Temple Works

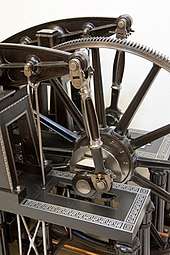

Temple Works is a former flax mill in Holbeck, Leeds, West Yorkshire, England. It was designed by engineer James Combe a former pupil of John Rennie,[2] David Roberts, architect Joseph Bonomi the Younger and built in the Egyptian Revival style by John Marshall between 1836 and 1840 with a 240 hp double beam engine by Benjamin Hick[1] (B. Hick and Sons). Temple Works is the only Grade I listed building in Holbeck.[3]

Facade of the Temple Works office block | |

| Flax | |

|---|---|

| Architectural style | Egyptian |

| Structural system | Largest single room in the world when built |

| Location | Holbeck, Leeds |

| Construction | |

| Built | 1836 |

| Employees | 2600 (1840) |

| Decommissioned | 1886 |

| Floor count | 1 |

| Main contractor | Marshall and Co. |

| Design team | |

| Architect | Joseph Bonomi the Younger |

| Structural engineer | James Combe |

| Other designers | David Roberts |

| Power | |

| Date | 1840 |

| Engine maker | B. Hick and Sons |

| Engine type | Two cylinder beam engine |

| Valve Gear | Double ended slide valves |

| rpm | 19 |

| Installed horse power (ihp) | 240 |

| Flywheel diameter | 26ft (7.9m)[1] |

| Other Equipment | 7000 Spindles |

Listed Building – Grade I | |

History

By 1842 John Marshall owned four mills in Holbeck known as Mills B to E, Mill A having been demolished in 1837. The early 1830s had been a time of great prosperity for the firm after the introduction of the wet spinning process in 1829, the transition to which took five years to complete. John Marshall's four sons all entered the business, but increasingly he relied on his son James concerning the manufacturing side. The firm's competitors in Leeds were all prospering and had built or had plans to build sizeable new mills. The firm at that time specialised in making fine yarns, principally for the French market, but this was starting to decline. Therefore, James Marshall decided upon a programme of diversification into thread and cloth manufacture. This decision to diversify required an extension to the manufacturing facility in Holbeck. James had two alternative plans, another six storey mill on the site of the demolished Mill A in Water Lane, or a single storey building extending from Mill C in Marshall Street south to the junction with Sweet Street. He compared the cost of the two mills and calculated the single storey structure would cost £24,000, about 15% cheaper than a comparable six storey building. The new building was modelled at one third the full size in the yard of Mill C. James persuaded his father, then in semi-retirement, that the single storey mill should be built.[4] A Mr Smith had already built the first single storey cotton mill in Deanston, near Stirling, but Messrs. Marshall planned a much larger and complete specimen.[5]

Temple Works, also known as Temple Mill, comprises an office building and factory. The office building has a stone facade consisting of 18 full height windows each separated by 18 pillars with an overhanging cornice in the Egyptian style, based on the temple at Antaeopolis and Temple of Horus at Edfu. The factory building derived from the Typhonium at Dendera. There was a chimney in the style of an obelisk or 'Cleopatra's Needle', which was demolished and replaced by a brick structure in 1852 when the original cracked. Hick's engine was modelled with Egyptian details including a regulator designed by his son Benjamin in the form of a winged solar disk,[6][7] and replaced the original Watt engines.[1]

James Marshall wrote to his father John in May 1838 describing the arrangements for lighting the building using about 60 conical glass skylights 14 foot in diameter and rising 10 feet above the roof. By this means light poured into the room at all hours of day. Underground in brick vaulted cellars ran a maze of passageways, tradesmen's shops and private baths for the use of the workers (cold, free; hot, 1 penny). In one room a fan pushed steam-heated air into the factory, which was kept at a constant temperature and humidity. In 1847–50 a church, St John the Evangelist, was constructed behind Temple Mill to a gothic design of George Gilbert Scott. Other outbuildings were added, including stables.[4]

The factory was opened in June 1840 and this was marked by a great Temperance Tea for the firm's 2,600 workers. Six months later machinery had been installed and the mill began production. The adjoining office building was completed a few years later. The new buildings did not extend as planned to Sweet Street. It was only half the size James Marshall had forecast and had only half the spindles it could house. All the extra yarn produced was turned into thread, and no cloth was ever woven, as had been planned. The reason for this is the slump in the demand for and the price of finished products in the 1840s. Everybody in the flax spinning industry expected boom to follow slump, but it never did. Leeds flax spinners lost their competitive edge due to the free trade in machinery and could not compete with those in Ireland, France and Belgium. The demand for linen was drastically reduced due to substitution with cotton. Furthermore, a creeping managerial paralysis set in within the Marshall family, virtually all of whom moved away from Leeds. It has been said that the third generation of Marshalls actually despised the business, whereas their fathers had merely neglected it. The day to day control of Temple Mill passed to the manager John Richardson who had been with the firm since the 1820s. He installed several of his friends and relations in senior positions with salaries of between £300 and £500 a year.[4]

On 11 August 1871 six hundred operatives at the Water Lane mills staged a one-day strike for a 10% pay rise. Richardson first threatened them, then closed all the mills the following day. Stephen Marshall, one of the third generation, traced the unrest to Temple Mill, 'as bad a lot of men as we have'. He proposed the public dismissal of the foreman at Temple Mill in such a way as to ruin him. Other members of the family persuaded Stephen Marshall to re-open the mills and negotiate, but talks dragged on for days. The Leeds Mercury published an article contrasting the poverty and insecurity of a worker's life with the spending and luxury of the Marshall family. The 10% wage increase was conceded after a family meeting, but the family determined it would deal with the trouble makers at Temple Mill in the long term.[4]

The Marshall firm continued in business longer than most of its Leeds competitors, eventually closing in 1886, although it made a loss in twenty one out of the last forty years of its existence. However, by the late 1870s Temple Mill was sub-let and ceased to be a net expense to the business. It was sold by auction in 1886 along with all the other assets of the firm.[4]

The Marshalls' inspiration for the design of Temple Works was their interest in Egyptology. When it was built it was said that Temple Works was the biggest single room in the world. An unusual feature of the Temple Works building is that sheep used to graze on the grass-covered roof. This served the purpose of retaining humidity in the flax mill to prevent the linen thread from becoming dried out and unmanageable.[8] Sheep are not able to use stairs so the first hydraulic lift was devised in order to resolve the problem of moving them onto the roof;[9] Hick was a hydraulics engineer, but it is not clear whether he was responsible for the invention, his youngest son, William Hick (1820–1844) supervised the installation of the 'Egyptian' beam engine from Leeds during 1841.[10][11]

1842 General Strike

The mill was caught up in the Plug Riots of August 1842. The Leeds Annals [12] described the events at the mill:

“The vicinity of the new mill in Marshall Street was completely crammed with an excited mob, many of whom were armed with bludgeons, stones &c. The yard-door leading to the boilers of the new mill was strongly defended by Mr J. G. Marshall, and a number of workmen; but the mob by repeated efforts forced down the door, and rushed into the yard. They could not find the plug of the boiler, and consequently did not succeed in stopping the mill. They left the premises without having done any serious mischief, and then proceeded to the mill of Messrs. Titley, Tatham and Walker, Water Lane, which they were engaged in stopping when Prince George with the Lancers came up at full speed and formed in a line in Camp Field. The riot act was read, and two or three of the ringleaders were taken prisoners … .”

Restoration

A planning application dated July 2005 proposed to partly demolish, refurbish, and extend the mill to form a retail centre, offices, cafes, 75 flats and parking. On 8 December 2008 a stone pillar in the mill's facade collapsed. A slab of millstone grit fell onto the pavement in Marshall Street and the roof parapet above the pillar bowed out.[13][14] English Heritage advised on a strategy for repairs; their spokesman said that the building was "probably the finest example of a carved stone elevation in the whole region."[15]

In November 2015, Burberry announced plans to use the site for manufacturing. However, following the Brexit vote, they put the plans on hold, finally abandoning them in 2017.[16][17] The building was put up for auction in 2017 with a starting price of £1.[18] The new buyer, CEG, gave an estimate of £35 million for the restoration works in June 2019, with the building forming part of plans for regeneration of the South Bank of Leeds.[19]

In March 2020 it was announced that the building was under consideration as the home of a planned Northern branch of the British Library.[20] The government's 2020 budget promised £25 million towards the restoration of Temple Works to enable its use by the British Library [21].

In popular culture

Temple Works features in a John Betjeman BBC film, John Betjeman Discovers Leeds made in 1968 about Leeds city architecture.[22][23]

In late 2009 the building was opened as an arts centre, with an initial exhibition and tour as part of Leeds Light Night on 9 October.[24]

References

- Graham, Stanley (2009). Steam Engine Research Resources. Lulu.com. p. 3. ISBN 1409290093.

- Percy, Sholto (July 1835). Nursey, Perry Fairfax (ed.). "On Railways. By John Herapath, Esq. No. VII. Sir John Rennie's Railway to Brighton and Shoreham". Iron: An Illustrated Weekly Journal for Iron and Steel Manufacturers, Metallurgists, Mine Proprietors, Engineers, Shipbuilders, Scientists, Capitalists ... 23: p. 308. Retrieved 22 January 2014.

- "Holbeck Conservation Area Appraisal" (PDF). leeds.gov.uk. p. 3. Retrieved 3 August 2020.

- W. G. Rimmer (1960). 'Marshalls of Leeds Flax Spinners', Cambridge University Press, Cambridge Studies in Economic History

- Penny Magazine, December 1843 supplement, 'A Day in a Leeds Flax Mill

- Robertson, J.C., ed. (15 May 1841). "Hick's Patent Governor for Steam-Engines and Water Wheels". The Mechanics' Magazine, Museum, Register, Journal, and Gazette. 34. pp. 369–372.

- Stevens Curl, James (2013). The Egyptian Revival. Routledge. p. 279. ISBN 1134234686.

- "Temple Mill, Leeds". The Victorian Society. Retrieved 27 October 2012.

- Cronshaw, Jon. "Temple Works: The most extreme venue in Leeds". Leeds Art Scene. Leeds Art Scene. Retrieved 19 October 2015.

- Pilling (1985), pp. 83, 475.

- Redfern, Diane. "William Hick". Diane Redfern Ancestry & Family History. dianeredfern.ca. Archived from the original on 27 November 2015. Retrieved 20 October 2015.

- The Annals and History of Leeds, and Other Places in the County of York: From the Earliest Period to the Present Time. Joseph Johnson. 12 March 1860. Retrieved 12 March 2020 – via Google Books.

- "Pillar collapses at historic mill". BBC News. 8 December 2008. Retrieved 11 December 2008.

- Smith, Bruce (8 December 2008). "Historic Leeds building collapses" (with video). Yorkshire Evening Post. Retrieved 11 December 2008.

- Marsh, David (10 December 2008). "'Egyptian temple' in Leeds shored up as owners take advice". Yorkshire Evening Post. Retrieved 11 December 2008.

- "A piece of Leeds heritage for £1?". The Yorkshire Evening Post. Retrieved 14 November 2017.

- "Burberry scraps plans for flagship site in Leeds". The Yorkshire Evening Post. Retrieved 14 November 2017.

- Iqbal, Aisha (13 November 2017). "A piece of Leeds heritage for £1?". Yorkshire Evening Post. Retrieved 15 November 2017.

- Worsley, Kayley (25 June 2019). "Restoration of Temple Works expected top £35m". The Business Desk. Retrieved 11 July 2019.

- Newton, Grace (12 March 2020). "Grade I-listed mill Temple Works in Leeds could become the new British Library North". Yorkshire Evening Post. Retrieved 12 March 2020.

- "Budget 2020: 2.19 Growth across the country". gov.uk. HM Treasury. Retrieved 22 July 2020.

- "John Betjeman Discovers Leeds" (PDF). www.yorkshirefilmarchive.com. 1968. Retrieved 21 December 2015.

- Grady, Kevin (13 March 2009). "John Bejteman on the architecture of Leeds". Building Design Online. Building Design 2014. Retrieved 15 January 2015.

- "Opportunities at Temple Works, Leeds". theculturevulture.co.uk. 24 July 2009. Retrieved 3 August 2020.

Bibliography

- Pilling, P.W. (1985). Hick Hargreaves and Co., The History of an Engineering Firm c. 1833 – 1939, a Study with Special Reference to Technological Change and Markets (Unpublished Doctoral Thesis). University of Liverpool.CS1 maint: ref=harv (link)

External links

- Double Beam Engine: Model of B. Hick and Son's 240 hp double beam engine on display at the Science Museum

- Historic England. "Details from listed building database (1375162)". National Heritage List for England.

- "Temple Works Leeds". Archived from the original on 13 August 2018. Retrieved 1 April 2020.

- Cronshaw, Jon (2 May 2013). "Temple Works: The most extreme venue in Leeds". Leeds Art Scene. Archived from the original on 29 August 2013.