Water distribution system

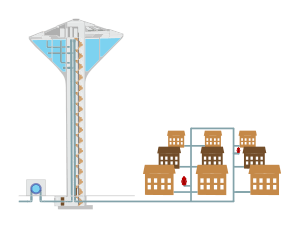

A water distribution system is a part of water supply network with components that carry potable water from a centralized treatment plant or wells to water consumers in order to adequately deliver water to satisfy residential, commercial, industrial and fire fighting requirements.[3][4]

Definitions

A definition uses the term water distribution network for a portion of a water distribution system up to the service points of bulk water consumers or demand nodes that many consumers are lumped up together.[5] World Health Organization (WHO) uses the term water transmission system for a network of pipes, generally in tree-like structure that is used to convey water from water treatment plants to service reservoirs, and uses the term water distribution system for a network of pipes that generally has a loop structure to supply water from the service reservoirs and balancing reservoirs to water consumers.[6]

Components

A water distribution system consists of pipelines, storage facilities, pumps, and other accessories.[7]

Pipelines laid within public right of way called water mains are used to transport water within a distribution system. Large diameter water mains called primary feeders are used to connect between water treatment plants and service areas. Secondary feeders are connected between primary feeders and distributors. Distributors are water mains that are located near the water users, which also supply water to individual fire hydrants.[8] A service line is a small diameter pipe used to connect from a water main through a small tap to a water meter at user's location. There is a service valve (also known as curb stop) on the service line located near street curb to shut off water to the user's building.[9]

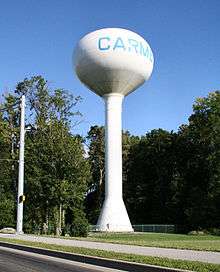

Storage facilities, or distribution reservoirs, provide clean drinking water storage to ensure the system has enough water to service in fluctuating demands (service reservoirs), or to equalize the operating pressure (balancing reservoirs). They can also be temporarily used to serve fire fighting demands during a power outage. There can be many types of distribution reservoirs. A surface reservoir is a larger storage facility built on the ground with the wall lined with concrete, shotcrete, asphalt, or membrane. When a surface reservoir at the ground level cannot provide a sufficient hydraulic head to the distribution system, an elevated water tower can also be used. A standpipe is slightly different from an elevated water tower in that the standpipe allows water storage from the ground level to the top of the tank. The bottom storage area is called supporting storage, and the upper part which would be at the similar height of an elevated water tower is called useful storage. Storage facilities are typically located at the center of the service locations. Being at the central location reduces the length of the water mains to the services locations. This reduces the friction loss when water is transported over a water main.[4]

Topologies

In general, a layout of a water distribution system can be classified as grid, ring, radial or dead end system.[10]

A grid system follows the general layout of the grid road infrastructure with water mains and branches connected in rectangles. With this topology, the water can be supplied from many directions allowing good water circulation and redundancy if a section of the network is broken down. Drawbacks of this topology include difficulties of sizing the system.

A ring system is a topology with each water main that go to each road, and there is a sub-main that is branched off the water main to provide a circulation of two directions. This system has some advantages of the grid system, but it is easier to make a determination of sizing.

A radial system delivers water into multiple zones. At the center of each zone, the water is delivered radially toward the customers.

A dead end system has water mains along the roads without a particular pattern for towns that do not have road network patterns. As there are no connectivities between the mains, water can have less circulation and can have stagnation.

Integrity of the systems

The integrity of the systems are broken down into physical, hydraulic, and water quality.[3]

The physical integrity includes concerns on the ability of the barriers to prevents contaminations from the external sources to get into water distribution systems. The deterioration can be caused by physical or chemical factors.

The hydraulic integrity is an ability to maintain adequate water pressure inside the pipes throughout distribution systems. It also includes the circulation and length of time that the water travels within a distribution system which has impacts on the effectiveness of the disinfectants.

The water quality integrity is a control of degradations as the water travels through distribution systems. The impacts of water quality can be caused by physical or hydraulic integrity factors. The water quality degradations can also take place within the distribution systems such as microorganism growth, nitrification, and internal corrosion of the pipes.

Network analysis and optimization

Analyses are done to assist in design, operation, maintenance and optimization of water distribution systems. There are two main types of analyses: hydraulic, and water quality behavior as it flows through a water distribution system.[11]

Hazards

Hazards in water distribution systems can be in the forms of microbial, chemical and physical.

Most microorganisms are harmless within water distribution systems. However, when infectious microorganisms enter the systems, they form biofilms and create microbial hazards to the users. Biofilms are usually formed near the end of the distribution where the water circulation is low. This supports their growth and makes disinfection agents less effective. Common microbial hazards in distribution systems come from contamination of human faecal pathogens and parasites which enter the systems through cross-connections, breaks, and water main works, and open storage tanks.

Chemical hazards are those of disinfection by-products, leaching of piping materials and fittings, and water treatment chemicals.

Physical hazards include turbidity of water, odors, colors, scales which are buildups of materials inside the pipes from corrosions, and sediment resuspension.

There are several bodies around the world that create standards to limit hazards in the distribution systems: NSF International in North America; European Committee for Standardization, British Standards Institution and Umweltbundesamt in Europe; Japanese Standards Association in Asia; Standards Australia in Australia; and Brazilian National Standards Organization in Brazil.[6]

Lead service lines

Lead contamination in drinking water can be from leaching of lead that was used in old water mains, service lines, pipe joints, plumbing fittings and fixtures. According to WHO, the most significant contributor of lead in water in many countries is the lead service line.[6]

Maintenance

Internal corrosion control

Water quality can be deteriorated by the internal corrosion of piping in distribution systems. This includes the corrosion of metal pipe surfaces and connections. The problems create health concerns, colors, taste and odor in water.

Health concerns are related to releases trace metal such as lead, copper or cadmium to the water. Lead exposure can cause delays in physical and mental development in children. Long term exposure to copper may cause liver and kidney damage. High or long term exposure of cadmium may cause damage to various organs. Corrosion of iron materials causes the discoloring of the water that is shown as rust-coloured water or red water. Corrosion of zinc and iron can cause metallic taste.[12]

Various techniques can be used to control internal corrosions, for example, pH level adjustment, adjustment of carbonate and calcium to create calcium carbonate as piping surface coating, and applying a corrosion inhibitor. An example of corrosion inhibitor is using phosphate products to form films over pipes. This reduces the chance of leaching of trace metal from the pipe materials into the water.[13]

Hydrant flushing

Hydrant flushing is scheduled releases of water from fire hydrants or special flushing hydrants to release iron and other mineral deposits from the water main. Another benefit of using fire hydrants for water main flushing is to ensure that the water is adequately supplied to fire hydrants for fire fighting. During the hydrant flushing, consumers may notice rust color in their water as the iron and mineral deposits are stirred up in the process.[14]

Water main renewals

After water mains are put in service for a long time, there will be deteriorations in structural, water quality, and hydraulic performances. Structural deterioration may be caused by many reasons. Metal-based pipes develop internal and external corrosion, causing the pipe walls to thin or degrade. They can eventually leak or bust. Cement-based pipes are subjected to cement matrix and reinforced steel deterioration. All pipes are subjected to joint failures. Water quality deterioration includes scaling or tuberculation, sedimentation, and biofilm formation. Scaling is a formation of hard deposits on the interior wall of the pipes. This can be a by-product of the pipe corrosion that is combined with calcium in the water, which is called tuberculation. Sedimentation is when solids are settled within the pipes, usually at recesses between the scaling build-ups. When there is a change in the velocity of water flow (such as sudden use of a fire hydrant), the settled solids will be stirred up causing water to be discolored. Biofilms can be developed in highly scaled pipes where bacteria is allowed to grow as the higher the roughness of the interior wall, the harder it is for disinfectant to be effective by reaching the surface of the pipe wall. Hydraulic deterioration which affect pressures and flows can be a result of other deteriorations that obstruct the water flow.[15]

When it is time for a water main renewal, there are many considerations involved in choosing the method of renewal. This can be open-trench replacement, or one of the pipeline rehabilitation methods. A few pipeline rehabilitation methods are pipe bursting, sliplining, and pipe lining.[15]

- Water main renewal methods

.jpg) Open-trench water main replacement

Open-trench water main replacement Feed hydrant supplies water to a temporary bypass piping

Feed hydrant supplies water to a temporary bypass piping Service connection of a temporary bypass piping

Service connection of a temporary bypass piping Temporary fire hydrant

Temporary fire hydrant

When an in-situ rehabilitation method is used, a benefit is the lower cost as there is no need to have excavation along the water main pipeline. Only small pits are excavated to access the existing water main. The unavailability of the water main during the rehabilitation, however, requires building a temporary water bypass system to serve as the water main in the affected area.[16] A temporary water bypass system (known as temporary bypass piping[17]) should be carefully designed to ensure the adequate water supply to the customers in the project area. Water is taken from a feed hydrant into a temporary pipe. When the pipe crosses a driveway or a road, a cover or a cold patch should be put in place in order to allow cars to cross the temporary pipe. Temporary service connections can be made to the temporary pipe to connect to homes. There are many ways to perform a connection, one of which is to connect the temporary service connection to a garden hose. The temporary pipe should also add temporary fire hydrants for fire protection.[18]

As water main work can disturb lead service lines which can result in elevated lead levels in drinking water, it is recommended that when water utility plans for water main renewal project, it considers working with property owners to replace lead service lines as part of the project.[19]

See also

References

- "Drinking Water Distribution Systems". United States Environmental Protection Agency. Retrieved 20 October 2019.

- "City, S&WB Host Preview of New Water Towers at Carrollton Water Plant". City of New Orleans. 25 May 2017. Retrieved 20 October 2019.

- Drinking water distribution systems : assessing and reducing risks. National Academies Press. 2006. ISBN 978-0-309-10306-0. Retrieved 6 October 2019.

- "Water Distribution Networks CE370" (PDF). King Fahd University of Petroleum and Minerals. Retrieved 6 October 2019.

- Bhave, Pramod R.; Gupta, Rajesh (2006). Analysis of water distribution networks. Alpha Science International. p. 4. ISBN 9781842653593.

- Water safety in distribution systems (PDF). 2014. ISBN 9789241548892. Retrieved 7 October 2019.

- "Water Distribution". Britannica Encyclopedia. Retrieved 6 October 2019.

- Rowett, Anthony Jr. "From Hoselines to Hydrants: Understanding Water Supply". Firehouse. Retrieved 7 October 2019.

- "Glossary". Mueller Water Products. Retrieved 7 October 2019.

- Adeosun, O. Oyedele (9 September 2014). "Water Distribution System Challenges And Solutions". Water Online. Retrieved 6 October 2019.

- Mala-Jetmarova, Helena; Barton, Andrew; Bagirov, Adil (April 2015). "A history of water distribution systems and their optimisation". Water Science and Technology: Water Supply. 15 (2): 224–235. doi:10.2166/ws.2014.115.

- Internal Corrosion Control in Water Distribution Systems (M37). American Water Works Association. 12 January 2011. pp. 2–9. ISBN 9781613001172. Retrieved 6 October 2019.

- The Use of Phosphates in Water Treatment for Corrosion Control & Sequestration (PDF). Carus Corporation. 13 April 2017. Retrieved 7 October 2019.

- "Hydrant Flushing Facts & Frequently Asked Questions". City of St. Charles. Retrieved 6 October 2019.

- Rehabilitation of water mains (PDF) (Third ed.). American Water Works Association. 2014. ISBN 9781583219706. Retrieved 14 October 2019.

- "Local Water System Assistance Program (LWSAP) For Member Communities Massachusetts Water Resources Authority". Massachusetts Water Resources Authority. Retrieved 14 October 2019.

- "ITEM C660.5X: Temporary Bypass Piping" (PDF). Monroe County, New York. Retrieved 14 October 2019.

- Cement Mortar Water Main Cleaning & Lining (PDF). Terrace Construction.

- Communicating About Lead Service Lines: A Guide for Water Systems Addressing Service Line Repair and Replacement (PDF). American Water Works Association. 2014. Retrieved 13 October 2019.