Electroplating

Electroplating is a general name for processes that create a metal coating on a solid substrate through the reduction of cations of that metal by means of a direct electric current. The part to be coated acts as the cathode (negative electrode) of an electrolytic cell; the electrolyte is a solution of a salt of the metal to be coated; and the anode (positive electrode) is usually either a block of that metal, or of some inert conductive material. The current is provided by an external power supply.

Electroplating is widely used in industry and decorative arts to improve the surface qualities of objects—such as resistance to abrasion and corrosion, lubricity, reflectivity, electrical conductivity, or appearance. It may also be used to build up thickness on undersized or worn-out parts, or to manufacture metal plates with complex shape, a process called electroforming. It is also used to purify metals such as copper.

The term "electroplating" may also be used occasionally for processes that use an electric current to achieve oxidation of anions on to a solid substrate, as in the formation of silver chloride on silver wire to make silver/silver-chloride electrodes.

Electropolishing, a process that uses an electric current to remove metal cations from the surface of a metal object, may be thought of as the opposite of electroplating.[1]

Process

.svg.png)

4. A copper anode is used to replenish the electrolyte with copper cations Cu2+

as they are plated out at the cathode.

The electrolyte should contain positive ions (cations) of the metal to be deposited. These cations are reduced at the cathode to the metal in the zero valence state. For example, the electrolyte for copper plating can be a solution of copper(II) sulphate, which dissociates into Cu2+ cations and SO2−

4 anions. At the cathode, the Cu2+ is reduced to metallic copper by gaining two electrons.

When the anode is made of the coating metal, the opposite reaction may occur there, turning it into dissolved cations. For example, copper would be oxidized at the anode to Cu2+ by losing two electrons. In this case, the rate at which the anode is dissolved will be equal to the rate at which the cathode is plated and thus the ions in the electrolyte bath are continuously replenished by the anode. The net result is the effective transfer of metal from the anode source to the cathode.[2]

The anode may instead be made of a material that resists electrochemical oxidation, such as lead or carbon. Oxygen, hydrogen peroxide, or some other byproducts are then produced at the anode instead. In this case, ions of the metal to be plated must be periodically replenished in the bath as they are drawn out of the solution.[3]

The plating is most commonly a single metallic element, not an alloy. However, some alloys can be electrodeposited, notably brass and solder. Plated "alloys" are not true alloys, i.e. solid solutions, but rather discrete tiny crystals of the metals being plated. In the case of plated solder, it is sometimes deemed necessary to have a "true alloy", and the plated solder is melted to allow the Tin and Lead to combine to form a true alloy. The true alloy is more corrosion resistant than the as-plated alloy.

Many plating baths include cyanides of other metals (such as potassium cyanide) in addition to cyanides of the metal to be deposited. These free cyanides facilitate anode corrosion, help to maintain a constant metal ion level and contribute to conductivity. Additionally, non-metal chemicals such as carbonates and phosphates may be added to increase conductivity.

When plating is not desired on certain areas of the substrate, stop-offs are applied to prevent the bath from coming in contact with the substrate. Typical stop-offs include tape, foil, lacquers, and waxes.[4]

The ability of a plating to cover uniformly is called throwing power; the better the throwing power the more uniform the coating.[5]

Strike

Initially, a special plating deposit called a strike or flash may be used to form a very thin (typically less than 0.1 μm thick) plating with high quality and good adherence to the substrate. This serves as a foundation for subsequent plating processes. A strike uses a high current density and a bath with a low ion concentration. The process is slow, so more efficient plating processes are used once the desired strike thickness is obtained.

The striking method is also used in combination with the plating of different metals. If it is desirable to plate one type of deposit onto a metal to improve corrosion resistance but this metal has inherently poor adhesion to the substrate, a strike can be first deposited that is compatible with both. One example of this situation is the poor adhesion of electrolytic nickel on zinc alloys, in which case a copper strike is used, which has good adherence to both.[3]

Electrochemical deposition

Electrochemical deposition is generally used for the growth of metals and conducting metal oxides because of the following advantages: the thickness and morphology of the nanostructure can be precisely controlled by adjusting the electrochemical parameters; relatively uniform and compact deposits can be synthesized in template-based structures; higher deposition rates are obtained; and the equipment is inexpensive due to the non-requirements of either a high vacuum or a high reaction temperature.[6][7][8]

Pulse electroplating

The pulse electroplating or pulse electrodeposition (PED) process involves the swift alternating of the electrical potential or current between two different values resulting in a series of pulses of equal amplitude, duration and polarity, separated by zero current. By changing the pulse amplitude and width, it is possible to change the deposited film's composition and thickness.[9]

The experimental parameters of pulse electroplating usually consist of peak current/potential, duty cycle, frequency and effective current/potential. Peak current/potential is the maximum setting of electroplating current or potential. Duty cycle is the effective portion of time in certain electroplating period with the current or potential applied. The effective current/potential is calculated by multiplying the duty cycle and peak value of current or potential. Pulse electroplating could help to improve the quality of electroplated film and release the internal stress built up during fast deposition. Combination of the short duty cycle and high frequency could decrease the surface cracks. However, in order to maintain the constant effective current or potential, a high performance power supply may be required to provide high peak current/potential and fast switch. Another common problem of pulse electroplating is that the anode material could get plated and contaminated during the reverse electroplating, especially for the high cost, inert electrode such as platinum.

Other factors that could affect the pulse electroplating include temperature, anode-to-cathode gap and stirring. Sometimes the pulse electroplating can be performed in heated electroplating bath to increase the depositing rate since the rate of almost all the chemical reaction increases exponentially with temperature per Arrhenius law. The anode-to-cathode gap is related to the current distribution between anode and cathode. Small gap to sample area ratio may cause uneven distribution of current and affect the surface topology of plated sample. Stirring may increase the transfer/diffusion rate of metal ions from bulk solution to the electrode surface. Stirring setting varies for different metal electroplating processes.

Brush electroplating

A closely related process is brush electroplating, in which localized areas or entire items are plated using a brush saturated with plating solution. The brush, typically a stainless steel body wrapped with an absorbent cloth material that both holds the plating solution and prevents direct contact with the item being plated, is connected to the anode of a low voltage direct current power source, and the item to be plated connected to the cathode. The operator dips the brush in plating solution then applies it to the item, moving the brush continually to get an even distribution of the plating material.

Brush electroplating has several advantages over tank plating, including portability, ability to plate items that for some reason cannot be tank plated (one application was the plating of portions of very large decorative support columns in a building restoration), low or no masking requirements, and comparatively low plating solution volume requirements. Disadvantages compared to tank plating can include greater operator involvement (tank plating can frequently be done with minimal attention), and inability to achieve as great a plate thickness.

Hard chrome in brush electroplating

Hard chrome is one of the most common plating materials used for hard plating and electroplating, due to its strength, resistance and sleek finish. However, chromium is very dangerous in its hexavalent state. When inhaled or consumed, airborne Cr6+[JT2] has been linked to lung cancer and causes damage to the throat, mouth and nose.

This is because, in its hexavalent state, chromium has carcinogenic and teratogenic properties, which has a mutagenic effect on cells.

Every year, 558,000 US technicians are exposed to hexavalent chromium in the workplace, with those working in the electroplating, welding and painting industries are most at risk, due to increased exposure to high levels of Cr6+ compounds.[10]

Because of the dangers linked to hexavalent chromium, finding safer, eco-friendly alternatives has been a main driver of brush electroplating research for the last decade. One alternative that has been developed is metal matrix composites (MMC). MMC offers unique and superior characteristics to metal plating solutions including hardness, wear resistance, and oxidation protection at high temperatures. This chrome alternative MMC includes cobalt chromium carbide, nickel tungsten carbide and nickel chromium carbide.[11]

Barrel plating

This technique of electroplating is one of the most common used in the industry for large numbers of small objects. The objects are placed in a barrel-shaped non-conductive cage, and then immersed in the chemical bath containing suspended atoms of the metal that is to be plated onto them. The barrel is then rotated, and electrical currents are run through the various pieces in the barrel which complete circuits as they touch one another. The result is a very uniform and efficient plating process, though the finish on the end products will likely suffer from abrasion during the plating process. It is unsuitable for highly ornamental or precisely engineered items.[12]

Cleanliness

Cleanliness is essential to successful electroplating, since molecular layers of oil can prevent adhesion of the coating. ASTM B322 is a standard guide for cleaning metals prior to electroplating. Cleaning includes solvent cleaning, hot alkaline detergent cleaning, electrocleaning, and acid treatment etc. The most common industrial test for cleanliness is the waterbreak test, in which the surface is thoroughly rinsed and held vertical. Hydrophobic contaminants such as oils cause the water to bead and break up, allowing the water to drain rapidly. Perfectly clean metal surfaces are hydrophilic and will retain an unbroken sheet of water that does not bead up or drain off. ASTM F22 describes a version of this test. This test does not detect hydrophilic contaminants, but electroplating can displace these easily since the solutions are water-based. Surfactants such as soap reduce the sensitivity of the test and must be thoroughly rinsed off.

Effects

Electroplating changes the chemical, physical, and mechanical properties of the workpiece. An example of a chemical change is when nickel plating improves corrosion resistance. An example of a physical change is a change in the outward appearance. An example of a mechanical change is a change in tensile strength or surface hardness which is a required attribute in tooling industry.[13] Electroplating of acid gold on underlying copper- or nickel-plated circuits reduces contact resistance as well as surface hardness. Copper-plated areas of mild steel act as a mask if case hardening of such areas are not desired. Tin-plated steel is chromium-plated to prevent dulling of the surface due to oxidation of tin.

Electroplating, or electroless plating may be used as a way to render a metal part radioactive, by using an aqueous solution prepared from nickel–phosphorus concentrates which contain radioactive hypophosphite 32P ions.[14]

Alternatives to electroplating

There are a number of alternative processes to produce metallic coatings on solid substrates that so not involve electrolytic reduction:

- Electroless plating uses a bath containing metal ions and chemicals that will reduce them to the metal by redox reactions. The reaction should be autocatalytic, so that new metal will be deposited over the growing coating, rather than precipitated as a powder through the whole bath at once. Electroless processes are widely used to deposit nickel-phosphorus or nickel-boron alloys for wear and corrosion resistance, silver for mirror-making, copper for printed circuit boards, and many more. A major advantage of these processes over electroplating is that they can produce coatings of uniform thickness over surfaces of arbitrary shape, even inside holes, and the substrate need not be electrically conducting. Another major benefit is that they don't need power sources or especially shaped anodes. Disadvantages include lower deposition speed, consumption of relatively expensive chemicals, and limited choice of coating metals.

- Immersion coating processes exploit displacement reactions in which the subtrate metal is oxidized to soluble ions while ions of the coating metal get reduced and deposited in its place. This process is limited to very thin coatings, since the reaction stops after the subtrate has been completely covered. Nevertheless it has some important applications, such as the electroless nickel immersion gold (ENIG) process used to obtain gold-plated electrical contacts on printed circuit boards.

- Sputtering uses a strong electron beam to ejectmicroscopic particles of the metal onto the substrate in a vaccum.

- Physical vapor deposition transfer the metal onto the subtrate by evaporating it.

- Chemical vapor deposition uses a gas containing a volatile compound of the metal, which gets deposited onto the substrate as a result of a chemical reaction.

History

Modern electrochemistry was invented by Italian chemist Luigi Valentino Brugnatelli in 1805. Brugnatelli used his colleague Alessandro Volta's invention of five years earlier, the voltaic pile, to facilitate the first electrodeposition. Brugnatelli's inventions were suppressed by the French Academy of Sciences and did not become used in general industry for the following thirty years. By 1839, scientists in Britain and Russia had independently devised metal-deposition processes similar to Brugnatelli's for the copper electroplating of printing press plates.

Boris Jacobi in Russia not only rediscovered galvanoplastics, but developed electrotyping and galvanoplastic sculpture. Galvanoplastics quickly came into fashion in Russia, with such people as inventor Peter Bagration, scientist Heinrich Lenz and science fiction author Vladimir Odoyevsky all contributing to further development of the technology. Among the most notorious cases of electroplating usage in mid-19th century Russia were gigantic galvanoplastic sculptures of St. Isaac's Cathedral in Saint Petersburg and gold-electroplated dome of the Cathedral of Christ the Saviour in Moscow, the tallest Orthodox church in the world.[15]

Soon after, John Wright of Birmingham, England discovered that potassium cyanide was a suitable electrolyte for gold and silver electroplating. Wright's associates, George Elkington and Henry Elkington were awarded the first patents for electroplating in 1840. These two then founded the electroplating industry in Birmingham from where it spread around the world. The Woolrich Electrical Generator of 1844, now in Thinktank, Birmingham Science Museum, is the earliest electrical generator used in industry.[16] It was used by Elkingtons.[17][18][19]

The Norddeutsche Affinerie in Hamburg was the first modern electroplating plant starting its production in 1876.[20]

As the science of electrochemistry grew, its relationship to electroplating became understood and other types of non-decorative metal electroplating were developed. Commercial electroplating of nickel, brass, tin, and zinc were developed by the 1850s. Electroplating baths and equipment based on the patents of the Elkingtons were scaled up to accommodate the plating of numerous large scale objects and for specific manufacturing and engineering applications.

The plating industry received a big boost with the advent of the development of electric generators in the late 19th century. With the higher currents available, metal machine components, hardware, and automotive parts requiring corrosion protection and enhanced wear properties, along with better appearance, could be processed in bulk.

The two World Wars and the growing aviation industry gave impetus to further developments and refinements including such processes as hard chromium plating, bronze alloy plating, sulfamate nickel plating, along with numerous other plating processes. Plating equipment evolved from manually operated tar-lined wooden tanks to automated equipment, capable of processing thousands of kilograms per hour of parts.

One of the American physicist Richard Feynman's first projects was to develop technology for electroplating metal onto plastic. Feynman developed the original idea of his friend into a successful invention, allowing his employer (and friend) to keep commercial promises he had made but could not have fulfilled otherwise.[21]

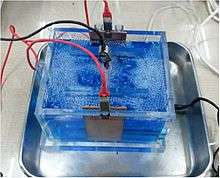

Hull cell

The Hull cell is a type of test cell used to qualitatively check the condition of an electroplating bath. It allows for optimization for current density range, optimization of additive concentration, recognition of impurity effects and indication of macro-throwing power capability.[22] The Hull cell replicates the plating bath on a lab scale. It is filled with a sample of the plating solution, an appropriate anode which is connected to a rectifier. The "work" is replaced with a Hull cell test panel that will be plated to show the "health" of the bath.

The Hull cell is a trapezoidal container that holds 267 mL of solution. This shape allows one to place the test panel on an angle to the anode. As a result, the deposit is plated at different current densities which can be measured with a hull cell ruler. The solution volume allows for a quantitative optimization of additive concentration: 1 gram addition to 267 mL is equivalent to 0.5 oz/gal in the plating tank.[23]

Haring–Blum cell

The Haring–Blum cell is used to determine the macro throwing power of a plating bath. The cell consists of two parallel cathodes with a fixed anode in the middle. The cathodes are at distances from the anode in the ratio of 1:5. The macro throwing power is calculated from the thickness of plating at the two cathodes when a direct current is passed for a specific period of time. The cell is fabricated out of perspex or glass.[24][25]

References

- https://www.electro-glo.com/faqs/

- Dufour 2006, p. IX-1.

- Dufour 2006, p. IX-2

- Dufour 2006, p. IX-3

- "Pollution Prevention Technology Profile Trivalent Chromium Replacements for Hexavalent Chromium Plating" (PDF). Northeast Waste Management Officials’ Association. 2003-10-18. Archived from the original (PDF) on 2011-07-20. Cite journal requires

|journal=(help) - US 4882014, Coyle, R. T. & J. A. Switzer, "Electrochemical synthesis of ceramic films and powders"

- Gal-Or, L.; Silberman, I.; Chaim, R. (1991). "Electrolytic ZrO2 Coatings: I. Electrochemical Aspects". Journal of the Electrochemical Society. 138 (7): 1939. Bibcode:1991JElS..138.1939G. doi:10.1149/1.2085904.

- Ju, Hyungkuk; Lee, Jae-Kwang; Lee, Jongmin; Lee, Jaeyoung (2012). "Fast and selective Cu2O nanorod growth into anodic alumina templates via electrodeposition". Current Applied Physics. 12 (1): 60–64. Bibcode:2012CAP....12...60J. doi:10.1016/j.cap.2011.04.042.

- kunji durai, M. S.; chaala, Mathy (2008). "Pulse and pulse reverse plating—Conceptual, advantages and applications". Electrochimica Acta. 53 (8): 3313–3322. doi:10.1016/j.electacta.2007.11.054.

- Proctor, Deborah M (2016). "Inhalation cancer risk assessment of hexavalent chromium based on updated mortality for Painesville chromate production workers". Journal of Exposure Science & Environmental Epidemiology. 26 (2): 224–31. doi:10.1038/jes.2015.77. PMC 4756268. PMID 26669850.

- Milosevic-Popovich, Danijela (2018). "Advancements in Brush Plated Metal Matrix Composites". SIFCO ASC.

- A.C. Tan (30 November 1992). Tin and Solder Plating in the Semiconductor Industry. Springer Science & Business Media. p. 122. ISBN 978-0-412-48240-3.

- Todd, Robert H.; Allen, Dell K.; Alting, Leo (1994). "Surface Coating". Manufacturing Processes Reference Guide. Industrial Press. pp. 454–458. ISBN 0-8311-3049-0. Archived from the original on 2013-10-09.

- US 6475644, Hampikian, Janet & Neal Scott, "Radioactive coating solutions methods, and substrates"

- "The history of galvanotechnology in Russia" (in Russian). Archived from the original on March 5, 2012.

- Birmingham Museums trust catalogue, accession number: 1889S00044

- Thomas, John Meurig (1991). Michael Faraday and the Royal Institution: The Genius of Man and Place. Bristol: Hilger. p. 51. ISBN 0750301457.

- Beauchamp, K. G. (1997). Exhibiting Electricity. IET. p. 90. ISBN 9780852968956.

- Hunt, L. B. (March 1973). "The early history of gold plating". Gold Bulletin. 6 (1): 16–27. doi:10.1007/BF03215178.

- Stelter, M.; Bombach, H. (2004). "Process Optimization in Copper Electrorefining". Advanced Engineering Materials. 6 (7): 558. doi:10.1002/adem.200400403.

- Feynman, Richard (1985). "Chapter 6: The Chief Research Chemist of the Metaplast Corporation". Surely You're Joking, Mr. Feynman!.

- Metal Finishing: Guidebook and Directory. Issue 98. 95. 1998. p. 588.

- Kushner, Arthur S. (December 1, 2006). "Hull Cell 101". Products Finishing. Archived from the original on March 13, 2010.

- Bard, Allan; Inzelt, György; Scholz, Fritz (2012). "Haring–Blum Cell". Electrochemical Dictionary. Springer. p. 444. doi:10.1007/978-3-642-29551-5_8. ISBN 978-3-642-29551-5.

- Wendt, Hartmut; Gerhard, Kreyse (1999). Electrochemical Engineering: Science and Technology in Chemical and Other Industries. Springer. p. 122. ISBN 3540643869.

Bibliography

- Dufour, Jim (2006). An Introduction to Metallurgy (5th ed.). Cameron.