Nanocrystal

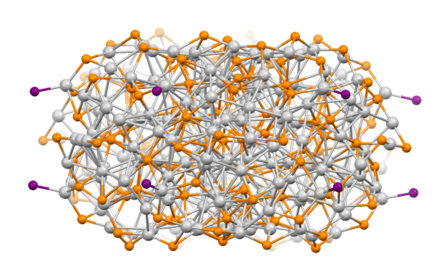

A nanocrystal is a material particle having at least one dimension smaller than 100 nanometres, based on quantum dots[1] (a nanoparticle) and composed of atoms in either a single- or poly-crystalline arrangement.[2]

The size of nanocrystals distinguishes them from larger crystals. For example, silicon nanocrystals can provide efficient light emission while bulk silicon does not[3] and may be used for memory components.[4]

When embedded in solids, nanocrystals may exhibit much more complex melting behaviour than conventional solids[5] and may form the basis of a special class of solids.[6] They can behave as single-domain systems (a volume within the system having the same atomic or molecular arrangement throughout) that can help explain the behaviour of macroscopic samples of a similar material without the complicating presence of grain boundaries and other defects.

Semiconductor nanocrystals having dimensions smaller than 10 nm are also described as quantum dots.

Synthesis

The traditional method involves molecular precursors, which can include typical metal salts and a source of the anion. Most semiconducting nanomaterials feature chalcogenides (SS−, SeS−, TeS−) and pnicnides (P3−, As3−, Sb3−). Sources of these elements are the silylated derivatives such as bis(trimethylsilyl)sulfide (S(SiMe3)2 and tris(trimethylsilyl)phosphine (P(SiMe3)3).[7]

Some procedures use surfactants to solubilize the growing nanocrystals.[9] In some cases, nanocrystals can exchange their elements with reagents through atomic diffusion.[9]

Applications

Filter

Nanocrystals made with zeolite are used to filter crude oil into diesel fuel at an ExxonMobil oil refinery in Louisiana at a cost less than conventional methods.[10]

Wear resistance

Nanocrystals' level of hardness[11] is closer to the optimized molecular hardness[12] which attracts the wear resistance industry[13][14]

See also

References

- B. D. Fahlman (2007). Material Chemistry. 1. Springer: Mount Pleasant, Michigan. pp. 282–283.

- J. L. Burt (2005). "Beyond Archimedean solids: Star polyhedral gold nanocrystals". J. Cryst. Growth. 285 (4): 681–691. Bibcode:2005JCrGr.285..681B. doi:10.1016/j.jcrysgro.2005.09.060.

- L. Pavesi (2000). "Optical gain in silicon nanocrystals". Nature. 408 (6811): 440–444. Bibcode:2000Natur.408..440P. doi:10.1038/35044012.

- S. Tiwari (1996). "A silicon nanocrystal based memory". Appl. Phys. Lett. 68 (10): 1377–1379. Bibcode:1996ApPhL..68.1377T. doi:10.1063/1.116085.

- J. Pakarinen (2009). "Partial melting mechanisms of embedded nanocrystals". Phys. Rev. B. 79 (8): 085426. Bibcode:2009PhRvB..79h5426P. doi:10.1103/physrevb.79.085426.

- D. V. Talapin (2012). "Nanocrystal solids: A modular approach to materials design". MRS Bulletin. 37: 63–71. doi:10.1557/mrs.2011.337.

- Fuhr, O.; Dehnen, S.; Fenske, D. (2013). "Chalcogenide Clusters of Copper and Silver from Silylated Chalcogenide Sources". Chem. Soc. Rev. 42 (4): 1871–1906. doi:10.1039/C2CS35252D. PMID 22918377.

- Fenske, D.; Persau, C.; Dehnen, S.; Anson, C. E. (2004). "Syntheses and Crystal Structures of the Ag-S Cluster Compounds [Ag70S20(SPh)28(dppm)10] (CF3CO2)2 and [Ag262S100(St-Bu)62(dppb)6]". Angewandte Chemie International Edition. 43 (3): 305–309. doi:10.1002/anie.200352351. PMID 14705083.

- Ibanez, M.; Cabot, A. (2013). "All Change for Nanocrystals". Science. 340 (6135): 935–936. Bibcode:2013Sci...340..935I. doi:10.1126/science.1239221. PMID 23704562.

- P. Dutta and S. Gupta (eds.) (2006). Understanding of Nano Science and Technology (1 ed.). Global Vision Publishing House. p. 72. ISBN 81-8220-188-8.CS1 maint: extra text: authors list (link)

- Liu, Xiaoming; Yuan, Fuping; Wei, Yueguang (August 2013). "Grain size effect on the hardness of nanocrystal measured by the nanosize indenter". Applied Surface Science. 279: 159–166. Bibcode:2013ApSS..279..159L. doi:10.1016/j.apsusc.2013.04.062.

- "Kenneth Nordtvedt Molecular Hardness - the Genetic Atlas".

- Alabd Alhafez, Iyad; Gao, Yu; M. Urbassek, Herbert (30 December 2016). "Nanocutting: A Comparative Molecular-Dynamics Study of Fcc, Bcc, and Hcp Metals". Current Nanoscience. 13 (1): 40–47. Bibcode:2016CNan...13...40A. doi:10.2174/1573413712666160530123834.

- Kaya, Savaş; Kaya, Cemal (May 2015). "A new method for calculation of molecular hardness: A theoretical study". Computational and Theoretical Chemistry. 1060: 66–70. doi:10.1016/j.comptc.2015.03.004.

External links

| Wikimedia Commons has media related to Category:Nanocrystals. |