Wind turbine

A wind turbine, or alternatively referred to as a wind energy converter, is a device that converts the wind's kinetic energy into electrical energy.

.jpg)

| Part of a series on |

| Renewable energy |

|---|

|

|

Wind turbines are manufactured in a wide range of vertical and horizontal axis. The smallest turbines are used for applications such as battery charging for auxiliary power for boats or caravans or to power traffic warning signs. Larger turbines can be used for making contributions to a domestic power supply while selling unused power back to the utility supplier via the electrical grid. Arrays of large turbines, known as wind farms, are becoming an increasingly important source of intermittent renewable energy and are used by many countries as part of a strategy to reduce their reliance on fossil fuels. One assessment claimed that, as of 2009, wind had the "lowest relative greenhouse gas emissions, the least water consumption demands and... the most favourable social impacts" compared to photovoltaic, hydro, geothermal, coal and gas.[1]

History

The windwheel of Hero of Alexandria (10 AD – 70 AD) marks one of the first recorded instances of wind powering a machine in history.[2][3] However, the first known practical wind power plants were built in Sistan, an Eastern province of Persia (now Iran), from the 7th century. These "Panemone" were vertical axle windmills, which had long vertical drive shafts with rectangular blades.[4] Made of six to twelve sails covered in reed matting or cloth material, these windmills were used to grind grain or draw up water, and were used in the gristmilling and sugarcane industries.[5]

Wind power first appeared in Europe during the Middle Ages. The first historical records of their use in England date to the 11th or 12th centuries, there are reports of German crusaders taking their windmill-making skills to Syria around 1190.[6] By the 14th century, Dutch windmills were in use to drain areas of the Rhine delta. Advanced wind turbines were described by Croatian inventor Fausto Veranzio. In his book Machinae Novae (1595) he described vertical axis wind turbines with curved or V-shaped blades.

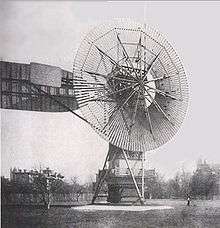

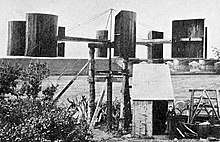

The first electricity-generating wind turbine was a battery charging machine installed in July 1887 by Scottish academic James Blyth to light his holiday home in Marykirk, Scotland.[7] Some months later American inventor Charles F. Brush was able to build the first automatically operated wind turbine after consulting local University professors and colleagues Jacob S. Gibbs and Brinsley Coleberd and successfully getting the blueprints peer-reviewed for electricity production in Cleveland, Ohio.[7] Although Blyth's turbine was considered uneconomical in the United Kingdom,[7] electricity generation by wind turbines was more cost effective in countries with widely scattered populations.[6]

In Denmark by 1900, there were about 2500 windmills for mechanical loads such as pumps and mills, producing an estimated combined peak power of about 30 MW. The largest machines were on 24-meter (79 ft) towers with four-bladed 23-meter (75 ft) diameter rotors. By 1908, there were 72 wind-driven electric generators operating in the United States from 5 kW to 25 kW. Around the time of World War I, American windmill makers were producing 100,000 farm windmills each year, mostly for water-pumping.[9]

By the 1930s, wind generators for electricity were common on farms, mostly in the United States where distribution systems had not yet been installed. In this period, high-tensile steel was cheap, and the generators were placed atop prefabricated open steel lattice towers.

A forerunner of modern horizontal-axis wind generators was in service at Yalta, USSR in 1931. This was a 100 kW generator on a 30-meter (98 ft) tower, connected to the local 6.3 kV distribution system. It was reported to have an annual capacity factor of 32 percent, not much different from current wind machines.[10][11]

In the autumn of 1941, the first megawatt-class wind turbine was synchronized to a utility grid in Vermont. The Smith–Putnam wind turbine only ran for 1,100 hours before suffering a critical failure. The unit was not repaired, because of a shortage of materials during the war.

The first utility grid-connected wind turbine to operate in the UK was built by John Brown & Company in 1951 in the Orkney Islands.[7][12]

Despite these diverse developments, developments in fossil fuel systems almost entirely eliminated any wind turbine systems larger than supermicro size. In the early 1970s, however, anti-nuclear protests in Denmark spurred artisan mechanics to develop microturbines of 22 kW. Organizing owners into associations and co-operatives lead to the lobbying of the government and utilities and provided incentives for larger turbines throughout the 1980s and later. Local activists in Germany, nascent turbine manufacturers in Spain, and large investors in the United States in the early 1990s then lobbied for policies that stimulated the industry in those countries.

It has been argued that expanding use of wind power will lead to increasing geopolitical competition over critical materials for wind turbines such as rare earth elements neodymium, praseodymium, and dysprosium. But this perspective has been criticised for failing to recognise that most wind turbines do not use permanent magnets and for underestimating the power of economic incentives for expanded production of these minerals.[13]

Resources

Wind Power Density (WPD) is a quantitative measure of wind energy available at any location. It is the mean annual power available per square meter of swept area of a turbine, and is calculated for different heights above ground. Calculation of wind power density includes the effect of wind velocity and air density.[14]

Wind turbines are classified by the wind speed they are designed for, from class I to class III, with A to C referring to the turbulence intensity of the wind.[15]

| Class | Avg Wind Speed (m/s) | Turbulence |

|---|---|---|

| IA | 10 | 16% |

| IB | 10 | 14% |

| IC | 10 | 12% |

| IIA | 8.5 | 16% |

| IIB | 8.5 | 14% |

| IIC | 8.5 | 12% |

| IIIA | 7.5 | 16% |

| IIIB | 7.5 | 14% |

| IIIC | 7.5 | 12% |

Efficiency

Conservation of mass requires that the amount of air entering and exiting a turbine must be equal. Accordingly, Betz's law gives the maximal achievable extraction of wind power by a wind turbine as 16/27 (59.3%) of the rate at which the kinetic energy of the air arrives at the turbine.[16]

The maximum theoretical power output of a wind machine is thus 16/27 times the rate at which kinetic energy of the air arrives at the effective disk area of the machine. If the effective area of the disk is A, and the wind velocity v, the maximum theoretical power output P is:

- ,

where ρ is the air density.

Wind-to-rotor efficiency (including rotor blade friction and drag) are among the factors affecting the final price of wind power.[17] Further inefficiencies, such as gearbox losses, generator and converter losses, reduce the power delivered by a wind turbine. To protect components from undue wear, extracted power is held constant above the rated operating speed as theoretical power increases at the cube of wind speed, further reducing theoretical efficiency. In 2001, commercial utility-connected turbines delivered 75% to 80% of the Betz limit of power extractable from the wind, at rated operating speed.[18][19]

Efficiency can decrease slightly over time, one of the main reasons being dust and insect carcasses on the blades which alters the aerodynamic profile and essentially reduces the lift to drag ratio of the airfoil. Analysis of 3128 wind turbines older than 10 years in Denmark showed that half of the turbines had no decrease, while the other half saw a production decrease of 1.2% per year.[20] Ice accretion on turbine blades has also been found to greatly reduce the efficiency of wind turbines, which is a common challenge in cold climates where in-cloud icing and freezing rain events occur.[21] Vertical turbine designs have much lower efficiency than standard horizontal designs.[22]

In general, more stable and constant weather conditions (most notably wind speed) result in an average of 15% greater efficiency than that of a wind turbine in unstable weather conditions, thus allowing up to a 7% increase in wind speed under stable conditions. This is due to a faster recovery wake and greater flow entrainment that occur in conditions of higher atmospheric stability. However, wind turbine wakes have been found to recover faster under unstable atmospheric conditions as opposed to a stable environment.[23]

Different materials have been found to have varying effects on the efficiency of wind turbines. In an Ege University experiment, three wind turbines (Each with three blades with diameters of one meter) were constructed with blades made of different materials: A glass and glass/carbon epoxy, glass/carbon, and glass/polyester. When tested, the results showed that the materials with higher overall masses had a greater friction moment and thus a lower power coefficient.[24]

Types

Wind turbines can rotate about either a horizontal or a vertical axis, the former being both older and more common.[25] They can also include blades, or be bladeless.[26] Vertical designs produce less power and are less common.[27]

Horizontal axis

.jpg)

Large three-bladed horizontal-axis wind turbines (HAWT) with the blades upwind of the tower produce the overwhelming majority of wind power in the world today. These turbines have the main rotor shaft and electrical generator at the top of a tower, and must be pointed into the wind. Small turbines are pointed by a simple wind vane, while large turbines generally use a wind sensor coupled with a yaw system. Most have a gearbox, which turns the slow rotation of the blades into a quicker rotation that is more suitable to drive an electrical generator.[28] Some turbines use a different type of generator suited to slower rotational speed input. These don't need a gearbox and are called direct-drive, meaning they couple the rotor directly to the generator with no gearbox in between. While permanent magnet direct-drive generators can be more costly due to the rare earth materials required, these gearless turbines are sometimes preferred over gearbox generators because they "eliminate the gear-speed increaser, which is susceptible to significant accumulated fatigue torque loading, related reliability issues, and maintenance costs."[29] There is also the pseudo direct drive mechanism, which has some advantages over the permanent magnet direct drive mechanism.[30][31]

Most horizontal axis turbines have their rotors upwind of the supporting tower. Downwind machines have been built, because they don't need an additional mechanism for keeping them in line with the wind. In high winds, the blades can also be allowed to bend, which reduces their swept area and thus their wind resistance. Despite these advantages, upwind designs are preferred, because the change in loading from the wind as each blade passes behind the supporting tower can cause damage to the turbine.

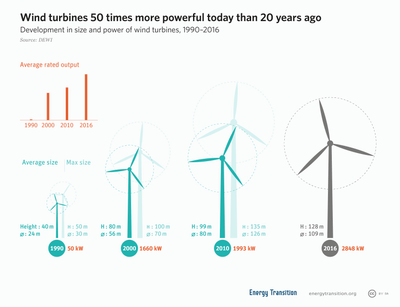

Turbines used in wind farms for commercial production of electric power are usually three-bladed. These have low torque ripple, which contributes to good reliability. The blades are usually colored white for daytime visibility by aircraft and range in length from 20 to 80 meters (66 to 262 ft). The size and height of turbines increase year by year. Offshore wind turbines are built up to 8 MW today and have a blade length up to 80 meters (260 ft). Designs with 10 to 12 MW are in preparation.[32] Usual multi megawatt turbines have tubular steel towers with a height of 70 m to 120 m and in extremes up to 160 m.

Vertical axis

Vertical-axis wind turbines (or VAWTs) have the main rotor shaft arranged vertically. One advantage of this arrangement is that the turbine does not need to be pointed into the wind to be effective, which is an advantage on a site where the wind direction is highly variable. It is also an advantage when the turbine is integrated into a building because it is inherently less steerable. Also, the generator and gearbox can be placed near the ground, using a direct drive from the rotor assembly to the ground-based gearbox, improving accessibility for maintenance. However, these designs produce much less energy averaged over time, which is a major drawback.[27][33]

The key disadvantages include the relatively low rotational speed with the consequential higher torque and hence higher cost of the drive train, the inherently lower power coefficient, the 360-degree rotation of the aerofoil within the wind flow during each cycle and hence the highly dynamic loading on the blade, the pulsating torque generated by some rotor designs on the drive train, and the difficulty of modelling the wind flow accurately and hence the challenges of analysing and designing the rotor prior to fabricating a prototype.[34]

When a turbine is mounted on a rooftop the building generally redirects wind over the roof and this can double the wind speed at the turbine. If the height of a rooftop mounted turbine tower is approximately 50% of the building height it is near the optimum for maximum wind energy and minimum wind turbulence. While wind speeds within the built environment are generally much lower than at exposed rural sites,[35][36] noise may be a concern and an existing structure may not adequately resist the additional stress.

Subtypes of the vertical axis design include:

Darrieus wind turbine

"Eggbeater" turbines, or Darrieus turbines, were named after the French inventor, Georges Darrieus.[37] They have good efficiency, but produce large torque ripple and cyclical stress on the tower, which contributes to poor reliability. They also generally require some external power source, or an additional Savonius rotor to start turning, because the starting torque is very low. The torque ripple is reduced by using three or more blades, which results in greater solidity of the rotor. Solidity is measured by blade area divided by the rotor area. Newer Darrieus type turbines are not held up by guy-wires but have an external superstructure connected to the top bearing.[38]

Giromill

A subtype of Darrieus turbine with straight, as opposed to curved, blades. The cycloturbine variety has variable pitch to reduce the torque pulsation and is self-starting.[39] The advantages of variable pitch are: high starting torque; a wide, relatively flat torque curve; a higher coefficient of performance; more efficient operation in turbulent winds; and a lower blade speed ratio which lowers blade bending stresses. Straight, V, or curved blades may be used.[40]

Savonius wind turbine

These are drag-type devices with two (or more) scoops that are used in anemometers, Flettner vents (commonly seen on bus and van roofs), and in some high-reliability low-efficiency power turbines. They are always self-starting if there are at least three scoops.

Twisted Savonius is a modified savonius, with long helical scoops to provide smooth torque. This is often used as a rooftop wind turbine and has even been adapted for ships.[41]

Parallel

The parallel turbine is similar to the crossflow fan or centrifugal fan. It uses the ground effect. Vertical axis turbines of this type have been tried for many years: a unit producing 10 kW was built by Israeli wind pioneer Bruce Brill in the 1980s.[42]

Unconventional types

Counter-rotating wind turbine |

Highway wind turbine |

Light pole wind turbine |

Design and construction

Wind turbine design is a careful balance of cost, energy output, and fatigue life.

Components

Wind turbines convert wind energy to electrical energy for distribution. Conventional horizontal axis turbines can be divided into three components:

- The rotor, which is approximately 20% of the wind turbine cost, includes the blades for converting wind energy to low speed rotational energy.

- The generator, which is approximately 34% of the wind turbine cost, includes the electrical generator,[43][44] the control electronics, and most likely a gearbox (e.g., planetary gear box),[45] adjustable-speed drive, or continuously variable transmission[46] component for converting the low-speed incoming rotation to high-speed rotation suitable for generating electricity.

- The surrounding structure, which is approximately 15% of the wind turbine cost, includes the tower and rotor yaw mechanism.[47]

A 1.5 (MW) wind turbine of a type frequently seen in the United States has a tower 80 meters (260 ft) high. The rotor assembly (blades and hub) weighs 22,000 kilograms (48,000 lb). The nacelle, which contains the generator, weighs 52,000 kilograms (115,000 lb). The concrete base for the tower is constructed using 26,000 kilograms (58,000 lb) reinforcing steel and contains 190 cubic meters (250 cu yd) of concrete. The base is 15 meters (50 ft) in diameter and 2.4 meters (8 ft) thick near the center.[48]

Turbine monitoring and diagnostics

Due to data transmission problems, structural health monitoring of wind turbines is usually performed using several accelerometers and strain gages attached to the nacelle to monitor the gearbox and equipment. Currently, digital image correlation and stereophotogrammetry are used to measure dynamics of wind turbine blades. These methods usually measure displacement and strain to identify location of defects. Dynamic characteristics of non-rotating wind turbines have been measured using digital image correlation and photogrammetry.[49] Three dimensional point tracking has also been used to measure rotating dynamics of wind turbines.[50]

Recent developments in technology

Wind turbine rotor blades are being made longer to increase efficiency. This requires them to be stiff, strong, light and resistant to fatigue.[51] Materials with these properties are composites such as polyester and epoxy, while glass fiber and carbon fiber have been used for the reinforcing.[52] Construction may use manual layup or injection molding.

New designs

Companies seek ways to draw greater efficiency from their designs. A predominant way has been to increase blade length and thus rotor diameter. Retrofitting existing turbines with larger blades reduces the work and risks of redesigning the system. The current longest blade is 88.4 m (from LM Wind Power), but by 2021 offshore turbines are expected to be 10-MW with 100 m blades. Longer blades need to be stiffer to avoid deflection, which requires materials with higher stiffness-to-weight ratio. Because the blades need to function over a 100 million load cycles over a period of 20–25 years, the fatigue of the blade materials is also critical.

Blade materials

Materials commonly used in wind turbine blades are described below.

Glass and carbon fibers

The stiffness of composites is determined by the stiffness of fibers and their volume content. Typically, E-glass fibers are used as main reinforcement in the composites. Typically, the glass/epoxy composites for wind turbine blades contain up to 75% glass by weight. This increases the stiffness, tensile and compression strength. A promising composite material is glass fiber with modified compositions like S-glass, R-glass etc. Other glass fibers developed by Owens Corning are ECRGLAS, Advantex and WindStrand.[53]

Carbon fiber has more tensile strength, higher stiffness and lower density than glass fiber. An ideal candidate for these properties is the spar cap, a structural element of a blade which experiences high tensile loading.[52] A 100-m glass fiber blade could weigh up to 50 metric tons, while using carbon fiber in the spar saves 20% to 30% weight, about 15 metric tons.[54] However, because carbon fiber is ten times more expensive, glass fiber is still dominant.

Hybrid reinforcements

Instead of making wind turbine blade reinforcements from pure glass or pure carbon, hybrid designs trade weight for cost. For example, for an 8 m blade, a full replacement by carbon fiber would save 80% of weight but increase costs by 150%, while a 30% replacement would save 50% of weight and increase costs by 90%. Hybrid reinforcement materials include E-glass/carbon, E-glass/aramid. The current longest blade by LM Wind Power is made of carbon/glass hybrid composites. More research is needed about the optimal composition of materials [55]

Nano-engineered polymers and composites

Additions of small amount (0.5 weight %) of nanoreinforcement (carbon nanotubes or nanoclay) in the polymer matrix of composites, fiber sizing or interlaminar layers can improve fatigue resistance, shear or compressive strength, and fracture toughness of the composites by 30% to 80%. Research has also shown that incorporating small amounts of carbon nanotubes (CNT) can increase the lifetime up to 1500%.

Costs

As of 2019, a wind turbine may cost around $1 million per megawatt.[56]

For the wind turbine blades, while the material cost is much higher for hybrid glass/carbon fiber blades than all-glass fiber blades, labor costs can be lower. Using carbon fiber allows simpler designs that use less raw material. The chief manufacturing process in blade fabrication is the layering of plies. Thinner blades allow reducing the number of layers and so the labor, and in some cases, equate to the cost of labor for glass fiber blades.[57]

Non-blade materials

Wind turbine parts other than the rotor blades (including the rotor hub, gearbox, frame, and tower) are largely made of steel. Smaller turbines (as well as megawatt-scale Enercon turbines) have begun using aluminum alloys for these components to make turbines lighter and more efficient. This trend may grow if fatigue and strength properties can be improved. Pre-stressed concrete has been increasingly used for the material of the tower, but still requires much reinforcing steel to meet the strength requirement of the turbine. Additionally, step-up gearboxes are being increasingly replaced with variable speed generators, which requires magnetic materials.[51] In particular, this would require an greater supply of the rare earth metal neodymium.

Modern turbines use a couple of tons of copper for generators, cables and such.[58] As of 2018, global production of wind turbines use 450,000 tonnes of copper per year.[59]

Material supply

A study of the material consumption trends and requirements for wind energy in Europe found that bigger turbines have a higher consumption of precious metals but lower material input per kW generated. The current material consumption and stock was compared to input materials for various onshore system sizes. In all EU countries the estimates for 2020 doubled the values consumed in 2009. These countries would need to expand their resources to meet the estimated demand for 2020. For example, currently the EU has 3% of world supply of fluorspar and it requires 14% by 2020. Globally, the main exporting countries are South Africa, Mexico and China. This is similar with other critical and valuable materials required for energy systems such as magnesium, silver and indium. The levels of recycling of these materials are very low and focusing on that could alleviate supply. Because most of these valuable materials are also used in other emerging technologies, like light emitting diodes (LEDs), photo voltaics (PVs) and liquid crystal displays (LCDs), their demand is expected to grow.[60]

A study by the United States Geological Survey estimated resources required to fulfill the US commitment to supplying 20% of its electricity from wind power by 2030. It did not consider requirements for small turbines or offshore turbines because those were not common in 2008 when the study was done. Common materials such as cast iron, steel and concrete would increase by 2%–3% compared to 2008. Between 110,000 and 115,000 metric tons of fiber glass would be required per year, a 14% increase. Rare metal use would not increase much compared to available supply, however rare metals that are also used for other technologies such as batteries which are increasing its global demand need to be taken into account. Land required would be 50,000 square kilometers onshore and 11,000 offshore. This would not be a problem in the US due to its vast area and because the same land can be used for farming. A greater challenge would be the variability and transmission to areas of high demand.[61]

Permanent magnets for wind turbine generators contain rare metals such as neodymium (Nd), praseodymium (Pr), Terbium (Tb) and dysprosium (Dy). Systems that use magnetic direct drive turbines require greater amounts of rare metals. Therefore, an increase in wind turbine manufacture would increase the demand for these resources. By 2035, the demand for Nd is estimated to increase by 4,000 to 18,000 tons and for Dy by 200 to 1200 tons. These values are a quarter to half of current production. However, these estimates are very uncertain because technologies are developing rapidly.[62]

Reliance on rare earth minerals for components has risked expense and price volatility as China has been main producer of rare earth minerals (96% in 2009) and was reducing its export quotas.[63] However, in recent years other producers have increased production and China has increased export quotas, leading to a higher supply and lower cost, and a greater viability of large scale use of variable-speed generators.[64]

Glass fiber is the most common material for reinforcement. Its demand has grown due to growth in construction, transportation and wind turbines. Its global market might reach US$17.4 billion by 2024, compared to US$8.5 billion in 2014. In 2014, Asia Pacific produced more than 45% of the market; now China is the largest producer. The industry receives subsidies from the Chinese government allowing it to export cheaper to the US and Europe. However, price wars have led to anti-dumping measures such as tariffs on Chinese glass fiber.[65]

Recycling

Interest in recycling blades varies in different markets and depends on the waste legislation and local economics. A challenge in recycling blades is related to the composite material, which is made of a thermosetting matrix and glass fibers or a combination of glass and carbon fibers. Thermosetting matrix cannot be remolded to form new composites. So the options are either to send the blade to landfill, to reuse the blade and the composite material elements found in the blade, or to transform the composite material into a new source of material. In Germany, wind turbine blades are commercially recycled as part of an alternative fuel mix for a cement factory. In the USA the town of Casper, Wyoming has buried 1,000 non-recyclable blades in its landfill site, earning $675,000 for the town. It pointed out that wind farm waste is less toxic than other garbage. Wind turbine blades represent a “vanishingly small fraction” of overall waste in the US, according to the American Wind Energy Association.[66]

Wind turbines on public display

A few localities have exploited the attention-getting nature of wind turbines by placing them on public display, either with visitor centers around their bases, or with viewing areas farther away.[67] The wind turbines are generally of conventional horizontal-axis, three-bladed design, and generate power to feed electrical grids, but they also serve the unconventional roles of technology demonstration, public relations, and education.

Small wind turbines

Small wind turbines may be used for a variety of applications including on- or off-grid residences, telecom towers, offshore platforms, rural schools and clinics, remote monitoring and other purposes that require energy where there is no electric grid, or where the grid is unstable. Small wind turbines may be as small as a fifty-watt generator for boat or caravan use. Hybrid solar and wind powered units are increasingly being used for traffic signage, particularly in rural locations, as they avoid the need to lay long cables from the nearest mains connection point.[68] The U.S. Department of Energy's National Renewable Energy Laboratory (NREL) defines small wind turbines as those smaller than or equal to 100 kilowatts.[69] Small units often have direct drive generators, direct current output, aeroelastic blades, lifetime bearings and use a vane to point into the wind.

Larger, more costly turbines generally have geared power trains, alternating current output, and flaps, and are actively pointed into the wind. Direct drive generators and aeroelastic blades for large wind turbines are being researched.

Wind turbine spacing

On most horizontal wind turbine farms, a spacing of about 6–10 times the rotor diameter is often upheld. However, for large wind farms distances of about 15 rotor diameters should be more economical, taking into account typical wind turbine and land costs. This conclusion has been reached by research[70] conducted by Charles Meneveau of Johns Hopkins University[71] and Johan Meyers of Leuven University in Belgium, based on computer simulations[72] that take into account the detailed interactions among wind turbines (wakes) as well as with the entire turbulent atmospheric boundary layer.

Recent research by John Dabiri of Caltech suggests that vertical wind turbines may be placed much more closely together so long as an alternating pattern of rotation is created allowing blades of neighbouring turbines to move in the same direction as they approach one another.[73]

Operability

Maintenance

Wind turbines need regular maintenance to stay reliable and available. In the best case turbines are available to generate energy 98% of the time.[74][75]

Modern turbines usually have a small onboard crane for hoisting maintenance tools and minor components. However, large, heavy components like generator, gearbox, blades, and so on are rarely replaced, and a heavy lift external crane is needed in those cases. If the turbine has a difficult access road, a containerized crane can be lifted up by the internal crane to provide heavier lifting.[76]

Repowering

Installation of new wind turbines can be controversial. An alternative is repowering, where existing wind turbines are replaced with bigger, more powerful ones, sometimes in smaller numbers while keeping or increasing capacity.

Demolition

Older turbines were in some early cases not required to be removed when reaching the end of their life. Some still stand, waiting to be recycled or repowered.[77][78]

A demolition industry develops to recycle offshore turbines at a cost of DKK 2–4 million per (MW), to be guaranteed by the owner.[79]

Comparison with fossil-fuel turbines

Advantages

Wind turbines produce electricity at between two and six cents per kilowatt hour, which is one of the lowest-priced renewable energy sources.[80][81] As technology needed for wind turbines continued to improve, the prices decreased as well. In addition, there is currently no competitive market for wind energy, because wind is a freely available natural resource, most of which is untapped.[80] The main cost of small wind turbines is the purchase and installation process, which averages between $48,000 and $65,000 per installation. The energy harvested from the turbine will offset the installation cost, as well as provide virtually free energy for years.[82]

Wind turbines provide a clean energy source, use little water,[1] emitting no greenhouse gases and no waste products. Over 1,500 tons of carbon dioxide per year can be eliminated by using a one-megawatt turbine instead of one megawatt of energy from a fossil fuel.[83]

Disadvantages

Wind turbines can be very large, reaching over 140 m (460 ft) tall and with blades 55 m (180 ft) long,[84] and people have often complained about their visual impact.

Environmental impact of wind power includes effect on wildlife, but can be mitigated if proper monitoring and mitigation strategies are implemented.[85] Thousands of birds, including rare species, have been killed by the blades of wind turbines,[86] though wind turbines contribute relatively insignificantly to anthropogenic avian mortality. Wind farms and nuclear power stations are responsible for between 0.3 and 0.4 bird deaths per gigawatt-hour (GWh) of electricity while fossil fueled power stations are responsible for about 5.2 fatalities per GWh. In 2009, for every bird killed by a wind turbine in the US, nearly 500,000 were killed by cats and another 500,000 by buildings.[87] In comparison, conventional coal fired generators contribute significantly more to bird mortality, by incineration when caught in updrafts of smoke stacks and by poisoning with emissions byproducts (including particulates and heavy metals downwind of flue gases). Further, marine life is affected by water intakes of steam turbine cooling towers (heat exchangers) for nuclear and fossil fuel generators, by coal dust deposits in marine ecosystems (e.g. damaging Australia's Great Barrier Reef) and by water acidification from combustion monoxides.

Energy harnessed by wind turbines is intermittent, and is not a "dispatchable" source of power; its availability is based on whether the wind is blowing, not whether electricity is needed. Turbines can be placed on ridges or bluffs to maximize the access of wind they have, but this also limits the locations where they can be placed.[80] In this way, wind energy is not a particularly reliable source of energy. However, it can form part of the energy mix, which also includes power from other sources. Notably, the relative available output from wind and solar sources is often inversely proportional (balancing). Technology is also being developed to store excess energy, which can then make up for any deficits in supplies.

Records

See also List of most powerful wind turbines

- Most powerful, tallest, largest and with highest 24-hour production

- GE Wind Energy's Haliade-X is the most powerful wind turbine in the world, at 12MW. It also is the tallest, with a hub height of 150 m and a tip height of 260m. It also has the largest rotor of 220 m and largest swept area at 38000 m2[88] It also holds the record for the highest production in 24 hours [89]

- Largest capacity conventional (non-direct) drive

- The Vestas V164 has a rated capacity of 8 MW,[90] later upgraded to 9.5 MW.[91][92] The wind turbine has an overall height of 220 m (722 ft), a diameter of 164 m (538 ft), is for offshore use, and is the world's largest-capacity wind turbine since its introduction in 2014. Conventional drive trains consist of a main gearbox and a medium-speed PM generator. Prototype installed in 2014 at the National Test Center Denmark nearby Østerild. Series production began end of 2015.

- Largest vertical-axis

- Le Nordais wind farm in Cap-Chat, Quebec, has a vertical axis wind turbine (VAWT) named Éole, which is the world's largest at 110 m.[93] It has a nameplate capacity of 3.8 MW.[94]

- Largest 1-bladed turbine

- The largest single-bladed wind turbine design to be put into complete operation is the MBB Messerschmitt Monopteros M50, with a total power output of no less than 640 kW at full capacity. As far as the number of units is concerned, only three ever have been installed at an actual wind park, of which all went to the Jade Wind Park.[95]

- Largest 2-bladed turbine

- The biggest 2-bladed turbine is built by Mingyang Wind Power in 2013. It is a SCD6.5MW offshore downwind turbine, designed by aerodyn Energiesysteme.[96][97][98]

- Highest tower

- Fuhrländer installed a 2.5 MW turbine on a 160m lattice tower in 2003 (see Fuhrländer Wind Turbine Laasow and Nowy Tomyśl Wind Turbines).

- Most rotors

- Lagerwey has build Four-in-One, a multi rotor wind turbine with one tower and four rotors near Maasvlakte. In April 2016, Vestas installed a 900 kW four rotor test wind turbine at Risø, made from 4 recycled 225 kW V29 turbines.[99][100][101]

- Most productive

- Four turbines at Rønland Offshore Wind Farm in Denmark share the record for the most productive wind turbines, with each having generated 63.2 GWh by June 2010.[102]

- Highest-situated

- Since 2013 the world's highest-situated wind turbine was made and installed by WindAid and is located at the base of the Pastoruri Glacier in Peru at 4,877 meters (16,001 ft) above sea level.[103] The site uses the WindAid 2.5 kW wind generator to supply power to a small rural community of micro entrepreneurs who cater to the tourists who come to the Pastoruri glacier.[104]

- Largest floating wind turbine

- The world's largest floating wind turbine is any of the five 6 MW turbines in the 30 MW Hywind Scotland offshore wind farm.[105]

See also

References

- Evans, Annette; Strezov, Vladimir; Evans, Tim (June 2009). "Assessment of sustainability indicators for renewable energy technologies". Renewable and Sustainable Energy Reviews. 13 (5): 1082–1088. doi:10.1016/j.rser.2008.03.008.

- Drachmann, A.G. (1961). "Heron's Windmill". Centaurus. 7: 145–151.

- Lohrmann, Dietrich (1995). "Von der östlichen zur westlichen Windmühle". Archiv für Kulturgeschichte (in German). Bohlau Verlag. 77 (1): 1–32. doi:10.7788/akg.1995.77.1.1. ISSN 0003-9233.

- Ahmad Y. al-Hassan; Donald R. Hill (1992). Islamic Technology: An Illustrated History. Cambridge University Press. p. 54. ISBN 978-0-521-42239-0.

- Donald Routledge Hill, "Mechanical Engineering in the Medieval Near East", Scientific American, May 1991, pp. 64–69. (cf. Donald Routledge Hill, Mechanical Engineering)

- Morthorst, Poul Erik; Redlinger, Robert Y.; Andersen, Per (2002). Wind energy in the 21st century: economics, policy, technology and the changing electricity industry. Houndmills, Basingstoke, Hampshire: Palgrave/UNEP. ISBN 978-0-333-79248-3.

- Price, Trevor J. (2004). "Blyth, James (1839–1906)". Oxford Dictionary of National Biography (online ed.). Oxford University Press. doi:10.1093/ref:odnb/100957. (Subscription or UK public library membership required.)

- A Wind Energy Pioneer: Charles F. Brush. Danish Wind Industry Association. Archived from the original on 8 September 2008. Retrieved 28 December 2008.

- "Quirky old-style contraptions make water from wind on the mesas of West Texas". Archived from the original on 3 February 2008.

- Alan Wyatt (1986). Electric Power: Challenges and Choices. Book Press. ISBN 978-0-920650-01-1.

- "Bauer, Lucas. "Krasnovsky WIME D-30 – 100,00 kW – Wind turbine"". en.wind-turbine-models.com.

- Anon. "Costa Head Experimental Wind Turbine". Orkney Sustainable Energy Website. Orkney Sustainable Energy Ltd. Retrieved 19 December 2010.

- Overland, Indra (1 March 2019). "The geopolitics of renewable energy: Debunking four emerging myths". Energy Research & Social Science. 49: 36–40. doi:10.1016/j.erss.2018.10.018. ISSN 2214-6296.

- "NREL: Dynamic Maps, GIS Data, and Analysis Tools – Wind Maps". Nrel.gov. 3 September 2013. Retrieved 6 November 2013.

- Appendix II IEC Classification of Wind Turbines. Wind Resource Assessment and Micro-siting, Science and Engineering. 2015. pp. 269–270. doi:10.1002/9781118900116.app2. ISBN 9781118900116.

- "The Physics of Wind Turbines Kira Grogg Carleton College, 2005, p. 8" (PDF). Retrieved 6 November 2013.

- "Wind Energy Basics". Bureau of Land Management. Archived from the original on 9 May 2019. Retrieved 23 April 2016.

- "Enercon E-family, 330 Kw to 7.5 MW, Wind Turbine Specification" (PDF). Archived from the original (PDF) on 16 May 2011.

- Tony Burton; David Sharpe; Nick Jenkins; Ervin Bossanyi (12 December 2001). Wind Energy Handbook. John Wiley & Sons. p. 65. ISBN 978-0-471-48997-9.

- Sanne Wittrup (1 November 2013). "11 års vinddata afslørede overraskende produktionsnedgang" [11 years of wind data shows surprising production decrease]. Ingeniøren (in Danish).

- Barber, S.; Wang, Y.; Jafari, S.; Chokani, N.; Abhari, R. S. (28 January 2011). "The Impact of Ice Formation on Wind Turbine Performance and Aerodynamics". Journal of Solar Energy Engineering. 133 (1): 011007–011007–9. doi:10.1115/1.4003187. ISSN 0199-6231.

- E. Hau., Wind Turbines: Fundamentals, Technologies, Application, Economics. Springer. Germany. 2006

- Han, Xingxing; Liu, Deyou; Xu, Chang; Shen, Wen Zhong (2018). "Atmospheric stability and topography effects on wind turbine performance and wake properties in complex terrain". Renewable Energy. Elsevier BV. 126: 640–651. doi:10.1016/j.renene.2018.03.048. ISSN 0960-1481.

- Ozdamar, G. (2018). "Numerical Comparison of the Effect of Blade Material on Wind Turbine Efficiency". Acta Physica Polonica A. 134: 156–158. doi:10.12693/APhysPolA.134.156.

- "Wind Energy Basics". American Wind Energy Association. Archived from the original on 23 September 2010. Retrieved 24 September 2009.

- Elizabeth Stinson (15 May 2015). "The Future of Wind Turbines? No Blades". Wired.

- Paul Gipe (7 May 2014). "News & Articles on Household-Size (Small) Wind Turbines". Wind-works.org.

- "Wind Turbine Components". Danish Wind Industry Association. 10 May 2003. Archived from the original on 7 June 2008.

- G. Bywaters; P. Mattila; D. Costin; J. Stowell; V. John; S. Hoskins; J. Lynch; T. Cole; A. Cate; C. Badger; B. Freeman (October 2007). "Northern Power NW 1500 Direct-Drive Generator" (PDF). National Renewable Energy Laboratory. p. iii.

- "T 3.2 - Magnetic Pseudo direct drive generator -". innwind.eu.

- "Innwind: Overview of the project and research" (PDF).

- "MHI Vestas Launches World's First* 10 Megawatt Wind Turbine". 26 September 2018.

- Michael Barnard (7 April 2014). "Vertical Axis Wind Turbines: Great In 1890, Also-rans In 2014". CleanTechnica.

- Michael C Brower; Nicholas M Robinson; Erik Hale (May 2010). "Wind Flow Modeling Uncertainty" (PDF). AWS Truepower. Archived from the original on 2 May 2013.CS1 maint: unfit url (link)

- Hugh Piggott (6 January 2007). "Windspeed in the city – reality versus the DTI database". Scoraigwind.com. Retrieved 6 November 2013.

- "Urban Wind Turbines" (PDF).

- "Vertical-Axis Wind Turbines". Symscape. 7 July 2008. Retrieved 6 November 2013.

- Exploit Nature-Renewable Energy Technologies by Gurmit Singh, Aditya Books, pp 378

- Eric Eggleston & AWEA Staff. "What Are Vertical-Axis Wind Turbines (VAWTs)?". American Wind Energy Association. Archived from the original on 3 April 2005.

- Marloff, R.H. (January 1978). "Stresses in turbine-blade tenons subjected to bending". Experimental Mechanics. 18 (1): 19–24. doi:10.1007/BF02326553.

- Rob Varnon (2 December 2010). "Derecktor converting boat into hybrid passenger ferry". Connecticut Post. Retrieved 25 April 2012.

- "Modular wind energy device – Brill, Bruce I". Freepatentsonline.com. 19 November 2002. Retrieved 6 November 2013.

- Navid Goudarzi (June 2013). "A Review on the Development of the Wind Turbine Generators across the World". International Journal of Dynamics and Control. 1 (2): 192–202. doi:10.1007/s40435-013-0016-y.

- Navid Goudarzi; Weidong Zhu (November 2012). "A Review of the Development of Wind Turbine Generators Across the World". ASME 2012 International Mechanical Engineering Congress and Exposition. 4 – Paper No: IMECE2012-88615: 1257–1265.

- "Hansen W4 series". Hansentransmissions.com. Archived from the original on 15 March 2012. Retrieved 6 November 2013.

- John Gardner; Nathaniel Haro & Todd Haynes (October 2011). "Active Drivetrain Control to Improve Energy Capture of Wind Turbines" (PDF). Boise State University. Retrieved 28 February 2012. Cite journal requires

|journal=(help) - ""Wind Turbine Design Cost and Scaling Model", Technical Report NREL/TP-500-40566, December, 2006, page 35, 36" (PDF). Retrieved 6 November 2013.

- "Pomeroy Wind Farm" (PDF). Archived from the original (PDF) on 15 July 2011.

- Baqersad, Javad; Niezrecki, Christopher; Avitabile, Peter (2015). "Full-field dynamic strain prediction on a wind turbine using displacements of optical targets measured by stereophotogrammetry". Mechanical Systems and Signal Processing. 62–63: 284–295. Bibcode:2015MSSP...62..284B. doi:10.1016/j.ymssp.2015.03.021.

- Lundstrom, Troy; Baqersad, Javad; Niezrecki, Christopher; Avitabile, Peter (4 November 2012). "Using High-Speed Stereophotogrammetry Techniques to Extract Shape Information from Wind Turbine/Rotor Operating Data". In Allemang, R.; De Clerck, J.; Niezrecki, C.; Blough, J.R. (eds.). Topics in Modal Analysis II, Volume 6. Conference Proceedings of the Society for Experimental Mechanics Series. Springer New York. pp. 269–275. doi:10.1007/978-1-4614-2419-2_26. ISBN 978-1-4614-2418-5.

- Ancona, Dan; Jim, McVeigh. "Wind Turbine – Materials and Manufacturing Fact Sheet". CiteSeerX 10.1.1.464.5842. Cite journal requires

|journal=(help) - Watson, James; Serrano, Juan (September 2010). "Composite Materials for Wind Blades". Wind Systems. Archived from the original on 11 November 2017. Retrieved 6 November 2016.

- "Materials and Innovations for Large Blade Structures: Research Opportunities in Wind Energy Technology" (PDF). windpower.sandia.gov.

- "Wind turbine blades: Glass vs. carbon fiber". www.compositesworld.com. Retrieved 12 November 2016.

- "Wind Power Monthly Webpage".

- "IntelStor expects wind turbine prices to recover 5% in next two years". Windpower Engineering & Development. 22 October 2019.

- Ong, Cheng-Huat & Tsai, Stephen W. (2000). "The Use of Carbon Fibers in Wind Turbine Blade Design" (PDF). energy.sandia.gov.

- Frost and Sullivan, 2009, cited in Wind Generator Technology, by Eclareon S.L., Madrid, May 2012; www.eclareon.com; Available at Leonardo Energy – Ask an Expert; "Archived copy". Archived from the original on 26 November 2012. Retrieved 12 December 2012.CS1 maint: archived copy as title (link)

- "Fast pace of growth in wind energy driving demand for copper". Riviera Maritime Media.

- Kim, Junbeum; Guillaume, Bertrand; Chung, Jinwook; Hwang, Yongwoo (1 February 2015). "Critical and precious materials consumption and requirement in wind energy system in the EU 27". Applied Energy. 139: 327–334. doi:10.1016/j.apenergy.2014.11.003. ISSN 0306-2619.

- Wilburn, D.R.—Wind Energy in the United States and Materials Required for the Land-Based Turbine Industry From 2010 Through 2030—SIR 2011–5036

- Buchholz, Peter; Brandenburg, Torsten (1 January 2018). "Demand, Supply, and Price Trends for Mineral Raw Materials Relevant to the Renewable Energy Transition Wind Energy, Solar Photovoltaic Energy, and Energy Storage". Chemie Ingenieur Technik. 90 (1–2): 141–153. doi:10.1002/cite.201700098. ISSN 1522-2640.

- Wilburn, David. "Wind Energy in the United States and Materials Required for the Land-Based Wind Turbine Industry From 2010 Through 2030" (PDF). U.S. Department of the Interior.

- Yap, Chui-Wei. "China Ends Rare-Earth Minerals Export Quotas". wsg.com.

- "Glass fiber market to reach to US$17 billion by 2024". Reinforced Plastics. 60 (4): 188–189. 1 July 2016. doi:10.1016/j.repl.2016.07.006. ISSN 0034-3617.

- "Turbines Tossed Into Dump Stirs Debate on Wind's Dirty Downside". Bloomberg. 31 July 2019. Retrieved 6 December 2019.

- Young, Kathryn (3 August 2007). "Canada wind farms blow away turbine tourists". Edmonton Journal. Archived from the original on 25 April 2009. Retrieved 6 September 2008.

- Anon. "Solar & Wind Powered Sign Lighting". Energy Development Cooperative Ltd. Retrieved 19 October 2013.

- Small Wind Archived 15 November 2011 at the Wayback Machine, U.S. Department of Energy National Renewable Energy Laboratory website

- Meyers, Johan (2011). "Optimal turbine spacing in fully developed wind farm boundary layers". Wind Energy. 15 (2): 305–317. Bibcode:2012WiEn...15..305M. doi:10.1002/we.469.

- "New study yields better turbine spacing for large wind farms". Johns Hopkins University. 18 January 2011. Retrieved 6 November 2013.

- M. Calaf; C. Meneveau; J. Meyers (2010). "Large eddy simulation study of fully developed wind-turbine array boundary layers". Phys. Fluids. 22 (1): 015110–015110–16. Bibcode:2010PhFl...22a5110C. doi:10.1063/1.3291077.

- Dabiri, John O. (1 July 2011). "Potential order-of-magnitude enhancement of wind farm power density via counter-rotating vertical-axis wind turbine arrays". Journal of Renewable and Sustainable Energy. 3 (4): 043104. arXiv:1010.3656. doi:10.1063/1.3608170.

- G.J.W. van Bussel, PhD; M.B. Zaaijer, MSc (2001). "Reliability, Availability and Maintenance aspects of large-scale offshore wind farms" (PDF). Delft University of Technology: 2. Cite journal requires

|journal=(help) - "Iberwind builds on 98% availability with fresh yaw, blade gains". 15 February 2016. Retrieved 30 May 2016.

- Morten Lund (30 May 2016). "Dansk firma sætter prisbelønnet selvhejsende kran i serieproduktion". Ingeniøren. Archived from the original on 31 May 2016. Retrieved 30 May 2016.

- Jeremy Fugleberg (8 May 2014). "Abandoned Dreams of Wind and Light". Atlas Obscura. Retrieved 30 May 2016.

- Tom Gray (11 March 2013). "Fact check: About those 'abandoned' turbines …". American Wind Energy Association. Retrieved 30 May 2016.

- "Aldrende havmølleparker åbner marked for klog nedrivning". Ingeniøren. Retrieved 20 May 2016.

- "Advantages and Disadvantages of Wind Energy – Clean Energy Ideas". Clean Energy Ideas. 19 June 2013. Retrieved 10 May 2017.

- "Levelized Cost of Energy and Levelized Cost of Storage 2018". 8 November 2018. Retrieved 11 November 2018.

- "Residential Wind Energy Systems – Bergey Wind Power". bergey.com. Retrieved 10 May 2017.

- "About Wind Energy: Factsheets and Statistics". www.pawindenergynow.org. Retrieved 10 May 2017.

- "Turbine Size". Fraunhofer Wind Monitor.

- Parisé, J.; Walker, T. R. (2017). "Industrial wind turbine post-construction bird and bat monitoring: A policy framework for Canada". Journal of Environmental Management. 201: 252–259. doi:10.1016/j.jenvman.2017.06.052. PMID 28672197.

- Hosansky, David (1 April 2011). "Wind Power: Is wind energy good for the environment?". CQ Researcher.

- Sovacool, B. K. (2013). "The avian benefits of wind energy: A 2009 update". Renewable Energy. 49: 19–24. doi:10.1016/j.renene.2012.01.074.

- "World's Most Powerful Offshore Wind Turbine: Haliade-X 12 MW GE Renewable Energy". Retrieved 15 April 2020.

- "GE's Haliade-X generates record-breaking 288 MWh in 24 hours". Retrieved 15 April 2020.

- Wittrup, Sanne. "Power from Vestas' giant turbine" (in Danish. English translation ). Ingeniøren, 28 January 2014. Retrieved 28 January 2014.

- "The world's most powerful available wind turbine gets major power boost | MHI Vestas Offshore". www.mhivestasoffshore.com. 2018. Retrieved 22 September 2018.

- "MHI Vestas launches 9.5MW V164 turbine in London". www.mhivestasoffshore.com. Retrieved 22 September 2018.

- "Visits : Big wind turbine". Archived from the original on 1 May 2010. Retrieved 17 April 2010.

- "Wind Energy Power Plants in Canada – other provinces". 5 June 2010. Retrieved 24 August 2010.

- "MBB Messerschmitt Monopteros M50 - 640,00 kW - Wind turbine". en.wind-turbine-models.com.

- Vries, Eize de. "Close up - Aerodyn's 6MW offshore turbine design". www.windpoweroffshore.com.

- "Ming Yang completes 6.5MW offshore turbine". www.windpowermonthly.com.

- Weston, David (12 March 2015). "EWEA Offshore: Aerodyn 6MW connected to grid". Windpower Monthly. Archived from the original on 14 March 2015. Retrieved 4 November 2019.

- "EXCLUSIVE: Vestas tests four-rotor concept turbine". Windpower Monthly. Retrieved 20 April 2016.

- Sanne Wittrup. "Vestas rejser usædvanlig ny multirotor-vindmølle". Ingeniøren. Retrieved 20 April 2016.

- Video of quadrotor on YouTube

- "Surpassing Matilda: record-breaking Danish wind turbines". Archived from the original on 22 March 2011. Retrieved 26 July 2010.

- "Highest altitude wind generator". Guinness World Records.

- Satullo, Sara (4 August 2013). "Northampton Community College students help set Guinness World Record in Peru". lehighvalleylive.

- "Floating wind farm to be UK first". 2 November 2015 – via www.bbc.com.

Further reading

- Tony Burton, David Sharpe, Nick Jenkins, Ervin Bossanyi: Wind Energy Handbook, John Wiley & Sons, 2nd edition (2011), ISBN 978-0-470-69975-1

- Darrell, Dodge, Early History Through 1875, TeloNet Web Development, Copyright 1996–2001

- Ersen Erdem, Wind Turbine Industrial Applications

- Robert Gasch, Jochen Twele (ed.), Wind power plants. Fundamentals, design, construction and operation, Springer 2012 ISBN 978-3-642-22937-4.

- Erich Hau, Wind turbines: fundamentals, technologies, application, economics Springer, 2013 ISBN 978-3-642-27150-2 (preview on Google Books)

- Siegfried Heier, Grid integration of wind energy conversion systems John Wiley & Sons, 3rd edition (2014), ISBN 978-1-119-96294-6

- Peter Jamieson, Innovation in Wind Turbine Design. Wiley & Sons 2011, ISBN 978-0-470-69981-2

- J. F. Manwell, J. G. McGowan, A. L. Roberts, Wind Energy Explained: Theory, Design and Application, John Wiley & Sons, 2nd edition (2012), ISBN 978-0-47001-500-1

- David Spera (ed,) Wind Turbine Technology: Fundamental Concepts in Wind Turbine Engineering, Second Edition (2009), ASME Press, ISBN 9780791802601

- Alois Schaffarczyk (ed.), Understanding wind power technology, John Wiley & Sons, (2014), ISBN 978-1-118-64751-6

- Hermann-Josef Wagner, Jyotirmay Mathur, Introduction to wind energy systems. Basics, technology and operation. Springer (2013), ISBN 978-3-642-32975-3

- GA Mansoori, N Enayati, LB Agyarko (2016), Energy: Sources, Utilization, Legislation, Sustainability, Illinois as Model State

External links

| Wikimedia Commons has media related to Wind turbine. |

- Harvesting the Wind (45 lectures about wind turbines by professor Magdi Ragheb

- DIY wind turbine at home Complete video and image Guide by Newphysicist

- Guided tour on wind energy

- Wind Energy Technology World Wind Energy Association

- Wind turbine simulation, National Geographic

- Airborne Wind Industry Association international

- Top 21 Biggest Wind Turbines in the World

- The Tethys database seeks to gather, organize and make available information on potential environmental effects of offshore wind energy development