Baffle (heat transfer)

Baffles are flow-directing or obstructing vanes or panels used in some industrial process vessels (tanks), such as shell and tube heat exchangers, chemical reactors, and static mixers. Baffles are an integral part of the shell and tube heat exchanger design. A baffle is designed to support tube bundles and direct the flow of fluids for maximum efficiency. Baffle design and tolerances for heat exchangers are discussed in the standards of the Tubular Exchanger Manufacturers Association (TEMA).

Use of baffles

The main roles of a baffle in a shell and tube heat exchanger are to:

- Hold tubes in position (preventing sagging), both in production and operation

- Prevent the effects of steam starvation, which is increased with both fluid velocity and the length of the exchanger

- Direct shell-side fluid flow along tube field. This increases fluid velocity and the effective heat transfer co-efficient of the exchanger

In a static mixer, baffles are used to minimize tangential component of velocity which cause vortex formation thus promote mixing.[1]

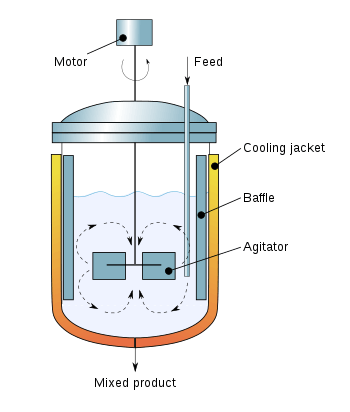

In a chemical reactor, baffles are often attached to the interior walls to promote mixing[2] and thus increase heat transfer and possibly chemical reaction rates.

Types of baffles

Implementation of baffles is decided on the basis of size, cost and their ability to lend support to the tube bundles and direct

- Longitudinal Flow Baffles (used in a two-pass shell)

- Impingement Baffles (used for protecting bundle when entrance velocity is high)

- Orifice Baffles

- Single segmental

- Double segmental

- Support/Blanking baffles

- Deresonating (detuning) baffles used to reduce tube vibration

Installation of baffles

As mentioned, baffles deal with the concern of support and fluid direction in heat exchangers. In this way it is vital that they are spaced correctly at installation. The minimum baffle spacing is the greater of 50.8 mm or one fifth of the inner shell diameter. The maximum baffle spacing is dependent on material and size of tubes. The Tubular Exchanger Manufacturers Association [3] sets out guidelines. There are also segments with a "no tubes in window" design that affects the acceptable spacing within the design. An important design consideration is that no recirculation zones or dead spots form – both of which are counterproductive to effective heat transfer.

References

- SPE/ANTEC 1999 Proceedings edited by SPE Staff pp. 163–164

- Chemical reactor modeling: multiphase reactive flows by Hugo A. Jakobsen, published in 2008 by Springer-Verlag in Berlin Heidelberg, pp. 681–683

- Tubular Exchanger Manufacturers Association, Inc.