Sandwich-structured composite

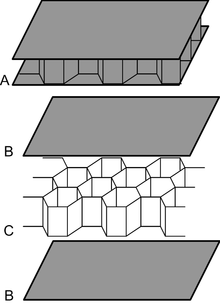

A sandwich-structured composite is a special class of composite materials that is fabricated by attaching two thin but stiff skins to a lightweight but thick core. The core material is normally low strength material, but its higher thickness provides the sandwich composite with high bending stiffness with overall low density.

Open- and closed-cell-structured foams like polyethersulfone polyvinylchloride, polyurethane, polyethylene or polystyrene foams, balsa wood, syntactic foams, and honeycombs are commonly used core materials. Sometimes, the honeycomb structure is filled with other foams for added strength. Open- and closed-cell metal foam can also be used as core materials.

Laminates of glass or carbon fiber-reinforced thermoplastics or mainly thermoset polymers (unsaturated polyesters, epoxies...) are widely used as skin materials. Sheet metal is also used as skin material in some cases.

The core is bonded to the skins with an adhesive or with metal components by brazing together.

History

A summary of the important developments in sandwich structures is given below.[1]

- 230 BC Archimedes describes the laws of levers and a way to calculate density.

- 25 BC Vitruvius reports about the efficient use of materials in Roman truss roof structures.

- 1493 Leonardo da Vinci discovers the neutral axis and load deflection relation in three-point bending.

- 1570 Palladio presents truss-beam constructions with diagonal beams to prevent shear deformations.

- 1638 Galileo Galilei describes the efficiency of tubes versus solid rods.

- 1652 Wendelin Schildknecht reports about sandwich beam structures with curved wooden beam reinforcements.

- 1726 Jacob Leupold documents tubular bridges with compression loaded roofs.

- 1786 Victor Louis uses iron sandwich beams in the galleries of the Palais-Royal in Paris.

- 1802 Jean-Baptiste Rondelet analyses and documents the sandwich effect in a beam with spacers.

- 1820 Alphonse Duleau discovers and publishes the moment of inertia for sandwich constructions.

- 1830 Robert Stephenson builds the Planet locomotive using a sandwich beam frame made of wood plated with iron

- 1940 The de Havilland Mosquito was built with sandwich composites; a balsawood core with plywood skins.[2]

Types of sandwich structures

Metal composite material (MCM) is a type of sandwich formed from two thin skins of metal bonded to a plastic core in a continuous process under controlled pressure, heat, and tension.[3]

Recycled paper is also now being used over a closed-cell recycled kraft honeycomb core, creating a lightweight, strong, and fully repulpable composite board. This material is being used for applications including point-of-purchase displays, bulkheads, recyclable office furniture, exhibition stands, and wall dividers.

To fix different panels, among other solutions, a transition zone is normally used, which is a gradual reduction of the core height, until the two fiber skins are in touch. In this place, the fixation can be made by means of bolts, rivets, or adhesive.

With respect to the core type and the way the core supports the skins, sandwich structures can be divided into the following groups: homogeneously supported, locally supported, regionally supported, unidirectionally supported, bidirectionally supported.[4] The latter group is represented by honeycomb structure which, due to an optimal performance-to-weight ratio, is typically used in most demanding applications including aerospace.

Properties of sandwich structures

The strength of the composite material is dependent largely on two factors:

- The outer skins: If the sandwich is supported on both sides, and then stressed by means of a downward force in the middle of the beam, then the bending moment will introduce shear forces in the material. The shear forces result in the bottom skin in tension and the top skin in compression. The core material spaces these two skins apart. The thicker the core material the stronger the composite. This principle works in much the same way as an I-beam does.[5]

- The interface between the core and the skin: Because the shear stresses in the composite material change rapidly between the core and the skin, the adhesive layer also sees some degree of shear force. If the adhesive bond between the two layers is too weak, the most probable result will be delamination.

Application of sandwich structures

.jpg)

Sandwich structures can be widely used in sandwich panels, this kinds of panels can be in different types such as FRP sandwich panel, aluminium composite panel etc. FRP polyester reinforced composite honeycomb panel (sandwich panel) is made of polyester reinforced plastic, multi-axial high-strength glass fiber and PP honeycomb panel in special antiskid tread pattern mold through the process of constant temperature vacuum adsorption & agglutination and solidification.

Theory

Sandwich theory[6][7] describes the behaviour of a beam, plate, or shell which consists of three layers - two face sheets and one core. The most commonly used sandwich theory is linear and is an extension of first order beam theory. Linear local buckling sandwich theory is of importance for the design and analysis of Sandwich plates or sandwich panels, which are of use in building construction, vehicle construction, airplane construction and refrigeration engineering.

See also

| Wikimedia Commons has media related to Composite honeycombs. |

- Honeycomb Structures

- Sandwich theory

- Flitch beam

- Bending

- Beam theory

- Composite material

- Hill yield criteria

- Sandwich plate system

- Composite honeycomb

- Timoshenko beam theory

- Plate theory

- Sandwich Panel

References

- EconHP Holding – History without Flash /index.php Archived 2011-07-18 at the Wayback Machine. Econhp.de. Retrieved on 2012-09-06.

- Cutler, John Henry; Koppel, Ivan; Liber, Jeremy. Understanding Aircraft Structures. Blackwell Publishing Limited. p. 14. ISBN 1-4051-2032-0.

- Flanagan, Jim (2007). "The Realm of Building Possibilities Created by MCM and Insulated Metal Panels". Metal construction news. 28 (10).

- "Sandwich panel classification (by type of core)". EconCore.com. Retrieved 2014-10-07.

- Gere, James M (2004). Mechanics of Materials. Thomson Brooks/Cole. pp. 393–463. ISBN 0-534-41793-0.

- Plantema, F, J., 1966, Sandwich Construction: The Bending and Buckling of Sandwich Beams, Plates, and Shells, Jon Wiley and Sons, New York.

- Zenkert, D., 1995, An Introduction to Sandwich Construction, Engineering Materials Advisory Services Ltd, UK.

External links

- SandwichPanels.org – Composite sandwich structure information

- Diab Sandwich Handbook

- Honeycomb Sandwich Design Technology

- Engineered timber sandwich core materials – Composite sandwich structure information

- -Application of aluminium honeycomb sandwich panel as an energy absorber of high-speed train nose