Stowage plan for container ships

Stowage plan for container ships or bay plan is the plan and method by which different types of container vessels are loaded with containers of specific standard sizes. The plans are used to maximize the economy of shipping and safety on board.

Purpose

In order to maximize the economy of handling and shipping of containers on a container ship, stowage plans[1] sometimes known as bay plans,[2] have become essential in the shipping trade. The plans are also vital for safety on board the ship and it is recommended that personnel working on ships are familiar with them.[3][4][5][6] Modern stowage plans are executed by computer programs using mathematical calculations similar to those used for solving complicated Tetris problems.[7] One such system of programs is the [[MACS3][8],[Cloud CASP], [CASP]].

Containers and ship sections

The most common and noted type of containers are the 20 feet and 40 feet containers. There are also containers with an extent in height called "High Cube" containers.[3][9] The fixed exterior dimension of the standard size boxes are:[9][10]

- 20 feet container size is: 20 ft (6.1 m) length by 8 ft (2.4 m) width by 8.6 ft (2.6 m) height.

- 40 feet container size is: 40 ft (12 m) length by 8 ft (2.4 m) width by 8.6 ft (2.6 m) height.

Container vessels are built to contain as many containers as possible, accordingly the vessels are divided into sections:

- Accommodation, the space which contains all crew cabins

- Bridge, the command center of the ship, the space which contains steering wheel, telegraph, radars, ECDIS, charts for navigation and publications

- Engine room, the space which the engine and machines can be served, maintained

- Generator

- Fuel tanks

- Water ballast tanks

- On-deck

- Hatches

- Cargo holds (below deck)

The cargo hold and on-deck are the spaces where the cargo, stored in containers, is kept.[11]

Stowage terms

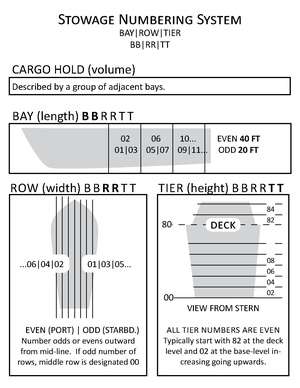

On container ships the position of containers are identified by a bay-row-tier coordinate system. The bays illustrate the cross sections of the ship and are numbered from bow to stern. The rows run the length of the ship and are numbered from the middle of the ship outwards, even numbers on the port side and odd numbers on the starboard side. The tiers are the layers of containers, numbered from the bottom and up.[12]

- Bay – a space in the ship that can hold containers, container ships has several bays, these bays are divided into two parts: on-deck and under-deck (hold). If the bay number is odd it is suitable for 20 feet containers, if the bay number is even it is suitable for 40 feet containers.[3][12]

- Container slot, position or cell – names of the spaces that containers can be loaded in. On a stowage plan their positions are identified by a six-digit coordinate number: Bay-Bay-Row-Row-Tier-Tier.[3][5][12]

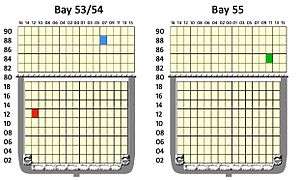

In the example image the position coordinates of the containers are:

- Blue container; 530788

- Red Container: 531212

- Green container: 551184

Preloading planning

In order to stow the cargo on a vessel, planners have specific computer programs to aid them. Planners use ports of call and vessel schedule to adjust vessel's route in the planning program. To plan the stowing the following parameters are essential:[4][5]

- Vessel route

- Ports of call

- Vessel schedule

- Current cargo in the vessel, in an EDI format called BAPLIE[13]

- Expected cargo to load

After that, planners get discharge lists/plans in the form of an EDI file (the COPRAR) and send information to the container terminals for all the re-stows (discharging containers and re-loading them) which may be required for completing the discharge process. Planners will also classify the loading data according to the kind of cargo in the containers as well as the size and shape of the containers and their destinations.[4][5][14] Each container is marked with a series of numbers and codes to identify the container's operator, specifications and what kind of cargo it may hold.[3] The parameters are:

- Refrigerated cargo

- Dangerous cargo

- Out of gauge cargo

- Dry hide container

- Port of discharge

- Cargo weight

- Container size

- Hatch cover clearance

- Visibility

The stowage plan shows crossections of the ship bay by bay, to indicate where all the containers should be loaded. The plans change with each port of call as container are discharged or re-stowed and new containers are taken on board.[3][14]

Cargo units

.jpg)

Refrigerated cargo units – Container vessels are equipped with power source for specific places to plug in the refrigerated containers known as "reefers", hence, the reefer containers places are known and are usually the first type of containers to consider in the stowage plan.[14][15][16]

Dangerous cargo – Containers where certain segregation rules must be followed, for example dangerous cargo that should be kept away from direct sunlight, from reefer container's motors, of some kind of another dangerous cargo or segregated away from all of the above. Accordingly, planners start with reefer units then continue with dangerous cargo units when planning the vessel.[14][16]

Out of gauge cargo – For most international shipping, cargo that cannot be packed within a 40' high cube container is out of gauge. It may be possible to pack such cargo in specialty containers. Open top containers are suitable for over height cargo. flat rack containers can accommodate over height, over width or over weight cargo. Container platforms can handle over height, width or length cargo, but require slings to load and unload. Also out of gauge for most ships are containers between 45' and 53' long used in some countries for domestic rail and truck transport. These loads are usually added after planning all other containers and are usually stowed on top of other containers (on deck or in hold) as the planners strive to minimize the number of "lost slots" (unused positions) as much as possible.[14][16]

Dry hide containers – Normal containers packed with cargo that may result in some leakage (such as liquid from fresh leather), they are usually stowed in outer road/first tier in order to make the necessary arrangements in case of leakage.[17]

Dry cargo containers – Usually stowed according to next port of calls depending on container size and weight of cargos, the heavy weights below and the lighter weights on top.[18]

Logistical factors

Port of discharge – When trying to find a suitable stowage position for containers, the planners must take into consideration the sequence of the ports of call. For example, if the port of calls are A, B and C, for the port A discharge, the planner must take into consideration not to choose a stowage position for a container for ports B or C on top of the container destined for port A.[14]

Container size – A 20 feet container can not be loaded up on a 40 feet container, but the reverse is possible if the vessel structure allows it. Planners can also load a 40 feet container on top of two units of 20 feet container, this known as a "Russian stowage" or "mixed stowage".[19]

Hatch cover clearance – Hatch cover clearance refers to how many "High Cube" (height over 8.6 ft (2.6 m)) containers allowed to load in the hold without preventing the hatch cover from closing correctly.[3]

Visibility – The number of High cube containers shouldn't exceed a set number of High cube containers in each row/bay on-deck. If the number of high cube units exceeded the set number it will prevent the full/clear line of sight of the ship from the bridge or other vital vantage points.[20][21][22]

Additional factors

Other factors included at stowing are:[16][23]

- Vessel stability. The weight of the cargo should be evenly distributed in the ship. For example, extra heavy weight units should not be stowed in the port side and light weight units in starboard side, but should stow it tier by tier starting with similar weights to avoid any problem may accrue in stability.

- Stack weights violation. Each bay/row has a stack weight that should not be exceed as it may cause damage to other containers or vessel structure.

- Weight inversion. Weight inversion should be avoided.

- Un-used slots under deck should be avoided and the planning should be done from bottom to top.

- Decrease lashing force.

Discharging

Once a ship has arrived in port, other plans for handling, sorting and storage at the terminal go into operation.[24]

Problems

As stowage plans are transmitted electronically as data files between ships and terminals, they can be intercepted by modern pirates working with organized crime syndicates. These attacks are called Major Criminal Hijacks (MCH) or South China Sea Piracy and are usually "made to order" with pirates boarding the ship having good knowledge of its layout and where the most coveted cargo is stowed.[25]

References

- "stowage plan". www.thefreedictionary.com. Dictionary of Military and Associated Terms. 2005. Retrieved 22 May 2016.

- "Bay plan". www.businessdictionary.com. BusinessDictionary. Retrieved 22 May 2016.

- Mukherjee, Paromita (28 September 2015). "Handling Containers On Ships: Dimensions, Markings and Bay Plan". www.marineinsight.com. MarineInsight. Retrieved 21 May 2016.

- Grunau, Peter (2015). Cargo Handling and Stowage: A Guide for Loading, Handling, Stowage, Securing, and Transportation of Different Types of Cargoes, Except Liquid Cargoes and Gas. BoD – Books on Demand. ISBN 978-3-7392-6636-7.

- "Cargo work: Loading, discharging & stowing cargo" (PDF). www.pfri.uniri.hr. Sveučilište u Rijeci. pp. 16–22. Retrieved 21 May 2016.

- Ambrosino, Daniela; Sciomachen, Anna; Tanfani, Elena (February 2004). "Stowing a containership: the master bay plan problem". Transportation Research Part A: Policy and Practice. 38 (2): 81–99. doi:10.1016/j.tra.2003.09.002.

- Tavares de Azevedo, Anibal; Fernandes de Arruda, Edilson; Leduino de Salles Neto, Luiz; Au-gusto Chaves, Antônio; Carlos Moretti, Antônio (2013). "Solution of the 3D Stochastic Stowage Planning for Container Ships through Representation by Rules". www.atlantis-press.com. Eureka-2013. Fourth International Workshop Proceedings. Retrieved 22 May 2016.

- "MEECOS suite". www.interschalt.com. INTERSCHALT maritime systems AG. Retrieved 22 May 2016.

- "Container sizes". www.shipsbusiness.com. ShipsBusiness.com. 2015. Retrieved 21 May 2016.

- Tuohy, Cyril (1 September 2011). "Concentrating on the cargo: the concentration of cargo on tomorrow's huge container ships is rewriting the rules of ocean-marine transport.(RISK REPORT: MARINE CARGO)". Risk & Insurance. Archived from the original on 18 November 2018. Retrieved 22 April 2016.

- Shimomura, Yasuteru (11 April 2016). "Supersized container ships leading to overcapacity". Nikkei Inc.

- Sirohi, Aamir. "1.3.3 Container stowage plans". Container handbook. www.containerhandbuch.de. German Marine Insurers. Retrieved 22 May 2016.

- "EDI BAPLIE". www.1edisource.com. 1 EDI Source, Inc. Retrieved 5 April 2016.

- "Case Study StowMan" (PDF). www.interschalt.de. Interschalt maritime systems AG. Retrieved 21 May 2016.

- Anish (28 October 2010). "Everything You Ever Wanted to Know About Container Refrigeration Unit". MarineInsight. Retrieved 21 May 2016.

- Fan, Liu; Yoke Hean Low, Malcolme; Shell Ying, Huang; Wen Jing, Hsu; Min, Zeng; Cho Aye, Win (2010). Stowage Planning of Large Containership with Tradeoff between Crane Workload Balance and Ship Stability (PDF). Hong Kong: International MultiConference of Engineers and Computer Scientists 2010. pp. 1–7. ISBN 978-988-18210-5-8.

- "Carriage of hides in containers". www.shippingaustralia.com. Shipping Australia Limited. 2012. Retrieved 22 May 2016.

- "On deck stowage of containers". www.aimu.org. American Institute of Marine Underwriters. Retrieved 22 May 2016.

- Belamaric, Goran (2011). "Lashing forces – Easeacon lashing module" (PDF). Faculty of Maritime Studies – SPLIT. p. 50.

- "Patent US5809489 – Method for determining a stowage plan". Retrieved 22 April 2016.

- Avriel, Mordecai (1998). "Stowage planning for container ships to reduce the number of shifts". Annals of Operations Research. 76: 55–71. doi:10.1023/A:1018956823693.

- Karanc. "How to Plan Cargo Containers Stowage on Container Ship?". www.marineinsight.com. MarineInsight. Retrieved 21 May 2016.

- Avriel, Mordecai; Penn, Michal; Shpirer, Naomi (15 July 2000). "Container ship stowage problem: complexity and connection to the coloring of circle graphs". Discrete Applied Mathematics. 103 (1–3): 271–279. doi:10.1016/S0166-218X(99)00245-0.

- Taleb-Ibrahimi, Mounira; de Castilho, Bernardo; Daganzo, Carlos F. (February 1993). "Storage space vs handling work in container terminals". Transportation Research Part B: Methodological. 27 (1): 13–32. doi:10.1016/0191-2615(93)90009-Y.

- Corbett, Peter; Hill, Peter (2009). A Modern Plague of Pirates. Captain Peter Corbett. p. 38. ISBN 978-0-9562107-0-8.

Further reading

- Blecker, Thorsten; Kersten, Wolfgang (2006). Complexity Management in Supply Chains: Concepts, Tools and Methods. 2. Erich Schmidt Verlag GmbH & Co KG. ISBN 978-3-503-09737-1.