Lift-induced drag

In aerodynamics, lift-induced drag, induced drag, vortex drag, or sometimes drag due to lift, is an aerodynamic drag force that occurs whenever a moving object redirects the airflow coming at it. This drag force occurs in airplanes due to wings or a lifting body redirecting air to cause lift and also in cars with airfoil wings that redirect air to cause a downforce.

Samuel Langley observed higher aspect ratio flat plates had higher lift and lower drag and stated in 1902 “A plane of fixed size and weight would need less propulsive power the faster it flew”, the counter-intuitive effect of induced drag.[1]

Source of induced drag

The total aerodynamic force acting on a body is usually thought of as having two components, lift and drag. By definition, the component of force parallel to the oncoming flow is called drag; and the component perpendicular to the oncoming flow is called lift.[5] At practical angles of attack the lift greatly exceeds the drag.[6]

Lift is produced by the changing direction of the flow around a wing. The change of direction results in a change of velocity (even if there is no speed change, just as seen in uniform circular motion), which is an acceleration. To change the direction of the flow therefore requires that a force be applied to the fluid; lift is simply the reaction force of the fluid acting on the wing.

To produce lift, air below the wing is at a higher pressure than the air pressure above the wing. On a wing of finite span, this pressure difference causes air to flow from the lower surface wing root, around the wingtip, towards the upper surface wing root. This spanwise flow of air combines with chordwise flowing air, causing a change in speed and direction, which twists the airflow and produces vortices along the wing trailing edge. The vortices created are unstable, and they quickly combine to produce wingtip vortices.[7] The resulting vortices change the speed and direction of the airflow behind the trailing edge, deflecting it downwards, and thus inducing downwash behind the wing.

Wingtip vortices modify the airflow around a wing, reducing the wing's ability to generate lift, so that it requires a higher angle of attack for the same lift, which tilts the total aerodynamic force rearwards and increases the drag component of that force. The angular deflection is small and has little effect on the lift. However, there is an increase in the drag equal to the product of the lift force and the angle through which it is deflected. Since the deflection is itself a function of the lift, the additional drag is proportional to the square of the lift.[8]

Reducing induced drag

According to the equations below, a wing of infinite aspect ratio (wingspan/chord length) and constant airfoil section would produce no induced drag. The characteristics of such a wing can be measured on a section of wing spanning the width of a wind tunnel, since the walls block spanwise flow and create what is effectively two-dimensional flow.

A rectangular planform wing produces stronger wingtip vortices than does a tapered or elliptical wing, therefore many modern wings are tapered. However, an elliptical planform is more efficient as the induced downwash (and therefore the effective angle of attack) is constant across the whole of the wingspan. Few aircraft have this planform because of manufacturing complications — the most famous examples being the World War II Spitfire and Thunderbolt. Tapered wings with straight leading and trailing edges can approximate to elliptical lift distribution. Typically, straight edged non-tapered wings produce 5%, and tapered wings produce 1-2% more induced drag than an elliptical wing.[9]

Similarly, for a given wing area, a high aspect ratio wing will produce less induced drag than a wing of low aspect ratio because there is less air disturbance at the tip of a longer, thinner wing.[10] Induced drag can therefore be said to be inversely proportional to aspect ratio.[11] The lift distribution may also be modified by the use of washout, a spanwise twist of the wing to reduce the incidence towards the wingtips, and by changing the airfoil section near the wingtips. This allows more lift to be generated nearer the wing root and less towards the wingtip, which causes a reduction in the strength of the wingtip vortices.

Some early aircraft had fins mounted on the tips of the tailplane which served as endplates. More recent aircraft have wingtip mounted winglets to reduce the intensity of wingtip vortices.[12] Wingtip mounted fuel tanks or in extreme cases, propellers, may also provide some benefit, by preventing the spanwise flow of air around the wingtip.

Calculation of induced drag

For a planar wing with an elliptical lift distribution, induced drag can be calculated as follows:

- ,

where

- is the lift,

- is the air density,

- is the true airspeed, and

- is the wingspan.

From this equation it is clear that the induced drag decreases with flight speed and with wingspan. Deviation from the non-planar wing with elliptical lift distribution are taken into account by dividing the induced drag by the span efficiency factor .

To compare with other sources of drag, it can be convenient to express this equation in terms of lift and drag coefficients[13]:

- , where

and

- is the aspect ratio,

- is a reference wing area.

This indicates how high-aspect ratio wings are beneficial to flight efficiency. With being a function of angle of attack, induced drag increases as the angle of attack increases,[8] up to the stall angle.

The above equation can be derived using Prandtl's lifting-line theory. Similar methods can also be used to compute the minimum induced drag for non-planar wings or for arbitrary lift distributions.

Combined effect with other drag sources

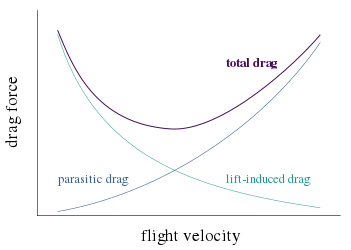

Induced drag must be added to the parasitic drag to find the total drag. Since induced drag is inversely proportional to the square of the airspeed (at a given lift) whereas parasitic drag is proportional to the square of the airspeed, the combined overall drag curve shows a minimum at some airspeed - the minimum drag speed (VMD). An aircraft flying at this speed is operating at its optimal aerodynamic efficiency. According to the above equations, the speed for minimum drag occurs at the speed where the induced drag is equal to the parasitic drag.[14] This is the speed at which for unpowered aircraft, optimum glide angle is achieved. This would also be the speed for greatest range if the efficiency of the engine were constant with speed (although for a given air density VMD will decrease as the plane consumes fuel and becomes lighter). But in fact, the efficiency of jet engines increases with speed, so greatest range is achieved at a speed greater than the speed of minimum drag. The speed for greatest range (i.e., distance travelled) is the speed at which a straight line from the origin is tangent to the fuel flow rate curve. The curve of range versus airspeed is normally very flat and it is customary to operate at the speed for 99% best range since this gives about 5% greater speed for only 1% less range.

Of course, flying higher where the air is thinner will raise the speed at which minimum drag occurs, and so permits a faster voyage for the same amount of fuel. If the plane is flying at the maximum permissible speed, then there is an altitude at which the air density will be what is needed to keep it aloft while flying at the optimal angle of attack. The optimum altitude at maximum speed, and the optimum speed at maximum altitude, change during the flight as the plane consumes fuel and becomes lighter. For this reason airliners normally climb during long flights (see Step climb).

The speed for maximum endurance (i.e., time in the air) is the speed for minimum fuel flow rate, and is less than the speed for greatest range. The fuel flow rate is calculated as the product of the power required and the engine specific fuel consumption (fuel flow rate per unit of power[15]). The power required is equal to the drag times the speed.

References

- L. J. Clancy (1975), Aerodynamics, Pitman Publishing Limited, London. ISBN 0-273-01120-0

- Abbott, Ira H., and Von Doenhoff, Albert E. (1959), Theory of Wing Sections, Dover Publications, Standard Book Number 486-60586-8

- Luciano Demasi, Antonio Dipace, Giovanni Monegato, and Rauno Cavallaro. Invariant Formulation for the Minimum Induced Drag Conditions of Nonplanar Wing Systems, AIAA Journal, Vol. 52, No. 10 (2014), pp. 2223–2240. doi: 10.2514/1.J052837

Notes

- Bjorn Fehrm (Nov 3, 2017). "Bjorn's Corner: Aircraft drag reduction, Part 3". Leeham.

- Hurt, H. H. (1965) Aerodynamics for Naval Aviators, Figure 1.30, NAVWEPS 00-80T-80

- Clancy, L.J. (1975) Aerodynamics Fig 5.24. Pitman Publishing Limited, London. ISBN 0-273-01120-0

- Kermode, A.C. (1972). Mechanics of Flight, Figure 3.29, Ninth edition. Longman Scientific & Technical, England. ISBN 0-582-42254-X

- Clancy, L.J., Aerodynamics, Section 5.3

- Abbott, Ira H., and Von Doenhoff, Albert E., Theory of Wing Sections, Section 1.2 and Appendix IV

- Clancy, L.J., Aerodynamics, Section 5.14

- Clancy, L.J., Aerodynamics, Section 5.17

- Glauert, H. The Elements of Aerofoil and Airscrew Theory (1926); referenced in Fig. 5.4 of Airplane Aerodynamics by Daniel O. Dommasch, Sydney S. Sherby, Thomas F. Connolly, 3rd ed. (1961)

- "Induced Drag". Retrieved 5 May 2015.

- More correctly stated, induced drag is inversely proportional to the square of the wingspan.

- Richard T. Witcomb (1976), A design approach and selected wind-tunnel results at high subsonic speeds for wing-tip mounted winglets (PDF), NASA

- Anderson, John D. (2005), Introduction to Flight, McGraw-Hill. ISBN 0-07-123818-2. p318

- Clancy, L.J., Aerodynamics, Section 5.25

- The engine specific fuel consumption is normally expressed in units of fuel flow rate per unit of thrust or per unit of power depending on whether the engine output is measured in thrust, as for a jet engine, or shaft horsepower, as for a propeller engine. To convert fuel rate per unit thrust to fuel rate per unit power one must divide by the speed.