Malt

Malt is germinated cereal grain that has been dried in a process known as "malting". The grain is made to germinate by soaking in water and is then halted from germinating further by drying with hot air.[1][2][3][4]

Malting grain develops the enzymes (α-amylase, β-amylase) required for modifying the grains' starches into various types of sugar, including monosaccharide glucose, disaccharide maltose, trisaccharide maltotriose, and higher sugars called maltodextrines.

It also develops other enzymes, such as proteases, that break down the proteins in the grain into forms that can be used by yeast. The point at which the malting process is stopped affects the starch to enzyme ratio and partly converted starch becomes fermentable sugars.

Malt also contains small amounts of other sugars, such as sucrose and fructose, which are not products of starch modification but which are already in the grain. Further conversion to fermentable sugars is achieved during the mashing process.

Malted grain is used to make beer, whisky, malted milk, malt vinegar, confections such as Maltesers and Whoppers, flavored drinks such as Horlicks, Ovaltine, and Milo, and some baked goods, such as malt loaf, bagels, and rich tea biscuits. Malted grain that has been ground into a coarse meal is known as "sweet meal".[5][6]

Various cereals are malted, though barley is the most common. A high-protein form of malted barley is often a label-listed ingredient in blended flours typically used in the manufacture of yeast breads and other baked goods.[7]

The term "malt" (see Wiktionary entry malt) refers to several products of the process: the grains to which this process has been applied, for example malted barley; the sugar, heavy in maltose, derived from such grains, such as the baker's malt used in various cereals; or a product based on malted milk, similar to a malted milkshake (i.e., "malts").

History and traditional usage

Malted grains have probably been used as an ingredient of beer since ancient times, for example in Egypt (Ancient Egyptian cuisine), Sumer, and China.

In Persian countries, a sweet paste made entirely from germinated wheat is called Samanū (Persian: سمنو) in Iran, Samanak (Persian: سمنک), (Tajik: суманак); (Uzbek: sumalak) or Sümölök (Kyrgyz: сүмөлөк), which is prepared for Nowruz (Persian new year celebration) in a large pot (like a kazan). A plate or bowl of Samanu is a traditional component of the Haft sin table symbolising affluence. Traditionally, women have a special party to prepare it during the night, and cook it from late in the evening till the daylight, singing related songs. In Tajikistan and Afghanistan they sing: Samanak dar Jūsh u mā Kafcha zanēm - Dīgarān dar Khwāb u mā Dafcha zanēm.[8][9][10] (Meaning: "Samanak is boiling and we are stirring it, others are asleep and we are playing daf"). In modern times, making samanu can be a family gathering. It originally comes from the Great Persian Empire.

Mämmi, or Easter Porridge, is a traditional Finnish Lenten food. Cooked from rye malt and flour, mämmi has a great resemblance (in recipe, color, and taste) to Samanū. Today, this product is available in shops from February until Easter. A (non-representative) survey in 2013 showed that almost no one cooks mämmi at home in modern-day Finland.[11]

Malting

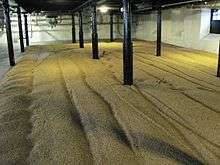

Malting is the process of converting barley or other cereal grains into malt for use in brewing, distilling, or in foods and takes place in a maltings, sometimes called a malthouse, or a malting floor. The cereal is spread out on the malting floor in a layer of 8 to 12 cm (3 to 4.5 in) depth.[12]

- Drying

- The malting process starts with drying the grains to a moisture content below 14% and then storing for around six weeks to overcome seed dormancy.

- Steeping

- When ready, the grain is immersed or steeped in water two or three times for two or three days to allow the grain to absorb moisture and to start to sprout.

- Germination

- When the grain has a moisture content of around 46%, it is transferred to the malting or germination floor, where it is constantly turned over for about four to six days while it is air-dried.[13]

- Pre-toasting

- The grain at this point is called "green malt". The green malt is then dried and pre-toasted in an oven (or kiln) to the desired color and specification.[14] Malts range in color from very pale through crystal and amber to chocolate or black malts.[15]

- Smoking

- The sprouted grain is then further dried and smoked by spreading it on a perforated wooden floor. Smoke coming from an oasting fireplace (via smoke channels) is then used to heat the wooden floor and the sprouted grains. The temperature is usually around 55 °C (131 °F).

A "maltings" is typically a long, single-story building with a floor that slopes slightly from one end of the building to the other. Floor maltings began to be phased out in the 1940s in favor of "pneumatic plants" where large industrial fans are used to blow air through the germinating grain beds and to pass hot air through the malt being kilned. Like floor maltings, these pneumatic plants use batch processes, but of considerably greater size, typically 100 ton batches compared with 20 ton batches floor maltings.

As of 2014, the largest malting operation in the world was Malteurop, which operates in 14 countries.[16]

Production

Barley is the most commonly malted grain, in part because of its high content of enzymes, though wheat, rye, oats, rice, and corn are also used.[17] Also very important is the retention of the grain's husk, even after threshing, unlike the bare seeds of threshed wheat or rye. This protects the growing acrospire (developing plant embryo) from damage during malting, which can easily lead to mold growth; it also allows the mash of converted grain to create a filter bed during lautering (see brewing).

Malts

Diastatic and nondiastatic

As all grains sprout, natural enzymes within the grain break down the starch the grain is composed of into simpler sugars which taste sweet and are easier for yeast to use as growth food. Malt with active enzymes is called "diastatic malt". Malt with inactive enzymes is called "nondiastatic malt". The enzymes are deactivated by heating the malt.

Base and specialty

Malt is often divided into two categories by brewers: base malts and specialty malts.

Base malts have enough diastatic power to convert their own starch and usually that of some amount of starch from unmalted grain, called adjuncts.

Specialty malts have little diastatic power, but provide flavor, color, or "body" (viscosity) to the finished beer. Specialty caramel or crystal malts have been subjected to heat treatment to convert their starches to sugars nonenzymatically. Within these categories is a variety of types distinguished largely by the kilning temperature (see mash ingredients).

Two-row and six-row

In addition, malts are distinguished by the two major cultivar types of barley used for malting, two-row and six-row.[18] The most common varieties of barley used for malting in the United States from 2009 to 2013 are two-row AC Metcalfe and Conrad and six-row Tradition and Lacey cultivars.[19]

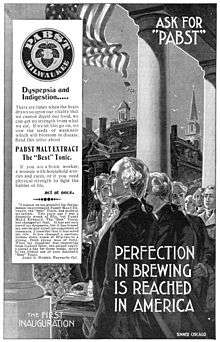

Malt extract

Malt extract, also known as extract of malt, is a sweet, treacly substance used as a dietary supplement.[20] It was popular in the first half of the 20th century as a nutritional enhancer for the children of the British urban working class, whose diet was often deficient in vitamins and minerals. Children were given cod liver oil for the same reason, but it proved so unpalatable that it was combined with extract of malt to produce "Malt and Cod-Liver Oil."

The 1907 British Pharmaceutical Codex's instructions for making nutritional extract of malt do not include a mashout at the end of extraction, and include the use of lower mash temperatures than is typical with modern beer-brewing practices. The Codex indicates that diastatic activity is to be preserved by the use of temperatures not exceeding 55 °C (131 °F).

Malt extract production

Malt extract is frequently used in the brewing of beer. Its production begins by germinating barley grain in a process known as malting, immersing barley in water to encourage the grain to sprout, then drying the barley to halt the progress when the sprouting begins. The drying step stops the sprouting, but the enzymes remain active due to the low temperatures used in base malt production.[21] In one before-and-after comparison, malting decreased barley's extractable starch content by about 7% on a dry matter basis and turned that portion into various other carbohydrates.[22]

In the next step, brewers use a process called mashing to extract the sugars. Brewers warm cracked malt in temperature-modulated water, activating the enzymes,[23] which cleave more of the malt's remaining starch into various sugars, the largest percentage of which is maltose.[22] Modern beer mashing practices typically include high enough temperatures at mash-out to deactivate remaining enzymes, thus it is no longer diastatic. The liquid produced from this, wort, is then concentrated by using heat or a vacuum procedure to evaporate water[20] from the mixture. The concentrated wort is called malt extract.

Liquid malt extract (LME) is a thick syrup and is used for a variety of purposes, such as baking and brewing. It is also sold in jars as a consumer product.

The LME may be further dried to produce dry malt extract (DME), which is crystalline in form similar to common sugar.

Brewers have the option of using a liquid (LME) or dry (DME) form of it. Each has its pros and cons, so the choice is dependent solely on the individual brewer's preferences.[24] Some brewers choose to work only with LME because they feel it works best for the result they wish to achieve. Also, it requires one fewer processing step, so it is appealing to those favoring the purest form of product available. However, it is very sticky and, therefore, messier to work with and has a shorter shelf life. Some feel the results are just as good with DME.

A new encapsulating technology permits the production of malt granules. Malt granules are the dried liquid extract from malt used in the brewing or distilling process.[25]

Research

Scientists aim to discover what happens inside barley grains as they become malted to help plant breeders produce better malting barley for food and beverage products. The United States Agricultural Research Service scientists are interested in specialized enzymes called serine-class proteases[26] that digest beta-amylases, which convert carbohydrates into "simple sugars" during the sprouting process.[27] The enzyme also breaks down stored proteins into their amino acid derivatives. The balance of proteins and carbohydrates broken down by the enzyme affect the malt's flavor.

See also

References

- "How to brew manually by John Palmer". Retrieved 6 October 2014.

- "Quality Factors for Malting, Brewing and other End-uses". Oregon State University. Retrieved 13 April 2007.

- "What is malting?". Retrieved 6 October 2014.

- Kirk-Othmer Food and Feed Technology. New York: Wiley-Interscience. 2007. pp. 116–120. ISBN 0-470-17448-X. Retrieved 7 July 2010.

- Horace Kephart (1922). Our southern highlanders (eBook ed.). New York: The Macmillan Company. p. 134. Retrieved 10 April 2011.

The sprouted corn is then dried and ground into meal. This sweet meal is then made into a mush with boiling water, and is let stand two or three days.

- Mills, Margaret H.; Claus, Peter J.; Diamond, Sarah (2003). South Asian folklore: an encyclopedia: Afghanistan, Bangladesh, India, Nepal, Pakistan, Sri Lanka. New York: Routledge. p. 5. ISBN 0-415-93919-4. Retrieved 10 April 2011.

The grain's own conversion of stored starch to sugar while sprouting ("malting") results in a sweet meal, which is then cooked for hours with water, oil, and additional wheat flour.

- Evers, A. D.; Kent, N. (1994). Technology of cereals: an introduction for students of food science and agriculture. New York: Pergamon Press. p. 181. ISBN 0-08-040834-6. Retrieved 7 July 2010.

- "Nowruz in Tajikistan, BBC Persian".

- "Nowruz in Afghanistan, BBC Persian". Retrieved 6 October 2014.

- "24 ساعت - نو روز باستانی در کشور عزیز ما افغانستان". 24sahat.com. Retrieved 27 March 2013.

- "How to tame your mämmi? Porridge and Potatoes

- "Malting – Whisky.com". www.whisky.com.

- "UK Malt, the Maltsters' Association of Great Britain | How malt is made". www.ukmalt.com. Retrieved 24 February 2019.

- "How Malt is Made". www.ukmalt.com. Archived from the original on 17 July 2011. Retrieved 26 March 2011.

- Michael Lewis; Tom W. Young (31 October 2002). Brewing. Springer, 2002. p. 204. ISBN 9780306472749. Retrieved 26 March 2011.

- "Bad barley crop probably won't affect beer prices". Frederick News-Post. Associated Press. 4 January 2015.

- "Wheat and Rye Malt Use in Brewing Beer". www.beer-brewing.com. Archived from the original on 24 May 2013. Retrieved 26 March 2011.

- Goldhammer, Ted (2008), The Brewer's Handbook, 2nd ed., Apex, ISBN 0-9675212-3-8, p. 31 ff.

- USDA/NASS Barley Variety Surveys and Industry Data via http://ambainc.org/media/AMBA_PDFs/Pubs/KYMBV_2014.pdf

- British pharmaceutical codex. Pharmaceutical Society of Great Britain. 1907. pp. 401–404. Retrieved 28 March 2011.

The extract is given to children and adults for its nutritive properties. ... Extract of malt is used as a vehicle for the administration of cod-liver oil (see Extractum Malti cum Oleo Morrhuae), ...

- Joseph La Villa (2010). The Wine, Beer, and Spirits Handbook: A Guide to Styles and Service. John Wiley & Sons, Inc. p. 347. ISBN 978-0-470-53757-2. Retrieved 30 March 2011.

The base malt in any brewing process is called pale malt. It is dried at around 122 °F (50 °C). Specialty malts are made either by heating the barley before it is dry or by roasting the dried malt.

- Stevens, Roger; Dennis E. Briggs; Chris Boulton; Brookes, Peter (2004). Brewing: science and practice. Cambridge: Woodhead. p. 123. ISBN 0-8493-2547-1. Retrieved 29 March 2011. See tables 4.15 & 4.16

- "How to Brew - By John Palmer - Mashing Defined". Retrieved 28 March 2011.

- "What is Malted Barley?". Retrieved 18 June 2016.

- "Patent EP1385931 Malt Granules". www.freepatentsonline.com. Archived from the original on 2 October 2012. Retrieved 25 May 2009.

- "Like Malt? You'll Love This Malting Barley Research!". USDA Agricultural Research Service. 2 February 2010.

- "Secrets to Superb Malting Barleys Explored by ARS Researchers". USDA Agricultural Research Service. 3 February 2010. Retrieved 7 March 2011.

Bibliography

- D.E. Briggs, Malts and Malting, Kluwer Academic / Plenum Publishers (30 September 1998), ISBN 0-412-29800-7

- Christine Clark, The British Malting Industry Since 1830, Hambledon Continuum (1 July 1998), ISBN 1-85285-170-8

External links

| Look up malt in Wiktionary, the free dictionary. |