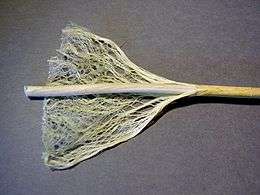

Shives

Shives, also known as shoves or boon, are the wooden refuse removed during processing flax, hemp, or jute, as opposed to the fibres (tow). Shives consist of "the woody inner portion of the hemp stalk, broken into pieces and separated from the fiber in the processes of breaking and scutching" and "correspond to the shives in flax, but are coarser and usually softer in texture".[1] Shives have traditionally been a by-product of fiber production.[2]

Decortication

Decortication separates bast fiber from the shive. The fine bast fiber is used to make textiles. Decortication is accomplished by manually crushing, a labor-intensive process, or by a hemp decorticator machine.[3][4]

Uses

Shives can be used as stock in papermaking;[5][1] particleboard, hempcrete,[6] and other construction composites;[7] or bedding for animals,[5] particularly in horse stalls, which is the most common use (by weight) in Europe.[8][9]

Development of water-repellent coatings

Hemp shives are a renewable organic raw material used for the production of insulation boards.[10] The use of biomaterials for insulation boards in walls is attracting increasing interest, but wider acceptance in the construction industry has so far been slowed-down by adverse material properties. Because such materials consist mainly from cellulose, they are flammable and their hydrophilic surface leads to high water uptake, which can lead to mold or rot.[11][12][13]

Therefore, engineering studies have investigated whether a coating with a water-repellent thin film provides the desired benefits. For the hydrophobic coating with silica particles, a colloidal sol-gel dispersion was successfully synthesized by the Stöber process, characterized and deposited on hemp shive. These samples passed a 72-hour test in the humidity chamber without loss of their hydrophobic property and no signs of mold growth.[14]

When the hemp shive was coated several times with functionalized silica particles, uniform and complete coverage of the surface was achieved. Such a treatment provided the hemp shive with a comprehensive water repellency: The hydrophilic character of the untreated hemp shive was modified to durably hydrophobic, once the bio-materials were coated with functionalised silica particles. Mould growth was delayed when exposed to humidity, whilst the liquid water repellent property of the treated hemp shive was maintained despite the humid conditions. The treatment developed in this study could be a viable solution for use on bio-materials that need to repel liquid water, whilst preserving the integrity of the insulation panel in common environmental conditions. There are of course still further tests to be carried out before adopting this treatment in the construction sector, such as additional moisture tests, mechanical tests, biodegradation tests, etc. However, the promising results described here give a good first assessment of feasibility. Before being fully adopted in the construction sector, these treatments and materials must be fully tested in accordance with the building codes. In addition, with the recent use of biomaterials, new standards and test methods for these specific materials should be developed.[14]

See also

References

Citations

- Pulp and Paper 1917.

- Fike 2017.

- Horne 2012, p. 133.

- Bouloc 2013, p. 152 (diagram of decortication and fiber extraction process)

- Dewey & Merrill 1916.

- "'Growing' a Truly Green Home", Manila Bulletin, December 23, 2013, archived from the original on September 7, 2017 – via HighBeam (subscription required)

- Aguilera 2013, p. 288.

- Carus, Vogt & Breuer 2008.

- Carus & Sarmento 2016, p. 6.

- CAVAC Biomaterials: Applications.

- Mahmoud Khazma, Adeline Goullieux, Rose-Marie Dheilly and Michèle Quéneudec: "Coating of a lignocellulosic aggregate with pectin/polyethylenimin mixtures: Effects on flax shiv and cement-shiv composite properties". In: Cement and Concrete Composites, Volume 34, Issue 2, February 2012, pp. 223–230. doi:10.1016/j.cemconcomp.2011.07.008 10.1016/j.cemconcomp.2011.07.008.

- Nadjla Mostefai, Rabah Hamzaoui, Sofiane Guessasma, Amadou Aw and Hedi Nouri: "Microstructure and mechanical performance of modified hemp fibre and shiv mortars: Discovering the optimal formulation". In: Materials & Design, Volume 84, 5 November 2015, pp. 359–371. doi:10.1016/j.matdes.2015.06.102 10.1016/j.matdes.2015.06.102.

- Atif Hussain, Juliana Calabria-Holley, Diane Schorr, Yunhong Jiang, Mike Lawrence and Pierre Blanchet: Hydrophobicity of hemp shiv treated with sol-gel coatings. In: Applied Surface Science. Volume 434, 15 March 2018, pp. 850–860. doi:10.1016/j.apsusc.2017.10.210 10.1016/j.apsusc.2017.10.210.

- Stephan W. Kallee: "Entwicklung von wasserabweisenden Siliciumdioxid-Partikeln zum Schutz von Hanfschnittgut als Isoliermaterial". German translation of an English Open Access article by Marion A. Bourebrab, Géraldine G. Durand and Alan Taylor: Development of Highly Repellent Silica Particles for Protection of Hemp Shiv Used as Insulation Materials, published on 21 December 2017, retrieved on 25 November 2017. DOI: 10.3390/ma11010004.

General sources

- Dewey, Lyster H.; Merrill, Jason L. (October 14, 1916), Hemp hurds as paper-making material, U.S. Department of Agriculture, p. 5, USDA Bulletin 404 – via Internet Archive

- "Advertisements". Pulp and Paper Magazine. XV (1): 53. January 11, 1917.

- Aguilera, Alfredo (2013), "Non-wood lignocellulosic composites", Research Developments in Wood Engineering and Technology, IGI Global, ISBN 9781466645554

- Carus, Michael; Vogt, Dominik; Breuer, Thomas (2008), Studie zur Markt- und Konkurrenzsituation bei Naturfasern und Naturfaser-Werkstoffen (Deutschland und EU) [Studies on the markets for natural fibers and natural fiber materials (Germany and EU)] (PDF), Gülzower technical discussions (in German), Band 26, Gülzow: Fachagentur Nachwachsende Rohstoffe

- Horne, M. R. L. (2012), "Bast fibres: hemp cultivation and production § fibre extraction (6.5)", in Kozłowski, Ryszard M. (ed.), Handbook of Natural Fibres: Types, Properties and Factors Affecting Breeding and Cultivation, Woodhead Publishing Series in Textiles, Elsevier Science, pp. 131–137, ISBN 978-0-85709-550-3

- Bouloc, Pierre (2013), "The industrial hemp economy", Hemp: Industrial Production and Uses, CABI, pp. 145–161, ISBN 978-1-84593-793-5

- Fike, John (4 January 2017), "Industrial Hemp: Renewed Opportunities for an Ancient Crop", Critical Reviews in Plant Sciences, 35 (5–6): 406–424, doi:10.1080/07352689.2016.1257842

- Carus, Michael; Sarmento, Luis (May 2016), The European Hemp Industry: Cultivation, processing and applications for fibres, shivs, seeds and flowers (PDF), European Industrial Hemp Association

External links