Cyanoacrylate

Cyanoacrylates are a family of strong fast-acting adhesives with industrial, medical, and household uses. They are various esters of cyanoacrylic acid. The acryl groups in the resin rapidly polymerize in the presence of water to form long, strong chains. They have some minor toxicity.

Specific cyanoacrylates include methyl 2-cyanoacrylate (MCA), ethyl 2-cyanoacrylate (ECA, commonly sold under trade names such as "Super Glue" and "Krazy Glue", or Toagosei), n-butyl cyanoacrylate (n-BCA), octyl cyanoacrylate and 2-octyl cyanoacrylate (used in medical, veterinary and first aid applications). Octyl cyanoacrylate was developed to address toxicity concerns and to reduce skin irritation and allergic response. Cyanoacrylate adhesives are sometimes known generically as instant glues, power glues or superglues. The abbreviation "CA" is commonly used for industrial grade cyanoacrylate.

Development

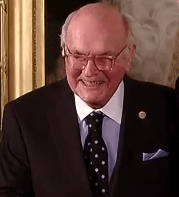

The original patent for cyanoacrylate was filed in 1942 by the B.F. Goodrich Company[1] as an outgrowth of a search for materials suitable for clear plastic gun sights for the war effort. In 1942, a team of scientists headed by Harry Coover Jr. stumbled upon a formulation that stuck to everything with which it came in contact.[2] The team quickly rejected the substance for the wartime application, but in 1951, while working as researchers for Eastman Kodak, Coover and a colleague, Fred Joyner, rediscovered cyanoacrylates. The two realized the true commercial potential, and a form of the adhesive was first sold in 1958 under the title "Eastman #910" (later "Eastman 910").

During the 1960s, Eastman Kodak sold cyanoacrylate to Loctite, which in turn repackaged and distributed it under a different brand name "Loctite Quick Set 404". In 1971, Loctite developed its own manufacturing technology and introduced its own line of cyanoacrylate, called "Super Bonder". Loctite quickly gained market share, and by the late 1970s it was believed to have exceeded Eastman Kodak's share in the North American industrial cyanoacrylate market. National Starch and Chemical Company purchased Eastman Kodak's cyanoacrylate business and combined it with several acquisitions made throughout the 1970s forming Permabond. Other manufacturers of cyanoacrylate include LePage (a Canadian company acquired by Henkel in 1996), the Permabond Division of National Starch and Chemical, which was a subsidiary of Unilever. Together, Loctite, Eastman and Permabond accounted for approximately 75% of the industrial cyanoacrylate market.[3] As of 2019 Permabond continued to manufacture the original 910 formula.[4]

Properties

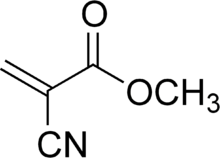

In its liquid form, cyanoacrylate consists of monomers of cyanoacrylate ester molecules. Methyl 2-cyanoacrylate (CH2=C(C≡N)COOCH3) has a molecular weight of 111.1 g/mol, a flashpoint of 79 °C (174 °F; 352 K), and a density of 1.1 g/mL.[5] Ethyl 2-cyanoacrylate ((CH2=C(C≡N)COOCH2CH3)) has a molecular weight of 125 g/mol and a flashpoint of more than 75 °C (167 °F; 348 K). To facilitate easy handling, a cyanoacrylate adhesive is frequently formulated with an ingredient such as fumed silica to make it more viscous or gel-like. More recently, formulations are available with additives to increase shear strength, creating a more impact resistant bond. Such additives may include rubber, as in Loctite's "Ultra Gel", or others which are not specified.

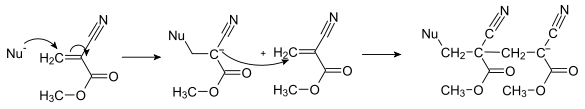

In general, the acryl groups rapidly undergo chain-growth polymerisation in the presence of water (specifically hydroxide ions), forming long, strong chains, joining the bonded surfaces together. Because the presence of moisture causes the glue to set, exposure to normal levels of humidity in the air causes a thin skin to start to form within seconds, which very greatly slows the reaction; hence, cyanoacrylates are applied as thin coats to ensure that the reaction proceeds rapidly for bonding.

Cyanoacrylate adhesives have a short shelf life—about one year from manufacture if unopened, and one month once opened. The reaction with moisture can cause a container of glue which has been opened and resealed to become unusable more quickly than if never opened. To minimise this reduction in shelf life, cyanoacrylate, once opened, should be stored in an airtight container with a package of silica gel desiccant. Another technique is to insert a hypodermic needle into the opening of a tube. After using the glue, residual glue soon clogs the needle, keeping moisture out. The clog is removed by heating the needle (e.g. with a lighter) before use. The polymerisation is also temperature-dependent: storage below freezing point of water, 0 °C (32 °F; 273 K), stops the reaction, so keeping it in the freezer is also effective.

Uses

Behaviours

Cyanoacrylates are mainly used as adhesives. They require some care and knowledge for effective use: they do not bond some materials; they do not fill spaces, unlike epoxies, and a very thin layer bonds more effectively than a thicker one that does not cure properly; they bond many substances, including human skin and tissues. They have an exothermic reaction to natural fibres: cotton, wool, leather, see reaction with cotton below.

Cyanoacrylate glue has a low shearing strength, which has led to its use as a temporary adhesive in cases where the piece needs to be sheared off later. Common examples include mounting a workpiece to a sacrificial glue block on a lathe, and tightening pins and bolts. It is also used in conjunction with another, slower, but more resilient adhesive as a way of rapidly forming a joint, which then holds the pieces in the appropriate configuration until the second adhesive has set.

Cyanoacrylate-based glue has a weak bond with smooth surfaces and as such easily gives to friction; a good example of this is the fact that cyanoacrylates may be removed from human skin by means of abrasives (e.g. sugar or sandpaper).

Electronics

Cyanoacrylates are used to assemble prototype electronics (used in wire wrap), flying model aircraft, and as retention dressings for nuts and bolts. Their effectiveness in bonding metal and general versatility have made them popular among modeling and miniatures hobbyists.[6]

Aquaria

Cyanoacrylate glue's ability to resist water has made it popular with marine aquarium hobbyists for fragmenting corals. The cut branches of hard corals, such as Acropora, can be glued to a piece of live rock (harvested reef coral) or Milliput (epoxy putty) to allow the new fragment to grow out. It is safe to use directly in the tank, unlike silicone which must be cured to be safe. However, as a class of adhesives, traditional cyanoacrylates are classified as having "weak" resistance to both moisture and heat[7] although the inclusion of phthalic anhydride reportedly counteracts both of these characteristics.[8] Cyanoacrylate glue is also used frequently in aquascaping both freshwater and marine aquariums for the purpose of securing the rhizomes of live plants to pieces of wood or stone.

Smooth surfaces

Most standard cyanoacrylate adhesives do not bond well with smooth glass, although they can be used as a quick, temporary bond prior to application of an epoxy or cyanoacrylate specifically formulated for use on glass.[9] A mechanical adhesive bond may be formed around glass fibre mat or tissue to reinforce joints or to fabricate small parts.

Filler

When added to baking soda (sodium bicarbonate), cyanoacrylate glue forms a hard, lightweight adhesive filler. This works well with porous materials that do not work well with the adhesive alone. This method is sometimes used by aircraft modelers to assemble or repair polystyrene foam parts. It is also used to repair small nicks in the leading edge of wood propeller blades on light aircraft,[10] although this technique is limited to use on aircraft registered in the "experimental" category (composite propellers can be repaired in a similar way using two-part epoxies[11]). This technique can also be used to fill in the slots in the nut of a guitar so that new ones can be cut. The reaction between cyanoacrylate and baking soda is very exothermic (heat-producing) and also produces noxious vapors.

One brand of cyanoacrylate, "SupaFix", uses calcium oxide as a filler giving an even harder (mortar-like in texture) result that can be used to join hard materials and even repair cracked castings.[12]

Forensics

Cyanoacrylate is used as a forensic tool to capture latent fingerprints on non-porous surfaces like glass, plastic, etc.[13] Cyanoacrylate is warmed to produce fumes that react with the invisible fingerprint residues and atmospheric moisture to form a white polymer (polycyanoacrylate) on the fingerprint ridges. The ridges can then be recorded. The developed fingerprints are, on most surfaces (except on white plastic or similar), visible to the naked eye. Invisible or poorly visible prints can be further enhanced by applying a luminescent or non-luminescent stain.

Woodworking

Thin cyanoacrylate glue has application in woodworking.[14] It can be used as a fast-drying, glossy finish. The use of oil, such as boiled linseed oil, may be used to control the rate at which the cyanoacrylate cures. Cyanoacrylate glue is also used in combination with sawdust (from a saw or sanding) to fill voids and cracks. These repair methods are used on piano soundboards, wood instruments, and wood furniture. Cyanoacrylate glue is also used in the finishing of pen blanks (wooden blanks for turning pens) that have been turned on a lathe by applying multiple thin layers to build up a hard, clear finish that can then be sanded and polished to a glossy finish.

Medical and veterinary

Cyanoacrylate glue was in veterinary use for mending bone, hide, and tortoise shell by the early 1970s or before. Harry Coover said in 1966 that a cyanoacrylate spray was used in the Vietnam War to reduce bleeding in wounded soldiers until they could be taken to a hospital.[15] n-Butyl cyanoacrylate has been used medically since the 1970s. In the US, due to its potential to irritate the skin, the U.S. Food and Drug Administration (FDA) did not approve its use as a medical adhesive until 1998 with Dermabond (2-octyl cyanoacrylate).[16] A 1986 independent study suggests that cyanoacrylate can be safer and more functional for wound closure than traditional suturing (stitches).[17] The adhesive is superior in time required to close wounds, incidence of infection (suture canals through the skin's epidermal, dermal, and subcutaneous fat layers introduce additional routes of contamination),[17] and finally cosmetic appearance.[18][19]

Some rock climbers use cyanoacrylate to repair damage to the skin on their fingertips.[20][21] Similarly, stringed-instrument players can form protective finger caps (typically, when they lose their calluses due to inactivity or accidents) with cyanoacrylates. While the glue is not very toxic and wears off quickly with shed skin, applying large quantities of glue and its fumes directly to the skin can cause chemical burns.[22]

While standard "superglue" is 100% ethyl 2-cyanoacrylate, many custom formulations (e.g., 91% ECA, 9% poly(methyl methacrylate), <0.5% hydroquinone, and a small amount of organic sulfonic acid,[23] and variations on the compound n-butyl cyanoacrylate for medical applications[17]) have come to be used for specific applications. There are three cyanoacrylate compounds currently available as topical skin adhesives. 2-Octyl cyanoacrylate is marketed as Dermabond, SurgiSeal and more recently LiquiBand Exceed. n-Butyl cyanoacrylate is marketed as Histoacryl, Indermil, GluStitch, GluSeal, PeriAcryl, and LiquiBand. The compound ethyl 2-cyanoacrylate is available as Epiglu.[24]

Archery

Cyanoacrylate is used in archery to glue fletching to arrow shafts. Some special fletching glues are primarily cyanoacrylate repackaged in special fletching glue kits.[25] Such tubes often have a long, thin metal nozzle for improved precision in applying the glue to the base of the fletching and to ensure secure bonding to the arrow shaft.

Cosmetics

Cyanoacrylate is used in the cosmetology and beauty industry as an eyelash extension glue, or a "nail glue" for some artificial nail enhancements such as nail tips and nail wraps, and is sometimes mistaken for eye drops causing accidental injury (chemical eye injury).[26]

Safety issues

Skin injuries

Cyanoacrylate adhesives may adhere to body parts, and injuries may occur when parts of the skin are torn off.[27][28] Without force, however, the glue will spontaneously separate from the skin in time (up to four days). Separation can be accelerated by applying vegetable oil near, on, and around the glue. In the case of glued eyelids, a doctor should be consulted.[29]

Toxicity

The fumes from cyanoacrylate are a vaporized form of the cyanoacrylate monomer that irritate the sensitive mucous membranes of the respiratory tract (i.e., eyes, nose, throat, and lungs). They are immediately polymerized by the moisture in the membranes and become inert. These risks can be minimized by using cyanoacrylate in well-ventilated areas. About 5% of the population can become sensitized to cyanoacrylate fumes after repeated exposure, resulting in flu-like symptoms.[30] Cyanoacrylate may also be a skin irritant, causing an allergic skin reaction. The American Conference of Governmental Industrial Hygienists (ACGIH) assign a threshold limit value exposure limit of 200 parts per billion. On rare occasions, inhalation may trigger asthma. There is no singular measurement of toxicity for all cyanoacrylate adhesives because of the large number of adhesives that contain various cyanoacrylate formulations.

The United Kingdom's Health and Safety Executive and the United States National Toxicology Program have concluded that the use of ethyl cyanoacrylate is safe and that additional study is unnecessary.[31] The compound 2-octyl cyanoacrylate degrades much more slowly due to its longer organic backbone (series of covalently bonded carbon molecules) and the adhesive does not reach the threshold of tissue toxicity. Due to the toxicity issues of ethyl cyanoacrylate, the use of 2-octyl cyanoacrylate for sutures is preferred.

Reaction with cotton, wool, and other fibrous materials

Applying cyanoacrylate to some natural materials such as cotton (jeans, cotton swabs, cotton balls, and certain yarns or fabrics), or leather or wool results in a powerful, rapid, exothermic reaction. This reaction also occurs with fiberglass and carbon fiber. The heat released may cause serious burns[32] or release irritating white smoke. Material Safety Data Sheets for cyanoacrylate instruct users not to wear cotton (jeans) or wool clothing, especially cotton gloves, when applying or handling cyanoacrylates.[33]

Solvents and debonders

Acetone, commonly found as a fraction of nail polish remover (or at hardware stores in pure form), is a widely available solvent capable of softening cured cyanoacrylate.[34] Other solvents include nitromethane, dimethyl sulfoxide, and methylene chloride.[35] gamma-Butyrolactone may also be used to remove cured cyanoacrylate.[36] Commercial debonders are also available.

Shelf life

Cyanoacrylate adhesives have a short shelf life. Date-stamped containers help to ensure that the adhesive is still viable. One manufacturer supplies the following information and advice:

When kept unopened in a cool, dry location such as a refrigerator at a temperature of about 55 °F (13 °C), the shelf life of cyanoacrylate will be extended from about one year from manufacture to at least 15 months. If the adhesive is to be used within six months, it is not necessary to refrigerate it. Cyanoacrylates are moisture-sensitive, and moving from a cool to a hot location will create condensation; after removing from the refrigerator, it is best to let the adhesive reach room temperature before opening. After opening, it should be used within 30 days. Open containers should not be refrigerated.[37]

Another manufacturer says that the maximum shelf life of 12 months is obtained for some of their cyanoacrylates if the original containers are stored at 35 to 40 °F (2 to 4 °C).[38] User forums and some manufacturers say that an almost unlimited shelf life is attainable by storing unopened at −4 °F (−20 °C), the typical temperature of a domestic freezer, and allowing the contents to reach room temperature before use.[39] Rechilling an opened container may cause moisture from the air to condense in the container; however, reports from hobbyists suggest that storing cyanoacrylate in a freezer can preserve opened cyanoacrylate indefinitely.

As cyanoacrylates age, they polymerize, become thicker, and cure more slowly. They can be thinned with a cyanoacrylate of the same chemical composition with lower viscosity.[30] Storing cyanoacrylates below 0 °F (−18 °C) will nearly stop the polymerization process and prevent aging.

References

- Ardis, Alan. "Patent for synthesis of cyanoacrylate". Google patents. Retrieved 22 February 2016.

- "Inventor of the Week Archive". Lemelson-MIT Program. September 2004. Archived from the original on 3 May 2009. Retrieved 13 February 2010.

- HBS, "Loctite Corporation: Industrial Product Group," 15 July 1991, p.3

- https://www.permabond.com/wp-content/uploads/2016/04/910_TDS.pdf |date=August 2019

- "ICSC 1272 - METHYL 2-CYANOACRYLATE".

- "Metal adhesive guide". Adhesiveplatform.com. Adhesiveplatform.com. Retrieved 20 May 2020.

- Petrie, Edward M. (2000). Handbook of adhesives and sealants. New York: McGraw-Hill. p. 354. ISBN 978-0-07-049888-4.

- Petrie, Edward M. (2000). Handbook of adhesives and sealants. New York: McGraw-Hill. p. 389. ISBN 978-0-07-049888-4.

- "Archived copy". Archived from the original on 3 December 2014. Retrieved 11 August 2010.CS1 maint: archived copy as title (link)

- "Propeller Field Repair". www.eaavideo.org. Archived from the original on 31 January 2018. Retrieved 30 January 2018.

- "Composite Propeller Repair". www.eaavideo.org. Archived from the original on 31 January 2018. Retrieved 30 January 2018.

- "S-FIXX APX4 Ultra Strength Superglue Adhesive and Powders Kit".

- Eric W. Brown "The Cyanoacrylate Fuming Method" Archived 20 October 2007 at the Wayback Machine

- "Fine Woodworking: Super Glue to the Rescue". 30 March 2016. Retrieved 30 June 2018.

- "Harry Coover, Super Glue's Inventor, Dies at 94". Retrieved 30 June 2018.

- Singer, A. J.; McClain, S. A.; Katz, A. (2004). "A porcine epistaxis model: hemostatic effects of octylcyanoacrylate". Otolaryngology–Head and Neck Surgery. 130 (5): 553–557. doi:10.1016/j.otohns.2003.09.035. PMID 15138419.

- Dalvi, A A; Faria, M M; Pinto, A A (1986). "Non-suture closure of wound using cyanoacrylate". J Postgrad Med [serial online]. 32: 97–100.

- Fischl, Robert A. (November 1962). "An adhesive for primary closure of skin incisions: a preliminary report". Plastic and Reconstructive Surgery. 30 (6): 607–610. doi:10.1097/00006534-196211000-00009. PMID 13963055.

- Rothnie, N. G.; Taylor, G. W. (26 October 1963). "Sutureless Skin Closure". BMJ. 2 (5364): 1027–1030. doi:10.1136/bmj.2.5364.1027. PMC 1873305. PMID 14056909.

- "Bouldering" Archived 27 November 2010 at the Wayback Machine. climbingaction.com. Retrieved 19 February 2011.

- Anahad O'Connor (4 December 2007). "The Claim: Super Glue Can Heal Wounds". The New York Times. Retrieved 19 February 2011.

- "Document: Cyanoacrylate adhesives (GOLD)". Chemwatch.

- Safety data for ethyl cyanoacrylate from the Physical and Theoretical Chemistry Laboratory of Oxford University

- "Topical skin adhesives. DermNet NZ". www.dermnetnz.org. Retrieved 29 June 2016.

- "ds-archery". ds-archery. website. Retrieved 11 January 2017.

- Needham, A. D (2001). "Similarities in the packaging of cyanoacrylate nail glue and ophthalmic preparations: an ongoing problem". British Journal of Ophthalmology. 85 (4): 496a–496. doi:10.1136/bjo.85.4.496a. ISSN 0007-1161. PMC 1723922. PMID 11302128.

- Clarke, T.F.E. (2011). "Cyanoacrylate glue burn in a child – lessons to be learned". Journal of Plastic, Reconstructive & Aesthetic Surgery. 64 (7): e170–e173. doi:10.1016/j.bjps.2011.03.009. ISSN 1748-6815. PMID 21481658.

- Reddy, S.C. (2012). "Superglue injuries of the eye". International Journal of Ophthalmology. 5 (5): 634–637. doi:10.3980/j.issn.2222-3959.2012.05.18. PMC 3484698. PMID 23166877.

- First aid information (in German) by Industrieverband Klebstoffe e.V.

- "CA PLUS Adhesives, Inc". Archived from the original on 8 July 2011. Retrieved 3 August 2009.

- Methyl Cyanoacrylate and Ethyl Cyanoacrylate from inchem.org

- Clarke, TFE (March 2011). "Superglue (Cyanoacrylate) in the Nose". Journal of Plastic, Reconstructive & Aesthetic Surgery. 64 (7): e170–3. doi:10.1016/j.bjps.2011.03.009. PMID 21481658.

- "Material Safety Data Sheet" (PDF). accumetricinc.com. Archived from the original (PDF) on 19 February 2009. Retrieved 9 June 2008.

- Moschos, M.; Droutsas, D.; Boussalis, P.; Tsioulias, G. (1997). "Clinical experience with cyanoacrylate tissue adhesive". Documenta Ophthalmologica. Soringer. 93 (3): 237–245. doi:10.1007/BF02569064. PMID 9550352.

- Duvvi, Sham K.; Lo, Stephen; Kumar, R; Spraggs, P (2005). "Superglue (Cyanoacrylate) in the Nose". Otolaryngology–Head and Neck Surgery. 133 (5): 803–804. doi:10.1016/j.otohns.2004.09.090. PMID 16274815.

- Shantha, K.L.; Krishnamurti, N.; Krishnamurti, N. (1989). "Developments and applications of cyanoacrylate adhesives". Journal of Adhesion Science and Technology. VSP. 3 (1): 237–260. doi:10.1163/156856189X00191.

- Palm Labs Adhesives: Cyanoacrylate Adhesive Shelf Life Archived 14 July 2014 at the Wayback Machine

- MASTER BOND MB SERIES CYANOACRYLATES: Technical Data Sheet

- WEICON Contact Cyanoacrylate Adhesives

Further reading

- derma+flex QS 510k Letter: http://www.accessdata.fda.gov/cdrh_docs/pdf10/K101276.pdf

- LiquiBand 510k Letter: http://www.accessdata.fda.gov/cdrh_docs/pdf8/K083531.pdf

- Fernandez, Tania & Bliskovsky, Val (2 January 2003). "Cyanoacrylate Technology: Stay Glued". Pharmbiz.com. Missing or empty

|url=(help) - Hayes, Sharon Caskey (11 July 2004). "Discovery of Super Glue helped land Coover in National Inventors Hall of Fame". Kingsport Times-News.

- Jueneman, F. (August 1981). "Stick it to um". Industrial Research & Development. p. 19.

- Perry, L. C. "An evaluation of acute incisional strength with Traumaseal surgical tissue adhesive wound closure". Dimensional Analysis Systems Inc.

- Quinn, J. & Kissack, J. (1994). "Tissue Adhesives for Laceration Repair During Sporting Events". Clinical Journal of Sport Medicine. 4 (4): 245–248. doi:10.1097/00042752-199410000-00006.

- Schwade, Nathan D. (10 April 2002). "Wound Adhesives, 2-Octyl Cyanoacrylate". eMedicine article.

- Vinters, H. V.; Galil, K. A.; Lundie, M. J.; Kaufmann, J. C. (1985). "The histotoxicity of cyanoacrylates. A selective review". Neuroradiology. 27 (4): 279–291. doi:10.1007/BF00339559. PMID 3900798.

External links

- Was Super Glue invented to seal battle wounds in Vietnam? (from The Straight Dope)

- Cyanoacrylate Toxicity

- Cyanoacrylate Adhesive / Super Glue Safety Data Sheets

- Safety in the Home: Super Glue - Queensland Health

- Cyanoacrylate Technical Data Sheet

- U.S. Patent 2,768,109 Alcohol-Catalyzed α-Cyanoacrylate Adhesive Compositions, filed June 1954, issued October 1956.

- 3M Activators, Primers and Debonder

- Application note on measuring cure kinetics of cyanoacrylate glues