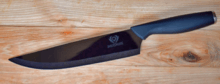

Ceramic knife

A ceramic knife is a knife designed with a ceramic blade typically made from zirconium dioxide (ZrO2; also known as zirconia).[1] These knife blades are usually produced through the dry-pressing and firing of powdered zirconia using solid-state sintering. It is 8.5 on the Mohs scale of mineral hardness, compared to 4.5 for normal steel and 7.5 to 8 for hardened steel and 10 for diamond. The resultant blade has a hard edge that stays sharper for longer when compared to conventional steel knives. While the edge is harder than a steel knife, it is less tough and thus more brittle. The ceramic blade is sharpened by grinding the edges with a diamond-dust-coated grinding wheel.

Zirconium oxide

Zirconium oxide is used due to its polymorphism. It exists in three phases: monoclinic, tetragonal and cubic. Cooling to the monoclinic phase after sintering causes a large volume change, which often causes stress fractures in pure zirconia. Additives such as magnesia, calcia and yttria are used in manufacturing the knife material to stabilize the high-temperature phases and minimize this volume change. The highest strength and toughness is produced by the addition of 3 mol% yttrium oxide yielding partially stabilized zirconia. This material consists of a mixture of tetragonal and cubic phases with a bending strength of nearly 1,200 MPa. Small cracks allow phase transformations to occur, which essentially close the cracks and prevent catastrophic failure, resulting in a relatively tough ceramic material, sometimes known as TTZ (transformation-toughened zirconia).

Properties

Ceramic knives are substantially harder than steel knives, will not corrode in harsh environments,[2] are non-magnetic, and do not conduct electricity at room temperature. Because of their resistance to strong acid and caustic substances,[3] and their ability to retain a cutting edge longer than forged metal knives[2], ceramic knives are better suited for slicing boneless meat, vegetables, fruit and bread. Since ceramics are brittle, blades may break if dropped on a hard surface although improved manufacturing processes have reduced this risk. They are also unsuitable for chopping through bones, or frozen foods, or in other applications which require prying, which may result in chipping. Several brands now offer either a black-coloured or a designed blade made through an additional hot isostatic pressing step, which increases the toughness.

Sharpening and general care

Unlike a traditional steel blade that benefits from regular honing and resharpening in order to keep a sharp edge, a ceramic knife will stay sharp and retain its cutting edge for much longer—up to 10x longer according to some tests.[4] The inherent hardness of the ceramic material also makes it more difficult for the consumer to resharpen.[5] Although a ceramic knife therefore does not need regular sharpening in the same way as steel, its blade edge will eventually degrade or chip and lose its cutting edge, at which point specialized sharpening services are required for the ceramic edge.[6]

References

- "Archived copy". Archived from the original on 2015-12-10. Retrieved 2015-12-20.CS1 maint: archived copy as title (link)

- The Ceramic Society of Japan (31 July 2012). "22.1 Ceramic Knife, Grater, Slicer and Scissors (1984)*". In Yoshihiko Imanaka (ed.). Advanced Ceramic Technologies & Products. Springer Science & Business Media. pp. 529–530. doi:10.1007/978-4-431-54108-0. ISBN 978-4-431-53913-1.

- Wilson, Bee (22 Jun 2012). "At the cutting edge: ceramic knives". The Telegraph. Retrieved 27 July 2016.

- http://kyoceraadvancedceramics.com/ceramic-advantage/kyocera-technology Archived 2015-10-13 at the Wayback Machine. "Recent tests show that the life of a Kyocera ceramic blade without resharpening is approximately 10 times that of a typical steel blade." The Cutlery and Allied Trades Research Association (CATRA), an independent testing organization.

- Wolfgang Puck (8 April 2007). Wolfgang Puck Makes It Easy: Delicious Recipes for Your Home Kitchen. Thomas Nelson. pp. 269–. ISBN 978-1-4185-7093-4.

- Sur La Table; Sarah Jay (21 October 2008). Knives Cooks Love: Selection. Care. Techniques. Recipes. Andrews McMeel Publishing. pp. 12–. ISBN 978-0-7407-7002-9.

External links