Freeze-drying

Freeze drying, also known as lyophilisation or cryodesiccation, is a low temperature dehydration process[1] that involves freezing the product, lowering pressure, then removing the ice by sublimation.[2] This is in contrast to dehydration by most conventional methods that evaporate water using heat.[3]

Freeze drying results in a high quality product because of the low temperature used in processing.[1] The original shape of the product is maintained and quality of the rehydrated product is excellent.[4] Primary applications of freeze drying include biological (e.g., bacteria and yeasts), biomedical (e.g., surgical transplants), food processing (e.g., coffee) and preservation.[1]

History

Freeze drying began as early as 1890 by Richard Altmann who devised a method to freeze dry tissues (either plant or animal), but went virtually unnoticed until the 1930s.[5] In 1909, Shackell independently created the vacuum chamber by using an electrical pump.[6] No further freeze drying information was documented until Tival in 1927 and Elser in 1934 had patented freeze drying systems with improvements to freezing and condenser steps.[6]

A significant turning point for freeze drying occurred during World War II. Blood plasma and penicillin were needed to treat the wounded in the field, and because of the lack of refrigerated transport, many serum supplies spoiled before reaching their recipients.[6] The freeze-drying process was developed as a commercial technique that enabled blood plasma and penicillin to be rendered chemically stable and viable without refrigeration.[6] In the 1950s–1960s, freeze drying began to be viewed as a multi-purpose tool for both pharmaceuticals and food processing.[6]

Early uses in food

Freeze-dried foods became a major component of astronaut and military rations. What began for astronaut crews as tubed meals and freeze-dried snacks that were difficult to rehydrate,[7] were transformed into hot meals in space by improving the process of rehydrating freeze-dried meals with water.[7] As technology and food processing improved, NASA looked for ways to provide a complete nutrient profile while reducing crumbs, disease-producing bacteria, and toxins.[8] The complete nutrient profile was improved with the addition of an algae-based vegetable-like oil to add polyunsaturated fatty acids.[8] Polyunsaturated fatty acids are beneficial in mental and vision development, and as it remains stable during space travel, can provide astronauts with its added benefits.[8] The crumb problem was solved with the addition of a gelatin coating on the foods to lock in and prevent crumbs.[7] Disease-producing bacteria and toxins were reduced by quality control and the development of the Hazard Analysis Critical Control Point (HACCP) plan, which is widely used today to evaluate food material before, during and after processing.[8] With the combination of these three innovations, NASA could provide safe and wholesome foods to their crews from freeze-dried meals.[8]

Military rations have also come a long way, from being served spoiled pork and corn meal to beefsteak with mushroom gravy.[9] How rations are chosen and developed are based on acceptance, nutrition, wholesomeness, producibility, cost, and sanitation.[10] Additional requirements for rations include a minimum shelf life of three years, be deliverable by air, consumable in worldwide environments, and provide a complete nutritional profile.[10] The new tray rations (T Rations) which has been improved upon by increasing acceptable items and provide high quality meals while in the field. Freeze-dried coffee was also incorporated by replacing spray-dried coffee in the meal, ready-to-eat category.[10]

Stages of freeze drying

There are four stages in the complete freeze drying process: pretreatment, freezing, primary drying, and secondary drying.

Pretreatment

Pretreatment includes any method of treating the product prior to freezing. This may include concentrating the product, formulation revision (i.e., addition of components to increase stability, preserve appearance, and/or improve processing), decreasing a high-vapor-pressure solvent, or increasing the surface area. Food pieces are often IQF treated to make them free flowing prior to freeze drying. In many instances the decision to pretreat a product is based on theoretical knowledge of freeze-drying and its requirements, or is demanded by cycle time or product quality considerations.[11]

Freezing and annealing

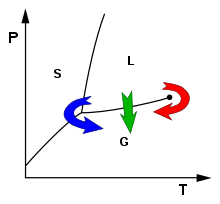

During the freezing stage, the material is cooled below its triple point, the lowest temperature at which the solid, liquid and gas phases of the material can coexist. This ensures that sublimation rather than melting will occur in the following steps. To facilitate faster and more efficient freeze drying, larger ice crystals are preferable. The large ice crystals form a network within the product which promotes faster removal of water vapor during sublimation.[2] To produce larger crystals, the product should be frozen slowly or can be cycled up and down in temperature in a process called annealing. The freezing phase is the most critical in the whole freeze-drying process, as the freezing method can impact the speed of reconstitution, duration of freeze-drying cycle, product stability, and appropriate crystallization.[12]

Amorphous materials do not have a eutectic point, but they do have a critical point, below which the product must be maintained to prevent melt-back or collapse during primary and secondary drying.

Structurally sensitive goods

In the case of goods where preservation of structure is required, like food or objects with formerly-living cells, large ice crystals will break the cell walls which can result in increasingly poor texture and loss of nutritive content. In this case, the freezing is done rapidly, in order to lower the material to below its eutectic point quickly, thus avoiding the formation of large ice crystals.[2] Usually, the freezing temperatures are between −50 °C (−58 °F) and −80 °C (−112 °F).

Primary drying

During the primary drying phase, the pressure is lowered (to the range of a few millibars), and enough heat is supplied to the material for the ice to sublime. The amount of heat necessary can be calculated using the sublimating molecules' latent heat of sublimation. In this initial drying phase, about 95% of the water in the material is sublimated. This phase may be slow (can be several days in the industry), because, if too much heat is added, the material's structure could be altered.

In this phase, pressure is controlled through the application of partial vacuum. The vacuum speeds up the sublimation, making it useful as a deliberate drying process. Furthermore, a cold condenser chamber and/or condenser plates provide a surface(s) for the water vapour to re-liquify and solidify on.

It is important to note that, in this range of pressure, the heat is brought mainly by conduction or radiation; the convection effect is negligible, due to the low air density.

Secondary drying

The secondary drying phase aims to remove unfrozen water molecules, since the ice was removed in the primary drying phase. This part of the freeze-drying process is governed by the material's adsorption isotherms. In this phase, the temperature is raised higher than in the primary drying phase, and can even be above 0 °C (32 °F), to break any physico-chemical interactions that have formed between the water molecules and the frozen material. Usually the pressure is also lowered in this stage to encourage desorption (typically in the range of microbars, or fractions of a pascal). However, there are products that benefit from increased pressure as well.

After the freeze-drying process is complete, the vacuum is usually broken with an inert gas, such as nitrogen, before the material is sealed.

At the end of the operation, the final residual water content in the product is extremely low, around 1% to 4%.

Applications of freeze drying

Freeze-drying causes less damage to the substance than other dehydration methods using higher temperatures. Nutrient factors that are sensitive to heat are lost less in the process as compared to the processes incorporating heat treatment for drying purposes.[2] Freeze-drying does not usually cause shrinkage or toughening of the material being dried. In addition, flavours, smells, and nutritional content generally remain unchanged, making the process popular for preserving food. However, water is not the only chemical capable of sublimation, and the loss of other volatile compounds such as acetic acid (vinegar) and alcohols can yield undesirable results.

Freeze-dried products can be rehydrated (reconstituted) much more quickly and easily because the process leaves microscopic pores. The pores are created by the ice crystals that sublimate, leaving gaps or pores in their place. This is especially important when it comes to pharmaceutical uses. Freeze-drying can also be used to increase the shelf life of some pharmaceuticals for many years.

Pharmaceuticals and biotechnology

Pharmaceutical companies often use freeze-drying to increase the shelf life of the products, such as live virus vaccines,[13] biologics[14] and other injectables. By removing the water from the material and sealing the material in a glass vial, the material can be easily stored, shipped, and later reconstituted to its original form for injection. Another example from the pharmaceutical industry is the use of freeze drying to produce tablets or wafers, the advantage of which is less excipient as well as a rapidly absorbed and easily administered dosage form.

Freeze-dried pharmaceutical products are produced as lyophilized powders for reconstitution in vials and more recently in prefilled syringes for self-administration by a patient.

Examples of lyophilized biological products include many vaccines such as live measles virus vaccine, typhoid vaccine, and meningococcal polysaccharide vaccine groups A and C combined. Other freeze-dried biological products include antihemophilic factor VIII, interferon alfa, anti-blood clot medicine streptokinase, and wasp venom allergenic extract.[15]

Many bio-pharmaceutical products based on therapeutic proteins such as monoclonal antibodies require lyophilization for stability. Examples of lyophilized biopharmaceuticals include blockbuster drugs such as etanercept (Enbrel by Amgen), infliximab (Remicade by Janssen Biotech), rituximab, and trastuzumab (Herceptin by Genentech).

Freeze-drying is also used in manufacturing of raw materials for pharmaceutical products. Active Pharmaceutical Product Ingredients (APIs) are lyophilized to achieve chemical stability under room temperature storage. Bulk lyophilization of APIs is typically conducted using trays instead of glass vials.

Cell extracts that support cell-free biotechnology applications such as point-of-care diagnostics and biomanufacturing are also freeze-dried to improve stability under room temperature storage.[16][17]

Dry powders of probiotics are often produced by bulk freeze-drying of live microorganisms such as lactic acid bacteria and bifidobacteria.[18]

Freeze drying of food

.jpg)

The primary purpose of freeze drying within the food industry is to extend the shelf-life of the food while maintaining the quality.[1] Freeze-drying is known to result in the highest quality of foods amongst all drying techniques because structural integrity is maintained along with preservation of flavors.[1] Because freeze drying is expensive, it is used mainly with high-value products.[4] Examples of high-value freeze-dried products are seasonal fruits and vegetables because of their limited availability, coffee; and foods used for military rations, astronauts/cosmonauts, and/or hikers.[4]

NASA and military rations

Because of its light weight per volume of reconstituted food, freeze-dried products are popular and convenient for hikers, as military rations, or astronaut meals.[1] A greater amount of dried food can be carried compared to the same weight of wet food. In replacement of wet food, freeze dried food can be easily be rehydrated with water if desired and shelf-life of the dried product is longer than fresh/wet product making it ideal for long trips taken by hikers, military personnel, or astronauts. The development of freeze drying increased meal and snack variety to include items like shrimp cocktail, chicken and vegetables, butterscotch pudding, and apple sauce.[7]

Coffee

Coffee contains flavor and aroma qualities that are created due to the Maillard reaction during roasting[19] and can be preserved with freeze-drying.[2] Compared to other drying methods like room temperature drying, hot-air drying, and solar drying, Robusta coffee beans that were freeze-dried contained higher amounts of essential amino acids like leucine, lysine, and phenylalanine.[19] Also, few non-essential amino acids that significantly contributed to taste were preserved.[19]

Fruits

With conventional dehydration, berries can degrade in quality as their structure is very delicate and contains high levels of moisture. Strawberries were found to have the highest quality when freeze dried; retaining color, flavour, and ability to be re-hydrated.[20]

Insects

Freeze-drying is used extensively to preserve insects for the purposes of consumption. Whole freeze-dried insects are sold as exotic pet food, bird feed, fish bait, and increasingly for human consumption.[21][22] Powdered freeze-dried insects are used as a protein base in animal feeds, and in some markets, as a nutritional supplement for human use.[22][21] Farmed insects are generally used for all of the aforementioned purposes versus harvesting wild insects, except in the case of grasshoppers which are often harvested out of field crops.[21]

Technological industry

In chemical synthesis, products are often freeze-dried to make them more stable, or easier to dissolve in water for subsequent use.

In bioseparations, freeze-drying can be used also as a late-stage purification procedure, because it can effectively remove solvents. Furthermore, it is capable of concentrating substances with low molecular weights that are too small to be removed by a filtration membrane. Freeze-drying is a relatively expensive process. The equipment is about three times as expensive as the equipment used for other separation processes, and the high energy demands lead to high energy costs. Furthermore, freeze-drying also has a long process time, because the addition of too much heat to the material can cause melting or structural deformations. Therefore, freeze-drying is often reserved for materials that are heat-sensitive, such as proteins, enzymes, microorganisms, and blood plasma. The low operating temperature of the process leads to minimal damage of these heat-sensitive products.

In nanotechnology, freeze-drying is used for nanotube purification[23] to avoid aggregation due to capillary forces during regular thermal vaporization drying.

Taxidermy

Freeze-drying is among the methods used to preserve animals in the field of taxidermy. When animals are preserved in this manner they are called "freeze-dried taxidermy" or "freeze-dried mounts". Freeze-drying is commonly used to preserve crustaceans, fish, amphibians, reptiles, insects, and smaller mammals.[24] Freeze-drying is also used as a means to memorialize pets after death. Rather than opting for a traditional skin mount when choosing to preserve their pet via taxidermy, many owners opt for freeze-drying because it is less invasive upon the pet's body.[25]

Other uses

Organizations such as the Document Conservation Laboratory at the United States National Archives and Records Administration (NARA) have done studies on freeze-drying as a recovery method of water-damaged books and documents. While recovery is possible, restoration quality depends on the material of the documents. If a document is made of a variety of materials, which have different absorption properties, expansion will occur at a non-uniform rate, which could lead to deformations. Water can also cause mold to grow or make inks bleed. In these cases, freeze-drying may not be an effective restoration method.

In bacteriology freeze-drying is used to conserve special strains.

Advanced ceramics processes sometimes use freeze-drying to create a formable powder from a sprayed slurry mist. Freeze-drying creates softer particles with a more homogeneous chemical composition than traditional hot spray drying, but it is also more expensive.

A new form of burial which previously freeze-dries the body with liquid nitrogen has been developed by the Swedish company Promessa Organic AB, which puts it forward as an environmentally friendly alternative to traditional casket and cremation burials.

Advantages

Freeze-drying is viewed as the optimal method of choice for dehydration because of the preservation of quality, meaning characteristics of the food product such as aroma, rehydration, and bioactivity, are noticeably higher compared to foods dried using other techniques.[1]

Shelf-life extension

Shelf-life extension is a result from low processing temperatures in conjunction with rapid transition of water through sublimation.[1] With these processing conditions, deterioration reactions, including nonenzymatic browning, enzymatic browning, and protein denaturation, are minimized.[1] When the product is successfully dried, packaged properly, and placed in ideal storage conditions the foods have a shelf life of greater than 12 months.[2]

Re-hydration

If a dried product cannot be easily or fully re-hydrated, it is considered to be of lower quality. Because the final freeze dried product is porous, complete re-hydration can occur in the food.[1] This signifies greater quality of the product and makes it ideal for ready-to-eat instant meals.[4]

Effect on nutrients and sensory quality

Due to the low processing temperatures and the minimization of deterioration reactions, nutrients are retained and color is maintained.[2] Freeze-dried fruit maintains its original shape and has a characteristic soft crispy texture.

Disadvantages

Microbial growth

Since the main method of microbial decontamination for freeze drying is the low temperature dehydration process, spoilage organisms and pathogens resistant to these conditions can remain in the product. Although microbial growth is inhibited by the low moisture conditions, it can still survive in the food product.[26] An example of this is a hepatitis A outbreak that occurred in the United States in 2016, associated with frozen strawberries.[27] If the product is not properly packaged and/or stored, the product can absorb moisture, allowing the once inhibited pathogens to begin reproducing as well.[2]

Cost

The cost for freeze-drying is about 5 times more expensive than conventional drying methods,[4] making it not an ideal choice if the value of the product is not increased after processing.[2] However, costs are also variable depending on the product, the packaging material, processing capacity, etc.[4] Also, the cost in terms of energy is highest to perform the sublimation process in comparison to the freezing, vacuum and condensation steps.[4]

Silicone oil leakage

Silicone oil is the common fluid that is used to heat or cool shelves in the freeze-dryer. The continuous heat/cool cycle can lead to a leakage of silicone oil at weak areas that connect the shelf and hose. This can contaminate the product leading to major losses of food product. Hence, to avoid this issue, mass spectrometers are used to identify vapors released by silicone oil to immediately take corrective action and prevent contamination of the product.[28]

Equipment and types of freeze dryers

There are many types of freeze-dryers available, however, they usually contain a few essential components. These are a vacuum chamber,[2] shelves, process condenser, shelf-fluid system, refrigeration system, vacuum system, and control system.

Function of essential components

Chamber

The chamber is highly polished and contains insulation, internally. It is manufactured with stainless steel and contains multiple shelves for holding the product. A hydraulic or electric motor is in place to ensure the door is vacuum-tight when closed.

Process condenser

The process condenser consists of refrigerated coils or plates that can be external or internal to the chamber.[29] During the drying process, the condenser traps water. For increased efficiency, the condenser temperature should be 20 °C (68 °F) less than the product during primary drying[29] and have a defrosting mechanism to ensure that the maximum amount of water vapor in the air is condensed.

Shelf fluid

The amount of heat energy needed at times of the primary and secondary drying phase is regulated by an external heat exchanger.[29] Usually, silicone oil is circulated around the system with a pump.

Refrigeration system

This system works to cool shelves and the process condenser by using compressors or liquid nitrogen, which will supply energy necessary for the product to freeze.[29]

Vacuum system

During the drying process, a vacuum of 50-100 microbar is applied, by the vacuum system, to remove the solvent.[29] A two-stage rotary vacuum pump is used, however, if the chamber is large then multiple pumps are needed. This system compresses non-condensable gases through the condenser.

Control system

Finally, the control system sets up controlled values for shelf temperature, pressure and time that are dependent on the product and/or the process.[30][31] The freeze-dryer can run for a few hours or days depending on the product.[29]

Contact freeze dryers

Contact freeze dryers use contact (conduction) of the food with the heating element to supply the sublimation energy. This type of freeze dryer is a basic model that is simple to set up for sample analysis. One of the major ways contact freeze dryers heat is with shelf-like platforms contacting the samples. The shelves play a major role as they behave like heat exchangers at different times of the freeze-drying process. They are connected to a silicone oil system that will remove heat energy during freezing and provide energy during drying times.[29]

Additionally, the shelf-fluid system works to provide specific temperatures to the shelves during drying by pumping a fluid (usually silicone oil) at low pressure. The downside to this type of freeze dryer is that the heat is only transferred from the heating element to the side of the sample immediately touching the heater. This problem can be minimized by maximizing the surface area of the sample touching the heating element by using a ribbed tray, slightly compressing the sample between two solid heated plates above and below, or compressing with a heated mesh from above and below.[2]

Radiant freeze dryers

Radiant freeze dryers use infrared radiation to heat the sample in the tray. This type of heating allows for simple flat trays to be used as an infrared source can be located above the flat trays to radiate downwards onto the product. Infrared radiation heating allows for a very uniform heating of the surface of the product, but has very little capacity for penetration so it is used mostly with very shallow trays and homogeneous sample matrices.[2]

Microwave-assisted freeze dryers

Microwave-assisted freeze dryers utilize microwaves to allow for deeper penetration into the sample to expedite the sublimation and heating processes in freeze-drying. This method can be very complicated to set up and run as the microwaves can create an electrical field capable of causing gases in the sample chamber to become plasma. This plasma could potentially burn the sample, so maintaining a microwave strength appropriate for the vacuum levels is imperative. The rate of sublimation in a product can affect the microwave impedance, in which power of the microwave must be changed accordingly.[2]

See also

| Look up freeze-drying in Wiktionary, the free dictionary. |

- Chuño, ancient Incan freeze dried potatoes

- Freeze-dried food and NASA

- List of dried foods

- Supercritical drying

- Frozen mummies

References

- Ratti, Cristina (2008-11-21). Advances in Food Dehydration. CRC Press. pp. 209–235. ISBN 9781420052534.

- Fellows, P. (Peter) (2017). "Freeze drying and freeze concentration". Food processing technology : principles and practice (4th ed.). Kent: Woodhead Publishing/Elsevier Science. pp. 929–940. ISBN 978-0081005231. OCLC 960758611.

- Prosapio, Valentina; Norton, Ian; De Marco, Iolanda (2017-12-01). "Optimization of freeze-drying using a Life Cycle Assessment approach: Strawberries' case study" (PDF). Journal of Cleaner Production. 168: 1171–1179. doi:10.1016/j.jclepro.2017.09.125. ISSN 0959-6526.

- Ratti, C (2001). "Hot air and freeze-drying of high-value foods: a review". Journal of Food Engineering. 49 (4): 311–319. doi:10.1016/s0260-8774(00)00228-4.

- Meryman, H. T. (October 1976). "Historical recollections of freeze-drying". Developments in Biological Standardization. 36: 29–32. ISSN 0301-5149. PMID 801137.

- Corver, Jos. "The Evolution of Freeze Drying" (PDF). Innovations in Pharmaceutical Technology.

- "NASA - Food for Space Flight". www.nasa.gov. SpaceFlight:JSC. Retrieved 2018-05-18.CS1 maint: others (link)

- "NASA Food Technology: Incredible Edibles from Space" (PDF).

- "Defense.gov News Article: New Rations in Pipeline for Service Members". archive.defense.gov. Retrieved 2018-05-18.

- Research, Institute of Medicine (US) Committee on Military Nutrition; Marriott, Bernadette M. (1995). Evolution of Rations: The Pursuit of Universal Acceptance. National Academies Press (US).

- J. Jeff Schwegman (2009) "Basic Cycle Development Techniques for Lyophilized Products".

- Freeze drying/lyophilization of pharmaceutical and biological products. Rey, Louis., May, Joan C. (Joan Christine) (3rd ed.). New York: Informa Healthcare. 2010. ISBN 9781439825761. OCLC 664125915.CS1 maint: others (link)

- Hansen, L.L.J.; et al. (2015). "Freeze-drying of live virus vaccines: A review". Vaccine. 33 (42): 5507–5519. doi:10.1016/j.vaccine.2015.08.085. PMID 26364685.

- Rey, Louis; May, Joan (2016). Freeze-Drying/Lyophilization of Pharmaceutical and Biological Products (Third ed.). Informa healthcare.

- "FDA Guideline for the Determination of Residual Moisture in Dried Biological Products" (PDF). US Food and Drug Administration.

- Wilding, Kristen (25 November 2019). "Thermostable lyoprotectant-enhanced cell-free protein synthesis for on-demand endotoxin-free therapeutic production". New Biotechnology. 53: 73–80. doi:10.1016/j.nbt.2019.07.004. PMID 31349031.

- Gregorio, Nicole (21 February 2020). "Unlocking applications of cell-free biotechnology through enhanced shelf-life and productivity of E. coli extracts". ACS Synthetic Biology. doi:10.1021/acssynbio.9b00433. PMID 32083847.

- "Stability evaluation of freeze-dried Lactobacillus paracasei subsp. tolerance and Lactobacillus delbrueckii subsp. bulgaricus in oral capsules". Res Pharm Sci. 2012.

- Dong, Wenjiang; Hu, Rongsuo; Chu, Zhong; Zhao, Jianping; Tan, Lehe (25 April 2017). "Effect of different drying techniques on bioactive components, fatty acid composition, and volatile profile of robusta coffee beans". Food Chemistry. 234 (234): 121–130. doi:10.1016/j.foodchem.2017.04.156. PMID 28551215.

- Shishehgarha, F; Makhlouf, J; Ratti, C (January 2002). "Freeze-Drying Characteristics of Strawberries". Drying Technology. 20 (1): 131–145. doi:10.1081/drt-120001370.

- Aaron T. Dossey; Juan A. Morales-Ramos; M. Guadalupe Rojas (23 June 2016). Insects as Sustainable Food Ingredients: Production, Processing and Food Applications. Elsevier Science. ISBN 978-0-12-802892-6.

- Bolden, Bonnie (7 December 2018). "Farm hopes to expand into edible insect market". APNews.com. The Associate Press. Retrieved 26 February 2020.

- Maugey, M; Neri, W; Zakri, C; Derré, A; Pénicaud, A; Noé, L; Chorro, M; Launois, P; Monthioux, M; Poulin, P (2007). "Substantial improvement of nanotube processability by freeze-drying". J Nanosci Nanotechnol. 7 (8): 2633–2639. doi:10.1166/jnn.2007.855. PMID 17685277.

- Khidas, Kamal (5 June 2015). "Plastination and Taxidermy: Which is Best for a Museum?". Canadian Museum of Nature blog. Canadian Museum of Nature. Retrieved 24 February 2020.

- Owens, Ryan (8 March 2012). "Grieving Pet Owners Can Opt for Stuffing, Freezing-Drying Deceased Pets". ABCnewsGo.com. ABC News Network. Retrieved 24 February 2020.

- Bourdoux, Siméon; Li, Dan; Rajkovic, Andreja; Devlieghere, Frank; Uyttendaele, Mieke (2016-09-07). "Performance of Drying Technologies to Ensure Microbial Safety of Dried Fruits and Vegetables". Comprehensive Reviews in Food Science and Food Safety. 15 (6): 1056–1066. doi:10.1111/1541-4337.12224. ISSN 1541-4337.

- "2016 - Multistate outbreak of hepatitis A linked to frozen strawberries (Final Update) | Hepatitis A Outbreaks | Outbreaks | Division of Viral Hepatitis | CDC". www.cdc.gov. Retrieved 2018-05-20.

- Meissner, U.; Stahl, Harald; Steinkellner, D. (2011-09-01). "Detection of Silicone Oil Leakages in Freeze Dryers". PDA Journal of Pharmaceutical Science and Technology. 65 (5): 481–485. doi:10.5731/pdajpst.2011.00748. ISSN 1079-7440. PMID 22293837.

- Nireesha, GR; Divya, L; Sowmya, C; Venkatesan, N; Niranjan Babu, M; Lavakumar, V (30 October 2013). "Lyophilization/Freeze Drying - An Review". International Journal of Novel Trends in Pharmaceutical Sciences. 3.

- Lopez-Quiroga, Estefania; Antelo, Luis T.; Alonso, Antonio A. (August 2012). "Time-scale modeling and optimal control of freeze–drying". Journal of Food Engineering. 111 (4): 655–666. doi:10.1016/j.jfoodeng.2012.03.001. hdl:10261/65243.

- Pisano, Roberto; Fissore, Davide; Velardi, Salvatore A.; Barresi, Antonello A. (November 2010). "In-Line Optimization and Control of an Industrial Freeze-Drying Process for Pharmaceuticals". Journal of Pharmaceutical Sciences. 99 (11): 4691–4709. doi:10.1002/jps.22166. PMID 20845466.

External links

| Wikimedia Commons has media related to Freeze drying. |