Introduction

Follow this guide to remove and replace the striker plate on an EDCO Floor Stripper TS8 .75L (2017).

Tools

Parts

-

-

Ensure the machine is unplugged.

-

Turn the power switch counterclockwise into the OFF position.

-

-

-

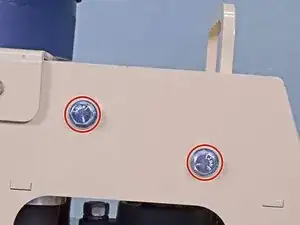

Use a 1/2 inch socket to remove the four bolts securing the hood to the frame, two on each side.

-

-

-

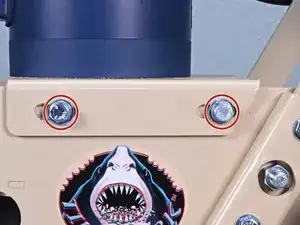

Use a 9/16 inch socket to loosen, but not remove, the four bolts securing the motor mount to the frame, two on each side.

-

-

-

Insert wheel chocks behind the wheels to ensure the device does not move or fall during the repair."

-

-

-

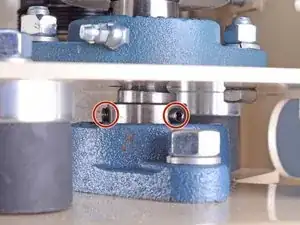

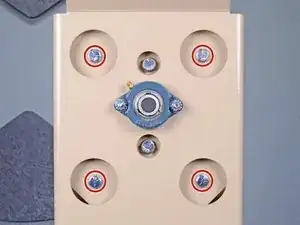

Use a 9/16 inch socket to remove the two nuts securing the upper flange bearing to the frame.

-

-

-

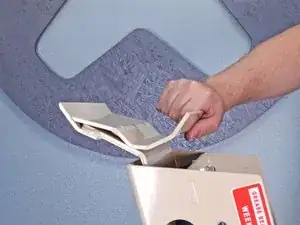

Use a mallet and an appropriately-sized brass punch to tap out the cam shaft assembly if you cannot remove it by hand.

-

-

-

Use a 9/16 inch socket to remove the four bolts securing the striker plate to the isolators.

-

To reassemble your device, follow these instructions in reverse order.