Narec

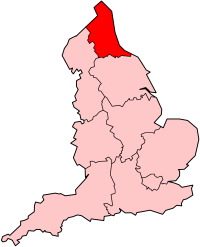

Narec, since 2014 known as the National Renewable Energy Centre, is a part of the Offshore Renewable Energy (ORE) Catapult, a British technology innovation and research centre for offshore wind power, wave energy, tidal energy and low carbon technologies. ORE Catapult's head office is in Glasgow, Scotland. The centre operates multi-purpose offshore renewable energy test and demonstration facilities.[1] It is similar to other centres, such as NREL in the US[2] and National Centre for Renewable Energies (CENER) in Spain. The National Renewable Energy Centre is based in Blyth, Northumberland.

| Not for profit company | |

| Industry | Renewable energy Energy efficiency |

| Founded | 2002 |

| Founder | One NorthEast |

| Headquarters | Blyth, Northumberland , England |

Key people | Andrew Jamieson (CEO) |

| Services | Testing Certification Demonstration |

| Website | https://ore.catapult.org.uk |

History

Originally known as NaREC (New and Renewable Energy Centre), the centre was created in 2002 by One NorthEast, the North East regional development agency, as part of the Strategy for Success programme.[3] In 2010 the organisation changed its name to Narec (National Renewable Energy Centre).[4] In April 2014, the organisation merged with the Offshore Renewable Energy (ORE) Catapult to focus on the development and cost reduction of offshore wind, wave and tidal energy across the UK.[5][6]

The organisation was originally involved in a wide range of technologies, including:

- Wind (onshore and offshore)

- Transmission and distribution

- Photovoltaics

- Oil and gas

- Marine renewables

- Fuel cells

- Microrenewables

- Biomass[7]

In 2010, due to UK government cutbacks, Narec closed, sold off or separated parts of the business. Now, Narec itself concentrates on testing blades and drive trains for marine renewables. Spin-off companies include:

Narec Distributed Energy – An organisation which deals with energy efficiency, solar farm design, preparation of MW scale battery sites, grid connection, and Life Cycle Assessment.[8] Narec Distributed Energy is 10% owned by ORE Catapult.

Solar Capture Technologies – A completely independent company which specialises on bespoke and novel solar photovoltaic systems, including off grid systems.[9][10]

Narec Capital – A financial organisation run by Narec and Ashberg Limited.[11]

Narec Capital Risk Solutions – Beyond its existence, there is very little information on what this organisation does.[9]

Following its merger with ORE Catapult, the National Renewable Energy Centre now focuses on helping to de-risk and accelerate the development and commercialisation of the offshore renewable energy industry in the UK.

Operations

The National Renewable Energy Centre is involved in:

Wind turbine rotor blades

Product certification, verification and investigations for the next generation offshore wind turbines.[12][13][14][15]

Power trains and components

3MW and 15MW facilities that can perform independent performance and reliability assessments of full systems and components.[16][17]

Electrical networks

UKAS accredited laboratories with specialist test and measurement facilities to help develop technologies needed for developing power systems and exploring life extension opportunities for ageing assets.[18]

Subsea trials and demonstrations

Controlled onshore salt water location for all stages of technology development.[19]

Resource measurement and assessment

Open access facility for testing, calibrating and verifying remote sensor technologies[20]

Closed facilities

Clothier High Voltage Laboratory

The Clothier Electrical Testing Laboratory was opened in 1970 by A. Reyrolle & Company. Narec took over the facility in 2004, to use it to test the robustness of electrical infrastructure offshore locations to onshore sites.[21]

Although one of the few high voltage testing facilities in the world, the facility was closed by Narec in 2011 due to a lack of government funding.[22] Many parts of the lab were relocated to Narec's main campus in Blyth. The ruins of the original lab are now the property of Siemens.[23]

Current facilities

Charles Parsons Technology Centre

Built in 2004, this £5m facility contains a low voltage electrical laboratory for the testing of connecting renewable energy systems to the transmission and distribution grid.[24] Some of the equipment and staff from the closed Narec Clothier Electrical Testing Laboratory were moved to this facility.[25]

Training tower

This is a 27m high tower, for training of offshore wind technicians.[26]

Dry docks

Tests marine devices with three modified dry docks.[27]

Power train test facilities – 3MW and 15MW

Facilities that can perform independent performance and reliability assessments of full systems and components.[17]

European funded research

ORE Catapult is involved in a number of European funded research projects including Tidal EC, Optimus and LIFES50+.[30]

Conferences and papers

Narec staff have written papers which have appeared in journals and international energy conferences. These are mainly in the subjects of photovoltaics, wind, marine, and electrical infrastructure. A short list of some of these is given below:

- Snapper, An efficient and compact direct electric power take-off device for wave energy converters.[31]

- Availability and Estimation of Marine Renewable Energy Resources[32]

- Marine Renewables: A Development Route Map for the UK[33]

- Bivariate empirical mode decomposition and its contribution to wind turbine condition monitoring[34]

- Experimental tests of an air-cored PM tubular generator for direct drive wave energy converters[35]

- Fatigue testing of wind turbine blades with computational verification.[36]

- Ensuring Reliability for Offshore Wind – Large Testing Facilities.[37]

- Accelerating Technology Development for Round 3 Offshore Deployment.[38]

- Electrical Network Testing & Simulation: An effective method of testing the fault ride through capabilities of Small Scale Distributed Generation[39]

- Ensuring Reliability for Marine Renewable Drive Train Systems – Nautilus Testing Facilities[40]

- LGBC Silicon Solar Cell with modified bus bar suitable for high volume wire bonding[41]

- Process and device modelling for enhancement of silicon solar cell efficiency[42]

- An intelligent approach to the condition monitoring of large scale wind turbines[43]

- Lightning Arresters and Substation Protection[44]

- Study on laser parameters for silicon solar cells with LCP selective emitters[45]

- Low Cost, 100X point focus silicon concentrator cells made by the LGBC process[46]

- Laser Grooved Buried Contact Concentrator Solar Cells[47]

- Studying the Groove Profiles Produced for Fine Line Screen Printed Front Contacts in Laser Grooved Buried Contact Solar Cells.[48]

- Investigation of cross wafer uniformity of production line produced LGBC concentrator solar cells[49]

- Process Development of Coloured LGBC Solar Cells for BIPV Applications[47]

- Process optimisation for coloured laser grooved buried contact solar cells[50]

- Colour and Shape in Laser Grooved Buried Contact Solar Cells for Applications in the Built Environment[51]

- Fine-Line Screen Printing in Large Area Laser Grooved, Buried Contact Silicon Solar Cells[52]

- Progress of the LAB2LINE Laser Grooved Buried Contact Screen Printed Solar Cells Hybrid p-type Monocrystalline Process[53]

- Development of Laser Fired Contact (LFC) Rear Passivated Laser Groove Buried Contact (LGBC) Solar Cells Using Thin Wafers[54]

- The LAB2LINE laser grooved buried contact screen printed solar cells hybrid p-type monocrystaline process[55]

- Integrated process and device 'TCAD' for enhancement of C-Si solar cell efficiency[56]

- Screen printing in laser grooved buried contact solar cells: The LAB2LINE hybrid processes[57]

- Surface passivation by silicon nitride in Laser Grooved Buried Contact (LGBC) silicon solar cells[58]

- Optimisation of the front contact for low to medium concentrations in LGBC silicon solar cells[59]

- Laser Grooved Buried Contact Solar Cells for Concentration Factors up to 100X[60]

- Device Design and Process Optimisation for LGBC Solar Cells for Use Between 50X and 100X Concentration[61]

- Design and Optimisation of Laser Grooved Buried Contact Solar Cells for Use At Concentration Factors Up To 100X[62]

- Development of Laser Grooved Buried Contact Solar Cells for Use at Concentration Factors up to 100X[63]

- Front contact modelling of monocrystaline silicon laser grooved buried contact solar cells[64]

- Laser Grooved Buried Contact Concentrator Cells[65]

- PC1D modelling of the efficiency of laser grooved buried contact solar cells designed for use at concentration factors up to 100X[66]

- Front Dicing Technique for Pre-isolation of Concentrator Silicon Solar Cells[67]

- Environmental sustainability of concentrator PV systems: Preliminary LCA results of the APOLLON project[68]

- Process development of shape and colour in LGBC solar cells for BIPV applications[69]

- A summary of the Havemor project – Process development of shaped and coloured solar cells for BIPV applications[70]

- Process and device modelling for enhancement of silicon solar cell efficiency

- Technological and Financial Aspects of Laser Grooved Buried Contact Silicon Solar Cell Based Concentrator Systems[71]

- First results on the APOLLON project multi-approach for high efficiency integrated and intelligent concentrating PV modules (systems)[72]

References

- "Test & Demonstration assets – Catapult". ore.catapult.org.uk. Retrieved 8 December 2015.

- http://www.narec.co.uk Archived 16 February 2008 at the Wayback Machine

- http://www.strategyforsuccess.info/page/news/article.cfm?articleId=1400

- "OFFSHORE RENEWABLE ENERGY CATAPULT". CompaniesInTheUK.

- "ORE Catapult and Narec merge". reNEWS – Renewable Energy News. Retrieved 8 December 2015.

- "Narec to merge with Glasgow's Offshore Renewable Energy Catapult". journallive. Retrieved 8 December 2015.

- "Welcome to NaREC". narec.co.uk. Archived from the original on 16 February 2008.

- "Narec Distributed Energy – National Renewable Energy Centre Group". Narec Distributed Energy.

- "Failure Page". companieshouse.gov.uk.

- "Solar Capture Technologies – Home – Solar Capture Technologies". Solar Capture Technologies.

- journallive Administrator (4 July 2011). "Narec Capital looking to raise £300m of funding". journallive.

- "North American Windpower: ETI Invests In Narec Offshore Wind Test Facility". nawindpower.com. 7 July 2011.

- http://www.onenortheast.com/page/news/article.cfm?articleId=4863

- "Narec reveals plans for giant turbine blade testing facility". businessgreen.com. 14 December 2009.

- http://www.wig.co.uk/NAREC

- "Construction begins on the world's largest wind turbine drive train test facility". ETI. Retrieved 8 December 2015.

- "Samsung to test 7MW offshore turbine at UK's new Narec facility – Renewable Energy Focus". www.renewableenergyfocus.com. Retrieved 8 December 2015.

- "Catapult lab raises HV ceiling". reNEWS – Renewable Energy News. Retrieved 8 December 2015.

- "UK: Tekmar Demonstrates Its Cable Protection Systems at ORE Catapult". Subsea World News. Retrieved 8 December 2015.

- "Axys to deploy WindSentinel at UK's ORE Catapult". www.rechargenews.com. Retrieved 8 December 2015.

- http://www.nebusiness.co.uk/business-news/latest-business-news/2010/05/13/narec-in-advanced-talks-on-wind-turbine-tests-51140-26434889/2/

- "Plug could be pulled on testing lab". shieldsgazette.com.

- "Urban explorers highlight the decay of the highest voltage lab in the world". newstatesman.com.

- "onenortheast.co.uk".

- http://www.narec.co.uk/electrical_networks_info/

- Elsevier Ltd, The Boulevard, Langford Lane, Kidlington, Oxford, OX5 1GB, United Kingdom. "Narec's wind turbine training tower ready for use". renewableenergyfocus.com.CS1 maint: multiple names: authors list (link)

- "New boss takes over at NaREC". newspostleader.co.uk.

- "Conference programme – EWEA 2015 Event". www.ewea.org. Retrieved 8 December 2015.

- "New Modular Blade Dynamics Wind Turbine Blade Begins Testing In Blyth". CleanTechnica. 13 August 2015. Retrieved 8 December 2015.

- "Our community – Catapult". ore.catapult.org.uk. Retrieved 8 December 2015.

- http://www.snapperfp7.eu/content/download/3176/48090/version/1/file/569309f66625676599b4b79a2547f9a3.pdf

- http://www.narec.co.uk/cmsfiles/narec/pdf/wmtc2006programmefinal.pdf

- http://www.narec.co.uk/cmsfiles/narec/pdf/36703.pdf

- Yang, Wenxian; Court, Richard; Tavner, Peter J.; Crabtree, Christopher J. (2011). "Bivariate empirical mode decomposition and its contribution to wind turbine condition monitoring". Journal of Sound and Vibration. 330 (15): 3766–3782. Bibcode:2011JSV...330.3766Y. doi:10.1016/j.jsv.2011.02.027.

- M.A. Mueller-N.J. Baker-L. Ran-N.G. Chong- Hong Wei-P.J. Tavner-P. McKeever (January 2008). "IET Digital Library: Experimental tests of an air-cored PM tubular generator for direct drive wave energy converters". theiet.org: 747–751. doi:10.1049/cp:20080621.

- http://www.supergen-wind.org.uk/Phase1/docs/Court,%20Ridley,%20Jones,%20Bonnet%20and%20Dutton-17ICCM2009.pdf

- http://www.taplondon.co.uk/bweaoffshore/files/RichardCourt.pdf

- http://www.bwea30.com/pdf/BWEA30Programme.pdf

- http://cired.ir/CIRED2011/papers/CIRED2011_0030_final.pdf

- http://www.narec.co.uk/cmsfiles/narec/Published_Papers/ICOE2010_Nautilus_Paper_Jamie_Grimwade.pdf

- http://www.narec.co.uk/cmsfiles/narec/Published_Papers/2010_PVSAT6_-_LGBC_Silicon_Solar_Cell_with_modified_bus_bar_suitable_for_high_volume_wire_bonding.pdf

- http://www.narec.co.uk/cmsfiles/narec/Published_Papers/2010_PVSAT6_-_Process_and_device_modelling_for_enhancement_of_silicon_solar_cell_efficiency.pdf

- http://www.narec.co.uk/cmsfiles/narec/pdf/An_Intelligent_Approach_to_the_Condition_Monitoring_of.pdf

- http://www.narec.co.uk/cmsfiles/narec/pdf/Chris_Ebden.pdf

- http://www.narec.co.uk/cmsfiles/narec/pdf/Study_on_Laser_Parameters.pdf

- http://b-dig.iie.org.mx/BibDig/P05-0850/pdffiles/papers/157_666.pdf

- http://www.pvsat.org.uk/PVSAT-4%20_Programme_Final.pdf

- http://www.casaccia.enea.it/sicri/uk/articoli/fr-0810.htm

- "BLDSS". bl.uk.

- Devenport, S.; Roberts, S.; Heasman, K.C.; Cole, A.; Tregurtha, D.; Bruton, T.M. (2008). "Process optimisation for coloured laser grooved buried contact solar cells". 2008 33rd IEEE Photovolatic Specialists Conference. pp. 1–4. doi:10.1109/PVSC.2008.4922438. ISBN 978-1-4244-1640-0.

- WIP Wirtschaft und Infrastruktur GmbH & Co Planungs KG (2008). "EU PVSEC Proceedings". Eupvsec-proceedings.com. 1-5 September 2008: 3516–3519. doi:10.4229/23rdEUPVSEC2008-5BV.2.63.

- WIP Wirtschaft und Infrastruktur GmbH & Co Planungs KG (2008). "EU PVSEC Proceedings". Eupvsec-proceedings.com. 1-5 September 2008: 1677–1681. doi:10.4229/23rdEUPVSEC2008-2CV.5.28.

- http://www.narec.co.uk/cmsfiles/narec/Published_Papers/2CV_1_71.pdf

- "BLDSS". bl.uk.

- WIP Wirtschaft und Infrastruktur GmbH & Co Planungs KG (2009). "EU PVSEC Proceedings". Eupvsec-proceedings.com. 21-25 September 2009: 1318–1322. doi:10.4229/24thEUPVSEC2009-2CV.1.55.

- "Emerging Technologies and Materials – School of Electrical and Electronic Engineering – Newcastle University". ncl.ac.uk. Archived from the original on 4 September 2012.

- "Photovoltaics International".

- "Surface passivation by silicon nitride in Laser Grooved Buried Contact (LGBC) si". Harvard.edu. Bibcode:2009SuMi...45..234C. doi:10.1016/j.spmi.2008.10.044.

- "Optimisation of the Front Contact for Low to Medium Concentrations in LGBC Silicon Solar Cells". cnki.com.cn.

- Cole, A.; Heasman, K.C.; Mellor, A.; Roberts, S.; Bruton, T.M. (2006). "Laser Grooved Buried Contact Solar Cells for Concentration Factors up to 100x". 2006 IEEE 4th World Conference on Photovoltaic Energy Conference. pp. 834–837. doi:10.1109/WCPEC.2006.279586. ISBN 1-4244-0016-3.

- http://www.eurosun2006.org/Annex6_ES06_Book-of-Abstracts.pdf

- http://p12611.typo3server.info/.../21st_EU_PVSEC_Proceedings_Table_of..

- Bruton, T. M.; Roberts, S.; Mellor, A.; Heasman, K. C.; Cole, A. (2006). "Laser grooved buried contact sola... preview & related info – Mendeley". Conference Record of the 2006 IEEE 4Th World Conference on Photovoltaic Energy Conversion, Wcpec-4. 1: 834–837. doi:10.1109/WCPEC.2006.279586.

- "FRONT CONTACT MODELLING OF MONOCRYSTALLINE SILICON LASER GROOVED". Docstoc.com.

- http://www.concentrating-pv.org/marburg2007/program.html

- "BLDSS". bl.uk.

- WIP Wirtschaft und Infrastruktur GmbH & Co Planungs KG (2010). "EU PVSEC Proceedings". Eupvsec-proceedings.com. 6-10 September 2010: 941–945. doi:10.4229/25thEUPVSEC2010-1DV.5.28.

- "apollon-eu.org".

- "process development of shape and colour in lgbc solar cells for – Docstoc Search – Page 1". docstoc.com.

- WIP Wirtschaft und Infrastruktur GmbH & Co Planungs KG (2009). "EU PVSEC Proceedings". Eupvsec-proceedings.com. 21-25 September 2009: 4276–4279. doi:10.4229/24thEUPVSEC2009-5BV.2.80.

- http://www.concentrating-pv.org/darmstadt2009/papers.html

- Timo, G.; Martinelli, A.; Minuto, A.; Schineller, B.; Sagnes, I.; Jakomin, R.; Beaudoin, G.; Gogneau, Noelle; Noack, M.; Padovani, S.; Borshchov, S.; Kenny, R.; Sarno, A.; Georghiou, G.E; Zurru, P.; Sturm, M.; Wild - Scholten, M.; Bellia, G.; Gigliucci, G.; Medina, E.; Heasman, K.; Martinelli, G. (2009). "First results on the apollon project multi-approach for high efficiency integrated and intelligent concentrating PV modules (Systems)". 2009 34th IEEE Photovoltaic Specialists Conference (PVSC). pp. 002424–002429. doi:10.1109/PVSC.2009.5411295. ISBN 978-1-4244-2949-3.