Polyvinyl butyral

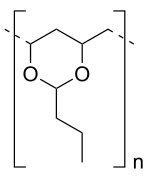

Polyvinyl butyral (or PVB) is a resin mostly used for applications that require strong binding, optical clarity, adhesion to many surfaces, toughness and flexibility. It is prepared from polyvinyl alcohol by reaction with butyraldehyde. The major application is laminated safety glass for automobile windshields.[1] Trade names for PVB-films include KB PVB, Saflex, GlasNovations, Butacite, WINLITE, S-Lec, Trosifol and EVERLAM. PVB is also available as 3D printer filament that is stronger and more heat resistant than polylactic acid (PLA).

| |

| Names | |

|---|---|

| Other names

Poly(vinyl butyral) Poly[(2-propyl-1,3-dioxane-4,6-diyl)methylene] | |

| Identifiers | |

| ChemSpider |

|

| ECHA InfoCard | 100.126.112 |

CompTox Dashboard (EPA) |

|

| Properties | |

| (C8H14O2)n | |

| Molar mass | Variable |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| Infobox references | |

Applications

Automotive and architectural

Laminated glass, commonly used in the automotive and architectural fields, comprises a protective interlayer, usually polyvinyl butyral, bonded between two panels of glass. The bonding process takes place under heat and pressure. When laminated under these conditions, the PVB interlayer becomes optically clear and binds the two panes of glass together. Once sealed together, the glass "sandwich" (i.e., laminate) behaves as a single unit and looks like normal glass. The polymer interlayer of PVB is tough and ductile, so brittle cracks will not pass from one side of the laminate to the other.

Colors

PVB interlayer can be purchased in colored sheets, such as for the blue or green "shade band" at the top edge of many automobile windshields. PVB interlayers can also be purchased in different colors for architectural laminated glass manufacture ranging from Bronze, Gray, Green, Brown, White and many more. Discovered in the late 1990s it was found that PVB degraded over time within laminated windows.

Solar modules

PVB has gained acceptance among manufacturers of photovoltaic thin film solar modules. The photovoltaic circuit is formed on a sheet of glass using thin film deposition and patterning techniques. PVB and a second sheet of glass (called back glass) are then placed directly on the circuit. The lamination of this sandwich encapsulates the circuit, protecting it from the environment. Current is extracted from the module at a sealed terminal box that is attached to the circuit through a hole in the back glass. Another common laminant used in the solar industry is ethylene-vinyl acetate (EVA).

Non-film applications

PVB resins (provided by the manufacturer in powdered or granulated form) are also utilized in a range of applications including technical ceramic (temporary) binders, inks, dye transfer ribbon inks, paints & coatings (including wash primers), binders for reflective sheet and binders for magnetic media. PVB resin is particularly useful at bonding to metals, ceramics and other inorganics.

Properties of PVB-laminated glass

Annealed glass, heat-strengthened or tempered glass can be used to produce laminated glass. While laminated glass will crack if struck with sufficient force, the resulting glass fragments tend to adhere to the interlayer rather than falling free and potentially causing injury.

In practice, the interlayer provides three beneficial properties to laminated glass panes: first, the interlayer functions to distribute impact forces across a greater area of the glass panes, thus increasing the impact resistance of the glass; second, the interlayer functions to bind the resulting shards if the glass is ultimately broken; third the viscoelastic interlayer undergoes plastic deformation during impact and under static loads after impact, absorbing energy and reducing penetration by the impacting object as well as reducing the energy of the impact that is transmitted to impacting object, e.g. a passenger in a car crash. Thus, the benefits of laminated glass include safety and security. Laminated glass also has decorative applications. The interlayer can be colored or patterned.[2]

History

PVB was invented in 1927 by the Canadian chemists Howard W. Matheson and Frederick W. Skirrow.[3] PVB has been the dominant interlayer material since the late 1930s.[4] It is currently manufactured and marketed by a number of companies worldwide, including Eastman (Kingsport, Tennessee, USA) (Saflex-brand PVB), Sekisui[5] (Kyoto, Japan)(Winchester, Kentucky) (Cuernavaca, Mexico)("S-Lec" brand PVB film and powdered PVB resins), Kuraray Europe GmbH [6] (Frankfurt, Germany) ("Trosifol"-brand PVB and "Mowital / Pioloform" for powdered PVB resins), Chang Chung Petrochemicals Co. Ltd, Taiwan ("WINLITE"-brand PVB) and EVERLAM (Hamm-Uentrop, Germany) ("Everlam" brand).

The market for laminated glass products is mature. With only minor modifications, the PVB interlayer sold today is essentially identical to the PVB sold 30 years ago. Since its introduction in 1938, the worldwide market for PVB interlayer has been dominated by a handful of large chemical companies. As a result, inventive efforts have tended toward methods of making the interlayer itself cheaper to manufacture, or making the interlayer easier to handle and less prone to material defects during the process of fabricating laminated glass.

Other interlayer materials

Other types of interlayer materials are in use, including polyurethanes such as Duraflex-brand thermoplastic polyurethane film, manufactured by Bayer MaterialScience, Leverkusen, Germany. As used herein, the term "interlayer" refers to any material now known or developed in the future for manufacturing laminated glass. PVB and thermoplastic polyurethanes (TPUs) are explicitly included within the definition of "interlayer."

See also

References

- Hallensleben, Manfred L. (2000). "Polyvinyl Compounds, Others". Ullmann's Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH. doi:10.1002/14356007.a21_743.

- "Window to the Future of Decorative Glass". Glassmagazine. March 28, 2014. Retrieved November 10, 2016.

- Howard W. Matheson and Frederick W. Skirrow, "Vinyl ester resins and process of making same," U.S. Patent no. 1,725,362 (filed: August 15, 1927 ; issued: August 20, 1929).

- Laminated glass containing PVB was patented in 1936. Within five years, 98% of laminated glass contained PVB. See:

- Earl L. Fix, "Safety glass," U.S. Patent no. 2,045,130 (filed: February 25, 1936 ; issued: June 23, 1936).

- Fred Aftalion, A History of the International Chemical Industry, 2nd ed. (Philadelphia, Pennsylvania: Chemical Heritage Foundation, 2001), p. 153.

- "Sekisui Chemical Co., Ltd". Sekisuichemical.com. Retrieved 2010-10-19.

- "Kuraray Europe GmbH - manufactures synthetic resins, fine chemicals, non-woven fabrics, man-made leather to laser discs and medical products". Kuraray.eu. Retrieved 2010-10-19.

Further reading

- Dhaliwal, A. K.; Hay, J. N. (2002). "The characterization of polyvinyl butyral by thermal analysis". Thermochimica Acta. 91 (1–2): 245–255. doi:10.1016/s0040-6031(02)00187-9. Study of PVB from several manufacturers that establishes the possibility of using recycled PVB from laminated glass.

- "Mowital-Technical Data Sheet" (PDF). Archived from the original (PDF) on January 8, 2014. (PDF; 75 kB)