I've had to do exactly this to reuse an old Nova rack from the 70s that had round holes.

First I tried clip-on cage nuts intended for round holes. These worked okay but have a fairly low maximum load. So okay for small switches but not servers.

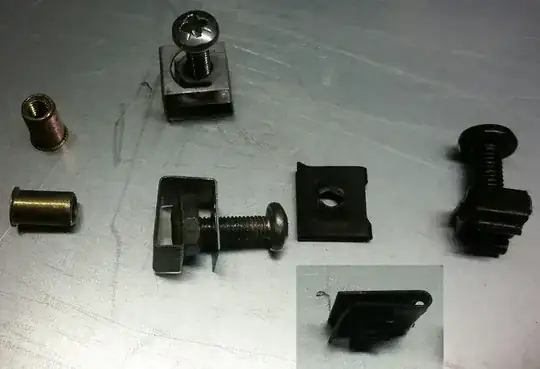

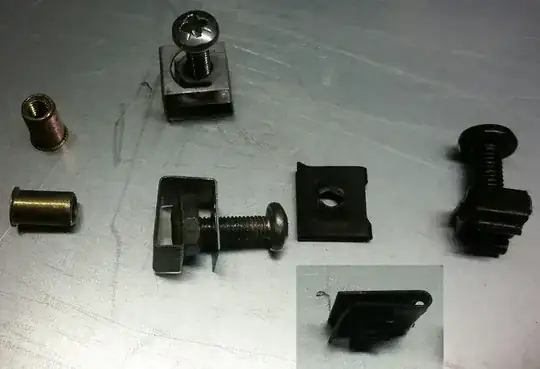

From Left, two rivnuts, uncompressed. Two clip-on cage nuts, with bolts. Then two slip threads (only had one spare) and last a common square cagenut for comparison.

Second I tried Rivnuts, which kinda worked but were too large or too small. I could have drilled out the rack holes to take the larger rivnuts, but they were expensive, and would have obstructed other rail systems from going home properly if I changed the rack content.

Likewise I thought about cutting square holes instead of round, but a quick test on a scrap of metal convinced me that was going to be a painfull lot of work for minimum gain.

Finally I used a combination of 1/4" bolts and nuts for rackmount items, and used some HP servers whose rails are designed to clip into round or square holes.

Two switches held in by bolts.

Workshop amp and tuner

Close up of a spare bolt

In theory I should have used a washer under the last nut, to spread the load over the equipment. In practice this hasn't been needed.

I should have used a much thinner first nut (the one holding the bolt in the rack, between the rack and the equipment) but locknuts were bonkers-expensive compared to normal ones - 12x the price.

Downside - you need a spanner or a tool to cinch the nut down tight and undo it. The ideal tool would be a deep nut driver on a screwdriver.

You could use wingnuts instead, but they run the risk of fouling on something. Super-deep nuts would help too, but they're not cheap.