Shock mount

In a variety of applications, a shock mount or isolation mount is a mechanical fastener that connects two parts elastically. They are used for shock and vibration isolation.

Isolation mounts allow a piece of equipment to be securely mounted to a foundation and/or frame and, at the same time, allow it to float independently from the substrate.

Uses

_shock_trials.jpg)

Shock mounts can be found in a wide variety of applications.

Shock mounts can be used to isolate the foundation or substrate from the dynamics of the mounted equipment. This is vital on submarines where silence is critical to mission success. Another common example of this are the motor and transmission mounts that are used in virtually every automobile manufactured today. Without isolation mounts, the interior noise and comfort level in today’s vehicles would be significantly different than what we have grown accustomed to. In this case, shock and vibration isolation mounts are often chosen by the nature of the dynamics produced by the equipment and the weight of the equipment.

Shock mounts can be used to isolate sensitive equipment from undesirable dynamics of the foundation or substrate. Sensitive laboratory equipment needs to be isolated from handling shocks and ambient vibration. Military equipment and ships need to be able to withstand nearby explosions. Shock mounts are found in some disc drives and compact disc players, in which soft bushings are all that mechanically hold the disk and reading assembly, thereby isolating it from outside vibrations and from other outside loads such as torsion.[1] In this case, isolation mounts are often chosen by the sensitivity of the equipment to shock (fragility) and vibration (natural frequency) and the weight of the equipment. This and nature of the input shock and vibration must be matched. A shock pulse is characterised by its peak acceleration, the duration, and the shape of the shock pulse (half sine, triangular, trapezoidal, etc.). The shock response spectrum is a method for further evaluating a mechanical shock.[2]

Shock mounts are used to isolate entire buildings from the movement of the ground in earthquakes, called base isolators.

The black rubber is glued to the wood and the bolt only connects the metal to the rubber. There are three similar shock mounts supporting the seat.

A similar idea, also known as a shock mount, is found in furniture design, introduced by Charles and Ray Eames. This provides some shock absorption and serves as a living hinge, allowing the seat back to pivot.

Shock mounts are also sometimes used in bicycle saddles,[3] or their handlebars.

Design

Maxwell and Kelvin–Voigt models of viscoelasticity use springs and dashpots in series and parallel circuits respectively. Hydraulic and pneumatic components can be included, depending on the use.[4]

Laminated pads

One common type of isolation mounts is laminated pads. Generally, these pads consist of a cork or polymeric foam core which has been laminated between two pieces of ribbed neoprene sheet.

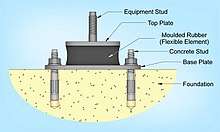

Molded rubber isolation mounts

Molded rubber isolation mounts are typically manufactured for specific applications. The best example of this is automotive engine and transmission mounts. Rubber bushings compress synthetic rubber rings on bolts to provide some isolation:operating temperature is sometimes a factor. Other shock mounts have mechanical springs or an elastomer (in tension or compression) engineered to isolate an item from specified mechanical shock and vibration. Some form of dashpot is usually used with a spring to provide viscous damping. Viscoelastic materials are common. Temperature is a factor in the dynamic response of rubber. Generally, a molded rubber mount is best suited for heavy loads producing higher frequency vibrations.

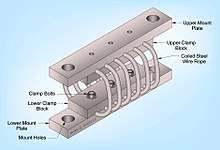

Cable isolation mounts

Cable mounts are based around a coil of wire rope fixed to an upper and lower mounting bar.[5][6] When properly matched to the load, these mounts provide isolation over a broad frequency range. They are typically applied to high performance applications, such as mounting sensitive instrumentation into off-road vehicles and shipboard.

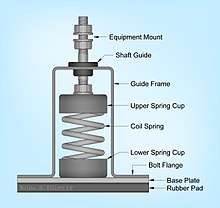

Coil spring isolation mounts

Coil spring isolation mounts generally provide the greatest degree of movement and the best low frequency performance. They are particularly popular for mounting equipment in buildings such as air handlers, filtration units, air conditioning and refrigeration systems and large pipes. Their degree of movement makes them ideal for applications where high flexure and/or expansion and contraction are a consideration.

Microphone mounts

Shock mounts for microphones can provide basic protection from damage, but their prime use is to isolate microphones from mechanically transmitted noise. This can originate as floor vibrations transmitted through a floor stand, or as "finger" and other handling noise on boom poles. All microphones behave to some extent as accelerometers, with the most sensitive axis being perpendicular to the diaphragm. Additionally, some microphones contain internal elements such as vacuum tubes and transformers which can be inherently microphonic. These are often cushioned by resilient internal methods, in addition to the employment of external isolation mounts.

Early microphones used a 'ring and spring' mount, where a single rigid ring was mounted and carried the microphone between a number of coil springs, usually four or eight. When early microphones were heavy and omnidirectional, this was adequate. However the single plane of suspension allowed the microphone to twist very easily; once microphones started to become directional, this twisting caused fading of the signal. A more three-dimensional and less planar suspension would be required.

Traditionally the large side-address studio microphone has been strung in a "cat's cradle" mount, using fabric-wound rubber elastic elements to provide isolation. These designs still find some favour, although the elements tend to deteriorate, and sag with time. Newer designs, such as Rycote's "USM" lyre[7], use plastic elastomers, and patented spring shapes to reduce this problem.

For end-fire microphones, most often employed for location work, similar elastic stringing was once used. More recently designs moved to o-ring elements, before the Rycote Lyre[8] and Cinela Osix suspensions were introduced. These use spring element designs that give far greater displacement along the microphone's prime axis, while limiting it on the other two. This enables excellent isolation while retaining good control of the microphone.

References

- US 5,761,031, Ajmani, R S, "Conductive shock mount for reducing electromagnetic interference in a disk drive system", issued 2 June 1998

- J E, Alexander (2009), The Shock Response Spectrum – A Primer (PDF), IMAC-XXVII, Society for Experimental Mechanics, archived from the original (PDF) on 2016-03-04, retrieved 9 Feb 2015

- US 6019422, Taormino, J S & Caselli, "Laterally pivoting bicycle saddle mount with shock absorber", published 1 Feb 2000

- US3598353A, DeGrey, "Air-damped shock mount", published 1971

- US4397069A, Camossi, "Device and process for the manufacture of vibration-damping and shockproof mountings incorporating at least one helically arranged metal cable and mounting thereby obtained", published 1983

- US4783038A, Gilbert, LeKuch, Ferri, "Isolator Apparatus", published 1988

- Rycote InVision™ Studio USM product page

- Rycote Lyre microphone shock mount product page

- DeSilva, C. W., "Vibration and Shock Handbook", CRC, 2005, ISBN 0-8493-1580-8

- Harris, C. M., and Peirsol, A. G. "Shock and Vibration Handbook", 2001, McGraw Hill, ISBN 0-07-137081-1

External links

| Wikimedia Commons has media related to Shock mounts. |