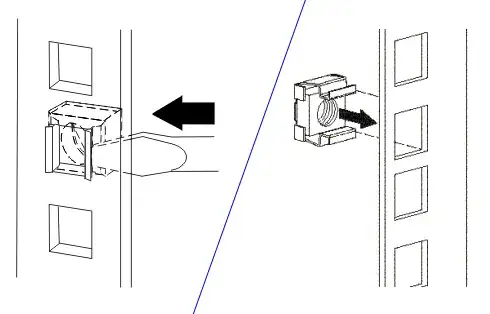

Cage nuts can be inserted (in square holes) either with the flaps horizontal or vertical. I've seen and used both methods, but am still not sure which is best. Is there a recommended way of inserting them? If so, why is it the best way?

From my own experience, the horizontal way (on the left) seems slightly better for no other reason than making it easier to insert or pry out the cage nut in a full rack (with the units above and below being populated), for example when replacing cage nuts with a snap-in rail.

Edit: Major vendors each seem to have their own preference too:

Vertical: HP (and Compaq), Sun/Oracle, Dell