Carrageenan

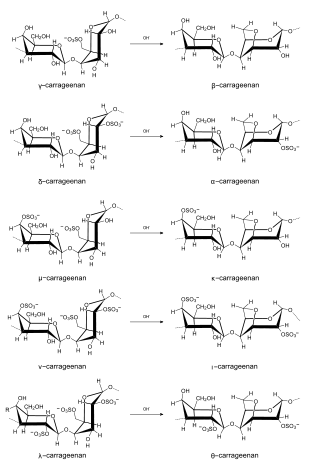

Carrageenans or carrageenins (/ˌkærəˈɡiːnənz/ karr-ə-gee-nənz, from Irish carraigín, "little rock") are a family of linear sulfated polysaccharides that are extracted from red edible seaweeds. They are widely used in the food industry, for their gelling, thickening, and stabilizing properties. Their main application is in dairy and meat products, due to their strong binding to food proteins. There are three main varieties of carrageenan, which differ in their degree of sulfation. Kappa-carrageenan has one sulfate group per disaccharide, iota-carrageenan has two, and lambda-carrageenan has three.

Gelatinous extracts of the Chondrus crispus (Irish moss) seaweed have been used as food additives since approximately the fifteenth century.[1] Carrageenan is a vegetarian and vegan alternative to gelatin in some applications or may be used to replace gelatin in confectionery.

Properties

Carrageenans are large, highly flexible molecules that form curling helical structures. This gives them the ability to form a variety of different gels at room temperature. They are widely used in the food and other industries as thickening and stabilizing agents.

All carrageenans are high-molecular-weight polysaccharides made up of repeating galactose units and 3,6 anhydrogalactose (3,6-AG), both sulfated and nonsulfated. The units are joined by alternating α-1,3 and β-1,4 glycosidic linkages.

There are three main commercial classes of carrageenan:

- Kappa forms strong, rigid gels in the presence of potassium ions, and reacts with dairy proteins. It is sourced mainly from Kappaphycus alvarezii.[2]

- Iota forms soft gels in the presence of calcium ions. It is produced mainly from Eucheuma denticulatum.[2]

- Lambda does not gel, and is used to thicken dairy products.

The primary differences that influence the properties of kappa, iota, and lambda carrageenan are the number and position of the ester sulfate groups on the repeating galactose units. Higher levels of ester sulfate lower the solubility temperature of the carrageenan and produce lower strength gels, or contribute to gel inhibition (lambda carrageenan).

Many red algal species produce different types of carrageenans during their developmental history. For instance, the genus Gigartina produces mainly kappa carrageenans during its gametophytic stage, and lambda carrageenans during its sporophytic stage.

All are soluble in hot water, but in cold water, only the lambda form (and the sodium salts of the other two) are soluble.

When used in food products, carrageenan has the EU additive E numbers E407 or E407a when present as "processed eucheuma seaweed".[3] Technically carrageenan is considered a dietary fibre.[4][5]

In parts of Scotland and Ireland, where it is known by a variety of local and native names, Chondrus crispus is boiled in milk and strained, before sugar and other flavourings such as vanilla, cinnamon, brandy, or whisky are added. The end-product is a kind of jelly similar to panna cotta, tapioca, or blancmange.

Production

Although carrageenans were introduced on an industrial scale in the 1930s, they were first used in China around 600 B.C. (where Gigartina was used) and in Ireland around 400 A.D.[6][7] Carrageen gelatin can be prepared by boiling 5 ounces (142 gm) of rinsed Irish moss in 8 quarts (7.57 litres) of water for 10 minutes, stirring the mixture as it boils. Two quarts (1.9 litres) of cold water are rapidly added to the hot brew, and after the mixture has cooled, it is strained through a cloth. It is then cooled for 24 hours, during which time it becomes gelatinous.

As of 2011, global sales of carrageenan were estimated at $640 million.[8] The largest producer of industrial carrageenan was the Philippines, where cultivated seaweed produces about 80% of the world supply,[9] while China is the main exporter to global markets in the US and Europe.[8] The most commonly used sources are E. cottonii (Kappaphycus alvarezii, K. striatum) and E. spinosum (Eucheuma denticulatum), which together provide about three-quarters of the world production. These grow from the sea surface to a depth of about 2 metres. The seaweed is normally grown on nylon lines strung between bamboo floats, and it is harvested after three months or so, when each plant weighs approximately 1 kg.

The E. cottonii variety has been reclassified as Kappaphycus cottonii by Maxwell Doty (1988), thereby introducing the genus Kappaphycus, on the basis of the phycocolloids produced (namely kappa carrageenan).

After harvest, the seaweed is dried, baled, and sent to the carrageenan manufacturer. There the seaweed is ground, sifted to remove impurities such as sand, and washed thoroughly. After treatment with hot alkali solution (e.g., 5–8% potassium hydroxide), the cellulose is removed from the carrageenan by centrifugation and filtration. The resulting carrageenan solution is then concentrated by evaporation. It is dried and ground to specification.

There are three types of industrial processing:

Semi-refined

This is only performed using E. cottonii or E. spinosum. The raw weed is first sorted and crude contaminants are removed by hand. The weed is then washed to remove salt and sand, and then cooked in hot alkali to increase the gel strength. The cooked weed is washed, dried, and milled. E. spinosum undergoes a much milder cooking cycle, as it dissolves quite readily. The product is called semi-refined carrageenan, Philippines natural grade, or, in the U.S., it simply falls under the common carrageenan specification.[10]

cleaned and washed seaweed

↓

extraction

↓

coarse filtration → seaweed residue

↓

fine filtration → used filter aids

↓

↓-------------- concentration --------------↓

preparation with KCl preparation with alcohol

↓ ↓

gel pressing alcohol recovery

↓ ↓

drying drying

↓ ↓

milling milling

↓ ↓

blending blending

↓ ↓

gel refined carrageenan refined carrageenan

Refined

The essential difference in the refining process is that the carrageenan is first dissolved and filtered to remove cell wall debris. The carrageenan is then precipitated from the clear solution either by isopropanol or by potassium chloride.[11]

Mixed processing

A hybrid technology in which seaweed is treated heterogeneously as in the semirefined process exists, but alcohol or high salt levels are used to inhibit dissolution. This process is often used on South American seaweeds and gives some of the cost benefits of semirefined processing, while allowing a wider range of seaweeds to be processed, however, the naturally low cellulose levels in some South American seaweeds allow them to be heterogeneously processed and still be sold under the EU refined specification.

Grades

There are two basic grades of carrageenan: refined carrageenan (RC) and semi-refined carrageenan (SRC). In the United States both grades are labeled as carrageenan. In the European Union, refined carrageenan is designated by the E number E-407, and semi-refined carrageenan as E-407a.[3] Refined carrageenan has a 2% maximum for acid insoluble material and is produced through an alcohol precipitation process or potassium chloride gel press process. Semi-refined carrageenan contains a much higher level of cellulosic content and is produced in a less complex process. Indonesia, the Philippines, and Chile are three main sources of raw material and extracted carrageenan.

Uses and applications

Food and other domestic uses

- Desserts, carrageen, ice cream, cream, milkshakes, yogurts, salad dressings, sweetened condensed milks

- Sauces: to increase viscosity

- Beer: clarifier to remove haze-causing proteins

- Pâtés and processed meats (e.g., ham): substitute for fat, increase water retention, increase volume, or improve slicing

- Toothpaste: stabilizer to prevent constituents separating

- Fruit Gushers: ingredient in the encapsulated gel

- Fire fighting foam: thickener to cause foam to become sticky

- Shampoo and cosmetic creams: thickener

- Air freshener gels

- Marbling: the ancient art of paper and fabric marbling uses a carrageenan mixture on which to float paints or inks; the paper or fabric is then laid on it, absorbing the colours

- Shoe polish: to increase viscosity

- Biotechnology: to immobilize cells and enzymes

- Pharmaceuticals: used as an inactive excipient in pills and tablets

- Soy milk and other plant milks: to thicken

- Diet sodas: to enhance texture and suspend flavours

- Pet food

- Personal lubricants

- Vegetarian hot dogs

Regulatory status

In the U.S., carrageenan is allowed under FDA regulations[12] as a direct food additive and is considered safe[13] when used in the amount necessary as an emulsifier, stabilizer, or thickener in foods, except those standardized foods that do not provide for such use. FDA also reviewed carrageenan safety for infant formula.[14] The European Food Safety Authority concluded "there is no evidence of any adverse effects in humans from exposure to food-grade carrageenan, or that exposure to degraded carrageenan from use of food-grade carrageenan is occurring",[15] Furthermore, the Joint FAO/WHO expert committee on food additives stated in a July 2014 review of carrageenan "that the use of carrageenan in infant formula or formula for special medical purposes at concentrations up to 1000 mg/L is not of concern".[16]

Although the National Organic Program (NOP) had added carrageenan to its National List of additives allowed to be included in organic foods in 2003,[17] and reviewed and reauthorized it in 2008,[18] noting it as "critical to organic production and handling operations",[19] on November 18, 2016 the NOP's National Organic Standards Board (NOSB) voted to recommend carrageenan be removed from the National List of additives allowed in organic food production.[20]

On April 4, 2018 the Agricultural Marketing Service (AMS) (USDA) published a document to announce the renewal of carrageenan on the National List, allowing its continued use in food products. The document states, “The NOSB recommended removing carrageenan because they determined that alternative materials, such as gellan gum, guar gum, or xanthan gum, are available for use in organic products” continuing, “AMS found sufficient evidence in public comments to the NOSB that carrageenan continues to be necessary for handling agricultural products because of the unavailability of wholly natural substitutes (§ 6517(c)(1)(ii)). Carrageenan has specific uses in an array of agricultural products, and public comments reported that potential substitutes do not adequately replicate the functions of carrageenan across the broad scope of use. Therefore, carrageenan continues to meet the OFPA criteria for inclusion on the National List.” [21] The rule went into effect May 29, 2018.

In the most recent review by an independent panel, the Joint Expert Committee of the Food and Agriculture Organization of the United Nations and World Health Organization on Food Additives released a technical report in 2015 on the use of carrageenan in infant formula and found that the additive was ‘not of concern’ in infant formula as food for special medical purposes at concentrations up to 1000 milligrams per litre.[22] The use of carrageenan in infant formula, organic or otherwise, is prohibited in the EU for precautionary reasons, but is permitted in other food items.[23]

In the UK, the Food Standards Agency issued a product recall for sweets containing carrageenan, stating that carrageenan “is not permitted as an ingredient in jelly confectionery products as it presents a choking hazard”.[24]

Toxicity research

Degraded carrageenan (poligeenan) has been found to cause inflammation of the gut, altering microbiota, and was found to be a triggering factor of inflammatory bowel diseases such as ulcerative colitis and Crohn Disease.[25][26][27]

Food-grade carrageenan has been confused with poligeenan, although they are completely different products, creating a controversy over the food-additive's safety. Food-grade carrageenan's safety has been proven through various studies.[28][29]

See also

References

- FAO Agar and Carrageenan Manual. Fao.org (1965-01-01). Retrieved on 2011-12-10.

- McHugh, Dennis J. (2003). "A guide to the seaweed industry: FAO Fisheries Technical Paper 441". www.fao.org. Food and Agriculture Organization of the United Nations. Retrieved 2017-07-29.

- "Current EU approved additives and their E Numbers". Food Standards Agency. 26 November 2010. Retrieved 12 August 2014.

- http://www.marine-science.co.jp/english/goods/carra.html, Marine Science Co. Ltd.

- DeSilver, Drew (April 1993). "Answering Machine: Carra-what?". Vegetarian Times: 28. Retrieved 12 August 2014.

- Loureiro, Rafael R.; Cornish, M.L.; Neish, Iain C. (2017). "Applications of carrageenan: With special reference to iota and kappa forms as derived from the Eucheumatoid seaweeds". In Hurtado, Anicia Q.; Critchley, Alan T.; Neish, Iain C. (eds.). Tropical Seaweed Farming Trends, Problems and Opportunities: …. Berlin, Germany: Springer International Publishing. p. 165. ISBN 9783319634982.

- Mitchell, M.E.; Guiry, M.D. (December 1983). "Carrageen: A local habitation or a name?". Journal of Ethnopharmacology. 9 (2–3): 347–351. doi:10.1016/0378-8741(83)90043-0. PMID 6677826.

- Carrageenan Industry Report 2012 Contents (PDF) (Report). CyberColloids Ltd. 2012. Retrieved 6 April 2014.

- Pareño, Roel (14 September 2011). "DA: Phl to regain leadership in seaweed production". The Philippine Star. Retrieved 6 April 2014.

- CyberColloids: E407 Specification Carrageenan, CyberColloids, Hydrocolloids research and development webpage.

- CyberColloids: E407a Specification Processed Eucheuma Seaweed, Hydrocolloids research and development webpage.

- 21 Code of Federal Regulations 172.620

- Generally Recognized As Safe 21 CRF §182.7255 GRAS ID Code 9000-07-1 (1973)

- Federal Food, Drug, and Cosmetic Act 21 U.S.C. 350(a) §412

- Opinion of the Scientific Committee on Food on Carrageenan (2003) p. 5

- Joint FAO/WHO Expert Committee on Food Additives. Who.int. Retrieved on 2014-8-11.

- 68 FR 61993 (2003)

- 65 FR 80548

- 73 FR 59481

- "Sunset 2018 Review Summary NOSB Final Review" (PDF). USDA Agricultural Marketing Service. 2016-11-30. Retrieved 2017-02-15.

- "83 FR 14347". USDA Agricultural Marketing Service. 2018-04-04. Retrieved 2018-04-21.

- Safety Evaluation of Certain Food Additives, 3. Joint Expert Committee on Food Additives, WHO Food Additive Series: 70. 2015. hdl:10665/171781. ISBN 9789241660709.

- "Opinion of the Scientific Committee on Food on Carrageenan" (PDF). European Commission, Scientific Committee on Food. 2003.

- "Tees Ltd recalls Sweetworld Yummys Jelly Cones because of a choking hazard".

- Martino, John Vincent; Van Limbergen, Johan; Cahill, Leah E. (1 May 2017). "The Role of Carrageenan and Carboxymethylcellulose in the Development of Intestinal Inflammation". Frontiers in Pediatrics. 5: 96. doi:10.3389/fped.2017.00096. PMC 5410598. PMID 28507982.

- Shang, Qingsen; Sun, Weixia; Shan, Xindi; Jiang, Hao; Cai, Chao; Hao, Jiejie; Li, Guoyun; Yu, Guangli (September 2017). "Carrageenan-induced colitis is associated with decreased population of anti-inflammatory bacterium, Akkermansia muciniphila , in the gut microbiota of C57BL/6J mice". Toxicology Letters. 279: 87–95. doi:10.1016/j.toxlet.2017.07.904. PMID 28778519.

- Moyana, TN; Lalonde, JM (1990). "Carrageenan-induced intestinal injury in the rat--a model for inflammatory bowel disease". Annals of Clinical and Laboratory Science. 20 (6): 420–6. PMID 2073092.

- McKim JM. 2014. “Food additive carrageenan: Part I: A critical review of carrageenan in vitro studies, potential pitfalls, and implications for human health and safety

- Weiner ML. 2014. “Food additive carrageenan: Part II: A critical review of carrageenan in vivo safety studies.

Further reading

- McHugh, Dennis J. FAO Fisheries Technical Paper 288 - Production and Utilization of Products from Commercial Seaweeds, Chapter 3 - Production, Properties and Uses of Carrageenan, Food and Agriculture Organization, Rome, 1987

- Guiry, Michael D.R. Carrageenans, The Seaweed Site: information on marine algae.