Mesoporous magnesium carbonate

Mesoporous magnesium carbonates (MMCs) constitute a family of magnesium carbonate materials with high specific surface areas. It was first reported in July 2013 by a group of researchers in nanotechnology at Uppsala University.[1][2] The highest reported surface area of any MMC is 800 m² per gram, which is the highest surface area ever measured for an alkali earth metal carbonate.[1] The average pore size of MMCs can be adjusted by tuning the synthesis conditions.[3] So far, all reported forms of MMCs are anhydrous and X-ray amorphous.

As with other types of mesoporous materials, the large surface area and the nanometer sized pores in makes MMCs interesting in a number of applications. In addition, MMC has excellent hygroscopic properties.[1]

The pores are formed via expanding CO2 gas during synthesis, no other templating molecules are needed to form the mesoporous network in the material. The first patent on MMCs was granted in 2017,[4] and it is now being commercialized by the spin-out company Disruptive Materials AB in Uppsala, Sweden, for applications within cosmetics, sport products and other technical areas. MMCs is also being investigated within pharmaceutical applications.

Naming

In the first publications on mesoporous magnesium carbonate, the material was given the name Upsalite as a reference to Uppsala University and the city of Uppsala, using the latin spelling with one p. Today, Upsalite is a registered trademark, and in general the material class is designated as mesoporous magnesium carbonates.

Synthesis

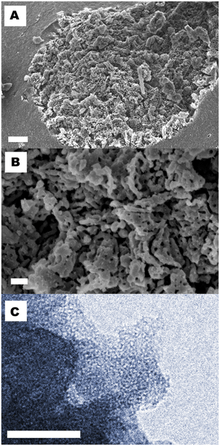

The general type of MMC is synthesized by reacting magnesium oxide (MgO) and methanol under a carbon dioxide (CO2) pressure.[1][3][5] Stirring and depressurization of the product results in an alcogel that swell as CO2 gas expand and is released. When physically bound CO2 is released, and residual methanol is evaporated from the gel upon heat treatment at moderate temperatures, the gel solidifies, and a porous network is formed in the material. The average pore diameter in the final product can be controlled by adjusting the energy input during the solidification process.[3]

Structure

MMCs are composed of an X-ray amorphous and mesoporous MgCO3 matrix with crystals of MgO embedded in the structure.[3] The synthesis route described above generally produces MMC particles in the millimetre to centimetre range, particles that can be reduced in size if desired.[6]

Pharmaceutical applications

MMCs have been shown to successfully increase the apparent solubility of several poorly soluble model drugs, including Ibuprofen,[6][7][8] itraconacole,[3] tolfenamic, rimonabant,[9] celecoxib, cinnarizine and griseofulvin.[10] They do so by suppressing crystallization of the drug substance incorporated into the pores of the materials. Amorphous drugs generally exhibit higher solubilities than their crystalline counterparts, and by stabilizing drugs in their amorphous state in the drug formulation, a higher solubility can be obtained at administration.[11] Poor aqueous solubility limits the bioavailability of many drugs, and thus their therapeutic effect.

The release of drugs from MMCs can be tuned via particle size[7] and pore size.[3] The release rate can also be tuned via chemical modification of the pore walls.[8] It has been shown that supersaturation of drugs formulated with MMCs can be enhanced, both in terms of drug solubility and time-period for supersaturation, by addition of the polymers during release.[10]

Sports

Due to its ability to adsorb moisture, MMCs can be used by climbers and other athletes to enhance grip. MMC under the brand name Upsalite, was introduced on the global market as an ingredient in climbing chalk, in 2018 by the company Black Diamond. When first presented on the world's largest sports exhibit ISPO, it was awarded best new and innovative climbing accessory 2018.[12]

Humidity control

As MMCs are found to adsorb more water at low relative humidities compared to the best materials previously available, the hygroscopic zeolites, they can be used to keep humidity at extremely low levels where needed.[1] Further, upsalite can release that water at lower temperatures than zeolites, requiring less energy.

Other potential uses

MMC can also be potentially used for collection of toxic waste, chemicals or oil spill and for odor control, sanitation after fire, and the collection of water from any source containing it.[1]

References

- Forsgren J, Frykstrand S, Grandfield K, et al. A template-free, ultra-adsorbing, high surface area carbonate nanostructure. PLoS One 8, e68486 (2013). doi:10.1371/journal.pone.0068486

- Freeman D. Upsalite, ‘Impossible’ Material Believed To Have Many Uses, Created In Swedish Lab. The Huffington Post (Aug 5, 2013). Available at: https://www.huffingtonpost.com/2013/08/05/upsalite-impossible-material-swedish-lab_n_3709055.html

- Cheung O, Zhang P, Frykstrand, S, et al. Nanostructure and pore size control of template-free synthesised mesoporous magnesium carbonate. RSC Advances 6, 74241-74249 (2016). doi:10.1039/C6RA14171D

- Strömme M, Mihranyan A, Gómez de la Torre J, Frykstrand S. Anhydrous, amorphous and porous magnesium carbonates and methods of production thereof, US9580330B2. Available at: https://patents.google.com/patent/US9580330B2

- Frykstrand S, Forsgren J, Mihranyan A, Strömme M. On the pore-forming mechanism of Upsalite, a micro- and mesoporous magnesium carbonate, Microporous and Mesoporous Materials 190, 99-104 (2014). doi:10.1016/j.micromeso.2013.12.011

- Zhang P, Forsgren J, Strømme M. Stabilisation of amorphous buprofen in Upsalite, a mesoporous magnesium carbonate, as an approach to increasing the aqueous solubility of poorly soluble drugs. International Journal of Pharmaceutics 472, 185-191 (2014). doi: 10.1016/j.ijpharm.2014.06.025

- Zhang P, Zardán Gómez de la Torre T, Forsgren J, et al. Diffusion-Controlled Drug Release From the Mesoporous Magnesium Carbonate Upsalite.Journal of Pharmaceutical Sciences 105, 657-663 (2016). doi:10.1002/jps.24553

- Vall M, Zhang P, Gao A, et al. Effects of amine modification of mesoporous magnesium carbonate on controlled drug release.International Journal of Pharmaceutics 524, 141-147 (2017). doi:10.1016/j.ijpharm.2017.03.063

- Yang J, Alvebratt C, Zhang P, et al. Enhanced release of poorly water-soluble drugs from synergy between mesoporous magnesium carbonate and polymers.International Journal of Pharmaceutics 525, 183-190 (2017). doi:10.1016/j.ijpharm.2017.04.018

- Zhang P, Zardán Gómez de la Torre T, Welch K, et al. Supersaturation of poorly soluble drugs induced by mesoporous magnesium carbonate.European Journal of Pharmaceutical Sciences93, 468-474. doi:10.1016/j.ejps.2016.08.059

- Forsgren J, Andersson M, Nilsson P, Mihranyan A. Mesoporous Calcium Carbonate as a Phase Stabilizer of Amorphous Celecoxib – An Approach to Increase the Bioavailability of Poorly Soluble Pharmaceutical Substances. Advanced Healthcare Materials 2, 1469-1476. doi:10.1002/adhm.201200391

- ISPO. ISPO awards 2018. Available at: https://www.ispo.com/en/awards/ispo-award/winners/2018/outdoor#!ts-76506-t-76421 [accessed on October 23, 2018]