Ruby Pipeline

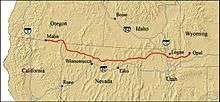

The Ruby Pipeline is a 42-inch (1,100 mm) natural gas pipeline running from Opal, Wyoming, to Malin, Oregon. The route crosses Northern Utah, and Northern Nevada.[1] Ruby Pipeline, L.L.C. filed an application with the Federal Energy Regulatory Commission (FERC) on January 27, 2009, authorizing the construction and operation of the Ruby Pipeline Project. On April 5, 2010, the FERC approved the application. Construction began on July 31, 2010, and the pipeline was placed in service on July 28, 2011. The pipe is 680 miles (1,090 km) long with an expected capacity of 1.5 billion cubic feet per day (42×106 m3/d).

| Ruby Pipeline | |

|---|---|

Ruby Pipeline | |

| Location | |

| Country | United States |

| General direction | east-west |

| From | Opal, Wyoming |

| Passes through | Wyoming, Utah, Nevada, Oregon |

| To | Malin, Oregon |

| General information | |

| Type | natural gas |

| Partners | El Paso Corporation |

| Operator | Ruby Pipeline, L.L.C. |

| Commissioned | 2010 |

| Technical information | |

| Length | 680 mi (1,090 km) |

| Maximum discharge | 1.5 billion cubic feet per day (15 billion cubic metres per year) |

| Diameter | 42 in (1,067 mm) |

Controversy

There is concern that the project crosses more than 1000 rivers and streams and, according to the Center for Biological Diversity, threatens some endangered fish species.[2]

The Center for Biological Diversity and Summit Lake Paiute Tribe of Nevada petitioned the Ninth Circuit Court of Appeals for an emergency action blocking the pipeline.[3] Despite not winning the injunction requests, the Court ultimately ruled in their favor, finding that environmental reviews for the pipeline's impacts to endangered fish species and sagebrush habitats did not comply with environmental laws.

Notes

- "Archived copy". Archived from the original on 2010-08-16. Retrieved 2012-09-20.CS1 maint: archived copy as title (link)

- http://www.wyomingbusinessreport.com/article.asp?id=53166

- http://elkodaily.com/news/local/article_cd7b903e-2e23-11e0-8693-001cc4c03286.html

8BLM.gov: Ruby Pipeline Project