Soft lithography

In technology, soft lithography is a family of techniques for fabricating or replicating structures using "elastomeric stamps, molds, and conformable photomasks".[1] It is called "soft" because it uses elastomeric materials, most notably PDMS.

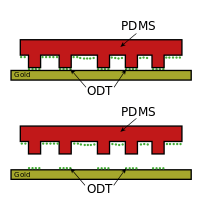

Figure 1 - "Inking" a stamp. PDMS stamp with pattern is placed in Ethanol and ODT (octadecanethiol) solution

Figure 2 - ODT from the solution settles down onto the PDMS stamp. Stamp now has ODT attached to it which acts as the ink.

Figure 3 - The PDMS stamp with the ODT is placed on the gold substrate. When the stamp is removed, the ODT in contact with the gold stays stuck to the gold. Thus the pattern from the stamp is transferred to the gold via the ODT "ink."

Soft lithography is generally used to construct features measured on the micrometer to nanometer scale. According to Rogers and Nuzzo (2005), development of soft lithography expanded rapidly from 1995 to 2005. Soft lithography tools are now commercially available.[2]

Advantages

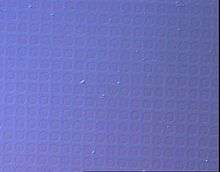

Sarfus image of streptavidin deposited by soft lithography with PDMS stamp.

Soft lithography has some unique advantages over other forms of lithography (such as photolithography and electron beam lithography). They include the following:

- Lower cost than traditional photolithography in mass production

- Well-suited for applications in biotechnology

- Well-suited for applications in plastic electronics

- Well-suited for applications involving large or nonplanar (nonflat) surfaces

- More pattern-transferring methods than traditional lithography techniques (more "ink" options)

- Does not need a photo-reactive surface to create a nanostructure

- Smaller details than photolithography in laboratory settings (~30 nm vs ~100 nm). The resolution depends on the mask used and can reach 6 nm.[3]

gollark: RNNs with attentions, which is of course ridiculous because attention is all you need.

gollark: Huh, the coral translator thing™ actually does use RNNs and not transformers?

gollark: We may convert you into Cauchy sequences at random.

gollark: In what way?

gollark: Also me.

References

- In the words of Rogers and Nuzzo, p. 50, as cited in "Further reading"

- "Research Micro Stamps: Commercially available micro stamps". RMS. Retrieved 2017-01-17.

- Waldner, Jean-Baptiste (2008). Nanocomputers and Swarm Intelligence. London: ISTE John Wiley & Sons. p. 93. ISBN 978-1-84704-002-2.

Further reading

- Xia, Y.; Whitesides, G. M. (1998). "Soft Lithography". Angew. Chem. Int. Ed. Engl. 37 (5): 551–575. doi:10.1002/(SICI)1521-3773(19980316)37:5<550::AID-ANIE550>3.0.CO;2-G. PMID 29711088. Archived from the original on 2011-08-12.

- Xia, Y.; Whitesides, G. M. (1998). "Soft Lithography. In". Annu. Rev. Mater. Sci. 28: 153–184. Bibcode:1998AnRMS..28..153X. doi:10.1146/annurev.matsci.28.1.153.

- Quake, S. R.; Scherer, A. (2000). "From micro- to nanofabrication with soft materials". Science. 290 (5496): 1536–1540. Bibcode:2000Sci...290.1536Q. doi:10.1126/science.290.5496.1536. PMID 11090344.

- Rogers, J. A.; Nuzzo, R. G. (2005). "February). Recent progress in soft lithography. In". Materials Today. 8 (2): 50–56. doi:10.1016/S1369-7021(05)00702-9.

This article is issued from Wikipedia. The text is licensed under Creative Commons - Attribution - Sharealike. Additional terms may apply for the media files.