ZiU-9

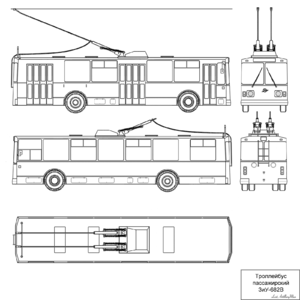

ZiU-9, or ZIU-9 (Cyrillic: ЗиУ-9) is a Soviet (and later Russian) trolleybus vehicle. Other names and indexes for the same vehicle include ZiU-682 and HTI-682 (Cyrillic: ЗиУ-682 and ХТИ-682). The ZiU acronym stands for Zavod imeni Uritskogo, which is a plant named after Moisei Uritsky, the Russian revolutionary. Before 1996 this acronym was also a trademark of the vehicle manufacturer. It has been changed to Trolza. The ZiU-9 was put in mass production in 1971 and it was still assembled along with other more advanced trolleybus vehicles in the Trolza (former ZiU) factory until 2014. The total number of produced ZiU-9s exceeds 42,000 vehicles. In addition, many copies of ZiU-9 were made in other factories of the former Soviet bloc. This model is the most numerous trolleybus vehicle in the world.

History and development

The explosion-like development of trolleybus systems in the Soviet Union in the 1960s required a large number of trolleybus vehicles. The mainstay of the contemporary Soviet trolley fleet, the ZiU-5, was not sufficient for huge urban passenger transfers. It was more suited for medium-size cities rather than large megapolises such as Moscow or Saint Petersburg. In addition the ZiU-5 had an aluminium hull, which was expensive and complicated from a technological point of view. The two doors in the ZiU-5 hull ends did not work well in overcrowded situations which were quite common in Soviet public transportation.

The ZiU-9 was a quite successful attempt to solve these problems. It has one extra door compared to the ZiU-5. Two doors are wide and placed in the middle and rear end of the vehicle hull. One small door in the front end of the vehicle was/is comfortable for the driver and for outgoing passengers. The hull of the ZiU-9 is a welded steel one and it is significantly cheaper and simpler in production than the hull of the ZiU-5.

The electrical equipment of the ZiU-9 had some minor differences from the ZiU-5. The power of the main motor was increased. The indirect resistor-based control system of electric current was slightly modified to deal with the increased power of the main motor. While western designers developed new semiconductor-based control devices, Soviet engineers decided to leave the old resistor-based system for service simplicity. The first prototype vehicles were tested in Moscow in 1971 and were approved for mass production after some minor design adjustments.

The '9' in the vehicle name was the initial project index of the design team. However, after launching mass production, the new trolleybus received a new index '682' from the united classification of non-rail public transport vehicles. So all series vehicles had a ZiU-682 designation. But the number 682 is difficult to pronounce and the shorter '9' still lives in the everyday language of drivers and servicemen. In 1986, the new classification was introduced and the former ZiU-682 was designated as HTI-682. But this was not an end of renaming the same vehicle. The Russian acronym HTI in the Cyrillic alphabet is ХТИ and these three Cyrillic letters in 1995 were confused with the Latin letters XTU. This Latin acronym became an official name of the vehicle.

Production

ZiU-9

The first prototype ZiU-9 was built in 1966. Elements of the appearance and number of design decisions were borrowed from contemporary to the time foreign firms MAN and Chausson.

ZiU-9A

ZiU-9A - experimental version with wide body to 2680 mm. The only prototype was made in 1968.

ZiU-682B

In August 1972, began production of the first production series ZiU-682B (with designation change ZiU ZiU -9 -682 was due to the labeling requirements of bringing industry classifier). First serial trolley cars differed from later releases. Until 1974, had an angular wheel arches, and not circular. The first batch of trolleybuses raised outdated engine DC-207G, which in 1973 was replaced by the DC-210 110 kW. Suspension on the first ZiU-682B was pneumatic, with torque rods as guiding elements, later became pnevmoressornoy. Rear funded playground had a reduced level of the floor, which reduced the number of steps one at the back door and to facilitate loading wheelchairs and prams and large items. However, this "advantage" was leveled by a high handrail on the steps of separating the rear and middle doors. Transition from high floor in the cabin to lower smoothly carried out in the aisle between the rear wheel arches, which caused inconvenience to passengers at peak hours (especially in winter), standing on an icy downhill "hill." In 1991, developers have replaced high-speed separator handrail attached to the door, but by this time all storage sites were at three stages from sidewalk level. For natural ventilation the roof of the cabin was equipped with four ceiling hatches, each equipped with a sliding side window pane. Currently, the only instance of ZIU-9B is preserved and operated in the linear regime in the city of Zaporozhye and has the side number 562.

ZiU-682V (B00/B0A)

At the end of 1976 began mass production next update ZiU- 682V, which replaced ZiU- 682B . Due to the presence of design flaws that emerged during the first years of operation, rather than jet thrust bearing elements as suspension springs were used . Since 1976, the number of fixtures in the cabin has been reduced from 12 to 11, every other window in the cabin lost air vents . Since 1978, the number of ceiling hatches reduced to three (due to hatch on the front axle ), steel trolley equipped with electric shtangoulovitelyami (apparently on the orders, since their machines Moscow was not until 1996 ) .

Since 1983, changed the shape and location of the front and rear position lamps . Lights original form, informally called " boats" have been replaced by unified and offset edges closer to route indicators . In 1985 a similar design changes undergone external signal lights and turn indicators .

From March - May 1984 trolleybuses were produced without the low -level rear accumulation area, which was due to the need to strengthen the base structure of the body in the rear overhang . In 1985, the nameplate trolley was partially aligned with the standards forming the VIN code, which led to a change in marking HTI682V00 .

Since 1988, the plant switched to production modifications ZiU- 682V -012 ( ZiU- 682V0A ) powered DC -213 capacity of 115 kW. Since 1989, changed the shape of the housing radioreaktors roof trolley, it has decreased in size and had a sharp edge. In 1989, production started in parallel transition modification ZiU- 682V0B on which electric drive door opener was replaced pneumatically .

ZiU-682G

By the end of 1980 . individual components trolley manufactured at that time was almost 20 years, significantly outdated. Therefore, simultaneously with the launch of a series of recent modifications ZiU- 682V preparing to produce more profound modernization of the model trolley, which was designated ZiU- 682G. Experienced instances ZiU- 682G were released in 1988, and since February 1, 1991 the plant was fully passed on their production.

In addition to the changes already introduced earlier models ZiU 682V0A - and - ZiU 682V0B model ZiU- 682G has received the following differences. Front, under the windshield, placed the intake grille. Changed the location of windows with vents along the starboard side. Undergone significant redevelopment salon trolley. Most of the seats along the left side of the body is replaced with a double row on row, which increased the number of standing places. Changed design seat themselves and their handrails. Big changes undergone cab. Partition behind the driver, which had previously oval window became deaf; extended sliding door in the driver's cabin. In the cabin itself changed the layout of the dashboard, which became made of black plastic. Out of the past neergonomichny remote control trolley bus right from the dashboard, consisting of two long rows of identical tumblers. Control of external light devices was moved to the steering column. On a dedicated right panel were only control door opening, the wiper switch and alarm. Other switches transferred to the new control panel by trolley to the left of the driver's side near the window. Redesigned suspension and brake pedals at the same time control approached the car.

On the other hand, ZiU- 682G supplied to provincial towns, 1993-2000., Compared with the previous model ZiU- 682V had significantly lighter load bearing elements of the frame component of the supporting frame (apparently, in order to reduce cost). As a result in severe operating conditions (e.g. in Nizhny Novgorod) for 5 years, these structural elements to rot completely corroded, punctured a gentle kick screwdriver. Since 1997, the base modification in mass production became ZiU- 682G -012 ( ZiU- 682G0A ). External difference between the new modification was reduced in height side window of the cab, also has another location pane. Minor changes have been planning the cabin. In fact it was adapted for the domestic market modification export version trolley ZiU- 682G -010, the production of which began in 1992.

On the basis of ZiU- 682G -012 began the further modernization of trolley conducted mainly commissioned Mosgortransa (as most other Russian cities at that time became insolvent ) and divided into several stages. For low voltage power generator instead of 63.3701 and auxiliary engine DC - 661B was set low noise static converter. Been improved waterproofing and grounding . Trolleybus began to possess higher corrosion protection, a number of sites now executes from aluminum, stainless steel and fiberglass. In parallel with ZiU- 682G -012, in 1998, started production in transition modification ZiU- 682G -014 ( ZiU- 682G0E ), which replace the old sofas in the lounge were installed individual padded seats, applied laser (source ?) Heaters cabin windows. This version is also equipped with a static converter.

ZiU-682G-016, 017 and 018

As a result of the continuation of the modernization of the trolley in the same 1998 there was a modification ZiU- 682G -016 ( ZiU- 682G0M ), which became the base model . Exterior siding boards became run from extruded galvanized steel sheet, which improved the appearance of the trolley and increased its corrosion resistance. Casement doors were subjected to additional rustproofing special compound. A great deal of work to improve the electrical trolley : applied dielectric coating rods susceptor set travel stops rods, improved insulation chicanery, installed in the cab indicator of leakage currents, improved design -board covers and sealing side compartments, redesigned heater . Also applied to the trolley locking system running with the doors open .

Back in the mid -1990s, it became apparent that the location of electrical underneath the trolley does not meet modern requirements of electric, because it does not protect it from moisture, anti-icing agents and many others, and also allows you to go through a puddle, if the depth exceeds ten centimeters. Then, in 1995, the model was designed ZiU- 52642, which is a major upgrade ZiU- 682G with the removal of electrical equipment on the roof of the trolley and other changes . However, for various reasons in the model series did not go.

The first production series with the removal of part of the apparatus on the roof became ZiU- 682G -017 ( ZiU- 682G0H ), launched in 2000. Unlike experienced ZiU- 52642 equipped with Thyristor-pulse control system, modification ZiU- 682G -017 remained equipped classical, uneconomical and unsupported acceptable smoothness Rheostat- contactor control system, electrical equipment factory "Dinamo " conventional platen doors. Some of the changes undergone interior, in particular, have been installed interior lights more modern form. From 2002 to request the trolley began to be produced in variants with altered appearance cabin (this applied fiberglass pad ) .

ZiU-682G-016.02 and ZiU-682G-016.03

.jpg)

Since October 2002, commercially produced modification ZiU- 682G - 016.02, which is a further development of the model ZiU- 682G -018 . Siding boards made of seamless steel sheet paneling front of the trolley combined with the use of fiberglass panels . The front bumper is also made of fiberglass. Passenger cabin windows are tinted glass, install new panoramic windshield . By trolley runs increased corrosion protection body, including the use of conductive soils firm «Sikkens» in lap welds, phosphate protective coating, as well as additional coverage base, sides, front and rear of the protective coating .

On trolley mounted traction motor DC - 213A production Moscow factory "Dinamo" 110 kW . Control system - rheostat- contactor . Most of traction electric trolley put to the roof . Collectors located on the roof, power resistors, group controller, radioreaktory circuit breaker WB -7 ( there is an option to install instead of the WB -7 breaker manual AV- 8 in the cab at the rear ), a static converter ( IPT-600/28 or BP -3G ), stroke limiter rods. Behind the driver is case inside of which has an electric panel protective relays . In this regard, the first window on the left side of the passenger compartment has reduced dimensions, there is no passenger seat facing the front wheel arch . Interior lighting passenger compartment carried fluorescent fixtures have modes full, partial and emergency lighting . Passenger room is equipped with separate comfortable seats ( which, however, often criticized for full passengers trouble and inconvenience) . Two passenger seats are equipped to transport people with limited mobility. Parking brake acts on the brakes the drive wheels of energy storage, control of air in the cab of the crane . Hydraulic oil tank is equipped with power steering oil level warning device .

To improve the electrical introduced fiberglass boards, electrical insulation flaps passenger doors from the body, external electrical insulation rod current collectors, insulation monitoring device UKI, emergency switch, the imposition of mostly electric traction kit from under the floor to the roof, technological track on the roof to move attendants, rear stopper rods pantographs fitted to three electrical insulators, locking the trolley system with open doors, emergency ( spare ) the passenger area lighting system ANTI passenger doors, emergency exits through the windows of the cabin, equipment service doors from inside and outside governments to open in an emergency installation on the roof of a high-speed circuit-breaker with remote control, etc.

Since 2004, also commercially produced trolley ZiU- 682G - 016.03 . Its main difference from ZiU - 682G - 016.02 is that the frame ( base) body made of an open profile ( sill ), which increases the rigidity and makes it more resistant to corrosion. Trolleybus body ZiU- 682G 016.03 - welded frame construction .

As an option, the setting of a wide front double doors swing- slide-type ( which is especially important for Moscow, used to pay for travel validator ) .

Since September 2009, in connection with the termination of a license to manufacture trolleybuses issue ZiU 682G016.02 - and - ZiU 682G016.03 discontinued.

ZiU-682G-016.04 and ZiU-682G-016.05

Since September 2009, JSC "Trolza" in accordance with the obtained license for production to start the production of trolleybuses ZiU-682G-016.04 and ZiU-682G-016.05. And apparently, these trolleys and constructive modifications almost completely replicate their predecessors ZiU-682G-016.02 and ZiU-682G-016.03. As changes in the rank of permanent options included installing electronic route signs and a marquee in the passenger compartment and ABS that ZiU-682G-ZiU 016.02 and 016.03-682G-performed by the customer.

Modifications as of 2012

Note that approximately 2003 JSC "Trolza" changed several notations produced models trolleybuses family ZiU- 682G, considering them all modifications ZiU- 682G -016 (VIN- code starts with all modifications XTU682G0M ) . As of 2010 the manufacturer offers the following serial modifications ( listed in order of increasing number of changes compared to ZiU- 682G )

- ZiU- 682G -016 (012 ) - basic model similar ZiU- 682G -012 (delivery in the form of a body 1st version)

- ZiU- 682G -016 (018) - modification, similar ZiU- 682G -018, and has a slight performance improvement ZiU- 682G -016 (delivery in the form of a body 1st version)

- ZiU- 682G - 016.02 (delivery in the form of a body 1st version)

- ZiU- 682G - 016.03 (delivery in the form of a body 1st version)

- ZiU- 682G - 016.04

- ZiU- 682G - 016.05

In 2009, Trolza developed a modified ZiU- 682G - 016.07 . This machine has a total 016.04 with different numbering and control system - TrSU " Chergos " instead of the standard rheostat- contactor . The only instance in operation in Murmansk.

The serial production for the ZiU-9 was discontinued in 2014 due to a lack of demand for the model.

Clones produced by other companies

Many factories in modern Russia or Belarus developed their unlicensed or semi-licensed copies of the ZiU-9 design. They may have different designations and trademarks, but in the colloquial language all of them are referred to as "ZiU-9 clones".

- ACSM -101 and their various modifications manufacturer Belkommunmash (Minsk)

- BTZ -5276 and modifications manufacturer Bashkir Trolleybus Plant ( Ufa)

- VZTM -5284 and modifications manufacturer Volgograd Plant of Transport Engineering ( Volgograd)

- VMZ -170 manufacturer Vologda Mechanical Plant (JSC " Trans- Alpha", Vologda )

- Trolleybuses production " Nizhtroll " (Nizhny Novgorod), officially passing as overhaul reconditioning

- CT- 682G production "Siberian trolley " (Novosibirsk), officially passing as overhaul reconditioning

- MTRZ - 6223 Moscow trolleybus production plant - modernization ZiU -682 for Moscow

- ZiU -682 ZiU BTRM production " Barnaul trolleybus repair shops " ( Barnaul), officially passing as overhaul reconditioning

- MTRZ - 6223 Altayelektrotrans production " CAU " Altayelektrotrans " " ( Barnaul)

- ZiU -682 Barnaul production of " Company " Altai electric transport company " " ( Barnaul)

Operators

In Hungary, Ziu-9 trolleys still operated in recent years, but they retired in Debrecen (DKV), Budapest (BKV) and Szeged (SzKT).[1] Originally 174 of them were used in the capital of the city, Budapest and a few dozens more in other cities. Although some buses are still in working condition and are used occasionally on retro and heritage trolley services.

ZiU-9s worked or are now working in all ex-USSR countries except the Baltic states. They are also in service in Belgrade, Serbia.

They were also sold to Greece, Argentina, in Colombia the EDTU (Empresa Distrital de Transportes Urbanos) was a larger operator of these buses; they was in a very bad conservation state in the former Eastern Bloc countries. Three cars were on loan in 1973 for testing purposes in Helsinki, Finland.

Greek donation

In 2004, the ILPAP, the operator of trolleybusses in Athens, Greece donated nearly all of its old ZiU-9 trolleybuses to the city of Belgrade and to Georgia. One was donated to the East Anglia Transport Museum.

Belgrade has had ZiU-9 trolleys of its own since late 1970s. In 2010 a public action was taken to save Belgrade's first ZiU-9 from being scrapped.

In fiction

See also

References

- "A hálózat csapdájában - ZIU troli búcsúteszt". Origo. 19 January 2013. Retrieved 31 December 2014.

External links

- ZiU-9 on the Nizhny Novgorod tram site (in Russian)

- Trolleybus in Budapest - Ziu 9 trolibuses (English, somewhat dated)

| Wikimedia Commons has media related to ZiU-9. |