Minerva Mill, Ashton-under-Lyne

Minerva Mill was a cotton spinning mill in Ashton-under-Lyne, Greater Manchester, England. It was built between 1891 and 1892 for the Minerva Spinning Company which was later known as the Ashton Syndicate. Minerva Mill was next to the later Texas mill, at Whitelands. It ceased spinning cotton in the 1920s and was demolished in 1937.

_from_scan.png) Minerva Mill (1895) | |

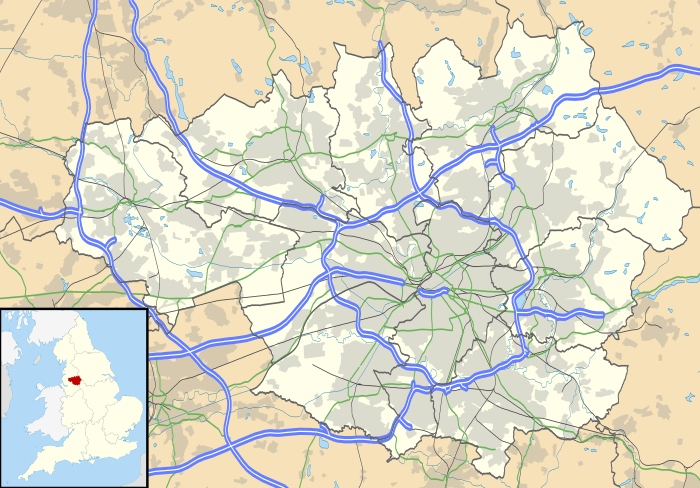

Location within Greater Manchester | |

| Cotton | |

|---|---|

| Spinning (mule mill) and doubling | |

| Serving canal | Huddersfield Narrow Canal |

| Serving railway | Lancashire and Yorkshire Railway |

| Owner | Minerva Spinning Company Ltd. |

| Coordinates | 53.4823°N 2.0882°W |

| Construction | |

| Built | 1891 |

| Completed | Feb 1892 |

| Demolished | 1937 |

| Floor count | 4 |

| Other dimensions | 283ft X |

| Main contractor | E. J. Smethurst Oldham |

| Power | |

| Date | 1892 |

| Engine maker | Daniel Adamsons |

| Engine type | Twin triple expansion |

| rpm | 55 |

| Boiler configuration | |

| Pressure | 11.249 bar |

| Equipment | |

| Manufacturer | John Hetherington and Sons, |

| Mule Frames | 86,868 spindles(1892) 93,828 spindles(1903) Medium counts +22,000 doubling spindles (1920) |

| References | |

| Haynes 1987, p. 48 | |

Location

Minerva mill was built in a bend in the River Tame, close to the Huddersfield Narrow Canal, at Whitelands. It was at the end of Minerva Road.

History

The Minerva Spinning Company Limited was registered in 1891 to build the Minerva Mill at Whitelands. The directors were Messrs Barlow, Marland, Coop, Newton, Pollitt and Pownall; they were later referred to as the Ashton syndicate. The syndicate went on to build the Rock Mill, Atlas Mill, Curzon Mill, Tudor Mill, Cedar Mill and finally the adjoining Texas Mill. The Minerva Spinning Company went out of business in the 1920s.[1]

Architecture

_plan.png)

It was designed by Sydney Stott. Four storeys over a basement.

Power

The steam engine was a 1500 hp twin triple expansion engine by Daniel Adamsons, of Openshaw built in 1906. The cylinders were christened Capital and Labour. It had an 18 ft flywheel that operated at 75 rpm. The flywheel drove 40 ropes that transmitted the power to each floor. The cylinders all had Corliss valves. They had a 48in throw, the High pressure was 22 ½" in diameter, the intermediate was 34 in and the low pressure was 56in. The air pump was driven from the low pressure crosshead, there was a Saxon governor on the high pressure end of the bed.[2]

Equipment

The mule frames were provided by John Hetherington and Sons Ltd. On startup here were 86,868 mule spindles spinning medium counts from American cotton, that was 40's twists and 65 wefts. By 1903, this had increased to 93828, and by 1920, 22,000 doubling spindles had been added.[3] In order to run these spindles in the spinning rooms, the cotton had to be prepared using openers, scutchers, carding engines.

| Number | Machines | Ratio |

|---|---|---|

| 2 | Vertical Openers and scutchers | 1 : 43,434 |

| 4 | Intermediate Scutchers | 1 :21,717 |

| 93 | Carding Engines | 1 :934 |

| 63 | finishing deliveries of drawing | 1 :1,380 |

| 792 | Slubbing spindles | 1 :109.7 |

| 1716 | Intermediate spindles | 1 :50.6 |

| 6680 | Roving spindles | 1 :13 |

| 86,868 | Mule spindles | 1 :1 |

Usage

Minerva Mill was used for spinning fine counts of Egyptian cotton, both twists and weft.

Owners

- The Ashton syndicate

See also

- Textile manufacturing

- Cotton Mill

References

- Notes

- Haynes 1987, p. 481

- Roberts 1921

- Haynes 1987, p. 51

- Nasmith 1895, p. 113

- Bibliography

- Haynes, Ian (1987). Cotton in Ashton. Libraries and Arts Committee, Tameside Metropolitan Borough. ISBN 0-904506-14-2.

- Nasmith, Joseph (1895). Recent Cotton Mill Construction and Engineering. London: John Heywood. ISBN 1-4021-4558-6. Retrieved March 2009. Check date values in:

|accessdate=(help) - Roberts, A S (1921). "Arthur Robert's Engine List". Arthur Roberts Black Book. One guy from Barlick-Book Transcription. Archived from the original on 2011-07-23. Retrieved 2009-01-11.

- Williams, Mike; Farnie (1992). Cotton Mills of Greater Manchester. Carnegie Publishing. ISBN 0-948789-89-1.