NIOSH air filtration rating

The NIOSH air filtration rating is the U.S. National Institute for Occupational Safety and Health (NIOSH)'s classification of filtering respirators. The ratings describe the ability of the device to protect the wearer from dust and liquid droplets in the air. The certification and approval process for respiratory protective devices is governed by Part 84 of Title 42 of the Code of Federal Regulations (42 CFR 84).[1] Respiratory protective devices so classified include air-purifying respirators (APR) such as filtering facepiece respirators (dust masks) and chemical protective cartridges that have incorporated particulate filter elements.

The classifications only cover the filtration of particles or aerosols, not the air-purifying respirator's ability to remove chemical gasses and vapors from air, which is regulated under 42 CFR 84 Subpart L. For more information see Cartridge (respirator). The classifications assume that the respirator is properly fitted.[2]

NIOSH classifications

NIOSH has currently established nine classifications of approved particulate filtering respirators based on a combination of the respirator series and efficiency level. The first part of the filter's classification indicates the series using the letters N, R, or P to indicate the filter's resistance to filtration efficiency degradation when exposed to oil-based aerosols (e.g., lubricants, cutting fluids, glycerine, etc.).[1][3][4] Definitions and intended use for each series is indicated below.[5]

- N for not resistant to oil. Used when oil particulates are not present. Tested using sodium chloride particles.

- R for resistant to oil. Used when oil particulates are present and the filter is disposed of after one shift. Tested using dioctyl phthalate (DOP) oil particles.

- P for oil-proof. Used when oil particulates are present and the filter is re-used for more than one shift. Tested with DOP oil particles.

The second value indicates the minimum efficiency level of the filter. When tested according to the protocol established by NIOSH each filter classification must demonstrate the minimum efficiency level indicated below.

| Respirator

Class |

Minimum

Efficiency Level |

|---|---|

| N95, R95, P95 | 95% |

| N99, R99, P99 | 99% |

| N100, R100, P100, HE | 99.97% |

HE (high-efficiency) filters are used only with powered air-purifying respirators. These are 99.97% efficient against 0.3 micron particles and are oil-proof, the same as a P100 filter.[6][7][8]

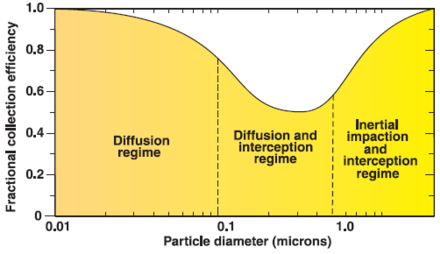

Since filters are tested against the most penetrating particle size of 0.3 μm, an APR with a P100 classification would be at least 99.97% efficient at removing particles of this size.[4] Particles with a size both less than and greater than 0.3 μm are filtered at an efficiency greater than 99.97%.[9] (That statement does not derive from given reference[10]). Although it is counter-intuitive that particle sizes of less than 0.3 μm are filtered with a greater efficiency, the forces which have the greatest impact on the effectiveness of filtration (aerosol impaction, interception, and diffusion) are weakest at this size for filters tested by NIOSH.[11] A filter's collection efficiency for particle sizes other than those for which it is least efficient is indicated by the filter's efficiency curve.

Similar standards

A few other jurisdictions use standards similar to the NIOSH scheme to classify mechanical filter respirators. They include:

- China (GB 2626-2019): Similar testing requirements and grades. Has "KN" and "KP" resistance levels, 90/95/99. Has additional EU-like rules on leakage.

- Mexico (NOM-116-2009): Same grades.

See also

References

- "42 CFR Part 84 - Approval of Respiratory Protective Devices". ecfr.gov. United States Government Publishing Office. 6 February 2020. Retrieved 9 February 2020.

- "To Beard or not to Beard? That's a good Question!". NIOSH Science Blog. CDC. 2 November 2017. Retrieved 27 February 2020.

- "Respirator Trusted-Source Information Section 1: NIOSH-Approved Respirators". The National Personal Protective Technology Laboratory (NPPTL). Centers for Disease Control and Prevention. 29 January 2018. Retrieved 9 February 2020.

- "NIOSH Guide to the Selection and Use of Particulate Respirators". The National Institute for Occupational Safety and Health (NIOSH). Centers for Disease Control and Prevention. 6 June 2014 [January 1996]. Retrieved 9 February 2020.

- "OSHA Technical Manual Section 8VII: Chapter 2 Respiratory Protection Appendix 2-4". OSHA (TED 01-00-015 ed.). Retrieved 9 February 2020.

- "Considerations for Optimizing the Supply of Powered Air-Purifying Respirators (PAPRs)". U.S. Centers for Disease Control and Prevention. 19 April 2020. Retrieved 25 May 2020.

- Vanessa, Roberts (Fall 2014). "To PAPR or Not to PAPR?". Canadian Journal of Respiratory Therapy. PMC 4456839. PMID 26078617. Retrieved 25 May 2020.

- "Understanding Respiratory Protection Against SARS". U.S. National Institute for Occupational Safety and Health. 9 April 2020. Retrieved 26 May 2020.

- "NIOSH Guide to the Selection and Use of Particulate Respirators Appendix E: Commonly Asked Questions and Answers About Part 84 Respirators". The National Institute for Occupational Safety and Health (NIOSH). Centers for Disease Control and Prevention. 6 June 2014. Retrieved 9 February 2020.

- "CDC - NIOSH Publications and Products - Appendices for 96-101". www.cdc.gov. 16 October 2018. Retrieved 22 June 2020.

- Guidance for Filtration and Air-Cleaning Systems to Protect Building Environments from Airborne Chemical, Biological, or Radiological Attacks (PDF). Cincinnati, OH: National Institute for Occupational Safety and Health. April 2003. pp. 8–12. Retrieved 9 February 2020.