Pratt & Whitney F135

The Pratt & Whitney F135 is an afterburning turbofan developed for the Lockheed Martin F-35 Lightning II, a single-engine strike fighter. The F135 family has several distinct variants; a conventional, forward thrust variant and a multi-cycle Short Take-Off Vertical Landing STOVL variant that includes a forward lift fan. The first production engines were delivered in 2009.[2]

| F135 | |

|---|---|

| |

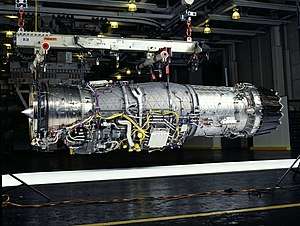

| F135 engine during the JSF System Development and Demonstration (SDD) phase | |

| Type | Turbofan |

| National origin | United States |

| Manufacturer | Pratt & Whitney |

| Major applications | Lockheed Martin F-35 Lightning II |

| Unit cost | F135-PW-100, US$ 13.3M per LRIP 9[1] F135-PW-600, US$ 19.05M[1] |

| Developed from | Pratt & Whitney F119 |

Developed from the Pratt & Whitney F119 engine used on the F-22 Raptor, the F135 produces around 40,000 lbf of thrust.[3] The F135 competed with the General Electric/Rolls-Royce F136 to power the F-35.

Development

The F135 originated with Lockheed Corporation Skunk Works, with efforts to develop a stealthy STOVL strike fighter for the U.S. Marine Corps under a 1986 DARPA program. Lockheed employee Paul Bevilaqua developed and patented[4] a concept aircraft and propulsion system, and then turned to Pratt & Whitney (P&W) to build a demonstrator engine.[5] The ground test demonstrator used the first stage fan from a F119 engine for the lift fan. The engine fan and core from the F100-220 were used for the core of the demonstrator engine, and the larger low-pressure turbine from the F100-229 was used for the low-pressure turbine of the demonstrator engine. The larger turbine was used to provide the additional power required to operate the lift fan. Finally, a variable thrust deflecting nozzle was added to complete the "F100-229-Plus" demonstrator engine. This engine proved the lift-fan concept and led to the development of the current F135 engine.[6]

The F135 team is made up of Pratt & Whitney, Rolls-Royce and Hamilton Sundstrand. Pratt & Whitney is the prime contractor for the main engine, and systems integration. Rolls-Royce is responsible for the vertical lift system for the STOVL aircraft. Hamilton Sundstrand is responsible for the electronic engine control system, actuation system, PMAG, gearbox, and health monitoring systems. Woodward, Inc. is responsible for the fuel system.

P&W developed the F135 from their F119 turbofan, which powers the F-22 Raptor, as the "F119-JSF". The F135 integrates the F119 core with new components optimized for the JSF.[7] The F135 is assembled at a plant in Middletown, Connecticut. Some parts of the engine are made in Longueuil, Quebec, Canada,[8] and in Poland.[9]

The first production propulsion system for operational service was scheduled for delivery in 2007 with the purpose of serving the U.S., UK, and other international customers. The initial F-35s went into production with the F135 engines, but the GE/Rolls-Royce team planned to develop a replacement F136 engine in July 2009. In 2010, the Pentagon planned for the two propulsion systems to be competitively tendered. However, since 2006 the Defense Department has not requested funding for the alternate F136 engine program, but Congress has maintained program funding.[10]

As of 2009, P&W developed a more durable version of the F135 engine to increase the service life of key parts. The life expectancy of the parts was reduced because the hot sections of the engine (combustor and high-pressure turbine blades specifically) ran hotter than expected. The test engine is designated XTE68/LF1, and testing is expected to begin in 2010.[11] This redesign has caused “substantial cost growth.”[12]

P&W expects to deliver the F135 below the cost of the F119, even though it is a more powerful engine.[13] However, in February 2013 a cracked turbine blade was found during a scheduled inspection. The crack was caused by operating at high turbine temperatures for longer periods than usual.[14] In December 2013 the hollow first stage fan blisk failed at 77% of its expected life during a ground test. It will be replaced by a solid part adding 6 lb (2.7 kg) in weight.[15] In 2013, a former P&W employee was caught attempting to ship "numerous boxes" of sensitive information about the F135 to Iran.[16]

Despite the troubles, the 100th engine was delivered in 2013.[17] LRIP-6 was agreed in 2013 for $1.1 billion for 38 engines of various types, which helped to decrease the unit cost.[18]

Air Force Lt. Gen. Christopher C. Bogdan, the executive officer of the F-35 program, has called out P&W for falling short on manufacturing quality of the engines and slow deliveries.[19] His deputy director Rear Admiral Randy Mahr said that P&W stopped their cost-cutting efforts after "they got the monopoly".[20] In 2013 the price of the F135 increased by $4.3 billion.[21]

In May 2014, Pratt & Whitney discovered conflicting documentation about the origin of titanium material used in some of its engines, including the F135. The company assessed that the uncertainty did not pose a risk to safety of flight but suspended engine deliveries as a result. Bogdan supported P&W's actions and said the problem was now with A&P Alloys, the supplier. The US Defense Contract Management Agency wrote in June 2014 that Pratt & Whitney's "continued poor management of suppliers is a primary driver for the increased potential problem notifications." A&P Alloys stated that they stood behind their product even though they were not given access to the parts to do their own testing. Tracy Miner, an attorney with Boston-based Demeo LLP representing A&P Alloys said, "it is blatantly unfair to destroy A&P’s business without allowing A&P access to the materials in question"[22][23][24]

In July 2014 there was an uncontained failure of a fan rotor while the aircraft was preparing for take-off. The parts passed through a fuel tank and caused a fire, grounding the F-35 fleet.[25] During high g-force maneuvering three weeks before the flight, flexing of the engine caused excessive rubbing at the seal between the fan blisk and the fan stator initiating the impending failure. The rub caused a temperature of over 1,000 °C (1,900 °F), well beyond the material limit of 540 °C (1,000 °F). Micro cracks appeared in third-stage fan blades, according to program manager Christopher Bogdan, causing blades to separate from the disk. The failed blades punctured the fuel cell and hot air mixing with jet fuel caused the fire.[26][27][28] As a short term fix, each aircraft is flown on a specific flight profile to allow the rotor seal to wear a mating groove in the stator to prevent excessive rubbing.[29]

Pratt & Whitney managed to meet their 2015 production goals, but "recurring manufacturing quality issues" in turbine blades and electronic control systems required engines to be pulled from the fleet.[30]

Design

Derived from the F119 engine, the F135 is a mixed-flow afterburning turbofan consisting of a new fan and LP turbine.[31]

There are 3 F135 variants: the -100 engine, -400 engine, and the -600 engine. The -400 is similar to the -100, the major difference being the use of salt-corrosion resistant materials.[32] The -600 is described below with an explanation of the engine configuration changes that take place for hovering. The engine and Rolls-Royce LiftSystem make up the Integrated Lift Fan Propulsion System (ILFPS).[33]

The lift for the STOVL version in the hover is obtained from a 2-stage lift fan (about 46%[34]) in front of the engine, a vectoring exhaust nozzle (about 46%[34]), and a nozzle in each wing using fan air from the bypass duct (about 8%[34]). These relative contributions to the total lift are based on thrust values of 18,680 lb, 18,680 lb and 3,290 lb respectively.[34] Another source gives thrust values of 20,000 lb, 18,000 lb and 3,900 lb respectively.[35]

In this configuration most of the bypass flow is ducted to the wing nozzles, known as roll posts. Some is used for cooling the rear exhaust nozzle, known as the 3-bearing swivel duct nozzle (3BSD).[36] At the same time an auxiliary inlet is opened on top of the aircraft to provide additional air to the engine with low distortion during the hover.[31]

The LP turbine drives the lift fan through a shaft extension on the front of the LP rotor and a clutch. The engine operates as a separate flow turbofan with a higher bypass ratio.[37] The power to drive the fan (about 30,000 SHP[37]) is obtained from the LP turbine by increasing the hot nozzle area.[37]

A higher bypass ratio increases the thrust for the same engine power as a fundamental consequence of transferring power from a small diameter propelling jet to a larger diameter one.[38] When the F135 is in the hover using the significantly increased bypass ratio from the liftfan, the thrust augmentation is 50%[34] with no increase in fuel flow. Thrust augmentation is 52%[34] in conventional flight when using the afterburner, but with a large increase in fuel flow.

The transfer of approximately 1⁄3[39] of the power available for hot nozzle thrust to the lift fan reduces the temperature and velocity of the rear lift jet impinging on the ground.[39] The F-35 can achieve a limited 100% throttle cruise without afterburners of Mach 1.2 for 150 miles.[40]

Like the F119, the F135 has a stealthy augmentor where traditional spray bars and flameholders are replaced by thick curved vanes coated with ceramic radar-absorbent materials (RAM). Afterburner fuel injectors are integrated into these vanes, which block line-of-sight of the turbines, contributing to aft-sector stealth. The axisymmetric nozzle consists of fifteen partially overlapping flaps that create a sawtooth pattern at the trailing edge. This creates shed vortices and reduces the infrared signature of the exhaust plume. The effectiveness is reportedly comparable to that of the F119's wedge nozzles, while being substantially more cost effective and lower maintenance.[41]

The engine uses thermoelectric-powered sensors to monitor turbine bearing health.[42]

Improving engine reliability and ease of maintenance is a major objective for the F135. The engine has fewer parts than similar engines, which improves reliability. All line-replaceable components (LRCs) can be removed and replaced with a set of six common hand tools.[43] The F135's health management system is designed to provide real time data to maintainers on the ground. This allows them to troubleshoot problems and prepare replacement parts before the aircraft returns to base. According to Pratt & Whitney, this data may help drastically reduce troubleshooting and replacement time, as much as 94% over legacy engines.[44]

Planned improvements

Although no service has issued a requirement for an upgraded engine, Pratt and Whitney is cooperating with the US Navy on a two-block improvement plan for the F135 engine. The goals of Block 1 are a 7–10% increase in thrust and a 5–7% lower fuel burn. The plans include better cooling technology for turbine blades; this would increase the longevity of the engine and substantially reduce maintenance costs. The goal of Block 2 is to work with the US Air Force's Adaptive Engine Transition Program, with the intention of introducing technology for an engine rated at 45,000 lb of thrust, to be used in a sixth-generation fighter.[45]

Growth Options

GO1

At the end of May 2017 Pratt and Whitney announced the F135 Growth Option 1 had finished testing and was available for production. The upgrade requires the changing of the power module on older engines and can be seamlessly inserted into future production engines at a minimal increase in unit cost and no impact to delivery schedule. The Growth Option 1 offers an improvement of 6-10% thrust across the F-35 flight envelope while also getting a 5-6% fuel burn reduction.[46]

GO2

In June 2018, United Technologies, parent company of P&W, announced Growth Option 2.0 to help provide increased power and thermal management system (PTMS) capacity, providing options for operators for instance if they are wishing to upgrade to heavier weapons.[47]

Variants

- F135-PW-100 : Used in the F-35A Conventional Take-Off and Landing variant

- F135-PW-400 : Used in the F-35C Naval variant built with salt-corrosion resistant materials

- F135-PW-600 : Used in the F-35B Short Take-Off Vertical Landing variant

Applications

Specifications (F135)

F135-PW-100

Data from F135engine.com[48] Tinker Air Force Base,[49] American Society of Mechanical Engineers[50]

General characteristics

- Type: Two-spool, axial flow, augmented turbofan

- Length: 220 in (559 cm)

- Diameter: 46 in (117 cm) max., 43 in (109 cm) at the fan inlet

- Dry weight: 3,750 lb (1,701 kg)

Components

- Compressor: 3-stage fan, 6-stage high-pressure compressor

- Combustors: annular combustor

- Turbine: 1-stage high-pressure turbine, 2-stage low-pressure turbine

- Bypass ratio: 0.57:1

Performance

- Maximum thrust:

- 28,000 lbf (128 kN) military thrust,

- 43,000 lbf (191 kN) with afterburner

- Overall pressure ratio: 28:1 overall pressure ratio

- Turbine inlet temperature: 3,600 °F (1,980 °C; 2,260 K)

- Thrust-to-weight ratio: 7.47:1 military thrust, 11.47:1 augmented

F135-PW-600

Data from F135engine.com,[48] Tinker AFB,[49] American Society of Mechanical Engineers[50]

General characteristics

- Type: Two-spool, axial flow, augmented turbofan with shaft driven remote lift fan

- Length: 369 in (937.3 cm)

- Diameter: 46 in (116.8 cm) maximum, 43 in (109.2 cm) fan inlet, 53 in (134.6 cm) lift fan inlet

- Dry weight:

Components

- Compressor: 3 stage fan, 6 stage high-pressure compressor, 2 stage, contra-rotating, shaft driven lift fan

- Combustors: annular combustor

- Turbine: Single stage high pressure turbine, 2-stage low pressure turbine

- Bypass ratio: 0.56:1 conventional, 0.51:1 powered lift

Performance

- Maximum thrust:

- 27,000 lbf (120 kN) military thrust

- 41,000 lbf (182 kN) with afterburner

- 40,650 lbf (181 kN) hovering

- Overall pressure ratio: 28:1 overall pressure ratio (conventional), 29:1 overall pressure ratio (powered lift),

- Turbine inlet temperature: 3,600 °F (1,980 °C; 2,260 K)

- Power-to-weight ratio:

See also

Related development

Comparable engines

Related lists

References

- "F-35 Joint Program Office Awards Pratt & Whitney LRIP 9 Contract for F135 Engines". 2016-04-12.

- "F135 Engine Exceeds 12,000 Engine Test Hours as Pratt & Whitney Prepares to Deliver First Production Engines" (2009). Pratt & Whitney press release. July 28, 2009. PR Newswire Link

- "Lockheed Martin F-35 Joint Strike Fighter Succeeds In First Vertical Landing". lockheedmartin.com, Press Release, 18 March 2010.

- "Propulsion system for a vertical and short takeoff and landing aircraft" Archived 2012-02-25 at the Wayback Machine, United States Patent 5209428. PDF of original : http://www.freepatentsonline.com/5209428.pdf

- "The Shaft Driven Lift Fan Propulsion System For The Joint Strike Fighter" Paul M. Bevilaqua, American Helicopter Society 53rd Annual Forum, Virginia Beach, April 29-May 1, 1997. Fig. 6 Turbine Performance Map

- Bevilaqua, Paul M. (September 2005). "Joint Strike Fighter Dual-Cycle Propulsion System". Journal of Propulsion and Power. 21 (5): 778-783. doi:10.2514/1.15228.

- Connors, p. 171.

- Communications and Marketing Branch. "Home - Industry Canada". ic.gc.ca. Retrieved 1 February 2015.

- "Pratt & Whitney's F-35 Victory Secures 4,250 Connecticut Jobs". Hartford Courant. Retrieved 1 February 2015.

- Trimble, Stephen. "US Senate axes F-35 alternate engine". Flightglobal.com, 23 July 2009.

- Harrington, Caitlin. (2009) "Pratt & Whitney starts development of new F-35 test engine". Jane's Defence Weekly, March 27, 2009.

- "Donley: No JSF Alternatives Exist". aviationweek.com. Retrieved 21 July 2017.

- Graham Warwick, Amy Butler "Pentagon Ramps Up Pressure On F-35 Price." Aviation Week, 3 December 2010.

- News Desk. "F-35 Lightning II Resume Flying – 'Blade Crack Caused By Stressful Testing'". defense-update.com. Retrieved 1 February 2015.

- "Investigators Eye Third-Stage Turbine As F-35 Remains Grounded". aviationweek.com. Retrieved 1 February 2015.

- DOWLING, BRIAN (13 January 2014). "Former Pratt Employee Arrested Trying To Ship F-35 Documents To Iran". www.courant.com. The Hartford Courant. Retrieved 13 January 2014.

- "Press Releases". utc.com. Retrieved 1 February 2015.

- MEHTA, AARON (23 October 2013). "Pratt & Whitney, Pentagon Reach $1.1B Deal on F-35 Engines". www.defensenews.com. Gannett Government Media Corporation. Retrieved 23 October 2013.

- Dowling, Brian (March 26, 2014). "Pentagon criticizes Pratt & Whitney for 'systemic' F-35 production issues". www.stripes.com. Hartford (Conn.) Courant. Retrieved March 26, 2014.

- Shalal, Andrea (7 April 2014). "Pratt must push harder to cut F-35 engine cost: Pentagon". www.reuters.com. Reuters. Retrieved 8 April 2014.

- Shalal, Andrea (17 April 2014). "Cost to buy F-35 up 2 percent; to operate down 9 percent: Pentagon". www.reuters.com. Thomson Reuters. Retrieved 18 April 2014.

- Krauskopf, Lewis (29 August 2014). "Pratt halted F-35 engine shipments in May over titanium". news.yahoo.com. Reuters. Retrieved 29 August 2014.

- MEHTA, AARON (3 September 2014). "F-35 Head: Delays Coming if Test Planes Grounded Through September". www.defensenews.com. Gannett. Retrieved 4 September 2014.

- Capaccio, Tony (29 August 2014). "Pratt & Whitney Halted F-35 Engine Delivery Over Titanium". Bloomberg. Retrieved 5 September 2014.

- Majumdar, Dave (7 July 2014). "Sources: Engine 'Definitely' To Blame in June F-35 Fire". news.usni.org. U.S. NAVAL INSTITUTE. Retrieved 7 July 2014.

- Sweetman, Bill, Butler Amy, and Guy Norris, There's the rub, Aviation Week & Space Technology, September 8, 2014, pp.22-23

- Butler, Amy (13 July 2014). "Blade 'Rubbing' At Root of F-35A Engine Fire". aviationweek.com. Penton. Retrieved 13 July 2014.

- McGarry, Brendan (15 September 2014). "Bogdan: F-35 Engine Fix May be Ready by Year's End". Retrieved 17 September 2014.

- Osborn, Kris (31 October 2014). "Pentagon Implements F-35 Engine Fixes". www.dodbuzz.com. Monster. Retrieved 31 October 2014.

- Capaccio, Anthony (31 March 2016). "United Technologies' F-35 Engines Found to Have Recurring Flaws". www.bloomberg.com. Bloomberg L.P. Retrieved 31 March 2016.

- "X to F: F-35 Lightning II And Its X-35 Predecessors". codeonemagazine.com. Retrieved 29 May 2016.

- "The Pratt & Whitney F135". Jane's Aero Engines. Jane's Information Group, 2009 (subscription version, dated 10 July 2009).

- National Aeronautic Association (25 February 2002). "Integrated Lift Fan Gets Nod for Collier Trophy" (PDF). Retrieved 29 May 2016.

- Pratt & Whitney. "Power for F-35B Short Take Off and Vertical Landing (STOVL)" (PDF). Archived from the original (PDF) on 24 September 2015. Retrieved 29 May 2016.

- Rolls-Royce plc (2016). "Technology". Retrieved 29 May 2016.

- "F-35B Lightning II Three-Bearing Swivel Nozzle". codeonemagazine.com. Retrieved 29 May 2016.

- "Genesis of the F-35 Joint Strike Fighter" Paul M. Bevilaqua, 2009 Wright Brothers Lecture, Journal of Aircraft, Vol. 46, No. 6, November–December 2009

- "V/STOL by Vertifan" William T. Immenschuh, Flight International, 1 October 1964

- "The Shaft Driven Lift Fan Propulsion System for the Joint Strike Fighter" Paul M. Bevilaqua, American Helicopter Society 53rd Annual Forum, Virginia Beach, April 29-May 1, 1997

- Tirpak, John (November 2012). "The F-35's Race Against Time". Air Force Association. Archived from the original on 8 November 2012. Retrieved 4 November 2012.

while not technically a "supercruising" aircraft, can maintain Mach 1.2 for a dash of 150 miles without using fuel-gulping afterburners

- Katz, Dan (7 July 2017). The Physics And Techniques Of Infrared Stealth. Aviation Week. Retrieved 12 April 2019.

- Swedberg, Claire. "Energy-Harvesting Sensors to Monitor Health of Jet Engines". RFID Journal, 31 May 2011.

- "Pratt & Whitney F135 Press release". Archived from the original on 2019-05-11. Retrieved 2008-10-17.

- Rajagopalan, R., Wood, B., Schryver, M. (2003). Evolution of Propulsion Controls and Health Monitoring at Pratt and Whitney. AIAA/ICAS International Air and Space Symposium and Exposition: The Next 100 Years. 14–17 July 2003, Dayton, Ohio. AIAA 2003-2645.

- Norris, Guy, Power plan, Aviation Week & Space Technology, April 13–26, 2015, p.26

- Whitney, Pratt &. "Pratt & Whitney Validates Growth Option for F135 Engine". www.prnewswire.com. Retrieved 21 July 2017.CS1 maint: extra punctuation (link)

- Pratt & Whitney launches Growth Option 2.0 upgrade for F135 engine, Air Force Technology, 2018-06-14

- "F135 Engine" (PDF). f135engine.com. Archived from the original (PDF) on 24 September 2015. Retrieved 29 May 2016.

- Ray, Mike W. (20 July 2012). "F135 engine depot stand-up has started". www.tinker.af.mil. Retrieved 15 March 2019.

- Langdon, Lee S. (1 April 2007). Fahrenheit 3,600. ASME.

- Bibliography

- Connors, Jack (2010). The Engines of Pratt & Whitney: A Technical History. Reston. Virginia: American Institute of Aeronautics and Astronautics. ISBN 978-1-60086-711-8.

- Jane's Information Group. Pratt & Whitney F135. Jane's Aero Engines. Modified 10 July 2009.

External links

| Wikimedia Commons has media related to Pratt & Whitney F135. |