Victaulic

Victaulic is a developer and producer of mechanical pipe joining systems and is the originator of the grooved pipe couplings joining system.[1] Victaulic is a global company with 15 major manufacturing facilities, 28 branches, and over 3600 employees worldwide. Currently, Victaulic headquarters is located in Easton, PA. John F. Malloy has served as CEO since 2002.

| Industry | Manufacturing, Fire Protection, HVAC, Mining, Oil & Gas, Maritime, Power, Clean & Waste Water Technologies, Plumbing |

|---|---|

| Headquarters | Easton, Pennsylvania |

Area served | Worldwide |

Key people | John F. Malloy (Chairman, President & CEO) |

| Website | victaulic.com |

Mechanical piping joining systems are used in HVAC, plumbing, fire protection and mining, water and waste water treatment, oilfield operations, power plants, military, marine systems and other industrial applications.[2] Mechanical piping systems offer an alternative to welding, threading, and flanging for joining two pipe ends.

Products

Grooved coupling pipe joining systems uses a roll grooving technique to join pipes and pipe joining components. A groove is placed on the outside of the pipes near the ends to be joined. Each groove receives a gasket, and these ends are then the male partners into a female coupling housing. The gasket creates a pressure responsive seal on the outside diameter of the pipe, unlike standard compression joints, where pressure acts to separate the seal. The gasket sealing is enhanced as the coupling housing is tightened onto the pipe end. "The economics of the grooved method derive from simplified assembly that involves three basic concepts: a pressure responsive gasket that creates a leak-tight seal; couplings that hold the pipe together; and fasteners that secure the couplings.[3]

Victaulic specializes in the development of couplings, valves, and fitting technologies for a variety of industries. Its main products are:

- Victaulic Grooved Couplings used to join mechanical pipes together.[4] The company produces a variety of these grooved couplings along with other technologies since it was founded.[5]

- The "Victaulic Vortex" fire suppression system, a product placed at critical locations like data centers. It emits a mix of water and nitrogen from a single source that simultaneously cools the affected area and extinguishes the fire.[6] It is approved for use in areas containing flammable liquids & hazardous machinery.[7]

- Victaulic Sprinkler Heads / Sprinkler Systems,[8] Grooved Valves / Grooved Pipe Fittings,[9] and expansion joints.[10]

History

The modern company known as Victaulic was founded in New York in 1925 to market mechanical, bolted couplings engage pipe grooves and use a gasket seal. The technology of joining pipe with bolted, mechanical couplings originated during World War I to speed up the deployment of fuel and water lines during battle.

The original purpose of the Victaulic pipe joint was mainly for military applications but quickly gained popularity in other commercial and industrial markets. The concept emerged when inventor Lieutenant Ernest Tribe, of the Royal Engineers, devised a special form of joint for use on pipes and cylinders containing gasses and chemicals under very high pressure. Tribe, in conjunction with Dr Henry Hele-Shaw, a noted English hydraulic engineer, had been engaged by the British Government during the war to advance trench warfare tactics.[11]

Lt Tribe was among the first group of soldiers that were trained to operate a trench warfare weapon called a flamethrower. According to Thomas Wictor, the Author of “Flamethrower Troops of World War I: The Central and Allied Powers,” Lt Tribe accompanied the delivery of Vincent battery flamethrowers to allies in World War I and also trained soldiers in the use of the weapon. In the early phases of utilizing the flamethrower operators were experiencing noxious design problems. The flame tube that transferred oil would come apart, spraying operators with burning oil. The faulty connector on the flamethrower was one of Mr. Tribe’s inspirations to develop a more reliable product to join two pipes together, thus the Victory Joint emerged.

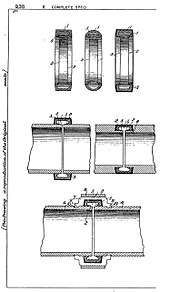

On 4 April 1919, Lt Tribe filed the patent for what is now known as the Victaulic coupling.

My invention is for an improved pipe joint which obviates the necessity for raising flanges at the ends of the pipes to be joined. I do not attempt to butt the ends of pipe together in order to form a fluid-tight joint, either with or without a packing ring between, but employ instead one packing ring made of flexible material, the form of which is an essential feature of the invention.

— Tribe U.K. Patent 149,381 filing – 4 April 1919.[12]

Shortly thereafter, the Victory Pipe Joint Co. was established in London, England and a second patent was filed in both names. Dr Hele-Shaw had numerous inventions including the multiple-plate clutch, stream-line filter, variable-pitch propeller, and Victaulic pipe joint. Dr Hele-Shaw was an enthusiast for inventing as well as an educator, engineer, pioneer, motorist, and sportsman.[13] Later, in 1922, the words "Victory" and "Hydraulics” were combined and shortened to form a single word, Victaulic. Subsequently, Victaulic Company of America was founded in New York City in February 1925.

The concept of joining pipe with bolted mechanical couplings quickly gained popularity throughout World War II. The Victaulic coupling was used by Allied forces to accelerate the distribution of fuel and water to the troops. The coupling was invaluable for the troops because it decreased the difficulty of assembling and de-assembling pipe lines and allowed them to hasten distribution. The early installations of the Victaulic pipe joints included systems that needed flexibility; systems withstanding vibrations, shifting of soil, or other external influences. Victaulic fittings were very economical on space and were valuable in tunnels, ship work, and borings. The demand for dependable pipeline systems increased during World War II in direct correlation to the troops needing oil and petroleum. The earlier methods of distributing petroleum during war included shipping it overseas and dispersing by tank car, truck, or rail.[14]

Realizing the potential of pipeline systems, the War Department approved the request by the Quartermaster Corps proposing a new gasoline dispensing system on February 26, 1941.[14] “The Quartermaster Corps proposed to develop a pipeline as the primary means of delivering gasoline from tank cars to can and drum refilling points whenever tank trucks were not available or wherever features of terrain made the use of trucks impractical. All pipe, pumps, engines, hose, tools, and Victaulic couplings were standard commercial design.”[14] Victaulic couplings or similarly designed couplings, consisting of a synthetic rubber gasket held in place by two semicircular metal castings, were used to assemble pipelines that would establish fuel dumps to the front line and keep the troops well supplied.[14]

See also

- ASHRAE – American HVAC professional association

- ASME

- Ductile iron pipe

- Factory Mutual

- Fire sprinkler system

- Heat fusion

- Mason Contractors Association of America

- Mechanical joint

- National Fire Protection Association – International nonprofit organization

- Pipe support

- Piping and plumbing fitting

- Plumbing – Systems for conveying fluids

- Potable water

- Underwriters Laboratories

- Vibration isolation

References

- "Victaulic to Provide Piping Systems for Four Landmark Buildings". ThomasNet News. Retrieved August 24, 2011.

- "Smart Solutions - Helping contractors save money and enhance productivity". http://www.mcaa.org/news/smartsolutions/Smart_Solutions-Summer_2011.pdf (2011)

- "Pipes in the groove with sustainability." accessmylibrary.com (December 1, 2009)

- "Victaulic - Mechanical Pipe Joining Systems". power-technology.com. Retrieved August 24, 2011.

- "Victaulic Marks 80 Years Of Innovation". Supplyhouse Times. BNP Media. May 4, 2005. Retrieved August 24, 2011.

- "Fire Protection Systems". Levitt=Safety. Retrieved August 24, 2011.

- "Technology Focus". Mechanical Engineering. American Society of Mechanical Engineers. Retrieved August 24, 2011.

- "Victaulic Sprinklers". Guardian Fire Protection Service. Retrieved August 24, 2011.

- "Victaulic grooved fittings and Victaulic grooved valves". Independent Pipe and Supply Corp. Retrieved August 24, 2011.

- "Victaulic Showcases Benefits of Grooved Piping in the Power Industry at #PowerGen". PRWeb. December 13, 2010. Retrieved August 24, 2011.

- Journal (American Water Works Association), Vol.9, No.6 (November,1922), pp. 921-927. And Associate Professor of Hydraulic and Sanitary Engineering, University of North Carolina, Chapel Hill, N.C., Chief Hydraulic Engineer, North Carolina Geological and Economic Survey

- Tribe, Ernest. "Improvements in and connected with Pipe Joints." Patent 149,381. 4 April 1919.

- Craddock, S.R. (1961). "H.S. Hele-Shaw". The Vocational Aspect of Education. 13 (27): 172–177. doi:10.1080/03057876180000181.

- A New Mission: Petroleum Distribution, 17 September 2013