Blade

A blade is the portion of a tool, weapon, or machine with an edge that is designed to puncture, chop, slice or scrape surfaces or materials. Blades are typically made from materials that are harder than those they are to be used on. Historically, humans have made blades from flaking stones such as flint or obsidian, and from various metal such as copper, bronze and iron. Modern blades are often made of steel or ceramic. Blades are one of humanity's oldest tools, and continue to be used for combat, food preparation, and other purposes.

Blades work by concentrating force on the cutting edge. Certain blades, such as those used on bread knives or saws, are serrated, further concentrating force on the point of each tooth.

Uses

During food preparation, knives are mainly used for slicing, chopping, and piercing.[1]

In combat, a blade may be used to slash or puncture, and may also be thrown or otherwise propelled.[2][3] The function is to sever a nerve, muscle or tendon fibers, or blood vessel to disable or kill the adversary. Severing a major blood vessel typically leads to death due to exsanguination. Shrapnel causes wounds via the fragments' blade-like nature.

Blades may be used to scrape, moving the blade sideways across a surface, as in an ink eraser, rather than along or through a surface. For construction equipment such as a grader, the ground-working implement is also referred to as the blade, typically with a replaceable cutting edge.

Physics

A simple blade intended for cutting has two faces that meet at an edge. Ideally this edge would have no roundness but in practice all edges can be seen to be rounded to some degree under magnification either optically or with an electron microscope. Force is applied to the blade, either from the handle or pressing on the back of the blade. The handle or back of the blade has a large area compared to the fine edge. This concentration of applied force onto the small edge area increases the pressure exerted by the edge. It is this high pressure that allows a blade to cut through a material by breaking the bonds between the molecules/crystals/fibres/etc. in the material. This necessitates the blade being strong enough to resist breaking before the other material gives way.

Geometry

The angle at which the faces meet is important as a larger angle will make for a duller blade while making the edge stronger. A stronger edge is less likely to dull from fracture or from having the edge roll out of shape.

The shape of the blade is also important. A thicker blade will be heavier and stronger and stiffer than a thinner one of similar design while also making it experience more drag while slicing or piercing. A filleting knife will be thin enough to be very flexible while a carving knife will be thicker and stiffer; a dagger will be thin so it can pierce while a camping knife will be thicker to it can be stronger and more durable. A strongly curved edge, like a talwar will allow the user to draw the edge of the blade against an opponent even while close to the opponent where a straight sword would be more difficult to pull in the same fashion. The curved edge of an axe means that only a small length of the edge will initially strike the tree, concentrating force as does a thinner edge whereas a straight edge could potentially land with the full length of its edge against a flat section of tree. A splitting maul has a convex section to avoid getting stuck in wood where chopping axes can be flat or even concave. A khopesh or falchion or kukri is angled and/or weighted at the distal end so that force is concentrated at the faster moving, heavier part of the blade maximising cutting power and making it largely unsuitable for thrusting where a rapier is thin and tapered allowing it to pierce and be moved with more agility while reducing its chopping power compared to a similarly sized sword.

A serrated edge, such as on a saw or a bread knife, concentrates force onto the tips of the serrations which increases pressure as well as allowing soft or fibrous material (like wood, rope, bread, vegetables) to be expand into the spaces between serrations. Whereas pushing any knife, even a bread knife, down onto a bread loaf will just squash the loaf as bread has a low elastic modulus (is soft) but high yield strain (loosely, can be stretched or squashed by a large proportion without breaking), drawing serrations across the loaf with little downward force will allow each serration to simultaneously cut the bread with much less deformation of the loaf. Similarly, pushing on a rope tends to squash the rope while drawing serrations across it sheers the rope fibres. Drawing a smooth blade is less effective as the blade is parallel to the direction draw but the serrations of a serrated blade are at an angle to the fibres. Serrations on knives are often symmetric allowing the blade to cut on both the forward and reverse strokes of a cut, a notable exception being Veff serrations which are designed to maximise cutting power while moving the blade away from the user. Saw blade serrations, for both wood and metal, are typically asymmetrical so that they cut while moving in only one direction. (Saws act by abrading a material into dust along a narrow channel, the kerf, whereas knives and similar act by forcing the material apart. This means that saws result in a loss of material and the serrations of a saw also serve to carry metal swarf and sawdust out of the cut channel.)

Fullers are longitudinal channels either forged into the blade or later machined/milled out of the blade though the later process is less desirable. This loss of material necessarily weakens the blade but serves to make the blade lighter without sacrificing stiffness. The same principle is applied in the manufacture of beams such as I-beams. Fullers are only of significant utility in swords. In most knives there is so little material removed by the fuller than it makes little difference to the weight of the blade and they are largely cosmetic.

Materials

Typically blades are made from a material that is about as hard, though usually harder, than the material to be cut. Insufficiently hard blades will be unable to cut a material or will wear away quickly as hardness is related to a material's ability to resist abrasion. However, blades must also be tough enough to resist the dynamic load of impact and as a general rule the harder a blade the less tough (the more brittle) a material. For example, a steel axehead is much harder than the wood it is intended to cut and is sufficiently tough to resist the impact resulting when swung against a tree while a ceramic kitchen knife, harder than steel, is very brittle (has low toughness) and can easily shatter if dropped onto the floor or twisted while inside the food it is cutting or carelessly stored under other kitchen utensils. This creates a tension between the intended use of the blade, the material it is to be made from, and any manufacturing processes (such as heat treatment in the case of steel blades that will affect a blade's hardness and toughness). A balance must be found between the sharpness and how well it can last. Methods that can circumvent this include differential hardening. This method yields an edge that can hold its sharpness as well as a body that is tough.[4]

Non-metals

Prehistorically, and in less technologically advanced cultures even into modern times, tool and weapon blades have been made from wood, bone and stone.[5] Most woods are exceptionally poor at holding edges and bone and stone suffer from brittleness making them suffer from fracture when striking or struck. In modern times stone, in the form of obsidian, is used in some medical scalpels as it is capable of being formed into an exceedingly fine edge. Ceramic knives are non-metallic and non-magnetic. As non-metals do not corrode they remain rust and corrosion free but they suffer from similar faults as stone and bone, being rather brittle and almost entirely inflexible. They are harder than metal knives and so more difficult to sharpen, and some ceramic knives may be as hard or harder than some sharpening stones. For example, synthetic sapphire is harder than natural sharpening stones and is as hard as alumina sharpening stones. Zirconium dioxide is also harder than garnet sharpening stones and is nearly as hard as alumina. Both require diamond stones or silicon carbide stones to sharpen and care has to be taken to avoid chipping the blade. As such ceramic knives are seldom used outside of a kitchen and they are still quite uncommon. Plastic knives are difficult to make sharp and poorly retain an edge. They are largely used as low cost, disposable utensils or as children's utensils or in environments such as air travel where metal blades are prohibited. They are often serrated to compensate for their general lack of sharpness but, as evidenced by the fact they can cut food, they are still capable of inflicting injury. Plastic blades of designs other than disposable cutlery are prohibited or restricted in some jurisdictions as they are undetectable by metal detectors.

Metals

Native copper was used to make blades by ancient civilizations due to its availability. Copper's comparative softness causes it to deform easily; it does not hold an edge well, and is poorly suited for working stone. Bronze is superior in this regard, and was taken up by later civilizations. Both bronze and copper can be work hardened by hitting the metal with a hammer. With technological advancement in smelting, iron came to be used in the manufacturing of blades. Steel, a range of alloys made from iron, has become the metal of choice for the modern age.

Various alloys of steel can be made which offer a wide range of physical and chemical properties desirable for blades. For example, surgical scalpels are often made of stainless steel so that they remain free of rust and largely chemically inert; tool steels are hard and impact resistant (and often expensive as retaining toughness and hardness requires expensive alloying materials, and, being hard, they are difficult to make into their finished shape) and some are designed to resist changes to their physical properties at high temperatures. Steels can be further heat treated to optimise their toughness, which is important for impact blades, or their hardness, which allows them to retain an edge well with use (although harder metals require more effort to sharpen).

Combined materials and heat-treatments

It is possible to combine different materials, or different heat treatments, to produce desirable qualities in a blade. For example, the finest Japanese swords were routinely made of up to seven sections of metals and even poorer quality swords were often made of two. These would include soft irons that could absorb the energy of impact without fracturing but which would bend and poorly retain an edge, and hard steels more liable to shatter on impact but which retained an edge well. The combination provided a sword that would resist impact while remaining sharp, even though the edge could chip if abused. Pattern welding involved forging together twisted bars of soft (bendable) low carbon and hard (brittle) higher carbon iron.[6] This was done because furnaces of the time were typically able to produce only one grade or the other, and neither was well suited for more than a very limited use blade. The ability of modern steel makers to produce very high quality steels of various compositions has largely relegated this technique to either historical recreations or to artistic works. Acid etching and polishing blades made of different grades of steel can be used to produce decorative or artistic effects.

Japanese sword makers developed the technique of differential hardening by covering their sword blades in different thicknesses of clay before quenching. Thinner clay allowed the heated metal to cool faster, particularly along the edge. Faster cooling resulted in a finer crystal structure, resulting in a blade with a hard edge but a more flexible body. European sword makers produced similar results using differential tempering.

Dulling

Blades dull with use and abuse. This is particularly true of acute blades and those made of soft materials. Dulling usually occurs due to contact between the blade and a hard substance such as a ceramic, stone, bone, glass or metal.

The more acute the blade, the more easily it will dull. As the blade near the edge is thinner, there is little material to remove before the edge is worn away to a thicker section. Thin edges can also roll over when force is applied it them, forming a section like the bottom part of a letter "J". For this reason, straight edge razors are frequently stropped to straighten the edge.

Drawing a blade across any material tends to abrade both the blade, usually making it duller, and the cut material. Though softer than glass or many types of stone used in the kitchen, steel edges can still scratch these surfaces. The resulting scratch is full of very fine particles of ground glass or stone which will very quickly abrade the blade's edge and so dull it.

In times when swords were regularly used in warfare, they required frequent sharpening because of dulling from contact with rigid armor, mail, metal rimmed shields, or other swords,[4] for example. Particularly, hitting the edge of another sword by accident or in emergency could chip away metal and even cause cracks through the blade.[7] Soft-cored blades are more resistant to fracturing on impact.

Nail pulls

Folding pocket knives often have a groove cut in the side of the blade near the spine. This is called a nail pull, and allows the fingernail to be inserted to swing the blade out of the holder.[8]

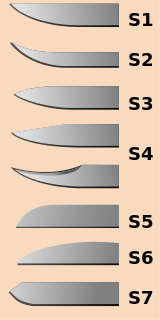

Knife patterns

Some of the most common shapes are listed below.

(S1) A normal blade has a curving edge, and straight back. A dull back lets the wielder use fingers to concentrate force; it also makes the knife heavy and strong for its size. The curve concentrates force on a smaller area, making cutting easier. This knife can chop as well as pick and slice. This is also the best single-edged blade shape for thrusting, as the edge cuts a swath that the entire width of the knife can pass through without the spine having to push aside any material on its path, as a sheepsfoot or drop-point knife would.

(S2) A trailing-point knife has a back edge that curves upward to end above the spine. This lets a lightweight knife have a larger curve on its edge and indeed the whole of the knife may be curved. Such a knife is optimized for slicing or slashing. Trailing point blades provide a larger cutting area, or belly, and are common on skinning knives.

(S3) A drop point blade has a convex curve of the back towards the point. It handles much like the clip-point, though with a stronger point typically less suitable for piercing. Swiss army pocket knives often have drop-points on their larger blades.

(S4) A clip-point blade is like a normal blade with the back "clipped". This clip can be either straight or concave. The back edge of the clip may have a false edge that could be sharpened to make a second edge. The sharp tip is useful as a pick, or for cutting in tight places. If the false edge is sharpened it increases the knife's effectiveness in piercing. As well, having the tip closer to the centre of the blade allows greater control in piercing. The Bowie knife has a clip point blade and clip-points are common on pocket knives and other folding knives.[9]

(S5) A sheepsfoot blade has a straight edge and a straight dull back that curves towards the edge at the end. It gives the most control, because the dull back edge is made to be held by fingers. Sheepsfoot blades were originally made to trim the hooves of sheep; their shape bears no similarity to the foot of a sheep.[10]

(S6) A Wharncliffe blade is similar in profile to a sheep's foot but the curve of the back edge starts closer to the handle and is more gradual. Its blade is much thicker than a knife of comparable size.[11] Wharncliffes were used by sailors, as the shape of the tip prevented accidental penetration of the work or the user's hand with the sudden motion of a ship.

(S7) A spey point blade (once used for neutering livestock) has a single, sharp, straight edge that curves strongly upwards at the end to meet a short, dull, straight point from the dull back. With the curved end of the blade being closer to perpendicular to the blade's axis than other knives and lacking a point, making penetration unlikely, spey blades are common on Trapper style pocketknives for skinning fur-bearing animals.[10]

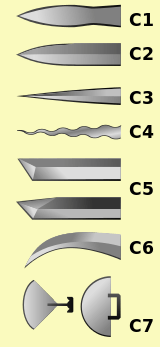

(C1) Leaf blade with a distinctive recurved "waist" adding some curved "belly" to the knife facilitating slicing as well as shifting weight towards the tip meaning that it is commonly used for throwing knives as well as improving chopping ability.

(C2) A spear point blade is a symmetrically-shaped blade with a point aligned with the centerline of the blade's long axis. True spear-point blades are double-edged with a central spine, like a dagger or spear head. The spear point is one of the stronger blade point designs in terms of penetration stress, and is found on many thrusting knives such as the dagger. The term spear point is occasionally and confusingly used to describe small single-edged blades without a central spine, such as that of the pen knife, a small folding-blade pocket knife formerly used in sharpening quills for writing. Pen-knife may also nowadays refer to a knifelike weapon blade pattern of some of larger pocket knife blades that would otherwise be termed drop-point designs.

(C3) A needle point blade has a sharply-tapered acuminated point. It is frequently found on daggers such as the stiletto (which had no sharpened edges) and the Fairbairn-Sykes fighting knife. Its long, narrow point reduces friction and increases the blade's penetrative capabilities, but is liable to stick in bone and can break if abused. When the needle point is combined with a reinforced 'T' section running the length of the blade's spine, it is called a reinforced tip. One example of a knife with a reinforced tip is the pesh-kabz.

(C4) Kris or flame-bladed sword. These blades have a distinct recurved blade form and are sharpened on both sides, typically tapering to (or approximating) a symmetrical point.

(C5) Referred to in English speaking countries as a "tanto" or "tanto point" (a corruption of the Japanese word tantō though the tip bears no resemblance to a tantō) or a chisel point. ("Chisel point" refers to the straightness of the edge that comprises the end of the blade,[12] whereas "chisel grind" usually refers to a blade ground on only one side[13] even though chisels can be ground on one or both sides.[14]) It is similar to, but not the same as, some early Japanese swords that had kamasu kissaki ("barracuda tip"), a nearly straight edge at the tip whereas the typical "tanto point" as found in the west has a straight edge. The barracuda tip sword was sharp but also fragile whereas modern tanto point are often advertised as being stronger at the tip for having nearly the whole thickness of the blade present until quite close to the end of the knife. Knife tests have shown that penetration ability of this style of blade is comparatively poor but it is possible, if the tip is strong, that more force can be applied allowing greater penetration without damaging the tip.

The lower illustration is a modified tanto where the end is clipped and often sharpened. This brings the tip closer to the centre of the blade increasing control of the blade and improves penetration potential by having a finer point and a sharpened back edge.

(C6) A hawkbill blade is sharpened on the inside edge and is similar to carpet and linoleum knives. The point will tear even if the rest of the knife is comparatively dull. The karambit from Far South-East Asia is a hawkbill knife which is held with the blade extending from the bottom of the fist and the tip facing forward. The outside edge of a karambit may be sharp and if so may also feature a backwards facing point.

(C7) An ulu (Inuit woman's knife) knife is a sharpened segment of a circle. This blade type has no point, and has a handle in the middle. It is good for scraping, and sometimes chopping. The semi-circular version appears elsewhere in the world and is called a head knife. It is used in leatherworking both to scrape down leather (reducing thickness, i.e. skiving), and to make precise, rolling cuts for shapes other than straight lines. The circular version is a popular tool for slicing pizzas. One corner is placed at the edge of the pizza and the blade is rolled across in a diameter cut.

Sword patterns

The sharp edges of a sword may be either curved or straight. Curved blades tend to glide more easily through soft materials, making these weapons more ideal for slicing. Techniques for such weapons feature drawing the blade across the opponent's body and back. For straight-edged weapons, many recorded techniques feature cleaving cuts, which deliver the power out to a point, striking directly in at the target's body, done to split flesh and bone rather than slice it. That being said, there also exist many historical slicing techniques for straight-edged weapons. Hacking cuts can be followed with a drawing action to maximize the cut's effectiveness. For more information see Western Martial Arts or kenjutsu.

Some weapons are made with only a single leading edge, such as the sabre or dusack. The dusack has a "false edge" near the tip, which only extends down a portion of the blade's backside. Other weapons have a blade that's entirely dull except for a sharpened point, like the épée or foil, which prefer thrusts over cuts. A blade cannot perform a proper cut without an edge, and so in competitive fencing such attacks reward no points.

Some variations include:

- The flame blade (undulated blade, for both psychological effect and some tactical advantage of using a non-standard blade: vibrations and easier parry)

- The colichemarde, found in smallsword

Marks and decoration

Blades are sometimes marked or inscribed, for decorative purposes, or with the mark of either the maker or the owner. Blade decorations are often realized in inlay in some precious metal (gold or silver).[15]

Early blade inscriptions are known from the Bronze Age, a Hittite sword found at Hattusa bears an inscription chiseled into the bronze, stating that the blade was deposited as an offering to the storm-god by king Tuthaliya.[16]

Blade inscriptions become particularly popular in the 12th century knightly sword, based on the earlier, 9th to 11th century, tradition of the so-called Ulfberht swords.[17]

See also

References

- Culinary Institute of America (2007). In the Hands of a Chef: The Professional Chef's Guide to Essential Kitchen Tools. John Wiley and Sons. p. 17. ISBN 978-0-470-08026-9.

- Echanis, Michael (1977). Knife Self-Defense for Combat. p. 4. ISBN 978-0-89750-022-7.

- Echanis, Michael (1979). Knife Throwing for Combat. p. 4. ISBN 978-0-89750-058-6.

- "Edge Damage on Swords". www.thearma.org. Retrieved 20 March 2018.

- Driscoll, Killian; García-Rojas, Maite (July 2014). "Their lips are sealed: identifying hard stone, soft stone, and antler hammer direct percussion in Palaeolithic prismatic blade production" (PDF). Journal of Archaeological Science. 47: 134–141. doi:10.1016/j.jas.2014.04.008. Retrieved 19 July 2017.

- Maryon, Herbert (1948). "A Sword of the Nydam Type from Ely Fields Farm, near Ely". Proceedings of the Cambridge Antiquarian Society. XLI: 73–76. doi:10.5284/1034398.

- [Taiji Sword, Classical Yang Style. Jwing-Ming Yang. YMAA Publications 1999, page 20 ISBN 978-1-886969-74-2]

- "Blade Nail Nicks and Long Pulls – Old and New".

- Goddard, Wayne (2000). The Wonder of Knifemaking. Krause. pp. 88–89. ISBN 978-0-87341-798-3.

- Overton, Mac (1990). "Two traditional designs". Blade Magazine. 17 (=12): 48–53.

- Neep, Rod (2005). "Wharncliffe Bladed Knives". Archived from the original on 1 November 2008. Retrieved 30 October 2013.

- "Drawing Lessons: How to Create a Chisel Point - Pencils.com". pencils.com. 13 September 2012. Archived from the original on 21 March 2018. Retrieved 20 March 2018.

- "Why do you use the chisel grind? - Emerson Knives Inc". emersonknives.com. Retrieved 20 March 2018.

- "Sharpening Carving Chisels". www.woodcraft.com. Retrieved 20 March 2018.

- Ewart Oakeshott, The Sword in the Age of Chivalry (1964)

- Kristian Kristiansen, Thomas B. Larsson, 'The rise of Bronze Age society: travels, transmissions and transformations (2005)290.

- Geibig, A. (1991), Beiträge zur morphologischen Entwicklung des Schwertes im Mittelalter.