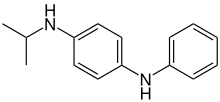

N-Isopropyl-N'-phenyl-1,4-phenylenediamine

N-Isopropyl-N′-phenyl-1,4-phenylenediamine (often abbreviated IPPD) is a chemical compound commonly used as an antiozonant in rubbers,[1] particularly those used for tires. Like other p-phenylenediamine based antiozonants it works by virtue of its low ionization energy which allows it to react with ozone faster than ozone will react with rubber.[2] This reaction converts it to the corresponding aminoxyl radical (R2N–O•), with the ozone being converted to a hydroperoxyl radical (HOO•),[2] these species can then be scavenged by other antioxidant polymer stabilizers.

| |

| Names | |

|---|---|

| IUPAC name

1-N-phenyl-4-N-propan-2-ylbenzene-1,4-diamine | |

Other names

| |

| Identifiers | |

3D model (JSmol) |

|

| ChEMBL | |

| ChemSpider | |

| ECHA InfoCard | 100.002.700 |

| EC Number |

|

PubChem CID |

|

| RTECS number |

|

| UNII | |

| UN number | 1673 |

CompTox Dashboard (EPA) |

|

| |

| |

| Properties | |

| C15H18N2 | |

| Molar mass | 226.323 g·mol−1 |

| Appearance | dark grey flakes |

| Density | 1.04 |

| Melting point | 75 °C (167 °F; 348 K) |

| Hazards | |

| GHS pictograms |    |

| GHS Signal word | Danger |

GHS hazard statements |

H302, H317, H320, H371, H372, H373, H400, H410 |

| P260, P261, P264, P270, P272, P273, P280, P301+312, P302+352, P305+351+338, P309+311, P314, P321, P330, P333+313, P337+313, P363, P391, P405, P501 | |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| Infobox references | |

IPPD is prone to process called blooming, where it migrates to the surface of the rubber.[3] This can be a cause of concern as IPPD is known to be a human allergen.[4][5]

See also

- N,N'-Di-2-butyl-1,4-phenylenediamine - a phenylenediamine based antioxidant used as a fuel additive

References

- Lewis, P.M. (January 1986). "Effect of ozone on rubbers: Countermeasures and unsolved problems". Polymer Degradation and Stability. 15 (1): 33–66. doi:10.1016/0141-3910(86)90004-2.

- Cataldo, Franco (January 2018). "Early stages of p-phenylenediamine antiozonants reaction with ozone: Radical cation and nitroxyl radical formation". Polymer Degradation and Stability. 147: 132–141. doi:10.1016/j.polymdegradstab.2017.11.020.

- Choi, Sung-Seen (5 July 1997). "Migration of antidegradants to the surface in NR and SBR vulcanizates". Journal of Applied Polymer Science. 65 (1): 117–125. doi:10.1002/(SICI)1097-4628(19970705)65:1<117::AID-APP15>3.0.CO;2-0.

- Lammintausta, K; Kalimo, K (1985). "Sensitivity to rubber. Study with rubber mixes and individual rubber chemicals". Dermatosen in Beruf und Umwelt. Occupation and environment. 33 (6): 204–8. PMID 2936592.

- Conde-Salazar, Luis; del-Río, Emilio; Guimaraens, Dolores; Domingo, Antonia González (August 1993). "Type IV allergy to rubber additives: A 10-year study of 686 cases". Journal of the American Academy of Dermatology. 29 (2): 176–180. doi:10.1016/0190-9622(93)70163-N.

This article is issued from Wikipedia. The text is licensed under Creative Commons - Attribution - Sharealike. Additional terms may apply for the media files.