Duralumin

Duralumin (also called duraluminum, duraluminium, duralum, dural(l)ium, or dural) is a trade name for one of the earliest types of age-hardenable aluminium alloys. Its use as a trade name is obsolete, and today the term mainly refers to aluminium–copper alloys, designated as the 2000 series by the International Alloy Designation System (IADS), as with 2014 and 2024 alloys used in airframe fabrication.

Alloying elements

In addition to aluminium, the main materials in duralumin are copper, manganese and magnesium. For instance, Duraluminium 2024 consists of 91-95% aluminium, 3.8-4.9% copper, 0.3-0.9% manganese, 1.2-1.8% magnesium, <0.5% iron, <0.5% silicon, <.0.25% zinc, <0.15% titanium, <0.10% chromium and no more than 0.15% of other elements together.[1]

History

Duralumin was developed by the German metallurgist Alfred Wilm at Dürener Metallwerke AG. In 1903, Wilm discovered that after quenching, an aluminium alloy containing 4% copper would slowly harden when left at room temperature for several days. Further improvements led to the introduction of duralumin in 1909.[2] The name is mainly used in popular science to describe the Al-Cu alloy system, or '2000' series, as designated by the International Alloy Designation System (IADS) originally created in 1970 by the Aluminum Association.

Aviation applications

.jpg)

Duralumin, its composition and heat treatment, was openly published in the German scientific literature before World War I. Despite this, it was not adopted beyond Germany until after World War I. Reports of German use during World War I, even in technical journals such as Flight, could still mis-identify its key alloying component as magnesium rather than copper.[3] In the UK there was little interest in its use until after the war.[4]

The earliest known attempt to use duralumin for a heavier-than-air aircraft structure occurred in 1916, when Hugo Junkers first introduced its use in the creation of the Junkers J 3's airframe, a single-engined monoplane "technology demonstrator" that marked the first use of the Junkers trademark duralumin corrugated skinning. Only the covered wings and tubular fuselage framework of the J 3 were ever completed, before the project was abandoned. The slightly later, solely IdFlieg-designated Junkers J.I armoured sesquiplane, known to the factory as the Junkers J 4, had its all-metal wings and horizontal stabilizer made in the same manner as the J 3's wings had been, along with the experimental and airworthy all-duralumin Junkers J 7 single-seat fighter design, which led to the Junkers D.I low-wing monoplane fighter, introducing all-duralumin aircraft structural technology to German military aviation in 1918.

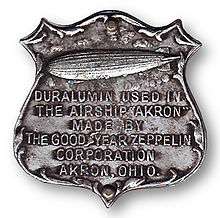

Its first use in aerostatic airframes was in rigid airship frames eventually including all those of the "Great Airship" era of the 1920s and 1930s: the British built R-100, the German passenger Zeppelins LZ 127 Graf Zeppelin, LZ 129 Hindenburg, LZ 130 Graf Zeppelin II, and U.S. Navy airships USS Los Angeles (ZR-3, ex-LZ 126), USS Akron (ZRS-4) and USS Macon (ZRS-5).[5][6]

Corrosion protection

Although the addition of copper improves strength, it also makes these alloys susceptible to corrosion. For sheet products, corrosion resistance can be greatly enhanced by metallurgical bonding of a high-purity aluminium surface layer. These sheets are referred to as alclad, and are commonly used by the aircraft industry.[7][8]

Applications

Aluminium alloyed with copper (Al-Cu alloys), which can be precipitation hardened, are designated by the International Alloy Designation System as the 2000 series. Typical uses for wrought Al-Cu alloys include:[9]

- 2011: Wire, rod, and bar for screw machine products. Applications where good machinability and good strength are required.

- 2014: Heavy-duty forgings, plate, and extrusions for aircraft fittings, wheels, and major structural components, space booster tankage and structure, truck frame and suspension components. Applications requiring high strength and hardness including service at elevated temperatures.

- 2017 or Avional (France): Around 1% Si.[10] Good machinability. Acceptable resistance to corrosion in air and mechanical properties. Also called AU4G in France. Used for aircraft applications between the wars in France and Italy.[11] Also saw some use in motor-racing applications from the 1960s,[12] as it is a tolerant alloy that could be press-formed with relatively unsophisticated equipment.

- 2024: Aircraft structures, rivets, hardware, truck wheels, screw machine products, and other structural applications.

- 2036: Sheet for auto body panels

- 2048: Sheet and plate in structural components for aerospace application and military equipment

References

- "United Aluminum - ALLOY 2024". Retrieved 8 October 2018.

- J. Dwight. Aluminium Design and Construction. Routledge, 1999.

- "Zeppelin or Schütte-Lanz?". Flight: 758. 7 September 1916.

- Thurston, A.P. (22 May 1919). "Metal Construction of Aircraft". Flight: 680–684.

- Burton, Walter E. (October 1929). "The Zeppelin Grows Up". Popular Science Monthly: 26.

- "The Great Airships" Century of Flight

- J. Snodgrass and J. Moran. Corrosion Resistance of Aluminum Alloys. In Corrosion: Fundamentals, Testing and Protection, volume 13a of ASM Handbook. ASM, 2003.

- Parker, Dana T. Building Victory: Aircraft Manufacturing in the Los Angeles Area in World War II, p. 39, 87, 118, Cypress, CA, 2013. ISBN 978-0-9897906-0-4.

- ASM Handbook. Volume 2, In Properties and Selection: Nonferrous alloys and special purpose materials. ASM, 2002.

- John P. Frick, ed. (2000). Woldman's Engineering Alloys. ASM International. p. 150. ISBN 9780871706911.

- "Italian Aircraft: Macchi C.200". Flight: 563. 27 June 1940.

- Sackey, Joe (2008). The Lamborghini Miura Bible. Veloce Publishing. p. 54. ISBN 9781845841966.