Magnesium stearate

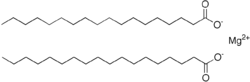

Magnesium stearate is the chemical compound with the formula Mg(C

18H

35O

2)

2. It is a soap, consisting of salt containing two equivalents of stearate (the anion of stearic acid) and one magnesium cation (Mg2+). Magnesium stearate is a white, water-insoluble powder. Its applications exploit its softness, insolubility in many solvents, and low toxicity. It is used as a release agent and as a component or lubricant in the production of pharmaceuticals and cosmetics.[1]

| |

| Names | |

|---|---|

| IUPAC name

Magnesium octadecanoate | |

| Identifiers | |

3D model (JSmol) |

|

| ChEBI | |

| ChemSpider |

|

| ECHA InfoCard | 100.008.320 |

| E number | E572 (acidity regulators, ...) |

PubChem CID |

|

| UNII | |

CompTox Dashboard (EPA) |

|

| |

| |

| Properties | |

| Mg(C 18H 35O 2) 2 | |

| Molar mass | 591.27 g/mol |

| Appearance | light white powder |

| Odor | slight |

| Density | 1.026 g/cm3 |

| Melting point | 88.5 °C (191.3 °F; 361.6 K) |

| 0.003 g/100 mL (15 °C) 0.004 g/100 mL (25 °C) 0.008 g/100 mL (50 °C) | |

| Solubility | negligible in ether and alcohol slightly soluble in benzene |

| Hazards | |

| Safety data sheet | External MSDS |

| NFPA 704 (fire diamond) | |

| Flash point | 250 °C (482 °F; 523 K) |

| Lethal dose or concentration (LD, LC): | |

LD50 (median dose) |

> 1000 mg/kg (oral, rat) |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| Infobox references | |

Manufacturing

Magnesium stearate is produced by the reaction of sodium stearate with magnesium salts or by treating magnesium oxide with stearic acid.[1] Some nutritional supplements specify that the sodium stearate used in manufacturing magnesium stearate is produced from vegetable-derived stearic acid.[2]

Uses

Magnesium stearate is often used as an anti-adherent[3] in the manufacture of medical tablets, capsules and powders.[4] In this regard, the substance is also useful because it has lubricating properties, preventing ingredients from sticking to manufacturing equipment during the compression of chemical powders into solid tablets; magnesium stearate is the most commonly used lubricant for tablets.[5] However, it might cause lower wettability and slower disintegration of the tablets and slower and even lower dissolution of the drug.[6]

Magnesium stearate can also be used efficiently in dry coating processes.[7][8][9]

In the creation of pressed candies, magnesium stearate acts as a release agent and it is used to bind sugar in hard candies such as mints.[10]

Magnesium stearate is a common ingredient in baby formulas.[11]

Occurrence

Magnesium stearate is a major component of bathtub rings. When produced by soap and hard water, magnesium stearate and calcium stearate both form a white solid insoluble in water, and are collectively known as soap scum.

Safety

Magnesium stearate is generally considered safe for human consumption at levels below 2500 mg/kg per day[12] and is classified in the United States as generally recognized as safe (GRAS). In 1979, the FDA's Subcommittee on GRAS Substances (SCOGS) reported, "There is no evidence in the available information on ... magnesium stearate ... that demonstrates, or suggests reasonable grounds to suspect, a hazard to the public when they are used at levels that are now current and in the manner now practiced, or which might reasonably be expected in the future."[13]

References

- Angelo Nora, Alfred Szczepanek, Gunther Koenen, "Metallic Soaps" in Ullmann's Encyclopedia of Industrial Chemistry 2005 Wiley-VCH, Weinheim. doi:10.1002/14356007.a16_361

- "Quick search results of the DSLD". Dietary Supplement Label Database. National Institutes of Health. Retrieved 27 December 2015.

- Ritter, Steve (2008). "What's That Stuff? Excipients: Inactive ingredients in medicines serve multiple functions in drug delivery". Chemical & Engineering News. 86 (1): 25. doi:10.1021/cen-v086n001.p025.

- Sworbrick, James; Boylan, James C. (1990). Encyclopedia of pharmaceutical technology. p. 2274. ISBN 9780824728243.

- Weiner, Myra L.; Kotkoskie, Lois A. (1999). Excipient Toxicity and Safety. p. 10. ISBN 9780824782108.

- Demuth; et al. (2017). "Investigation of Deteriorated Dissolution of Amorphous Itraconazole: Description of Incompatibility with Magnesium Stearate and Possible Solutions". Molecular Pharmaceutics. 14 (11): 3927–3934. doi:10.1021/acs.molpharmaceut.7b00629. PMID 28972782.

- Ouabbas Y, Dodds J., Galet L., Chamayou A. , Baron M. (2009). "Particle-particle coating in a cyclomix impact mixer" (PDF). Powder Technol. 189 (2): 245–252. doi:10.1016/j.powtec.2008.04.031.CS1 maint: multiple names: authors list (link)

- Thomas G., Ouabbas Y., Grosseau P., Baron M., Chamayou A., Galet L. (2009). "Modeling the main interaction forces between powder particles. Application to silica gel-magnesium stearate mixtures". Applied Surface Science. 255 (17): 7500–7507. Bibcode:2009ApSS..255.7500T. CiteSeerX 10.1.1.591.1899. doi:10.1016/j.apsusc.2009.03.099.CS1 maint: multiple names: authors list (link)

- Sato A., Serris E., Grosseau P., Thomas G., Galet L., Chamayou A. , Baron M. (2013). "Experiment and simulation of dry particle coating" (PDF). Chem. Eng. Science. 86: 164–172. doi:10.1016/j.ces.2012.07.037.CS1 maint: multiple names: authors list (link)

- https://www.ctahr.hawaii.edu/oc/freepubs/pdf/FST-9.pdf

- Erich Lück and Gert-Wolfhard von Rymon Lipinski (2002). "Foods, 3. Food Additives". Ullmann's Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH. doi:10.1002/14356007.a11_561. ISBN 978-3527306732.

- Søndergaarda, D.; Meyera, O.; Würtzena, G. (1980). "Magnesium stearate given peroprally to rats. A short term study". Toxicology. 17 (1): 51–55. doi:10.1016/0300-483X(80)90026-8. PMID 7434368.

- FDA's SCOGS Database; Report No. 60; ID Code: 557-04-0; Year: 1979