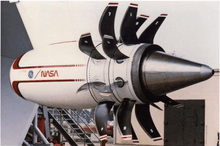

General Electric GE36

The General Electric GE36 was an experimental aircraft engine, a hybrid between a turbofan and a turboprop, known as an unducted fan (UDF) or propfan. The GE36 was developed by General Electric Aircraft Engines,[5] with its CFM International equal partner Snecma taking a 35 percent share of development.[6] Development was cancelled in 1989.

| GE36 | |

|---|---|

.jpg) | |

| A mockup of the GE36 at the Musée aéronautique et spatial Safran | |

| Type | Unducted fan |

| National origin | United States |

| Manufacturer | General Electric Aircraft Engines |

| First run | August 29, 1985[1] |

| Major applications | Boeing 7J7 (proposed) McDonnell Douglas MD-94X (proposed) |

| Number built | 2[2] |

| Program cost | $1.3 billion (estimated, 1989 US dollars)[3] |

| Unit cost | $5 million (estimated, 1986 US dollars)[4] |

| Developed from | General Electric F404 |

Development

General Electric (GE) started performing studies and component test work on the concept that would become the UDF in 1981, based on the initial results of early National Aeronautics and Space Administration (NASA) propfan technology studies that the aerospace agency first released to engine makers in 1980.[7] GE then followed up with full-scale development testing of the GE36 starting in 1982.[8] NASA gave GE a $20.4 million contract in February 1984 to study the concept[9] after the company showed the agency its work in December 1983, as NASA's own propfan research efforts were advancing at a slower pace and were dependent on additional grants from the U.S. Congress.

Around the same time, GE was negotiating with Boeing, which felt that the UDF technology could be useful for short-haul airliners, to test a demonstration engine on a Boeing 727 testbed aircraft.[10] Agreement to flight test the UDF was reached in April, with flights beginning in late 1986 to assess a 25,000 pounds-force (110 kN) demonstrator based on a General Electric F404 core. The engine would have a pair of six-stage contra-rotating free turbines, each with large diameters running at slow speeds, and they would be connected directly to a couple of eight-blade, 12-foot diameter (3.7 m; 140 in; 370 cm) unducted fans.[11] The effective bypass ratio (BPR) was estimated to be about 30:1 for the UDF, which was much larger than the 6:1 bypass ratios of modern turbofans at the time, but less than propeller/turboprop BPRs of approximately 50:1. The optimal mission would be on 1,000 nautical miles (1,200 mi; 1,900 km) flights with a cruise speed of Mach 0.75.[12] In May 1984, Boeing began testing a GE contra-rotating model test rig in its 9 by 9 ft (2.7 by 2.7 m) low-speed wind tunnel and 8 by 12 ft (2.4 by 3.7 m) transonic wind tunnel.[13]

GE unveiled a full-scale model of the engine at the Farnborough Air Show in September, promising a 30-percent reduction in fuel consumption compared to current airliner engines without decreasing the cruise speed. A dozen airlines "invited themselves" to see GE's UDF test facilities near Cincinnati, Ohio, claimed the engine maker, but not just due to the UDF's higher fuel efficiency. Airlines also appreciated the UDF's lack of a gearbox, which transfers power from the turbine to the propeller while allowing both to run at their respective optimal rotational speeds, but was difficult to design reliably for high speed and power. They also liked that the UDF had contra-rotating fans, as opposed to the single-rotating fans that NASA was primarily studying, since the double fans kept the diameter for a 140-seat airliner down to about 12 ft (3.7 m) instead of the 20 ft (6.1 m) diameters the airlines feared.[14] At the Paris Air Show in mid-1985, Snecma announced that it had obtained a 35-percent stake in the engine program.[6] Later in the decade, the 25,000-pound-force thrust (110-kilonewton) engine[15] became the power plant of choice for proposed aircraft such as the Boeing 7J7 twin-aisle airliner and the MD-91 and MD-92 derivatives of McDonnell Douglas's popular MD-80 single-aisle airplane.

The engine underwent 2,500 hours of model scale testing, after which a prototype was built. The prototype engine was ground-tested for 162 hours.[16] The GE36 prototype then flew 25 times,[17] accumulating over 41 hours of flight test time (out of a planned 75 hours) on a Boeing 727 from August 20, 1986[18] until mid-February of 1987, eventually reaching a flight speed of Mach 0.84 and altitude of 39,000 feet (12,000 metres).[19] In April 1987, Boeing formally selected the GE36 as the powerplant for the Boeing 7J7, deeming the IAE SuperFan ultra-high bypass (UHB) geared turbofan as less fuel efficient[20] and the Pratt & Whitney/Allison 578-DX geared propfan as insufficiently powered.[21] At the Paris Air Show in June 1987, GE and Snecma noted that they were building the components for a product design engine that would test on a Boeing 727 in 1989.[22] However, Boeing in August 1987 postponed the service entry date of the 7J7 from 1992 to 1993, and then it postponed the target date indefinitely in December 1987.[23]

GE's proof-of-concept engine was installed on a McDonnell Douglas MD-80 on April 5, 1987,[24] and its first flight on the MD-80 testbed was on May 18, 1987.[25] Initially the engine had an 8-blade forward and 8-blade aft fan configuration, and then it was replaced on the testbed by the second GE36 demonstrator engine, which had a 10-blade forward / 8-blade aft setup[26] and completed 33 hours of flight tests beginning on August 14, 1987.[27] Despite being quieter in that configuration, the engine was swapped back to the original 8x8 configuration because of a mechanical problem. GE also confirmed that for production, there would be more blades than on the demonstrator engine, and the number of blades on the front fan would be different from the number on the back fan.[28]

After the testbed was reconfigured with the 8x8 engine setup, McDonnell Douglas conducted 22 customer demonstration flights from the Long Beach Airport.[29] These customer demonstrations took place between January 22 and February 26 of 1988. The flights, which typically lasted about an hour and reached a cruise speed of Mach 0.76, hosted the prime minister of Finland,[30] 110 executives from 35 airlines and four leasing companies, and 70 representatives of media, the United States military, suppliers, and other airline manufacturers.[31] The general opinion was that the ride quality was little different than a normal flight, except for light vibration in the back seat during takeoff and climb.[32] On March 25, 1988, McDonnell Douglas declared the flight test program complete.[29] The MD-80 testbed had performed 93 flights and 165 flight test hours, cruising at a speed up to Mach 0.865 and an altitude of 37,000 feet (11,000 metres).[33]

McDonnell Douglas reinstalled the GE36 engine onto the MD-80 testbed for additional flight tests in July 1988.[34] The testbed airplane was then flown across the Atlantic Ocean, leaving its home test airfield of Edwards Air Force Base in California to stop in Minneapolis, Minnesota, Gander, Newfoundland, Canada, and Keflavik, Iceland before ending the 4,700 nmi trip (5,400 mi; 8,700 km) in Farnborough Airport in England on August 23. The trip was made to perform daily public demonstration flights at the Farnborough Air Show on September 4–11, 1988.[35] Private flight demonstrations for invited airline executives were to be given before the air show, and McDonnell Douglas was considering flying the testbed to Western Europe before returning to the US.[36] At the air show, McDonnell Douglas and GE began marketing discussions with seven airlines in the US and six in western Europe; they hoped to gain about 100 airline commitments by mid-1989 to launch the MD-91 and MD-92 programs, with entry into service in 1993 first for the MD-91, and then the MD-92 entering service a half-year later.[37] GE36 testing on the MD-80 finished that month after 137 flights and nearly 240 flight hours.[38] In total, there were 281 hours of flight tests between the two airplanes.[16]

With demonstrator flight testing completed, the focus moved to construction of a new core (instead of the off-the-shelf F404) to increase efficiency. The compressor, combustor, and turbine had all been run separately by late 1988,[39] and by mid-1989 the new core engine had been tested for about 50 hours. At the time of the project cancellation later in 1989, GE and Snecma were working on the design engineering of a full gas generator and a product propulsor.[40]

The downfall of this engine at the time was economic conditions (mostly a major drop in oil prices) post OPEC oil embargo. Even though these engines never made it past development and prototype testing, GE has retained the carbon composite technology behind the lightweight fan blades. Carbon fiber blades are currently being used in engines (General Electric GE90 and General Electric GEnx) that power the Boeing 747, Boeing 777, and Boeing 787 Dreamliner.[41][42]

General Electric donated one of the GE36 engines to the Smithsonian National Air and Space Museum via the Naval Air Systems Command[43] in 1991.[44]

Design

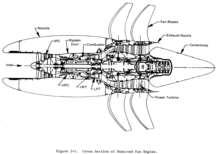

A General Electric F404 military turbofan on loan from the American government was used as the basis for the GE36 prototype.[45] The F404 mixed exhaust stream discharged through a turbine which drove two contra-rotating stages of fans. Although the demonstrator engines had 8x8 and 10x8 fan blade configurations, the most efficient setup that was tested had a 12x10 blade configuration.[46] The scimitar shape of the fan rotor blades can operate at high velocities to match turbojet or turbofan speeds, allowing the engine to power the proposed Boeing 7J7 airliner at a Mach 0.83 cruise speed.[47]

The UDF fan blades were 40 in (100 cm) in length, and the Rohr Industries-made rotating cowls that fit around the base of the blades were 62 in (160 cm) in diameter.[48] The blades for the initial tests were manufactured directly by General Electric, but the blades for the flight tests were then made by local Ohio manufacturer Hartzell Propeller.[49] For the production engines, the blades were to be made by British composite propeller specialist Dowty Rotol.[50] During the prototype/testing phase, the fan blades weighed 22.5 and 21.5 lb (10.2 and 9.8 kg) each on the front and back propellers, respectively,[51] but they were expected to weigh less than 20 lb (9.1 kg) by the time the engine entered production.[52]

While the GE36 demonstrator had a rated thrust of 25,000 lbf (110 kN), the GE36 family of engines would offer a range covering 12,000 to 30,000 lbf (53 to 133 kN) of thrust. The engine was initially sized to produce 14,000 lbf (62 kN) for the MD-91X and 20,000–22,000 lbf (89–98 kN) for the 7J7 and MD-92X,[53] but the thrust requirements were later changed to 22,000 lbf (98 kN) and 25,000 lbf (110 kN), respectively.[54]

The power turbine was a six-stage turbine plus inlet and outlet guide vanes.[55]:46 The twelve turbine blade rows rotated alternate rows in opposite directions. Each stage was a pair of rotors; there were no stators (static vanes), which usually follow the single-rotor section to straighten out the flow. The front propeller and the front half of each stage are attached to a rotating outer casing that encloses the turbine rotor blades, while the back propeller and the back half of each stage are attached conventionally to a central shaft. The counter-rotating turbine can run at half the rpm of a conventional turbine, since counter-rotation doubles the relative velocity, so the engine did not require a reduction gearbox to drive the fan.[56] The GE36 had a hub-to-blade tip radius ratio of 0.425,[57] which as a gearless design reflected about a 75 percent higher value than for geared propfan designs.[58] This characteristic occurred because the hub had to enclose a large turbine diameter; due to the low rotational speed demanded by the contra-rotating propellers, the turbine had to be wider than usual to generate enough power.[59] GE's UDF had a bypass ratio of 35, which was about halfway between the IAE SuperFan's BPR of 17 and the PW-Allison 578-DX's BPR of 56.[17] The contra-rotating propellers spun at a maximum rotational speed of at least 1,393 rpm.[15]

_McDonnell_Douglas_demonstrator%2C_Farnborough_UK_-_England%2C_September_1988_(5589809360).jpg)

The engine demonstrated an extremely low specific fuel consumption (SFC) of 0.232 lbs/lb-thrust/hr at ground level,[60] which GE claimed was over 20% more efficient than any of the existing turbofans on offer.[61] GE had also predicted a cruise SFC of 0.49 for the demonstrator engine; however, the cruise SFC would drop to 0.40-0.41 with a new gas generator design called "Supercore,"[62] compared with 0.56 for existing turbofans.[63] The engine configuration selected for the MD-91 and MD-92 was designed to meet the Chapter 4 community noise standards of the International Civil Aviation Organization's (ICAO's) Committee on Aviation Environmental Protection (CAEP), which would go into effect in 2006 and be a reduction of ten effective perceived noise decibels (EPNdB) from the existing Chapter 3 standards that were established in 1977.[64] The regulatory compliance, however, caused a five-percent reduction in fuel efficiency compared to the most efficient fan configuration.[65]

Variants

- GE36-B14

- 14,000 lbf thrust (62 kN) engine powering the McDonnell Douglas MD-91X.[66]

- GE36-B22A

- 25,000 lbf thrust (110 kN) engine powering the Boeing 7J7.[66]

- GE36-C22

- 22,000 lbf thrust (98 kN) derated engine powering the 114-seat McDonnell Douglas MD-91.[67][68]

- GE36-C25

- 25,000 lbf thrust (110 kN) engine powering the 165-seat McDonnell Douglas MD-92.[67]

Specifications

Data from GE engine test, pages 12, 17

General characteristics

- Type: gearless, contra-rotating, pusher unducted fan with modified production F404 turbofan gas generator

- Length:

- Diameter: 76.4 in (194 cm; 6.37 ft; 1.94 m) maximum nacelle diameter

- Forward fan diameter: 140.0 in (356 cm; 11.67 ft; 3.56 m)[69]

- Aft fan diameter (10 forward blade + 8 aft blade setup): 132.0 in (335 cm; 11.00 ft; 3.35 m)[69]

- Aft fan diameter (8 forward blade + 8 aft blade setup): 128.0 in (325 cm; 10.67 ft; 3.25 m)[69]

- Dry weight: 6,000 lb (2,700 kg)[70]

Components

- Compressor: 3-stage low-pressure axial flow compressor @13,270 rpm, 7-stage high-pressure axial compressor @16,810 rpm

- Turbine: 1-stage low-pressure turbine, 1-stage high-pressure turbine, 6-stage contra-rotating free power turbine

Performance

- Maximum thrust: 25,000 lbf (110 kN) @ 1,393 rpm

- Overall pressure ratio: 26:1

- Bypass ratio: 35[17][1]

- Air mass flow: about 140 pounds-mass/second

- Turbine inlet temperature: 1,310 °F (710 °C)

- Specific fuel consumption: Takeoff: 0.232 lb/(lbf⋅h) (6.6 g/(kN⋅s))[60]; Cruise: 0.49 lb/(lbf⋅h) (14 g/(kN⋅s))[62]

- Thrust-to-weight ratio: 8

Applications

- Boeing 727 (testbed)

- Boeing 7J7 (proposed)

- McDonnell Douglas MD-81 UHB testbed

- McDonnell Douglas MD-94X (proposed)

See also

Comparable engines

Related lists

References

- "UDF runs at full throttle". Propulsion. Flight International. Vol. 128 no. 3981. Peebles, Ohio, USA. October 12, 1985. pp. 20–21. ISSN 0015-3710.

- "No. 2 UDF engine prototype will fly on MD-80 by June". Aviation Week & Space Technology. Vol. 126 no. 15. April 13, 1987. pp. 58, 66–67. ISSN 0005-2175.

- Norris, Guy (December 6–12, 1989). "Jet futures". Flight International. pp. 31–34. ISSN 0015-3710.

- Air Transport World, 1986: Harrington estimated that production GE36 UDFs will cost $5 million each. CFM56s cost about $3.2 million today.

- Schmitman, Craig (1988). Ultra high bypass jet engine propfan technology. AeroSpaceNews.com – via YouTube.

- "Propfans ready by 1990". Paris Report. Flight International. June 8, 1985. p. 5. ISSN 0015-3710. Archived (PDF) from the original on September 25, 2014. Retrieved March 28, 2019.

- Haggerty, James J. (1987-08-01). "Toward future flight". Spinoff (PDF) (1987 ed.). NASA (published August 1987). pp. 30–33. Archived from the original on April 12, 2009.

- Sutcliffe, Peter L. (June 18, 1986). "The Boeing 7J7 advanced technology airplane: Keynote speech to the 1986 American Control Conference" (PDF). IEEE Control Systems Magazine. Seattle, Washington, USA: IEEE (published February 1987). 7 (1): 9–15. doi:10.1109/MCS.1987.1105251. ISSN 0272-1708. OCLC 4631908460. Archived from the original (PDF) on May 19, 2011. Retrieved May 7, 2019.

- Banks, Howard (May 7, 1984). "The next step: Jets drove propellers from the skies. But radical designs are bringing props back, creating engines that promise jetlike speeds and enormous fuel savings" (PDF). Forbes. pp. 31–33 – via NASA Langley Research Center Cultural Resources Geographic Information Systems (GIS) Team.

- "GE will test contrapropfan" (PDF). Propulsion. Flight International. Vol. 125 no. 3900. February 4, 1984. p. 324. ISSN 0015-3710.

- "GE launches 'unducted fan'" (PDF). World News. Flight International. Vol. 125 no. 3911. Lynn, Massachusetts, USA. April 21, 1984. p. 1055. ISSN 0015-3710.

- "More on GE's unducted fan" (PDF). Propulsion. Flight International. Vol. 125 no. 3912. Evendale, Ohio, USA. April 28, 1984. p. 1159. ISSN 0015-3710.

- Hager & Vrabel 1988, p. 80.

- Byczkowski, John J. (September 2, 1984). "GE showcases new engine design". Business/Real Estate. Cincinnati Enquirer. pp. F–1, F–3. ISSN 2575-5706 – via Newspapers.com.

- GE engine test, December 1987, page 1

- Khalid et al. 2013, p. 4

- Sutcliffe, Peter L. (November 13, 1987). The Boeing 7J7—The evolution of technology and design. International Pacific Air and Space Technology Conference and Exposition. SAE 1987 Transactions: Aerospace. 96. Melbourne, Australia: SAE International (published September 1988). pp. 6.1757–6.1768. doi:10.4271/872405. ISSN 0096-736X. JSTOR 44473078. OCLC 939484633.

- "GE's UDF flies again" (PDF). Air Transport. Flight International. Vol. 130 no. 4027. Mojave, California, USA. September 6, 1986. p. 23. ISSN 0015-3710.

- Hager & Vrabel 1988, pp. 93 to 97.

- "Boeing chooses UDF for 7J7" (PDF). Air Transport. Flight International. Vol. 131 no. 4058. Seattle, Washington, USA. April 18, 1987. p. 4. ISSN 0015-3710.

- Learmount, David (May 2, 1987). "Boeing offers long-range 7J7" (PDF). World News. Flight International. Vol. 131 no. 4060. Seattle, Washington, USA. p. 2. ISSN 0015-3710.

- "General Electric will expand collaborative engine programs" (PDF). Paris Air Show. Aviation Week & Space Technology. Vol. 126 no. 25. June 22, 1987. pp. 30–31. ISSN 0005-2175. Archived from the original (PDF) on November 25, 2019.

- "Company news; staff cutbacks for Boeing jet". New York Times. December 16, 1987. p. D3.

- Lewerenz, William T. (June 29 – July 2, 1987). UHB demonstrator flight test program. Joint Propulsion Conference (23rd ed.). San Diego, California, USA. doi:10.2514/6.1987-1732.

- Warwick, Graham (August 15, 1987). "UHB: The acid test". Flight International. pp. 22–23. Retrieved March 22, 2019.

- Moxon, Julian (September 5, 1987). "Boeing delays 7J7 certification". Air Transport. Flight International. Vol. 132 no. 4078. Washington, D.C., USA. p. 4. ISSN 0015-3710.

- Hager & Vrabel 1988, pp. 98 to 100.

- Moxon, Julian (December 19, 1987). "McDonnell Douglas ready to launch UDF airliners" (PDF). Air Transport. Flight International. Vol. 132 no. 4093. Long Beach, California, USA. p. 6. ISSN 0015-3710.

- Nichols, Herbert E. (July 11–13, 1988). UDF engine/MD80 flight test program. Joint Propulsion Conference (24th ed.). Boston, Massachusetts, USA. doi:10.2514/6.1988-2805. OCLC 1109549688.

- Reid, Carlyle (July 11–13, 1988). Overview of flight testing of GE aircraft engines' UDF engine. Joint Propulsion Conference (24th ed.). Boston, Massachusetts, USA. doi:10.2514/6.1988-3082. OCLC 1109479694.

- Mongelluzzo, Bill (April 10, 1988). "McDonnell Douglas says UHB aircraft saves fuel". Air Cargo. Journal of Commerce. ISSN 1530-7557.

- Moxon, Julian (February 13, 1988). "Douglas shows off propfan demonstrator". World News. Flight International. Vol. 133 no. 4100. Long Beach, California, USA. p. 3. ISSN 0015-3710.

- "MDC propfan tests complete" (PDF). Air Transport. Flight International. Vol. 133 no. 4109. Edwards Air Force Base, California, USA. April 16, 1988. p. 7. ISSN 0015-3710.

- "Allison propfan clear for flight" (PDF). Flight International. Vol. 134 no. 4127. August 20, 1988. p. 5. ISSN 0015-3710.

- "New engine passes test, GE reports". Business. Dayton Daily News. Evendale, Ohio, USA. Associated Press. August 27, 1988. ISSN 0897-0920 – via Newspapers.com.

- Donne, Michael (August 24, 1988). "Farnborough prepares arena for 'propfan'". UK News. Financial Times (30624). p. 6. ISSN 0307-1766.

- Donne, Michael (September 7, 1988). "Farnborough International Air Show: US launches propfan sales drive". UK News. Financial Times (30635). p. 8. ISSN 0307-1766.

- Mongelluzzo, Bill (December 28, 1988). "McDonnell Douglas sets tests for propfan engine". Air Cargo. Journal of Commerce. ISSN 1530-7557.

- "UDF: No sign of an order—yet" (PDF). Farnborough Report. Flight International. Vol. 134 no. 4131. September 17, 1988. p. 22. ISSN 0015-3710.

- "Fulfilling the promise of open-rotor technology". The Engine Yearbook: Aircraft Technology's annual publication for the aero-engine professional. UBM Aviation Publications. 2011. pp. 108–109, 111.

- "GE Reports – Honey I shrunk the World: How Materials Scientists Made the Globe Smaller".

- GE Reports (April 29, 2009). GE Aviation - Aircraft engine history and technology - Jet engine – via YouTube.

- "General Electric GE36 Unducted Fan (UDF) turboprop engine". Smithsonian National Air & Space Museum.

- "Annual list notes most recent additions to the nation's attic". San Francisco Examiner. Washington, D. C., USA. Associated Press. March 2, 1992. p. C–5. ISSN 2574-593X – via Newspapers.com.

- Hager & Vrabel 1988, pp. 86 to 92.

- Khalid et al. 2013, p. 15

- Air Transport World, 1986: G.E., however, insisted that open rotors' efficiency drops off at a much higher speed. Gordon said Boeing has G.E.'s and its own results from UDF windtunnel tests up to Mach 0.9 and continues to list the UDF as the baseline engine on the 7J7 that has a design cruise speed of Mach 0.83. 'Boeing is not crazy,' he told ATW.

- Jones, Sam L.; Salak, John (September 15, 1986). "Propfan engines output awaits resolution of design performance question". Business. American Metal Market. Vol. 94. Euromoney Trading Limited. pp. B+. ISSN 0002-9998.

- "Hartzell will produce UDF blades" (PDF). Propulsion. Flight International. Vol. 129 no. 4005. Piqua, Ohio, USA. April 5, 1986. p. 37. ISSN 0015-3710.

- "Dowty to build UDF blades" (PDF). World News. Flight International. Vol. 132 no. 4085. Cheltenham, England, United Kingdom. October 24, 1987. p. 3. ISSN 0015-3710.

- GE design report, page 163

- Hamilton, Martha M. (February 8, 1987). "Firms give propellers a new spin". Business. Washington Post. pp. H1, H4. Archived from the original on April 2, 2019. Alt URL

- "UDF readies for flight test". Air Transport World. Vol. 23. Penton Media. March 1986. p. 21. ISSN 0002-2543 – via Gale Research.

- Warwick, Graham; Moxon, Julian (May 23, 1987). "The power of persuasion". Flight International. Washington, DC, USA. pp. 39–41. ISSN 0015-3710.

- GE design report, December 1987

- Sweetman, Bill (September 2005). "The short, happy life of the Prop-fan: Meet the engine that became embroiled in round one of Boeing v. Airbus, a fight fueled by the cost of oil". Air & Space/Smithsonian Magazine. 20 (3). pp. 42–49. ISSN 0886-2257. OCLC 109549426. Archived from the original on August 14, 2017. Retrieved January 28, 2019.

- GE design report, December 1987, page 38

- Whitlow, John B., Jr.; Sievers, G. Keith (October 1988). "Building the foundation". Aircraft. Aerospace America. p. 15. ISSN 0740-722X – via Nexis Uni.

- Ziemianski, Joseph A.; Whitlow, John B., Jr. (August 28 – September 2, 1988). NASA/industry advanced turboprop technology program (PDF). Conference of the International Council of Aeronautical Sciences (16th ed.). Jerusalem, Israel. OCLC 4433879345.

- GE engine test, December 1987, page 239

- "UDF prepared for flight" (PDF). World News. Flight International. Vol. 130 no. 4022. August 2, 1986. p. 2. ISSN 0015-3710.

- Donoghue, J. A. (September 1984). "G.E.'s unducted fan spices propfan stew". Air Transport World. Vol. 21. pp. 38+. ISSN 0002-2543.

- Warwick, Graham (November 10, 1984). "UDF: GE dares to differ". Flight International. Vol. 126. pp. 1239, 1242. ISSN 0015-3710. Lay summary.

- Spencer, Jessica C. (October 25, 2017). "Stage 5 aircraft noise standards approved in US – what does it mean for airports?". Archived from the original on March 28, 2019. Retrieved March 28, 2019.

- Khalid et al. 2013, pp. 7 to 8

- "Airline Observer". Aviation Week & Space Technology. February 9, 1987. p. 35.

- Moxon, Julian (February 27, 1988). "Douglas begins MD-90 hard sell: McDonnell Douglas's campaign to launch the propfan-powered MD-90 series airliners by mid-year moved into higher gear this month as the company began flying airline executives in its ultrahigh-bypass demonstrator". Flight International. Vol. 133 no. 4102. pp. 30–31. ISSN 0015-3710.

- Henne, P. A. (July 31 – August 2, 1989). MD-90 transport aircraft design. AIAA/AHS/ASEE Aircraft Design, Systems and Operations Conference. Seattle, Washington, USA. doi:10.2514/6.1989-2023.

- Simpson et al. 1989, p. 8 to 9

- DiMaria, Eugene (June 3, 1985). "Propfan engine seen catalyst for change". American Metal Market. Vol. 93. Euromoney Trading Limited. pp. 1+. ISSN 0002-9998.

Bibliography

- Khalid, S. Arif; Lurie, David; Breeze-Stringfellow, Andrew; Wood, Trevor; Ramakrishnan, Kishore; Paliath, Umesh; Wojno, John; Janardan, Bangalore; Goerig, Trevor; Opalski, Anthony; Barrett, Jack (May 2013). "FAA CLEEN program open rotor aeroacoustic technology non-proprietary report" (PDF). Federal Aviation Administration. General Electric. Archived (PDF) from the original on 8 July 2018. Retrieved 8 July 2018.CS1 maint: ref=harv (link)

- Simpson, M. A.; Druez, P. M.; Kimbrough, A. J.; Brock, M. P.; Burge, P. L.; Mathur, G. P.; Cannon, M. R.; Tran, B. N. (October 1989). UHB demonstrator interior noise control flight tests and analysis (Report). Douglas Aircraft Company, McDonnell Douglas Corporation. hdl:2060/19900003882. Retrieved May 13, 2019. Lay summary.CS1 maint: ref=harv (link)

- "Farnborough quiet reflects sales bonanza". Air Transport World. Farnborough, England, United Kingdom. October 1988. pp. 16+. ISSN 0002-2543.

- Gavaghan, Helen (September 8, 1988). "New generation of aeroengines takes to the skies". Technology. New Scientist. Vol. 119 no. 1629. p. 44. ISSN 1032-1233.

- Whitlow, John B., Jr.; Sievers, G. Keith (August 8–11, 1988). NASA advanced turboprop research and concept validation program. Conference and Exposition on Future Transportation Technology. Society of Automotive Engineers (1988 ed.). San Francisco, California, USA. hdl:2060/19880013518. OCLC 47143980. Lay summary.CS1 maint: ref=harv (link)

- Donelson, John E.; Lewerenz, William T.; Durbin, Roger T. (July 11–13, 1988). UHB demonstrator flight test program: The final step. Joint Propulsion Conference (24th ed.). Boston, Massachusetts, USA. doi:10.2514/6.1988-2807.

- Donoghue, J. A. (March 1988). "McDonnell Douglas markets MD-90 transports with G.E. UDF power". Air Transport World. Vol. 25 no. 3. pp. 37+. ISSN 0002-2543.

- Vartabedian, Ralph (February 4, 1988). "McDonnell unveils plane with revolutionary engine". Los Angeles Times. ISSN 0458-3035. OCLC 3638237.

- Hager, Roy V.; Vrabel, Deborah (1988). Advanced turboprop project. NASA SP-495. Lewis Research Center, Cleveland, Ohio: National Aeronautics and Space Administration (NASA) Scientific and Technical Information Division. hdl:2060/19890003194. OCLC 17508419. Archived (PDF) from the original on March 13, 2017. Retrieved February 2, 2019. Lay summary.CS1 maint: ref=harv (link)

- GE Aircraft Engines, GE36 Project Department (December 1987). Full scale technology demonstration of a modern counterrotating unducted fan engine concept: Design report. NASA. hdl:2060/19900000732. OCLC 82995299 – via Internet Archive. Lay summary.

- GE Aircraft Engines, GE36 Project Department (December 1987). Full scale technology demonstration of a modern counterrotating unducted fan engine concept: Engine test. NASA. hdl:2060/19900000733. OCLC 82995299 – via Internet Archive. Lay summary.

- GE Aircraft Engines, GE36 Project Department (December 1987). Full scale technology demonstration of a modern counterrotating unducted fan engine concept: Component test. NASA. hdl:2060/19900000731. OCLC 82995299 – via Internet Archive. Lay summary.

- "Paris gives strong hints of changes to come". Air Transport World. Vol. 24. July 1987. pp. 18+. ISSN 0002-2543.

- Donoghue, J. A. (July 1987). "McDonnell Douglas opens UHB flight tests". Air Transport World. Vol. 24. pp. 36+. ISSN 0002-2543.

- Harris, Robert W.; Cuthbertson, R. D. (June 29 – July 2, 1987). UDF/727 flight test program. Joint Propulsion Conference (23rd ed.). San Diego, California, USA. doi:10.2514/6.1987-1733. OCLC 80141408.

- Donoghue, J. A. (April 1987). "SuperFan opponents dispute timing; UDF tests advance". Air Transport World. Vol. 24. pp. 42+. ISSN 0002-2543.

- "GE extols UDF results". Propulsion. Flight International. Vol. 130 no. 4042. Evendale, Ohio, USA. December 20, 1986. pp. 63–64. ISSN 0015-3710.

- "GE prepares for further UDF tests" (PDF). World News. Flight International. Vol. 130 no. 4028. Evendale, Ohio, USA. September 13, 1986. p. 2. ISSN 0015-3710.

- "Manufacturers positioning for coming competitive battles". Air Transport World. Vol. 23. September 1986. pp. 20+. ISSN 0002-2543.

- Moxon, Julian (August 9, 1986). "UDF cleared for flight" (PDF). Propulsion. Flight International. Vol. 130 no. 4023. Peebles, Ohio, USA. p. 43. ISSN 0015-3710.

- Hooper, Donald Moore (June 1986). Marketing strategy in the commercial aircraft engine business: A case study (PDF) (Thesis). Massachusetts Institute of Technology (MIT), Sloan School of Management. pp. 89–130. hdl:1721.1/14995. OCLC 655599820.

- "GE restarts UDF testing" (PDF). Propulsion. Flight International. Vol. 129 no. 3996. Evendale, Ohio, USA. February 1, 1986. p. 37. ISSN 0015-3710.

- Byzckowski, John J. (November 7, 1985). "GE fine tuning new engine: Great fuel efficiency expected". Business. Cincinnati Enquirer. pp. B–11, B–16. ISSN 2575-5706 – via Newspapers.com.

- "UDF suffers blade failure" (PDF). World News. Flight International. Vol. 128 no. 3983. Peebles, Ohio, USA. October 26, 1985. p. 3. ISSN 0015-3710.

- "UDF on target, says GE" (PDF). Propulsion. Flight International. Vol. 127 no. 3949. Evendale, Ohio, USA. March 2, 1985. p. 18. ISSN 0015-3710.

External links

| Wikimedia Commons has media related to General Electric GE36. |

- General Electric. UDF/GE36 engine: Executive summary. OCLC 55032766.

- GE Aircraft Engines (October 3, 1988). "This is the next generation". Aviation Week & Space Technology. pp. 84–85. ISSN 0005-2175.

- Unducted fan MD81 - SBAC Farnborough - 4 September 1988. Farnborough, England, United Kingdom: Phil Whalley (published March 14, 2011). September 4, 1988 – via YouTube.

- GE Aircraft Engines (September 1, 1988). "Many things can happen to a promise / Keeping the promise". Financial Times Survey: Aerospace. Financial Times (30630). pp. IX–XI. ISSN 0307-1766.

- GE Canada (April 14, 1987). "GE aerospace: Announcing a dramatic breakthrough in aircraft technology: The propellor". Report on Business. The Globe and Mail. Toronto, Ontario, Canada. p. B3. ISSN 0319-0714 – via ProQuest.

With potential fuel savings of up to 45% over the best high bypass turbofans, and at speeds of Mach .8, the UDF will mean major cost reductions and greater profitability for the airlines. This engine can also be scaled to any thrust size, to serve a wide variety of aircraft.

- Boeing UDF test footage. August 20, 1986. Archived from the original on April 2, 2015. Retrieved March 16, 2015 – via Vimeo.

- Snecma/General Electric: GE36 UDF. Safran Museum. November 6, 2012.

- "Boeing 727 UDF test plane in flight". Boeing Images. Retrieved September 23, 2019.

- "UDF deal signed" (PDF). Dowty Rotol Newsletter. No. 9. January 1988. pp. 1–2.

- "Boeing jetliner prototypes and testbeds: 727-63 General Electric unducted fan testbed, c/n 19846". Air-and-Space.com. Retrieved May 10, 2019.

- Bone, Dave (March 30 – April 1, 2011). DREAM: Validation of radical engine architecture systems. The alternative solution for a cleaner future (PDF). European Aeronautics Days (Aerodays 2011): Innovation for Sustainable Aviation in a Global Environment (sixth ed.). Madrid, Spain. Archived (PDF) from the original on March 2, 2018.

- Wilson, Douglas (February 2009). "Turboprop history: TPs continue their key role in bizav". Professional Pilot. pp. 72+. Archived from the original on November 29, 2010.