. Nimmerfroh (1993). "Peroxide Bleaching _ Technology Review". Workshop on Emerging Pulping and Chlorine-free Bleaching Technologies. Raleigh, N.C.

- Haugan, Marianne; Gregersen, Øyvind Weiby (2006). "Hydrogen peroxide bleaching of mechanical pulp fines". Nordic Pulp & Paper Research Journal. chemeng.ntnu.no. pp. 105–110. doi:10.3183/npprj-2006-21-01-p105-110.

- "Use of Ozone from web page by Air Liquide". Archived from the original on 8 August 2007. Retrieved 19 September 2007.

- "Dow Chem. data presented at 1994 and 1996 International Pulp Bleaching Conferences". Retrieved 19 September 2007.

- Ragauskas, A.J.; K.M. Poll; A.J. Cesternino (April 1993). "Effect of Xylanase Pretreatment Procedures for Nonchlorine Bleaching" (PDF). IPST Technical Paper Series, Institute of Paper Science Atlanta, Georgia and Technology. 482. Retrieved 20 September 2007.

- Bouchard, J.; Maine, C.; Berry, R.M.; Argyropoulos, D.S. (1996). "Kraft pulp bleaching using dimethyldioxirane: stability of the oxidants". Can. J. Chem. 74 (2): 232–237. doi:10.1139/v96-026. Archived from the original on 27 May 2012. Retrieved 20 September 2007.

- Springer, E.L. (December 1997). "Delignification of Wood and Kraft Pulp with Peroxymonophosphoric Acid". Journal of Pulp and Paper Science. 23 (12): 582–584.

- Harazono, Koicho; Ryuichiro Kondo; Kokki Sak (March 1996). "Bleaching of Hardwood Kraft Pulp with Manganese Peroxidase from Phanerochaete sordida YK-624 without Addition of MnSO(inf4)" (PDF). Applied and Environmental Microbiology. 62 (3): 913–917. PMC 1388804. PMID 16535279. Retrieved 20 September 2007.

- Sonnenfeld, David A. (1999). "Social Movements and Ecological Modernization: The Transformation of Pulp and Paper Manufacturing, Paper: WP00-6-Sonnenfeld". Berkeley Workshop on Environmental Politics. Berkeley, CA: Institute of International Studies (University of California, Berkeley). Retrieved 20 September 2007.

- "Effluents from Pulp Mills using Bleaching - PSL1". Health Canada. 1991. ISBN 0-662-18734-2. Retrieved 21 September 2007.

- "Dioxins and their effects on human health". World Health Organization. 2010. Retrieved 11 June 2010.

- "Frequently Asked Questions on Kraft Pulp Mills" (PDF). gunnspulpmill.com.au. Ensis/CSIRO (Australia) joint research (www.csiro.au). 4 March 2005. Archived from the original (PDF) on 2 December 2007.

- "Chlorine Free Products Association". CFPA Today. Spring 1999.

- Duke University; Environmental Defense Fund; Johnson&Johnson (December 1995). "Environmental Comparison of Bleached Kraft Pulp Manufacturing" (PDF). Environmental Defense Fund. Archived from the original (PDF) on 1 December 2006. Retrieved 18 November 2007.

- Ad Hoc Working Group of European Commission (May 2006). "Revision of the Ecolabelling Criteria for Tissue Paper: Comments and background to the second draft proposal" (PDF). Archived from the original (PDF) on 6 August 2009. Cite journal requires

|journal=(help) - "ECF and TCF: Toxicity An Analysis of Recent Published Data". The Alliance for Environmental Technology (International Association) joint research . October 1994. Archived from the original on 4 November 2007. Retrieved 26 October 2007.

- Tarkpea, Maria; et al. (1999). "Toxicity of conventional, elemental chlorine-free, and totally chlorine–free kraft-pulp bleaching effluents assessed by shortterm lethal and subleathal bioassays". Environmental Toxicology and Chemistry. 18 (11): 2487–2496. doi:10.1002/etc.5620181115.