Experimental Breeder Reactor II

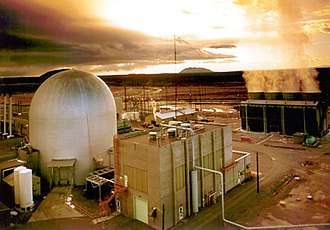

Experimental Breeder Reactor-II (EBR-II) is a sodium-cooled fast reactor designed, built and operated by Argonne National Laboratory at the National Reactor Testing Station in Idaho.[1] It was shut down in 1994. Custody of the reactor was transferred to Idaho National Laboratory after its founding in 2005.

Initial operations began in July 1964 and it achieved criticality in 1965 at a total cost of more than US$32 million. The original emphasis in the design and operation of EBR-II was to demonstrate a complete breeder-reactor power plant with on-site reprocessing of solid metallic fuel. Fuel elements enriched to about 67% 235-U were sealed in stainless steel tubes and removed when they reached about 65% enrichment. The tubes were unsealed and reprocessed to remove neutron poisons, mixed with fresh 235-U to increase enrichment, and placed back in the reactor.

Testing of the original breeder cycle ran until 1969, after which time the reactor was used to test concepts for the Integral Fast Reactor concept. In this role, the high-energy neutron environment of the EBR-II core was used for testing fuels and materials for future, larger, liquid metal reactors. As part of these experiments, in 1986 EBR-II underwent an experimental shutdown simulating complete cooling pump failure. It demonstrated its ability to self-cool its fuel through natural convection of the sodium coolant during the decay heat period following the shutdown. It was used in the IFR support role, and many other experiments, until it was decommissioned in September 1994.

At full power operation, which it reached in September 1969, EBR-II produced about 62.5 megawatts of heat and 20 megawatts of electricity through a conventional three-loop steam turbine system and tertiary forced-air cooling tower. Over its lifetime it has generated over two billion kilowatt-hours of electricity, providing a majority of the electricity and also heat to the facilities of the Argonne National Laboratory-West.

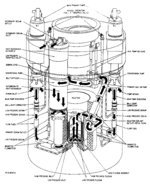

Design

The fuel consists of uranium rods 5 millimeters in diameter and 33 cm (13 inches) long . Enriched to 67% uranium-235 when fresh, the concentration dropped to approximately 65% upon removal. The rods also contained 10% zirconium. Each fuel element is placed inside a thin-walled stainless steel tube along with a small amount of sodium metal. The tube is welded shut at the top to form a unit 73 cm (29 inches) long. The purpose of the sodium is to function as a heat-transfer agent. As more and more of the uranium undergoes fission, it develops fissures and the sodium enters the voids. It extracts an important fission product, caesium-137, and hence becomes intensely radioactive. The void above the uranium collects fission gases, mainly krypton-85. Clusters of the pins inside hexagonal stainless steel jackets 234 cm (92 inches) long are assembled honeycomb-like; each unit has about 4.5 kg (10 lbs) of uranium. Altogether, the core contains about 308 kg (680 lbs) of uranium fuel, and this part is called the driver.

The EBR-II core can accommodate as many as 65 experimental sub-assemblies for irradiation and operational reliability tests, fueled with a variety of metallic and ceramic fuels—the oxides, carbides, or nitrides of uranium and plutonium, and metallic fuel alloys such as uranium-plutonium-zirconium fuel. Other sub-assembly positions may contain structural-material experiments.

Passive safety

The pool-type reactor design of the EBR-II provides passive safety: the reactor core, its fuel handling equipment, and many other systems of the reactor are submerged under molten sodium. By providing a fluid which readily conducts heat from the fuel to the coolant, and which operates at relatively low temperatures, the EBR-II takes maximum advantage of expansion of the coolant, fuel, and structure during off-normal events which increase temperatures. The expansion of the fuel and structure in an off-normal situation causes the system to shut down even without human operator intervention. In April 1986, two special tests were performed on the EBR-II, in which the main primary cooling pumps were shut off with the reactor at full power (62.5 megawatts, thermal). By not allowing the normal shutdown systems to interfere, the reactor power dropped to near zero within about 300 seconds. No damage to the fuel or the reactor resulted. The same day, this demonstration was followed by another important test. With the reactor again at full power, flow in the secondary cooling system was stopped. This test caused the temperature to increase, since there was nowhere for the reactor heat to go. As the primary (reactor) cooling system became hotter, the fuel, sodium coolant, and structure expanded, and the reactor shut down. This test showed that it will shut down using inherent features such as thermal expansion, even if the ability to remove heat from the primary cooling system is lost.[2]

EBR-II is now defueled. The EBR-II shutdown activity also includes the treatment of its discharged spent fuel using an electrometallurgical fuel treatment process in the Fuel Conditioning Facility located next to the EBR-II.

The clean-up process for EBR-II includes the removal and processing of the sodium coolant, cleaning of the EBR-II sodium systems, removal and passivating of other chemical hazards and placing the deactivated components and structure in a safe condition.

Related facilities

The objective of the EBR-II was to demonstrate the operation of a sodium-cooled fast reactor power plant with on-site reprocessing of metallic fuel. In order to meet this objective of on-site reprocessing, the EBR-II was part of a wider complex of facilities, consisting of

- Fuel Conditioning Facility: facility for reprocessing and treating spent fuel from the EBR-II and other reactors, using an electrorefiner for electrometallurgical treatment of spent fuel

- Fuel Manufacturing Facility: facility for the manufacturing of metallic fuel elements

- Hot Fuels Examination Facility: a "hot-cell" complex for handling and examining highly radioactive materials remotely

- Sodium Processing Facility: facility for processing of reactive sodium into low-level waste

Integral Fast Reactor

The EBR-II has served as prototype of the Integral Fast Reactor (IFR), which was the intended successor to the EBR-II. The IFR program was started in 1983, but funding was withdrawn by U.S. Congress in 1994, three years before the intended completion of the program. The Nuclear Energy division of General Electric, which was involved in the development of the IFR, has presented a design for a commercial version of the IFR: the S-PRISM reactor.

Gallery

EBR-II

EBR-II Electrorefiner

Electrorefiner Cathode processor

Cathode processor Control room of the EBR-II in 1986

Control room of the EBR-II in 1986 Schema of the EBR-II

Schema of the EBR-II Schema of the spent fuel treatment process

Schema of the spent fuel treatment process

See also

References

- Citations

- Bibliography

- Till, Charles; Chang, Yoon Il (2011). Plentiful energy : the story of the integral fast reactor, the complex history of a simple reactor technology, with emphasis on its scientific basis for non-specialists. ISBN 1466384603.

External links

- EBR-II at "Reactors designed by Argonne National Laboratory" web site.

- Experimental Breeder Reactor-II (21 MB) Leonard J. Koch

- Westfall, Catherine (Feb 2004). "Vision and reality: The EBR-II story" (PDF). Nuclear News: 25–32.

- Passively safe reactors rely on nature to keep them cool