Giga Nevada

Tesla Giga Nevada (or Gigafactory 1)[5] is a lithium-ion battery and electric vehicle subassembly factory near Reno, Nevada.[6][7][8] The facility is owned and operated by Tesla, Inc. to supply the battery packs for its electric vehicles and stationary storage systems. It is located at the Tahoe Reno Industrial Center (TRIC) in Storey County, and employs around 7,000 people at the end of 2018,[3] with a timetable and hiring goals of eventual thousands more jobs in Reno with nearly 10,000 statewide, and over $100 billion in economic activity. Future manufacturing programs may also move to Nevada.[9][10][11]

Drone view in December 2019 | |

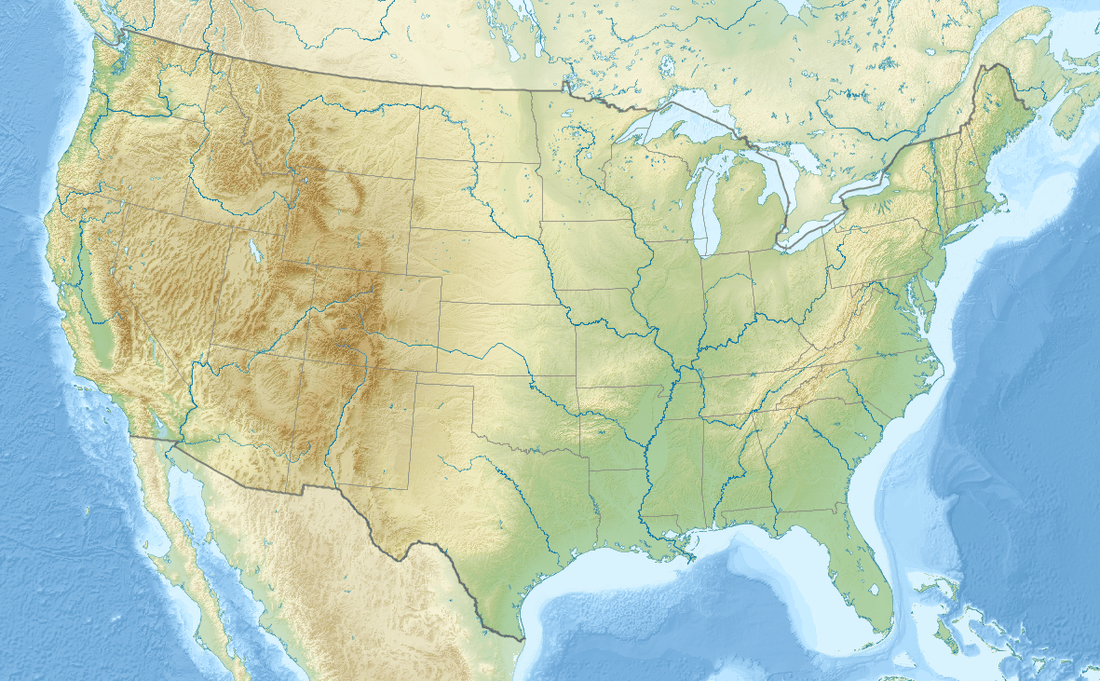

Location of Giga Nevada  Giga Nevada (the United States) | |

| |

| Built | January 2015[1] –2020s |

|---|---|

| Operated | January 2016[2] |

| Location | Storey County, Nevada, U.S. |

| Coordinates | 39.538°N 119.440°W |

| Industry | Energy storage |

| Products | Electric vehicle parts, Lithium-ion batteries |

| Employees | 7,000[3] |

| Area | 1,900,000 sq ft (180,000 m2)[4] |

| Owner(s) | Tesla Inc. |

The factory started limited production of Powerwalls and Powerpacks in the first quarter of 2016[12][2] using battery cells produced elsewhere, and began mass production of cells in January 2017.[13] Nevada Governor Brian Sandoval estimated that Nevada would enjoy $100 billion in economic benefit over two decades from the construction and operation of this factory.[10] The grand opening event was held on July 29, 2016.[14]

Gigafactory 1 is aligned on true north, which was done so that the equipment can be mapped by GPS and solar panels on the roof can be accurately aligned. The factory has also been designed to become entirely energy self-reliant. Tesla intends to power the structure through a combination of on-site solar, wind and geo-thermal sources.[15] When completed, the building will have the largest footprint in the world and second largest volume.[16]

Tesla’s Gigafactory 2 produces solar tiles and vehicle chargers in Buffalo, New York, and Giga Shanghai in Shanghai, China produces vehicles.[17][18][19][20] Gigafactory Europe near Berlin, Germany is currently being built and expected to complete in 2021.[21] Lastly, a 2nd North American factory (Giga Texas) is being built in Austin, TX.[22]

According to Elon Musk, one hundred factories like Giga Nevada, will be necessary to transit the world to a complete sustainable energy consumption.[23]

History

Initial public mention of the gigafactory concept was made in November 2013,[24][25] although Tesla's internal plans predated that; Tesla had investigated almost 100 sites.

In July 2014, it was announced that Panasonic had reached a basic agreement with Tesla to invest in a factory,[26][27][28] estimated to cost $5 billion.[29][30] The northern Nevada site and plans were announced with state officials on September 3, 2014.[8] Panasonic agreed to lead the battery cell production portion of the manufacturing, and Tesla CEO Elon Musk indicated in 2015 that the total Panasonic investment would be US$1.5–2 billion,[31] and that Tesla would not expand beyond original plans.[32] In early 2016 Panasonic president Kazuhiro Tsuga confirmed a planned total investment of about $1.6 billion by the company to equip the factory to full capacity.[33] However, after the number of Model 3 reservations became known in April 2016,[34] Panasonic moved production plans forward[35][36] and announced a bond sale for $3.86 billion, most of it to be invested in Gigafactory.[37][38][39]

Tesla held a grand opening on July 29, 2016 of the operational facility, having only three of the final 21 "blocks" of the gigafactory built out, or approximately 14 percent of the final factory size, which is expected to be completed by 2020.[40] By September 2016 Tesla had spent $608 million on the Gigafactory.[41]

In October 2016, it was announced that Tesla would build motors and drive units at the Gigafactory, in addition to the previously announced batteries and assembled battery packs called Powerpacks.[42]

By November 2018, as the Model 3 production had successfully ramped up to approximately 5000 vehicles a week for several months, the production rate of battery cells in the Gigafactory had reached 3.5 million '2170' cells per day.[43]:1:08

Rationale

.jpg)

Tesla expects that Gigafactory 1 will reduce the production cost for assembling electric vehicle battery packs from overseas suppliers of batteries and Powerwall and Powerpack packs assembly by 30%. Its projected capacity for 2018 is 50 (GWh)/yr of battery packs, and its final capacity upon completion was, as of May 2016, planned to be 150 GWh/yr of battery packs.[44] This would enable Tesla to produce 1,500,000 cars per year.[45][30]

The factory is designed to optimize quality while minimizing cost of production of battery packs and raw material utilization through vertical integration. Tesla expects to achieve a cost target for production battery packs of under US$100 per kWh of energy storage by 2020, near the "inflection point at which it begins [to cost] less to build an electric powertrain than [an internal combustion engine powertrain] even without subsidies or [considering] the savings of electricity vs. gas."[40]

Tesla claims that Gigafactory will assemble battery packs from batteries purchased overseas for significantly less cost using economies of scale, innovative manufacturing, reduction of waste, and the simple optimization of locating most manufacturing assembly processes under one roof.[46]

Factory location

Grants and tax abatements for Gigafactory until year 2034[47][48][49]

Tesla initially considered several sites, but northern Nevada was not one of them. A manager at Reno–Tahoe International Airport offered some of its 3,000 available acres at Reno Stead Airport, and persuaded TRIC owner to split the bill for a private jet to fly Tesla people to the area. They tried several times, and Tesla eventually came to TRIC and was pleased by the speed of regulatory work.[50][51][52]

State competition and incentives

At least five states competed to attract Gigafactory by offering tax incentives, cash grants[53][54] and other methods in the hope of future business; California,[55][56] Arizona,[57] Nevada,[58] New Mexico, and Texas,[59] where San Antonio had offered bigger incentives with no sales tax, but did not get the factory. States without sales tax were topping the list of preferred sites.[47][58][60][61][62]

Nevada estimates a tax base of $1.9 billion over 20 years.[49] After sticky negotiations,[62] Tesla chose the Tahoe-Reno Industrial Center (TRIC) as the location of the Gigafactory mainly due to speed[58] and a State of Nevada incentive package. Other location reasons were rail access, direct sale ability,[54][60] and low air humidity[63] to ensure less than 300 ppm humidity in production.[64] The TRIC owners gave the first 1,000 acres to Tesla for free.[65]

The incentives include $195 million in transferable tax credits depending on Tesla's investment schedule and job creation, similar to the Volkswagen Chattanooga Assembly Plant deal and others.[47][61][62][66] Tesla's investments earn them about $10 million in tax credits per quarter,[67][68][69] and by July 2016 had sold these for $20 million cash.[70] At the end of 2016, Tesla and Panasonic had 477 employees and 5,591 construction workers, mostly Nevada residents, and invested $1.1b earning $59m in tax credits.[71] By 2019, the gigafactory companies (now with 7,700 employees) had invested a combined $4.9 billion dollars ($3b by Tesla, $1.7b by Panasonic, and $100m by H&T plus some equipment). This qualified the companies for the full tax credit amount of $195 million[72] which were repurposed from other tax credit programs for the filming and insurance industries, keeping Nevada State tax programs neutral. The development surpassed the original 2014 plan for investments and 6,500 employees. Numbers for construction were $2 billion and 17,000 workers.[73][74]

The incentive package also includes 20 years free from sales tax and 10 years free from property tax, depending on Tesla's ability to meet performance expectations (like investing $3.5 billion in Nevada).[47][62] By 2034, this package could have accumulated to a value of $1.25 billion in missed taxes; the 10th largest in the US. The $725M sales tax abatement was particularly important, as 5 other states charge no sales tax at all, and 34 states (including Arizona and Texas) don't charge sales tax on manufacturing equipment.[47][61] With a tax base of $1.9 billion and an incentive package of $1.25 billion, the projected end result was calculated as a tax-per-abatement ratio of 1.52.[48][58][75] For 2014-2018, tax abatements were $240 million.[73] The nearby data centers from Apple Inc. and Switch also received incentives.[58][76]

Nevada estimates the construction impact at $2.4 billion and the economic impact from the project at $100 billion over two decades ($5 billion/year, of which $353-378 million are wages) yielding $57 million in state and local taxes.[48][49][73] Some economists said that number was "deeply flawed," for instance, it counted every Tesla employee as if they would otherwise have been unemployed and made no allowance for increased government spending to serve the influx of thousands of local residents.[10][77][78][79][80][81][82] The regional impact is estimated to be $3.5 billion per year. Other large companies chose to create activity in the area partly due to Gigafactory.[73] Tesla agreed to pay $7.5M per year for 5 years ($37.5M) to the school system.[47]

Logistics

The 6-mile Nevada State Route 439/USA Parkway was built by TRIC, and connects TRIC to Interstate 80. Since 2004, the TRIC owners had planned to extend SR 439 south to U.S. Route 50.[83] In 2014, Nevada Department of Transportation advanced the otherwise dormant south extension.[84][85][86][87] This improves traffic conditions for the many large logistics centres at TRIC and Gigafactory, bypassing Reno on the way to U.S. Route 50.[88][89] Tesla plans to ship batteries by rail[90] to its car factory in Fremont.[54][91]

Water is scarce in Nevada, and some of the water for the Gigafactory is piped from a treatment plant in neighboring Washoe County.[62] A 1.5 million U.S. gallons (5.7 million L) water tank is also used (about two Olympic-size swimming pools).[92][93][94]

TRIC built high-pressure natural gas lines to its sites, but Tesla decided to use electricity and not connect natural gas to Gigafactory.[95] Heat pump technology is used for heating,[96][97] and a $6.8 million hot water storage tank with 10 million gallons is used to balance heat.[92][64] In 2014 Navigant estimated 100 MW electricity delivery which could be supplied (on average) by nearby wind turbines and roof solar panels,[98] whereas a former Tesla logistics manager in 2016 estimated 300 MW to produce 35 GWh of battery capacity per year.[99] Tesla installed solar panels on the roof in early 2018,[100][101] to eventually reach 70 MW[102] from 200,000 solar panels.[103]

Tesla works with a mining company to extract lithium 200 miles (320 km) to the southeast, at Silver Peak in Esmeralda County. They intend to process the underground brine water industrially over hours rather than the traditional way of letting the water evaporate from ponds over a year.[59][104]

Construction

.jpg)

Tesla had already started brush clearing[105] and grading[58] during the summer of 2014[106] (prior to official announcement in September; permit date was June 26),[92] with vertical construction reported in January 2015.[1] Tesla and its partners intend to complete the facility by 2018.[107] On March 18, 2016 a group of journalists were allowed to visit the Gigafactory under strict conditions and found that 14% of the final building area had been completed.[108] By April 2016 there were around 600 construction workers.[109] Depending on season and building stage, the number of construction workers has fluctuated between 250 and 1,800.[110] On June 13, 2016, Tesla filed for a $63m expansion into section E on the site. By September 2016, the building had grown to 1.9 million sq ft (0.2 million m2) with further areas under construction.[111] As of January 2017 the building's footprint is 1.9 million sq ft (0.2 million m2) with 4.9 million sq ft (0.5 million m2) of usable area across several floors.[112] A combined permit value of $322m was registered in July 2016,[113] and $1.2b in July 2017.[92] Gigafactory and the other large companies affect the local area by increased needs in transportation (SR 439) and housing;[114] house prices increased by 17% in 2015 from half of the peak in the previous 2008 building bubble. Local businesses were wary of building new homes, which is being done mostly by out-of-state companies.[115]

- Design features

HVAC equipment is located "between the floors rather than on walls and ceilings of a floor."[40] All steel is from the United States. Tesla is its own contractor on the project, learning how to build other factories should they choose so.[34][93]

Future expansion

Prior to the building of more gigafactories (see below), Tesla may expand and potentially double the size of Gigafactory 1. In June 2015, Tesla announced it exercised its option to buy 1,864 acres (754 hectares) of land adjacent to the original 1,000-acre (400 ha) Gigafactory site. According to Tesla spokeswoman Alexis Georgeson, "The purchase gives us the opportunity for future growth." In Tesla's dealings with the state of Nevada expanding the size was always an option should the company choose to do so, said Steve Hill, director of the Governor's Office of Economic Development. "Tesla had said that the factory will be up to 10 million square feet [1 million square meters] in one or two stories," Hill said. "On the earnings call (in May 2015), Elon said they aren't yet committing to this but that they are considering increasing the size of the gigafactory here by 50 to 100 percent."[116]

Early estimates from 2014 projected that the factory would employ approximately 6,500 people by 2022, requiring at least half of them to be Nevadans.[48]

Operations

Tesla owns the land and building, and leases parts of the building to several suppliers.[117] The gigafactory is operated by a management team under executive Jens Peter Clausen, formerly a LEGO executive, who is VP of Gigafactory at Tesla.[118] By April 2016 Gigafactory had 317 Tesla employees and 52 by Panasonic, most of them from Nevada,[109] and 850 by December 2016.[119] In 2017, 3,249 employees were registered,[120][121] and by December 2018, 7,000 people worked at GF1,[117][122] increasing to 7,557 by June 2019, mostly Nevadans.[72]

Production

The factory is intended to gradually[123][124] provide cradle-to-cradle handling of batteries, from raw material over components to finished products, and recycling old batteries into new.[30] Cells constitute most of the value creation, whereas packing and electronics are minor parts.[125] Tesla views production as more important than products, and assigns more engineers to developing production equipment than to developing products.[126][127][128]

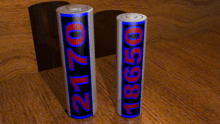

Cell level

The battery cells produced at the Gigafactory are the new form factor '2170', jointly designed and engineered by Tesla and Panasonic.[129] They are larger than the 18650 cells used in the Model S and Model X automobiles. While the cells were originally expected to be at least 20 mm in diameter and 70 mm in length,[130][131] revised specifications for the optimized form factor are 21 mm (0.83 in) by 70 mm (2.8 in). Tesla thus refers to it as the '21–70'[40] or '2170'[129] whereas Samsung refer to the size as '21700'.[132]

Panasonic was expected to begin cell production in 2016,[118] and continue for at least 10 years.[133] Among the machines spotted at the opening in July 2016 were presses and rollers for cathodes.[134] Gigafactory began mass production of 21700 cells in January 2017.[13][124] Only Panasonic cells are to be used in the US-made Model 3,[135] and Tesla uses 21-70 format for Model 3 and Powerwall/Powerpack.[124] Panasonic owns some of the cell production equipment[133] in an area not accessible to others. By December 2018, Panasonic operated 11 cell production lines.[117] Some of the lines were temporarily converted from storage (NMC) to vehicle (NCA) to increase supply for the Model 3.[136]

Tesla uses Nickel Manganese Cobalt (NMC) lithium cells for stationary storage (Powerwall and Powerpack), and Nickel Cobalt Aluminium Oxide (NCA) for vehicles.[137]

The cell components are then encased in aluminum cans made by Heitkamp & Thumann inside GF1,[138][117] using 10,000 tons per year.[139]

An April 2019 report quoting former and current employees at Panasonic's side of the Gigafactory described how half a million of battery cells per day were scrapped because of production defects related to carelessness, lack of respect for operating procedures, and the overall pressure to increase output.[140][141][142] Panasonic delivered three million battery cells daily to Tesla in 2018.[117]

At the end of 2019, Panasonic had 3000 US workers and 200 Japanese technicians at Gigafactory 1,[141] quality had improved to increase production to a rate of 30 GWh/year on the same equipment. Panasonic occupies more than half of the factory.[142]

Product level

The basis of the early Tesla products are lithium-ion cells in the 18650 form factor. These cylindrical cells have a diameter of 18 mm and are 65 mm in length, a size used for the batteries of laptops. Cylindrical cells are generally less expensive (costing 190–200 dollars per kWh as of 2014) than large format cells whose active layers are stacked or folded (approximately 240–250 dollars per kWh).[143] They are used in Model S and X, and Powerwall 1.

In October 2015, Tesla moved the Tesla Powerwall and Powerpack production from its Fremont factory to the Gigafactory. The Tesla Powerwall has been produced in the finished portion since the third quarter of 2015.[108]

2170-cells are transferred on autonomous vehicles from Panasonic to Tesla, where workers and robots assemble cells into packs using bandoliers, cooled by tubes made onsite by Valeo.[117][144]

Drive units (motor and gearbox) for Model 3 are made with 90% automation.[117]

Output goals

As of 2014, the projected capacity of Gigafactory for 2020 was to have been 35 gigawatt-hours per year of cells as well as 50 gigawatt-hours per year (5.7 MW) of battery packs.[26] Production could be equivalent of supplying 500,000 Tesla cars per year.[30][107][145] When finished, the factory is planned to produce more lithium ion batteries in a year than were produced in the entire world in 2013. As of May 2019, Gigafactory 1 has achieved a theoretical capacity of 35 gigawatt-hours per year but utilization levels have resulted in a 24 gigawatt-hour output, according to Panasonic President Kazuhiro Tsuga. Tesla is aiming to increase this utilization significantly in 2019 by optimizing their higher-speed production lines, rather than relying on further investments for new production lines.[146]

Controversy

In August 2018, Karl Hansen, a former member of the company's security team, filed a whistleblower tip with the Securities and Exchange Commission. In the tip, he alleged that Tesla suppressed an internal investigation into various criminal activities at the Nevada Gigafactory. Hansen said that the company refused to tell the DEA about several employees who were allegedly moving cocaine and crystal methamphetamine on behalf of a Mexican drug cartel. He also said that the company tried to get him to not report a $37 million theft of raw materials. Additionally, he said the company fired an employee who reported the theft, and gave the reason that the employee was "not a Tesla team player."[147]

Future Gigafactories

On April 30, 2015, Elon Musk announced that the factory heretofore known simply as the Gigafactory was now to be known as Gigafactory 1 as Tesla plans to build more such factories in the future. At the same event, Musk also said that he believed that other companies would build their own similar "Gigafactories".[6] After receiving $800M of orders ($179M PowerWall, $625M PowerPack) within 1 week of unveiling, Musk estimated that the Gigafactory 1 is not enough to supply demand.[148]

In May 2017 at a TED Talk, Elon Musk stated his intention to announce three or four new Gigafactory sites. These factories will manufacture both batteries and complete cars to enable "global production" of their products.[149]

In May 2019, Tesla announced that in order to alleviate the pressure from the trade war on its business in China, the company is pushing to rapidly start production at its new Giga Shanghai and avoid any tariffs. Tesla started construction in January and said that it “will take roughly two years” until they start volume production. They have since accelerated the plan and now want to produce 3,000 Model 3 vehicles in Shanghai by end of year.[150]

In November 2019, Tesla announced that they will build a Gigafactory Europe right outside Berlin, planned to be operational by end of 2021.[151]

In February 2020, Elon Musk Tweeted "Giga Texas?" and changed his location to Austin,TX causing speculation that Tesla would announce a new Gigafactory in Texas.[152]

See also

- Tesla Factory (Fremont)

- Giga New York

- Giga Shanghai

- Giga Berlin

- Giga Austin

- Tesla facilities in Tilburg

References

- "Photos: Structure taking shape on Tesla property". Reno Gazette-Journal. January 8, 2015. Retrieved January 5, 2017.

- Johnston, Adam (January 8, 2016). "Tesla Starts Off 2016 By Producing & Delivering Powerwall". CleanTechnica. Retrieved January 6, 2017.

- Tesla Annual Report (July 1, 2018 - June 30, 2019)

- Bond, Noah (September 3, 2019). "MADE IN NEVADA: Tesla". www.kolotv.com. 8abc. Archived from the original on November 10, 2019.

- Musk, Elon [@elonmusk] (January 25, 2020). "Going with nomenclature of Giga [most widely understood location name] vs Giga #, so Giga Shanghai, Giga Nevada, Giga New York & Giga Berlin" (Tweet). Retrieved January 26, 2020 – via Twitter.

- "Elon Musk Debuts the Tesla Powerwall". YouTube. April 30, 2015. Retrieved May 1, 2015.

- "Tahoe Reno Industrial Center". Retrieved September 22, 2014.

- Wald, Matthew L. (September 4, 2014). "Nevada a Winner in Tesla's Battery Contest". The New York Times. Retrieved January 5, 2017.

- "Tesla Gigafactory 1 now employs over 3,000 workers as it becomes biggest battery factory in the world". Electrek. August 21, 2018. Retrieved October 31, 2018.

- Nash, James; Ohnsman, Alan (September 5, 2014). "Nevada Lures Tesla Plant With $1.3 Billion in Tax Breaks". Bloomberg. Retrieved January 5, 2017.

- https://www.yahoo.com/news/elon-musk-says-tesla-moving-hq-181109558.html

- "Tesla Unveils Model 3". Tesla. March 31, 2016. Retrieved April 1, 2016.

- Randall, Tom (January 4, 2017). "Tesla Flips the Switch on the Gigafactory". Bloomberg.com. Archived from the original on January 4, 2017. Retrieved January 4, 2017.

- "Tesla sets July 29 date for Gigafactory Grand Opening event". Teslarati. May 27, 2016. Retrieved January 5, 2017.

- Musk, Elon (April 2017). "Elon Musk: The future we're building – and boring". TED Talk. Event occurs at . Retrieved July 2, 2017.

- O'Kane, Sean (November 30, 2018). "Tesla will live and die by the Gigafactory". The Verge. Retrieved December 4, 2018.

- "Hit by trade war, Tesla opens bid process to build China Gigafactory". South China Morning Post. December 6, 2018. Retrieved December 17, 2018.

Shanghai Construction Group is among several firms bidding … Shanghai Baoye Group, a China Minmetals subsidiary, is preparing for the delivery of a large amount of concrete pipe piles and steel pile tips in the second half of December [2018]

- "Tesla christens Buffalo solar factory 'Gigafactory 2', will finalize locations of Gigafactory 3, 4 and possibly 5 this year". Electrek. February 22, 2017.

- "Tesla acquisition of Grohmann automation production". The Verge. November 8, 2016.

- "Tesla to open new plant in Shanghai". www.cnbc.com..

- "Elon Musk: Tesla is going to build Gigafactory 4 in Berlin area". electrek.co. Retrieved November 12, 2019.

- Lambert, Fred (August 9, 2020). "Tesla paid almost $100 million for Gigafactory Texas land in Austin". Electrek. Retrieved August 9, 2020.

- "Welcome to the Gigafactory - Before the Flood". Event occurs at . Retrieved September 22, 2019.

- "2013: Tesla Motors may make its own batteries". Mercury News. November 15, 2014. Retrieved August 1, 2016.

- Savov, Vlad (November 6, 2013). "Tesla's solution to battery shortages is to build its own 'giga factory'". theverge.com. Retrieved August 1, 2016.

- "Panasonic to pour billions of yen in Tesla's gigafactory as initial investment". ZDNet. October 7, 2014. Retrieved October 9, 2014.

- "Panasonic, Tesla agree to partnership for US car battery plant". Nikkei Inc. July 29, 2014. Archived from the original on July 31, 2014. Retrieved August 1, 2014.

- John Kell (July 31, 2014). "Tesla, Panasonic team up to build Gigafactory". Fortune.

- "Tesla's Nevada Gigafactory to cost $5 billion". SlashGear. Retrieved May 29, 2016.

- "Planned 2020 Gigafactory Production Exceeds 2013 Global Production" (PDF). February 26, 2014. Archived (PDF) from the original on April 19, 2016. Retrieved June 5, 2014.

- Trudell, Craig (March 27, 2015). "Tesla Pushes Japanese Suppliers as It Seeks Battery Partners". Bloomberg.

- "1,800-acre purchase expands Tesla's footprint near Reno". Las Vegas Sun. July 15, 2015. Retrieved October 23, 2016.

- Ramsey, Mike (January 7, 2016), "Panasonic Will Bet Big on Gigafactory", www.wsj.com

- "Tesla's entire future depends on the Gigafactory". The Verge. Vox Media. July 28, 2016. Retrieved July 29, 2016.

- "Panasonic to jump-start US battery cell output for Tesla". Nikkei Asian Review. June 21, 2016. Archived from the original on July 10, 2016. Retrieved October 23, 2016.

- "Tesla slams the accelerator on Gigafactory". SFGate. July 27, 2016. Retrieved October 25, 2016.

- "Panasonic to raise $3.9 billion, partly to finance Tesla plant investment". Reuters. July 29, 2016. Retrieved July 28, 2019.

- "Tesla Motors, Inc. (NASDAQ:TSLA) Stock Jumps On Panasonic's $3.9 Billion For Gigafactory". The Country Caller. July 29, 2016. Archived from the original on September 11, 2016. Retrieved September 4, 2016.

- "Tesla Motors Inc Expects To Spend $2 Billion On Gigafactory Construction". The Country Caller. August 8, 2016. Archived from the original on September 11, 2016. Retrieved September 4, 2016.

- Weintraub, Seth (July 28, 2016). "Tesla Gigafactory tour roundup and tidbits: 'This is the coolest factory in the world'". Electrek. Retrieved July 30, 2016.

- "Form 10-Q For the quarterly period ended September 30, 2016. Commission File Number: 001-34756". Tesla Motors. November 1, 2016. p. 17. Retrieved January 6, 2017.

We have incurred $608.4 million of costs for our Gigafactory as of September 30, 2016.

- Lambert, Fred (October 15, 2016). "Tesla is building new 'drive unit production lines' at the Gigafactory, will not only manufacture battery packs". electrek.co. Retrieved February 4, 2017.

- Chris Lister, VP of Gigafactory; Jat Dhillon, Director of Manufacturing (November 30, 2018). This is Elon Musk's key to Tesla's future (video). The Verge. Retrieved December 2, 2018 – via YouTube.

- "Tesla could triple the planned battery pack output of 'Gigafactory 1' to 150 GWh, says Elon Musk". electrek.co. June 1, 2016. Retrieved January 2, 2018.

- "Tesla Gigafactory Grand Opening Video". July 30, 2016.

- "Tesla Gigafactory". Tesla Inc. Retrieved July 2, 2017.

- Damon, Anjeanette (September 16, 2014). "Inside Nevada's $1.25 billion Tesla tax deal". Reno Gazette Journal. Retrieved November 3, 2016.

the company must invest a minimum of $3.5 billion in manufacturing equipment and real property in the state. Five other states charge no sales tax at all and 34 states, including Arizona and Texas, don't charges sales tax on manufacturing equipment.

- Incentive Agreement Archived March 29, 2017, at the Wayback Machine page 5+6, pdf page 26+90, 57–69. Quote:"Tax abatements were considered by Tesla to be a crucial part of its financial plan for the Gigafactory". "Credits {TTC A – on jobs. Up to 6,000 jobs $12,500 / job; $75.0 million} {TTC B – on investment. $3.5 billion investment 5% on $1B, 2.8% on $2.5B; $120.0 million} {Subtotal $195.0 million}". Size: 9MB in 98 pages

- "Tesla's Gigafactory in Nevada" (PDF). Diversify Nevada. US. Retrieved December 5, 2016.

- Commissioner Lance Gilman RMC Presentation, at 13m on YouTube

- Higdon, Mike (January 28, 2016). "Northern Nevada's Direction: Seize opportunity and work hard". Reno Gazette Journal. Retrieved November 6, 2016.

Originally, they hadn't considered Northern Nevada at all. But Tina Iftiger, vice president of airport economic development at Reno-Tahoe International Airport, helped convince Tesla executives to visit the region over and over again until they put it on the list.

- Tesla – Tahoe Reno Industrial Center, Dean Haymore from Story County Commission, at 2m on YouTube

- Wesoff, Eric (March 1, 2014). "Tesla's $5B Giga Battery Factory and Deep Politics in AZ, TX, NV and NM". GTM. Retrieved November 4, 2016.

- "Why This State Is The Most Likely To Get Tesla's Gigafactory". Jalopnik. January 4, 2014. Retrieved November 4, 2016.

A variety of factors will enter into Tesla's decision. First, you have your obvious ones for any such project like land availability, taxes, and tax incentives

- "California's 'Improbable' Bid To Land Tesla's Gigafactory". Forbes. May 26, 2014.

- "California makes big plans to land Tesla battery 'gigafactory'". San Jose Mercury-News. June 6, 2014.

- "Atieva will launch its Tesla competitor by December". Recode. October 20, 2016. Retrieved October 21, 2016.

- Hidalgo, Jason (September 16, 2014). "Art of the Tesla deal: How Nevada won a gigafactory". Reno Gazette Journal. Retrieved October 25, 2016.

It's a real get things done state. That was a really important part of the decision .. Tesla does not want to deal with stalled development

- Gaar, Brian (September 4, 2014). "Tesla dashes Texas' hope for gigafactory". Austin American-Statesman. Retrieved October 21, 2016.

- How did Texas lose its bid for Tesla's 'gigafactory'? Archive 2014-09-04

- Kirkland, Joel (November 16, 2015). "TECHNOLOGY: Gigafactory lands on Tesla's fast track to Big Battery era". EnergyWire. Archived from the original on March 22, 2016. Retrieved November 6, 2016.

We didn't have the biggest incentive package, we know that," said Mike Kazmierski, president of the Economic Development Authority of Western Nevada. Since the Great Recession, states have shelled out billions of dollars in incentives. Tennessee, with the 11th highest poverty rate in the nation, helped Volkswagen amass $566 million in tax breaks in 2008 to build a $1 billion plant in Chattanooga. Nearly $400 million in additional state and local incentives have gone toward expanding the plant since then, according to the Institute for Southern Studies. In 2012, Pennsylvania agreed to $1.6 billion in tax credits for Royal Dutch Shell PLC to build an ethane cracker north of Pittsburgh. Shell hasn't said whether it plans to build the plant. The Legislature in Washington state agreed to a record $8.7 billion package for Boeing in 2013. Tesla was "really concerned about scheduling risk.

- Ralston, Jon (October 4, 2014). "The year that changed Nevada – the untold details of how the Tesla deal was done". Ralston Reports. Archived from the original on August 10, 2015. Retrieved November 6, 2016.

Nevada was fourth in line for the plant with its RFI, about $650 million short on the abatements and $900 million short overall. Hill said he believed that Texas and New Mexico were the main competition. But O’Connell said it was never that simple, that the process was multilayered and not linear. “It’s a dynamic process, it’s an iterative process and it’s taking place at at least two levels,” he explained. “At one level, we had teams literally looking at dirt…the viability of a physical location. At another level, the conversation was between ourselves and the economic development folks about what kinds of financial programs can be used.” ..if Nevada was going to win out over other states with larger incentive packages: “We’ve got to close this gap somehow. It just has to happen or we’re not going to be able to do this” said Steve Hill from the Nevada authorities

- Chafkin, Max (November 17, 2015). "Elon Musk Powers Up: Inside Tesla's $5 Billion Gigafactory". Fast Company. Retrieved November 29, 2016.

Battery production requires very low humidity

- "Impact report" (PDF). Tesla. p. 28.

- "Lance Gilman's $43 million Tesla payoff has believers — and critics". Las Vegas Sun. December 30, 2014. Archived from the original on March 30, 2016. Retrieved October 23, 2016.

Free of charge, they dished Tesla nearly 1,000 acres to build its factory at TRIC

- Lambert, Fred (November 25, 2016). "Tesla received only a fraction of the subsidies the Big Three and oil industry have received". Electrek. Retrieved November 26, 2016.

- Tesla Gigafactory Quarterly Activity Report (Q1 2016) Diversify Nevada

- Tesla Gigafactory Quarterly Activity Report (Q2 2016) Diversify Nevada

- Lambert, Fred (December 6, 2016). "Tesla receives $8 million in tax credit for the Gigafactory after passing audit for job & investment requirements". Electrek. Retrieved December 6, 2016.

331 employees at the factory with 89% of them Nevada residents.

- "Tesla Sold $20 Million In Tax Credits To Vegas Casino". June 29, 2016. Retrieved October 23, 2016.

- "Tesla Gigafactory Compliance Audit Report (Exhibit A)]" (PDF). US: Diversify Nevada / Office of Economic Development. June 1, 2017. p. 6+11. Retrieved September 11, 2017.

- "Combined Summary and Transferable Tax Credit" (PDF). September 13, 2019.

- "Tesla Gigafactory economic impact summary 2015-2018" (PDF). December 5, 2018. Archived from the original (PDF) on October 31, 2019.

- "Economic impact of Tesla on Washoe and Storey counties" (PDF). September 2014. Archived from the original (PDF) on July 28, 2019.

- "Inside Nevada's $1.3 billion gamble on Tesla". The Verge. Vox Media. February 8, 2016. Retrieved May 29, 2016.

- "Sandoval: $1B Switch data center coming to Reno area". Reno Gazette Journal. January 16, 2015. Retrieved October 23, 2016.

- Wesoff, Eric (September 3, 2014). "Reports: Tesla Selects Nevada as Giga Battery Factory Site". Greentech Media. US. Retrieved October 9, 2014.

- Hirsch, Jerry (May 30, 2015). "Elon Musk's growing empire is fueled by $4.9 billion in government subsidies". Los Angeles Times. Archived from the original on October 28, 2015. Retrieved October 29, 2015.

- Hirsch, Jerry (May 30, 2015). "Three companies, $4.9 billion in government support". Los Angeles Times. Archived from the original on October 25, 2015. Retrieved October 29, 2015.

- Hirsch, Jerry (June 2, 2015). "Elon Musk: 'If I cared about subsidies, I would have entered the oil and gas industry'". Los Angeles Times. Retrieved October 29, 2015.

- "Musk defends receiving $4.9 billion in government support for Tesla, SolarCity and SpaceX". RT English. Retrieved October 29, 2015.

- Lambert, Fred (June 2, 2015). "Complete breakdown of the $4.9 billion in government support the LA Times claims Elon Musk's companies are receiving". Electrek. Archived from the original on January 6, 2020. Retrieved August 19, 2016.

- "18 mile road next on slate for industrial center". Nevada Appeal. September 5, 2004. Retrieved January 3, 2007.(subscription required)

- "Nevada Department of Transportation".

- "Transportation Board of Directors". Nevada Department of Transportation. Retrieved July 2, 2017.

- "USA Parkway construction bids due in the fall".

- Velotta, Richard N. (October 11, 2014). "Nevada approves $70 million for Tesla-related road work". Las Vegas Review Journal. Retrieved January 5, 2017.

- "Nevada Department of Transportation Breaks Ground on USA Parkway (State Route 439) Extension Project".

- Nelson, Paul (September 8, 2017). "NDOT Officially Opens USA Parkway Extension". KTVN. Retrieved September 13, 2017.

- "OpenRailwayMap" Check

|url=value (help). ÖPNVKarte. Retrieved July 2, 2017. - BUREAU, SEAN WHALEY LAS VEGAS REVIEW-JOURNAL CAPITAL (March 18, 2016). "Tesla officials show off progress at Gigafactory in Northern Nevada". Archived from the original on August 3, 2016.

- "Building Permits at Electric Avenue, McCarran, NV, 89434". Archived from the original on September 10, 2017. Retrieved September 11, 2017.

- Cookson, Jack (June 23, 2016). "Tesla's Gigafactory: A Grand Opening and Nowhere Near Done with Construction". BuildZoom. Retrieved November 29, 2016.

- "21 incredible facts about Elon Musk's Gigafactory – Page 12 of 22 – Business Insider". Business Insider. November 13, 2016. Retrieved November 29, 2016.

- Edelstein, Stephen (August 5, 2016). "Tesla Gigafactory energy: no solar panels yet, but no natural gas at all". Green Car Reports. Retrieved December 20, 2016.

- Field, Kyle (November 10, 2015). "Gigafactory Renewable Energy Plans Slip Out". Cleantechnica. Retrieved December 20, 2016.

- Calhoun, Lisa (August 1, 2015). "Elon Musk's Tesla Gigafactory Launches Epic, Zero-Emission American Manufacturing Era". Inc.com. Retrieved December 20, 2016.

- Lombardo, Tom (September 7, 2014). "Can Tesla Power Its Gigafactory with Renewables Alone?". ENGINEERING.com. Retrieved November 29, 2016.

- "Tesla-avhopparen vill starta svensk batterifabrik". Ny Teknik. September 29, 2016. Retrieved November 18, 2016.

Battery production is both energy and power consuming and a Gigafactory about 35 GWh estimated to have a connection of 300 MW

- Alvarez, Simon (March 13, 2018). "Tesla's solar rooftop array at Gigafactory 1 is starting to take shape". TESLARATI.

- Take a tour inside Tesla’s first Gigafactory. CNBC Reports. May 2, 2019. Event occurs at 6min 24s.

- Golson, Jordan (January 11, 2017). "Tesla will power its Gigafactory with a 70-megawatt solar farm". The Verge.

- Peters, Adele (April 15, 2019). "Inside Tesla's 100% renewable design for the Gigafactory". Fast Company.

- LeBeau, Phil (July 26, 2016). "There is a race for lithium going on in Nevada".

- "Elon Musk: Tesla Gigafactory 'a huge bet'". Reno Gazette Journal. February 4, 2015. Retrieved October 22, 2016. Gallery of early construction

- "Tesla: Tahoe-Reno Industrial Center's appeal". August 1, 2014. Retrieved October 23, 2016.

- "Gigafactory | Blog | Tesla Motors". teslamotors.com. Retrieved December 3, 2016.

- "Tesla officials show off progress at Gigafactory in Northern Nevada". Reviewjournal.com. March 18, 2016. Retrieved March 20, 2016.

workers and robotic arms still processed some of the battery storage products that went on sale in October

- Lambert, Fred (May 9, 2016). "Panasonic doubled its investment in the Tesla Gigafactory during the last quarter [Q1 2016 Activity Report]".

- "Storey County bustling since Tesla Motors gigafactory announcement". March 19, 2015. Retrieved October 18, 2016.

- "Tesla Gigafactory: new aerial shots show plant more than doubling in size [September 2016 update]". Electrek. September 25, 2016. Retrieved October 18, 2016.

- Lambert, Fred (January 4, 2017). "Tesla Gigafactory: new aerial pictures of the expansion at the battery factory – January 2017". electrek.co. Retrieved February 4, 2017.

- Lambert, Fred (June 23, 2016). "Tesla will add new section (5th) to the Gigafactory by December, Battery cell manufacturing equipment by July 20th". Electrek.

- "Tesla gigafactory construction driving surge in NV business licenses". Construction Dive. December 7, 2015. Retrieved December 19, 2016.

- "Tesla and Competitors Fuel Housing Boom in Nevada". Curbed. January 5, 2016. Retrieved December 19, 2016.

- Hidalgo, Jason (July 20, 2015). "Going big: Will Tesla double size of gigafactory plant?". rgj.com. Retrieved August 15, 2015.

- Spillman, Benjamin (December 10, 2018). "It's big, loud and secretive: We got a tour of Tesla's Gigafactory and here's how it works". Reno Gazette Journal.

- Lambert, Fred (March 9, 2016). "Will human hands ever touch Tesla Gigafactory battery cells?". electrek. Retrieved March 12, 2016.

- Lambert, Fred (December 8, 2016). "Tesla Gigafactory now employs over 850 workers, 1,000 more to come in first half of 2017 with production ramp up". electrek. Retrieved December 9, 2016.

- "Tesla 2018 Economic Impact Summary" (PDF). Nevada Governor’s Office of Economic Development. December 5, 2018. Retrieved October 31, 2019.

- "Tesla Gigafactory 1 Timeline & Results — CleanTechnica Deep Dive". CleanTechnica. January 21, 2019.

- "Tesla Annual Report (July 1, 2018 - June 30, 2019)" (PDF). Nevada Governor’s Office of Economic Development. October 1, 2019. Retrieved October 31, 2019.

- Coren, Michael J. (August 3, 2016). "Tesla's (TSLA) future depends on the Gigafactory's success, and Elon Musk is doubling down on building the world's largest battery factory". Quartz. Archived from the original on October 19, 2016. Retrieved January 6, 2017.

it’s being built as a series of mini facilities, each one iterating on the design of the last. Although the first phase of the Gigafactory is not yet complete, construction is already underway on t the next (the factory’s exterior walls are removable). The first phase is more than double the capacity of a similar sized factory in Asia, said Yoshihiko Yamada, executive vice president of Panasonic, who was on-site working with Tesla’s engineers. Tesla plans to repeat this process numerous times.

- "Battery Cell Production Begins at the Gigafactory". Tesla. January 4, 2017. Retrieved January 5, 2017.

The Gigafactory is being built in phases so that Tesla, Panasonic, and other partners can begin manufacturing immediately inside the finished sections and continue to expand thereafter. Our phased approach also allows us to learn and continuously improve our construction and operational techniques.. ..bringing cell production to the U.S.

- Canis, Bill. "Battery Manufacturing for Hybrid and Electric Vehicles: Policy Issues" R41709. Congressional Research Service, April 4, 2013. Quote: "It has been estimated that 70% of the value added in making lithium-ion batteries is in making the cells, compared with only 15% in battery assembly and 10% in electrical and mechanical components."

- "Formation of Tesla Advanced Automation Germany". Tesla. November 8, 2016. Archived from the original on December 29, 2016. Retrieved January 5, 2017.

As the machine that builds the machine, our factories are so important that we believe they will ultimately deserve an order of magnitude more attention in engineering than what they produce.

- della Cava, Marco (July 26, 2016). "Elon Musk to ramp up Tesla's critical battery Gigafactory". USA TODAY. Archived from the original on October 17, 2016. Retrieved January 5, 2017.

The factory itself is a product. It's the machine that builds the machines and demands more problem solving than the product it makes

- Fehrenbacher, Katie (June 6, 2016). "Tesla's Quest to Build the Machine Behind the Machine". Fortune. Archived from the original on December 16, 2016. Retrieved January 5, 2017.

It takes a hundred to a thousand times more resources, and far more difficulty, to build the machine that builds the machine, compared to creating an individual product, said Musk.

- Leitman, Seth (January 12, 2018). "Next-Gen 2170 Lithium Ion Batteries". Panasonic.

cylindrical 2170 cell was jointly designed and engineered by Tesla and Panasonic

- Lambert, Fred (May 31, 2016). "Tesla could triple the planned battery output of 'Gigafactory 1' to 150 GWh, says Elon Musk". electrek.co. Retrieved June 19, 2016.

- Shahan, Zachary (July 27, 2016). "11 Key Tesla Gigafactory, Model 3, Solar, & Elon Romance Takeaways From Today's Statements". CleanTechnica. Retrieved January 5, 2017.

- "Samsung SDI Unveils E-bike Battery Capable of 100km on Single Charge". Be Korea-savvy. August 26, 2015. Archived from the original on December 26, 2015. Retrieved August 31, 2015.

- "NASDAQ – SEC Filing, October 11, 2016". October 11, 2016. pp. 16 of 26. Retrieved October 24, 2016.

- Lambert, Fred (July 29, 2016). "Tesla Gigafactory: a look at Panasonic's impressive machines for battery cell manufacturing". electrek.co. Retrieved December 7, 2016.

- "Elon: Nope, Not Jumping To Samsung SDI, Using Panasonic Battery Cells For Tesla Model 3, Model S, Model X". CleanTechnica. June 8, 2016. Retrieved September 4, 2016.

- "Column: After starving energy business to make cars, Tesla is interested in solar again". The Buffalo News. October 27, 2019. Archived from the original on December 28, 2019.

- Lambert, Fred (May 9, 2017). "Tesla battery researcher says they doubled lifetime of batteries in Tesla's products 4 years ahead of time". Electrek. Retrieved May 9, 2017.

- Lambert, Fred (March 16, 2017). "Tesla Gigafactory: Rare picture from inside production floor via new supplier". Electrek.

- Lambert, Fred (June 24, 2019). "Tesla secures tariff exemption on aluminum for battery cell, document shows massive ramp up". Electrek.

- "Insiders describe a world of chaos and waste at Panasonic's massive battery-making operation for Tesla". Business Insider. April 17, 2019. Retrieved April 20, 2019.

- Lambert, Fred (December 30, 2019). "Tesla Gigafactory 1: Panasonic ready to ramp up battery production to 54 GWh". Electrek.

- Hidalgo, Jason (November 22, 2019). "We asked a major Panasonic exec about the gigafactory: 'Our job is to make Tesla better'". Reno Gazette Journal.

Panasonic’s footprint accounts for about 60% to 65% of the Gigafactory

- Karius, Andreas (March 3, 2014). "Studie: Tesla-Gigafactory bedroht andere Batteriehersteller". www.automobil-produktion.de (in German). Archived from the original on April 1, 2016. Retrieved October 27, 2018.

- Secrets of the Superfactories (TV documentary, October 2019)

- Cuthbertson, Anthony (April 20, 2014). "Tesla to Create World's Largest Lithium-ion Battery Factory". IBT. Retrieved June 12, 2014.

- Alvarez, Simon (May 10, 2019). "Tesla battery partner Panasonic sees higher Gigafactory output, cites Model S/X demand increase". TESLARATI. Retrieved May 13, 2019.

- Vega, Nicolas (August 17, 2018). "Ex-employee: Tesla concealed drug trafficking at its factory". New York Post. Retrieved August 25, 2018.

- Randall, Tom (May 8, 2015). "Tesla's Battery Grabbed $800 Million in Its First Week". Bloomberg.com. Retrieved May 15, 2015.

- Lambert, Fred (May 1, 2017). "Tesla to announce not '2 or 3', but 'probably 4' more Gigafactories this year". Electrek. US. Retrieved July 2, 2017.

- https://electrek.co/2019/05/13/tesla-tsla-stock-china-tariff-news-gigafactory/

- "Elon Musk picks Berlin for Tesla's Europe Gigafactory". TechCrunch. Retrieved December 8, 2019.

- https://www.bizjournals.com/austin/news/2020/02/05/elon-musk-teases-giga-texas-facility-changes.html

External links

| Wikimedia Commons has media related to Tesla Gigafactory 1. |

| Development of Gigafactory | |

| Images | |

|---|---|

| Video | |

- Gigafactory official website

- “The Logic of Tesla’s Gigafactory: ‘The Economics Are a No-Brainer’”, The Wall Street Journal

- “Assault on batteries”, The Economist, 2014-06-14 (print edition date)

- Tesla timeline: A list of construction projects at gigafactory site so far, February 2015

- Inside Tour Of The Gigafactory 2016-04-25