Photofermentation

Photofermentation is the fermentative conversion of organic substrate to biohydrogen manifested by a diverse group of photosynthetic bacteria by a series of biochemical reactions involving three steps similar to anaerobic conversion. Photofermentation differs from dark fermentation because it only proceeds in the presence of light.

For example, photo-fermentation with Rhodobacter sphaeroides SH2C (or many other purple non-sulfur bacteria[1]) can be employed to convert small molecular fatty acids into hydrogen[2] and other products.

Light-dependent pathways

Phototropic bacteria

Phototropic bacteria produce hydrogen gas via photofermentation, where the hydrogen is sourced from organic compounds.[4]

Photolytic producers

Photolytic producers are similar to phototrophs, but source hydrogen from water molecules that are broken down as the organism interacts with light.[4] Photolytic producers consist of algae and certain photosynthetic bacteria.[4]

(algae)[4]

(photolytic bacteria)[4]

Sustainable energy production

Photofermentation via purple nonsulfur producing bacteria has been explored as a method for the production of biofuel.[5] The natural fermentation product of these bacteria, hydrogen gas, can be harnessed as a natural gas energy source.[6][7] Photofermentation via algae instead of bacteria is used for bioethanol production, among other liquid fuel alternatives.[8]

Mechanism

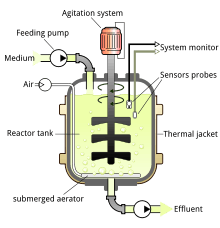

The bacteria and their energy source are held in a bioreactor chamber that is impermeable to air and oxygen free.[7] The proper temperature for the bacterial species is maintained in the bioreactor.[7] The bacteria are sustained with a carbohydrate diet consisting of simple saccharide molecules.[9] The carbohydrates are typically sourced from agricultural or forestry waste.[9]

Variations

In addition to wild type forms of Rhodopseudomonas palustris, scientists have used genetically modified forms to produce hydrogen as well.[5] Other explorations include expanding the bioreactor system to hold a combination of bacteria, algae or cyanobacteria.[7][9] Ethanol production is performed by the algae Chlamydomonas reinhardtii, among other species, in cycling light and dark environments.[8] The cycling of light and dark environments has also been explored with bacteria for hydrogen production, increasing hydrogen yield.[10]

Advantages

The bacteria are typically fed with broken down agricultural waste or undesired crops, such as water lettuce or sugar beet molasses.[11][5] The high abundance of such waste ensures the stable food source for the bacteria and productively uses human-produced waste.[5] In comparison with dark fermentation, photofermentation produces more hydrogen per reaction and avoids the acidic end products of dark fermentation.[12]

Limitations

The primary limitations of photofermentation as a sustainable energy source stem from the precise requirements of maintaining the bacteria in the bioreactor.[7] Researchers have found it difficult to maintain a constant temperature for the bacteria within the bioreactor.[7] Furthermore, the growth media for the bacteria must be rotated and refreshed without introducing air to the bioreactor system, complicating the already expensive bioreactor set up.[7][9]

See also

References

- Redwood MD, Paterson-Beedle M, Macaskie LE (June 2009). "Integrating dark and light bio-hydrogen production strategies: towards the hydrogen economy" (PDF). Reviews in Environmental Science and Bio/Technology. 8 (2): 149–185. doi:10.1007/s11157-008-9144-9.

- Tao Y, Chen Y, Wu Y, He Y, Zhou Z (February 2007). "High hydrogen yield from a two-step process of dark-and photo-fermentation of sucrose". International Journal of Hydrogen Energy. 32 (2): 200–6. doi:10.1016/j.ijhydene.2006.06.034.

- Gabrielyan, Lilit; Sargsyan, Harutyun; Trchounian, Armen (2015-09-04). "Novel properties of photofermentative biohydrogen production by purple bacteria Rhodobacter sphaeroides: effects of protonophores and inhibitors of responsible enzymes". Microbial Cell Factories. 14 (1): 131. doi:10.1186/s12934-015-0324-3. ISSN 1475-2859. PMC 4558839. PMID 26337489.

- Ghimire A, Frunzo L, Pirozzi F, Trably E, Escudie R, Lens PN, Esposito G (April 2015). "A review on dark fermentative biohydrogen production from organic biomass: Process parameters and use of by-products". Applied Energy. 144: 73–95. doi:10.1016/j.apenergy.2015.01.045.

- Corneli E, Adessi A, Olguín EJ, Ragaglini G, García-López DA, De Philippis R (December 2017). "Biotransformation of water lettuce (Pistia stratiotes) to biohydrogen by Rhodopseudomonas palustris". Journal of Applied Microbiology. 123 (6): 1438–1446. doi:10.1111/jam.13599. PMID 28972701.

- Laurinavichene T, Tekucheva D, Laurinavichius K, Tsygankov A (March 2018). "Utilization of distillery wastewater for hydrogen production in one-stage and two-stage processes involving photofermentation". Enzyme and Microbial Technology. 110: 1–7. doi:10.1016/j.enzmictec.2017.11.009. PMID 29310850.

- Uyar B (September 2016). "Bioreactor design for photofermentative hydrogen production". Bioprocess and Biosystems Engineering. 39 (9): 1331–40. doi:10.1007/s00449-016-1614-9. PMID 27142376.

- Costa RL, Oliveira TV, Ferreira J, Cardoso VL, Batista FR (April 2015). "Prospective technology on bioethanol production from photofermentation". Bioresource Technology. 181: 330–7. doi:10.1016/j.biortech.2015.01.090. PMID 25678298.

- Zhang Q, Wang Y, Zhang Z, Lee DJ, Zhou X, Jing Y, Ge X, Jiang D, Hu J, He C (April 2017). "Photo-fermentative hydrogen production from crop residue: A mini review". Bioresource Technology. 229: 222–230. doi:10.1016/j.biortech.2017.01.008. PMID 28108074.

- Chen CY, Yang MH, Yeh KL, Liu CH, Chang JS (September 2008). "Biohydrogen production using sequential two-stage dark and photo fermentation processes". International Journal of Hydrogen Energy. 33 (18): 4755–4762. doi:10.1016/j.ijhydene.2008.06.055.

- Keskin T, Hallenbeck PC (May 2012). "Hydrogen production from sugar industry wastes using single-stage photofermentation". Bioresource Technology. 112: 131–6. doi:10.1016/j.biortech.2012.02.077. PMID 22420990.

- Chandrasekhar K, Lee YJ, Lee DW (April 2015). "Biohydrogen production: strategies to improve process efficiency through microbial routes". International Journal of Molecular Sciences. 16 (4): 8266–93. doi:10.3390/ijms16048266. PMC 4425080. PMID 25874756.

External links

| Look up photofermentation in Wiktionary, the free dictionary. |