Introduction

This is a prerequisite-only guide! This guide is part of another procedure and is not meant to be used alone.

Tools

-

-

Use an opening tool, spudger, or your fingernail to flip up the small, hinged locking flap on the LCD ribbon cable ZIF connector.

-

-

-

Use a pair of tweezers to pull the ribbon cable straight out of its connector on the motherboard.

-

-

-

Use an opening tool, spudger, or your fingernail to flip up the small, hinged locking flap on the smaller LCD ribbon cable ZIF connector.

-

-

-

Use a pair of tweezers to pull the ribbon cable straight out of its connector on the motherboard.

-

-

-

Heat an iOpener and apply it to the bottom edge of the screen for around two minutes to to help soften the adhesive.

-

-

-

Apply a suction cup to the bottom-left corner of the screen.

-

Pull up on the suction up with strong, steady force to create a gap.

-

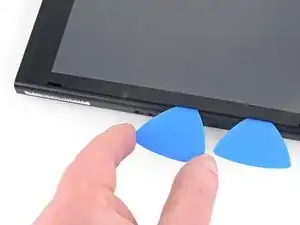

Insert the point of an opening pick into the gap, making sure to only insert the pick about 5 mm.

-

-

-

Slide the opening pick along the bottom edge of the screen to slice the adhesive.

-

Leave the pick inserted to prevent the adhesive from re-adhering to the frame.

-

-

-

Insert a second opening pick into the gap to the left of the first pick.

-

Slide the opening pick back towards the left side of the device.

-

Leave the opening pick inserted.

-

-

-

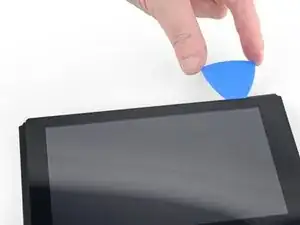

Continue sliding the opening pick around the top-left corner of the screen to slice the adhesive.

-

-

-

Heat the right edge of the screen for around two minutes to help soften the adhesive.

-

Place the flat end of a spudger into the gap along the left edge of the screen.

-

Carefully and slowly lift the left edge of the screen, opening it like a book.

-

-

-

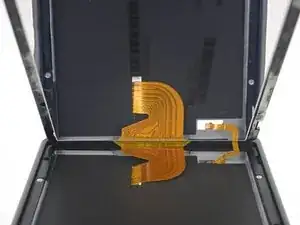

Lift the right edge of the screen straight off the device, threading the ribbon cables through the frame as you do so.

-

-

-

Heat the top edge of the screen assembly for around two minutes to help soften the adhesive holding the LCD panel to the digitizer.

-

-

-

Turn the screen assembly over.

-

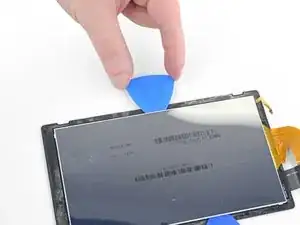

Insert an opening pick in between the LCD panel and the digitizer at the top-left corner.

-

Slide the opening pick along the top edge of the screen assembly to slice the adhesive.

-

-

-

Heat the left edge of the screen assembly for around two minutes to help soften the adhesive.

-

-

-

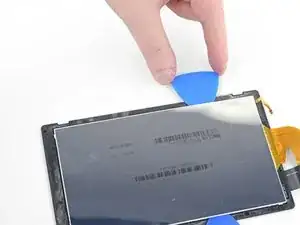

Insert and slide the opening pick along the left edge of the screen assembly to slice the adhesive.

-

-

-

Continue sliding the opening pick around the bottom-left corner of the screen assembly to slice the adhesive.

-

-

-

Heat the bottom edge of the screen assembly for around two minutes to help soften the adhesive.

-

-

-

Heat the right edge of the screen assembly for around two minutes to help soften the adhesive.

-

-

-

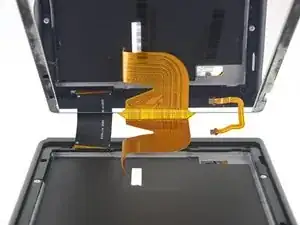

Insert the flat end of a spudger in between the LCD panel and the digitizer along the left edge of the screen assembly.

-

Carefully and slowly lift up the left side of the LCD panel, opening it like a book.

-

To reassemble your device, follow these instructions in reverse order.

How to replace locking flap incase it flys off

Jonathan D'Costa -