Package boiler

A package boiler is a factory-made boiler. Package boilers are available in a range of standard designs. Package boilers are used for heating and act as a steam generator for small power purposes such as self-powered industrial plants. They cannot be used for large-scale power plants such as co-generation plants due to their size and lack of efficiency. Advantages of package boilers are that they can be brought in as a whole assembly, perfect for tight spaces, and easily installed. They require steam pipes, water pipes, fuel supply, electrical connections and can be made ready almost immediately. Because of their compact design, these boilers are cheaper to operate due to their automatic burner management system as well as maintenance cost.[1]

The burner and centrifugal blower is at the left. Two vertical water level gauges can also be seen.

A great cost-saving for package boilers is their simple need for draughting. The chimney may either use an existing masonry chimney, or else a simple steel tube stack is provided, just sufficient to clear the nuisance of the exhaust fumes. As the burner provides its own draught from a fan, they do not require the tall brick chimneys needed to provide the draught for a coal-fired.

Internal arrangement

Package boilers are commonly called water or fire tube Boilers. Water tube boilers use convection heating, which draws the heat from the fire source, and passes against the generating tubes of the boiler, causing water inside those tubes to boil off into steam. The fire tube boiler arrangement utilizes conduction heating which transfers heat from physical contact. Fire tube boilers are not commonly used due to their method of conduction heating because pipes in direct contact with fire and cold water could damage the pipes. The package boiler is usually a two or three-pass fire-tube boiler with an internal furnace tube. This is similar to the much earlier Scotch boiler.

Generating tubes filled with water are in direct contact with the heat source inside the boiler, causing damage to the pipes as well as scaling. These boilers however are great with steam production due to the large volume inside the boiler and the surface area of the steam output. In order for these boilers to operate properly, they require a long warm-up process, and are prone to thermal shock of the boiler. These boilers can be rated up to 500,000 lb/hr.[2] The wall membrane of the boiler are dual welded, (welded on either side of the wall membrane) to provide extra reinforcement for high loads.

A-type, D-type and O-type are all water tube package boilers.

Combustion

Package boilers are fired from fuel oil in the form of liquid or gas. Fuel is ignited in the burners which creates an explosion within the boiler. Such package boiler do not require purifiers (filters) because they burn consistently removing all contaminants within the fuel. To create constant combustion within the boiler, the forced draft fan forces air into the burner, causing a tornado effect creating turbulence to keep the flame ignited and the furnace pressurized. Other essentials such as Burner electronics provide auto-ignition and on-demand lighting feature that monitors the flame and pressure within the boiler. tube boiler Package boilers are commonly called water or fire tube Boilers. Water tube boilers use convection heating, which draws the heat from the fire source, and passes against the generating tubes of the boiler, causing water inside those tubes to boil off into steam. The fire tube boiler arrangement utilizes conduction heating which transfers heat from physical contact. Fire tube boilers are not commonly used due to their method of conduction heating because pipes in direct contact with fire and cold water could damage the pipes. The package boiler is usually a two or three-pass fire-tube boiler with an internal furnace tube. This is similar to the much earlier Scotch boiler.

Pros and Cons

Pros[1]

- Compact design capable to fit tight engineering spaces

- Utilizes forced or induced draft system to provide greater efficiency and better air flow

- Many tube passes which provide greater heat transfer.

- High thermal wear levels.

- Inexpensive maintenance.

- Ease of installation.

- Less costly than water tube boiler erected on site of same capacity.

- Less man power is required.

Types of Package Boilers

The D-type Package Boiler

The D-type boiler has a water drum, steam drum, and generating tubes. Water flows into the steam drum, flows down the downcomers and into the water drum. Water is then sent from the water drum through the generating tubes, where the fire is located around causing water molecules to boil off into steam. Steam rises up more generating tubes and finally back into the steam drum where the dry pipe is located then into the plant. This configuration shaped the package boiler into a D-shape, hence the name D-type package boiler. These boilers are mostly used for plants that allow greater clearances.

The A-type Package Boiler

The A-type package boiler has two water drums and one steam drum compared to the D-type package boiler. Water boils off in the water drums shared by a common header, then sent up the generating tubes, into the steam drum and up the dry pipe. Just like the D-type package boiler, fire heats the tubes surroundings causing the tubes to increase in temperature thus boiling off water molecules to steam. A-type package boilers were designed to improve package boiler reliability and reduce tube replacements. A-type package boilers are smaller than D-type therefore will fit smaller plants, but does not have the same power output as D-type package boilers.

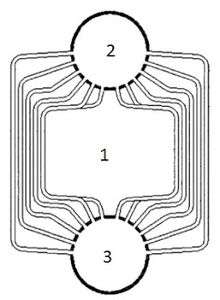

The O-type Package Boiler

The O-type boilers are a little simpler compared to D-type and A-type. They consist of one water drum and one steam drum. Generating tubes are lined up from either sides of the steam and water drums. When water boils due to convection heating, steam rises up through the tubes and into the steam drum. This is a symmetrical design for restrictive plant layouts. O-type boilers are mainly used for their fast steam production and reduced maintenance cost.[3]

References

| Wikimedia Commons has media related to Package boilers. |

- Punte, S. "Type of boilers". www.energyefficiencyasia.org. Retrieved 2016-04-14.

- Funk, Jason R. "Boilers Basics" (PDF). dol.ks. Hughes Machinery. Archived from the original (PDF) on 21 April 2016. Retrieved 14 April 2016.

- Bases, G. "Techs & Specs - National Insulation Association". www.insulation.org. Archived from the original on 2016-05-30. Retrieved 2016-04-14.