Intercooler

An intercooler is a mechanical device used to cool a gas after compression. Compressing a gas increases its internal energy which in turn raises its temperature and reduces its density. An intercooler typically takes the form of a heat exchanger that removes waste heat in a gas compressor.[1] Intercoolers have a variety of applications, and can be found in air compressors, air conditioners, refrigeration, and gas turbines, and automotive engines, for example. They are widely known as an air-to-air or air-to-liquid cooler for forced induction (turbocharged or supercharged) internal combustion engines, used to improve volumetric efficiency. This is accomplished by increasing intake air density through nearly constant pressure cooling.

Automotive intercoolers were first introduced in 1977 on the Porsche 911.

Air compressors

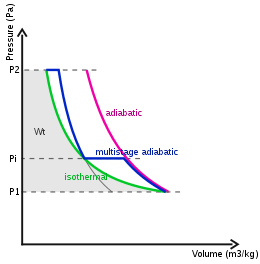

The two-stages cooling (blue) reduces the useful work wu given to air: the process is more energy efficient and closer to perfect isothermal compression, but its energy conversion efficiency is lower.[2]

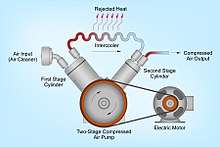

Intercoolers are used to remove the waste heat from the first stage of two-stage air compressors. Two-stage air compressors are manufactured because of their inherent efficiency. The cooling action of the intercooler is principally responsible for this higher efficiency, bringing it closer to Carnot efficiency. Removing the heat-of-compression from the discharge of the first stage has the effect of densifying the air charge. This, in turn, allows the second stage to produce more work from its fixed compression ratio. Adding an intercooler to the setup requires additional investments.

Internal combustion engines

Intercoolers increase the efficiency of the induction system by reducing induction air heat created by the supercharger or turbocharger and promoting more thorough combustion. This removes the heat of compression (i.e., the temperature rise) that occurs in any gas when its pressure is raised (i.e. its unit mass per unit volume - density - is increased).

A decrease in intake air charge temperature sustains use of a more dense intake charge into the engine, as a result of forced induction. The lowering of the intake charge air temperature also eliminates the danger of pre-detonation (knock) of the fuel/air charge prior to timed spark ignition. This preserves the benefits of more fuel/air burn per engine cycle, increasing the output of the engine.

Intercoolers also eliminate the need for using the wasteful method of lowering intake charge temperature by the injection of excess fuel into the cylinders' air induction chambers to cool the intake air charge prior to its flowing into the cylinders. This wasteful practice (before intercoolers were used) nearly eliminated the gain in engine efficiency from forced induction, but was necessitated by the greater need to prevent at all costs the engine damage that pre-detonation engine knocking causes.[3]

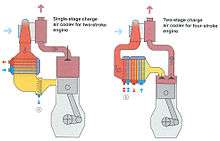

The inter prefix in the device name originates from its use as a cooler in between compression cycles. Typically in automobiles the intercooler is placed between the turbocharger (or supercharger) and the engine (the piston compression produces the next compression cycle). A more descriptive or informative term would be aftercooler/chargecooler, thereby removing any ambiguity that the vehicles have sequential two-stage turbocharging. Aircraft engines are sometimes built with charge air coolers that were installed between multiple stages of forced induction, thus the designation of inter. In a vehicle fitted with twin stage turbocharging, it is possible to have both an intercooler (between the two turbocharger units) and an aftercooler (between the second-stage turbo and the engine). The JCB Dieselmax diesel land speed record-holding car is an example of such a system. In general, an intercooler or aftercooler is said to be a charge-air cooler.

Intercoolers can vary dramatically in size, shape and design, depending on the performance and space requirements of the entire supercharger system. Common spatial designs are front mounted intercoolers (FMIC), top mounted intercoolers (TMIC) and hybrid mount intercoolers (HMIC). Each type can be cooled with an air-to-air system, air-to-liquid system, or a combination of both.

In supercharged engines

Turbochargers and superchargers are engineered to force more air mass (and thus more oxygen molecules) into an engine's intake manifold and combustion chamber. Intercooling is a method used to compensate for heating caused by supercharging, a natural byproduct of the semi-adiabatic compression process. Increased air pressure can result in an excessively hot intake charge, significantly reducing the performance gains of supercharging due to decreased density. Increased intake charge temperature can also increase the cylinder combustion temperature, causing detonation, excessive wear, or heat damage to an engine block or pistons.

Passing a compressed and heated intake charge through an intercooler reduces its temperature (due to heat rejection) and pressure (due to flow restriction of fins). If the device is properly engineered, the relative decrease in temperature is greater than the relative loss in pressure, resulting in a net increase in density. This increases system performance by recovering some losses of the inefficient compression process by rejecting heat to the atmosphere. Additional cooling can be provided by externally spraying a fine mist onto the intercooler surface, or even into the intake air itself, to further reduce intake charge temperature through evaporative cooling.

Intercoolers that exchange their heat directly with the atmosphere are designed to be mounted in areas of an automobile with maximum air flow. These types are mainly mounted in front mounted systems (FMIC). Cars such as the Nissan Skyline, Saab, Volvo 200 Series Turbo, Volvo 700 Series (and 900 series) turbo, Dodge SRT-4, 1st gen Mazda MX-6, Mitsubishi Lancer Evolution and Chevrolet Cobalt SS all use front mounted intercooler(s) mounted near the front bumper, in line with the car's radiator.

Many other turbo-charged cars, particularly where the aesthetics of the car are not to be compromised by top mount scoops, such as the Toyota Supra (JZA80 only), Nissan 300ZX Twin Turbo, Nissan Silvia (S13/14/14a/15), Nissan 180sx, Mitsubishi 3000gt, Saab 900, Volkswagen, Fiat Turbo diesels, Audi TT, and Turbo Mitsubishi Eclipse use side-mounted air-to-air intercoolers (SMIC), which are mounted in the front corner of the bumper or in front of one of the wheels. Side-mounted intercoolers are generally smaller, mainly due to space constraints, and sometimes two are used to gain the performance of a larger, single intercooler. Cars such as the Subaru Impreza WRX, MINI Cooper S, Toyota Celica GT-Four, Nissan Pulsar GTI-R, Acura RDX, Mazdaspeed3, Mazdaspeed6, and the PSA Peugeot Citroën turbo diesels, use air-to-air top mounted intercoolers (TMIC) located on top of the engine. Air is directed through the intercooler through the use of a hood scoop. In the case of the PSA cars, the air flows through the grille above the front bumper, then through under-hood ducting. Top mounted intercoolers sometimes suffer from heat diffusion due to proximity with the engine, warming them and reducing their overall efficiency. Some World Rally Championship cars use a reverse-induction system design whereby air is forced through ducts in the front bumper to a horizontally mounted intercooler.

Because FMIC systems require open bumper design for optimal performance, the entire system is vulnerable to debris. Some engineers choose other mount locations due to this reliability concern. FMICs can be located in front of or behind the radiator, depending on the heat dissipation needs of the engine.

As well as allowing a greater mass of air to be admitted to an engine, intercoolers have a key role in controlling the internal temperatures in a turbocharged engine. When fitted with a turbo (as with any form of supercharging), the engine's specific power is increased, leading to higher combustion and exhaust temperatures. The exhaust gases passing through the turbine section of the turbocharger are usually around 450 °C (840 °F), but can be as high as 1000 °C (1830 °F) under extreme conditions. This heat passes through the turbocharger unit and contributes to the heating of the air being compressed in the compressor section of the turbo. If left uncooled, this hot air enters the engine, further increasing internal temperatures. This leads to a build-up of heat that will eventually stabilise, but this may be at temperatures in excess of the engine's design limits- 'hot spots' at the piston crown or exhaust valve can cause warping or cracking of these components. High air charge temperatures will also increase the possibility of pre-ignition or detonation. Detonation causes damaging pressure spikes in the engine's cylinders, which can quickly damage an engine. These effects are especially found in modified or tuned engines running at very high specific power outputs. An efficient intercooler removes heat from the air in the induction system, preventing the cyclic heat build-up via the turbocharger, allowing higher power outputs to be achieved without damage.

Compression by the turbocharger causes the intake air to heat up and heat is added due to compressor inefficiencies (adiabatic efficiency). This is actually the greater cause of the increase in air temperature in an air charge. The extra power obtained from forced induction is due to the extra air available to burn more fuel in each cylinder. This sometimes requires a lower compression ratio be used, to allow a wider mapping of ignition timing advance before detonation occurs (for a given fuel's octane rating). On the other hand, a lower compression ratio generally lowers combustion efficiency and costs power.

Some high performance tuning companies measure the temperature before and after the intercooler to ensure the output temperature is as close to ambient as possible (without additional cooling; water/liquid gas spray kits).

Air-to-liquid intercoolers

.jpg)

Air-to-liquid intercoolers, also known as charge air coolers, are heat exchangers that transfer intake charge heat to an intermediate liquid, usually water, which finally rejects heat to the air. These systems use radiators in other locations, usually due to space constraints, to reject unwanted heat, similar to an automotive radiator cooling system. Air-to-liquid intercoolers are usually heavier than their air-to-air counterparts due to additional components making up the system (water circulation pump, radiator, fluid, and plumbing). The Toyota Celica GT-Four had this system from 1988 to 1989, 1994 to 1999, also in the Carlos Sainz Rally Championship Version from 1990 to 1993. The 1989-1993 Subaru Legacy with the 2.0 L DOHC flat-4 engine also used a top installed air-to-water intercooler on the GT and RS models sold in Japan, Europe, and Australia.

A big advantage of the air-to-liquid setup is the lower overall pipe and intercooler length, which offers faster response (lowers turbo lag) , giving peak boost faster than most front-mount intercooler setups. Some setups have reservoirs that can hold ice, producing intake temperatures lower than ambient air, giving a big advantage (but of course, ice would need constant replacement).

Ford had adopted the technology when they decided to use forced induction (via Supercharger) on their Mustang Cobra and Ford Lightning truck platforms. It uses a water/glycol mixture intercooler inside the intake manifold, just under the supercharger, and has a long heat exchanger front mounted, all powered by a Bosch pump made for Ford. Ford still uses this technology today with their Shelby GT500. The 2005-2007 Chevrolet Cobalt SS Supercharged also utilizes a similar setup.

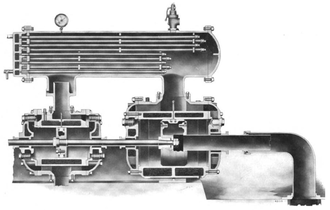

Air-to-liquid intercoolers are by far the most common form of intercooler found on marine engines, given that a limitless supply of cooling water is available and most engines are located in closed compartments where obtaining a good flow of cooling air for an air-to-air unit would be difficult. Marine intercoolers take the form of a tubular heat exchanger with the air passing through a series of tubes and cooling water circulating around the tubes within the unit's casing. The source of water for the intercooler depends on the exact cooling system fitted to the engine. Most marine engines have fresh water circulating within them which is passed through a heat exchanger cooled by sea water. In such a system, the intercooler will be attached to the sea water circuit and placed before the engine's own heat exchanger to ensure a supply of cool water.

Charge air cooler

A charge air cooler is used to cool engine air after it has passed through a turbocharger, but before it enters the engine. The idea is to return the air to a lower temperature, for the optimum power for the combustion process within the engine.

Charge air coolers range in size depending on the engine. The smallest are most often referred to as intercoolers and are attached to automobile engines or truck engines. The largest are reserved for use on huge marine diesel engines, and can weigh over 2 tonnes (see picture).

Marine diesel engine charge-air coolers are still manufactured in Europe, despite the very largest engines mostly being built in the Far East. Vestas aircoil A/S and GEA are the oldest makers still in business.

The first marine diesel engine charge air cooler was built by Vestas aircoil A/S in 1956.

There is some confusion in terminology between aftercooler, intercooler, and charge-air cooler. In the past, aircraft engines would run turbochargers in stages, where the first stage compressor would feed the inlet of the second stage compressor that would further compress the air before it enters the engine. Due to the extremely high pressures that would develop, an air cooler was positioned between the first and second stage compressors. That cooler was the "intercooler".

Another cooler would be positioned after the second stage, which was the final compressor stage, and that was the "aftercooler". An aftercooler was the cooler whose outlet fed the engine.

Charge-air cooler is simply an all-encompassing term referring to a system that cools the compressed charge air before it is routed into the engine. Usually a charge-air cooler means an air-to-air cooler where the heat is rejected using ambient air flowing through the heat exchanger, much like the engine's coolant radiator. While the multi-stage turbocharger systems are still in use in some tractor pull classes, selected high-performance diesels, and are also being used on newer late model commercial diesels, the term intercooler and aftercooler are used synonymously today. The term intercooler is widely used to mean in-between the Turbocharger and the engine. Both terms, intercooler or aftercooler, are correct, but this is the origin of the two terms that are used interchangeably by all levels of experts.

An intercooler, or "charge-air cooler", is an air-to-air or air-to-liquid heat exchange device used on turbocharged and supercharged (forced induction) internal combustion engines to improve their volumetric efficiency by increasing intake air-charge density through isochoric cooling. A decrease in air intake temperature provides a denser intake charge to the engine and allows more air and fuel to be combusted per engine cycle, increasing the output of the engine.

The inter- prefix in the device name originates from historic compressor designs. In the past, aircraft engines were built with charge-air coolers that were installed between multiple stages of supercharging, thus the designation of inter. Modern automobile designs are technically designated aftercoolers because of their placement at the end of supercharging chain. This term is now considered archaic in modern automobile terminology since most forced induction vehicles have single-stage superchargers or turbochargers. In a vehicle fitted with two-stage turbocharging, it is possible to have both an intercooler (between the two turbocharger units) and an aftercooler (between the second-stage turbo and the engine). In general, an intercooler or aftercooler is said to be a charge-air cooler. Text taken from Av-Tekk Charge-Air Coolers website

Notes

| Wikimedia Commons has media related to Intercoolers. |

- Dictionary definitions:

- intercooler, n. Oxford English Dictionary. Second edition, 1989; online version December 2011. Accessed 31 December 2011. First published in A Supplement to the OED II, 1976.

- Intercooler. Reference.com

- Intercooler. Merriam-Webster

- Young, Stephen M. (2017-03-01). Simulating air absorption in a hydraulic air compressor (pdf) (Thesis). Laurentian University. p. 8-10.

- "Garrett Turbochargers - Performance Parts and Accessories - D&W Performance". Dwperformance.com. Archived from the original on 2010-10-26. Retrieved 2010-07-04.